Patents

Literature

71results about How to "Improve homogenization efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

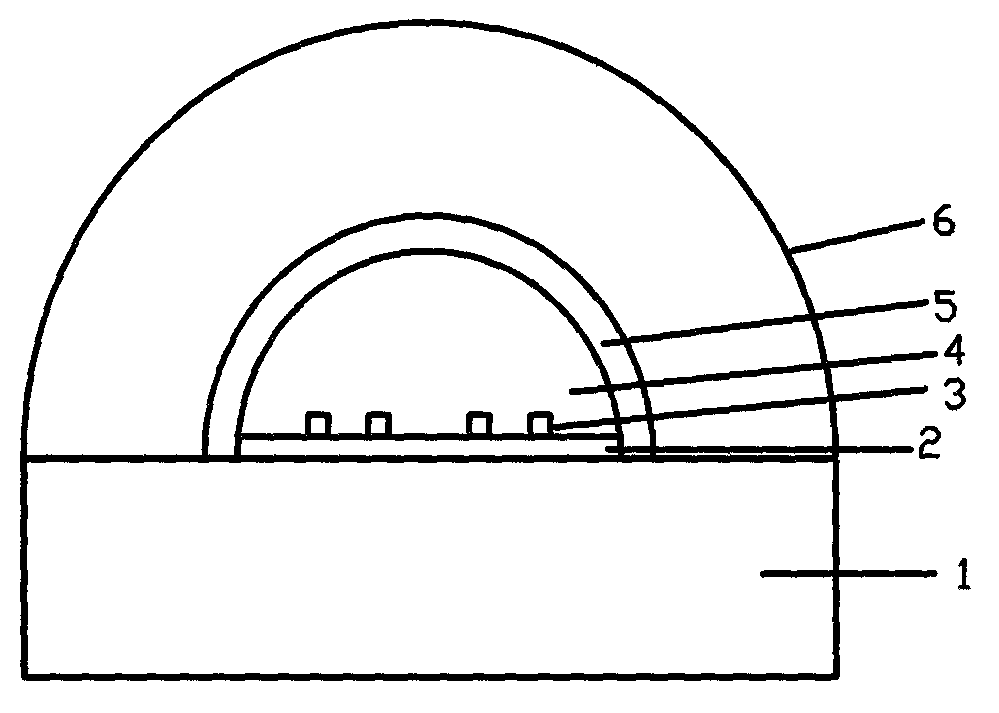

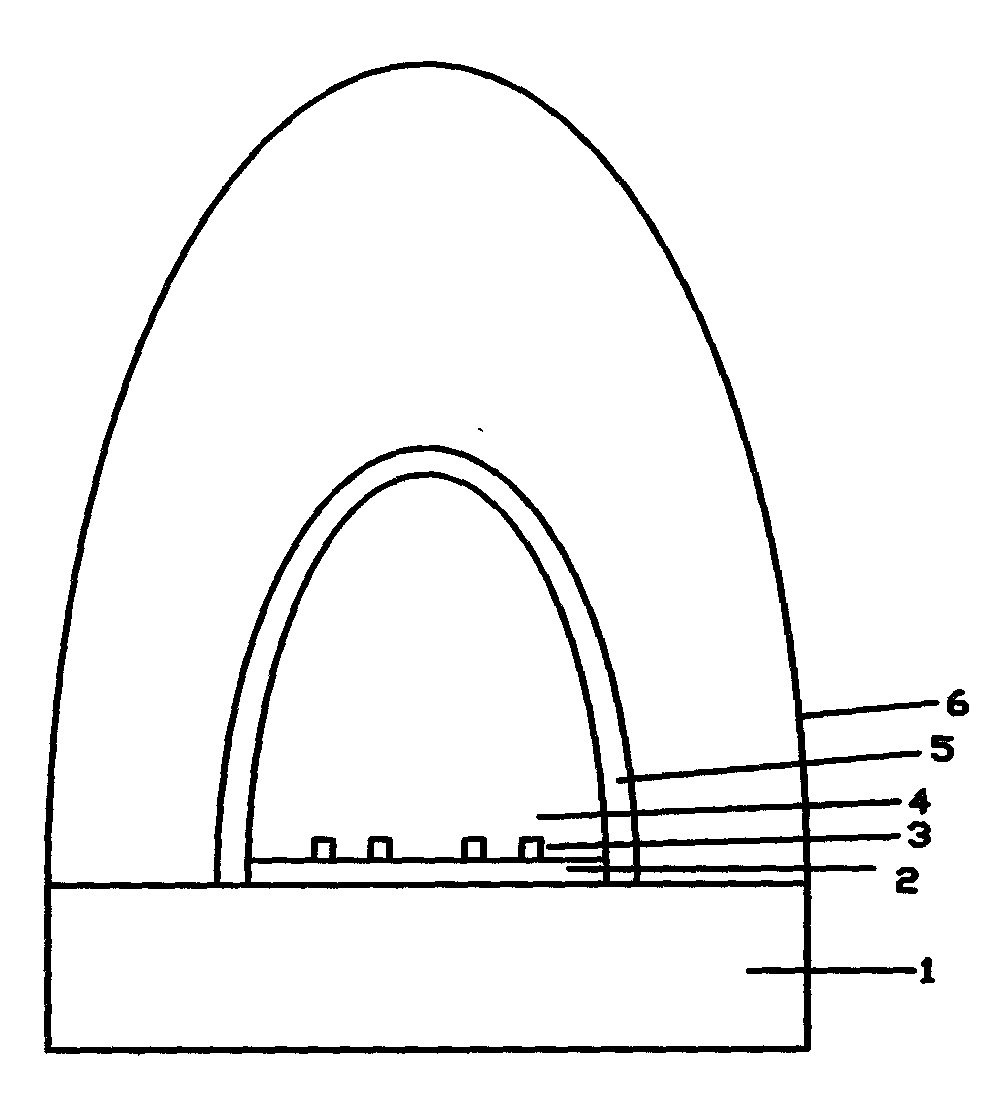

Light conversion module

InactiveCN102368496AIncrease the light output angleWell mixedSolid-state devicesSemiconductor devicesPhosphorScattering effect

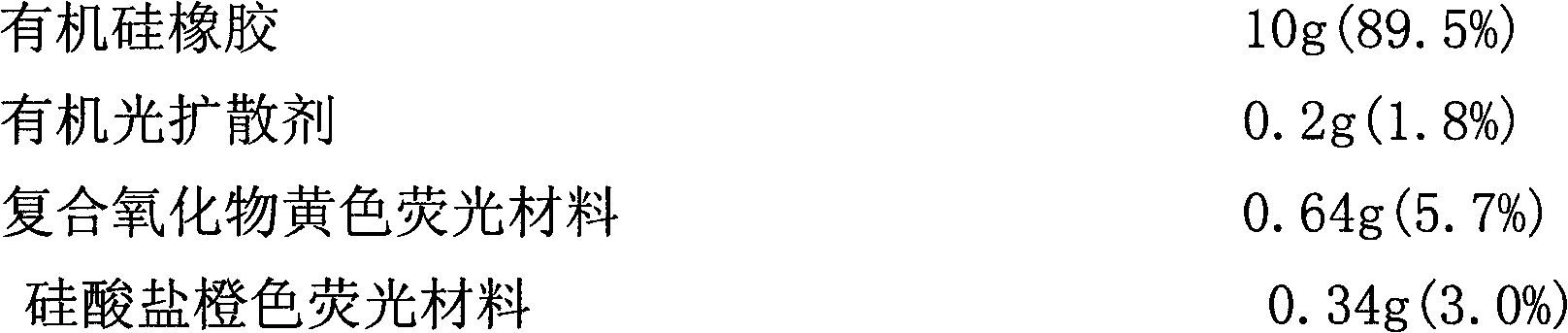

The invention relates to a module possessing a light conversion function. An organic silicone rubber is taken as a carrier. An LED phosphor and an organic light diffuser agent are added to form the light conversion module. The module is soft and elastic. A preparation method is characterized by: mixing organic silicon glue, the LED phosphor and the organic light diffuser agent uniformity; injecting into a mould, heating, curing and molding. The module can be used in a blue ray LED light source. The LED phosphor can be excited to glow by the blue ray emitted by the blue ray LED light source, and through reflection, refraction and scattering effects of the organic light diffuser agent, the light of the LED phosphor and the blue ray which is not be absorbed are composited into the white light or the light with other colors. The light color and intensity of the obtained compound light distribute uniformly, and are soft without glare. The compound light can realize the wide-angle light and can be applied in LEC illumination and decorative lamps.

Owner:DALIAN LUMINGLIGHT SCIENCE & TECHNOLOGY CO LTD

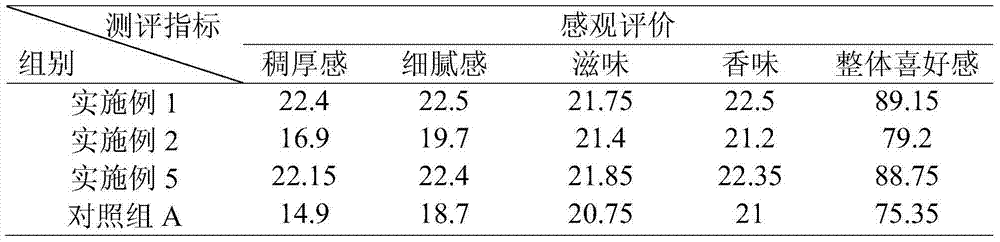

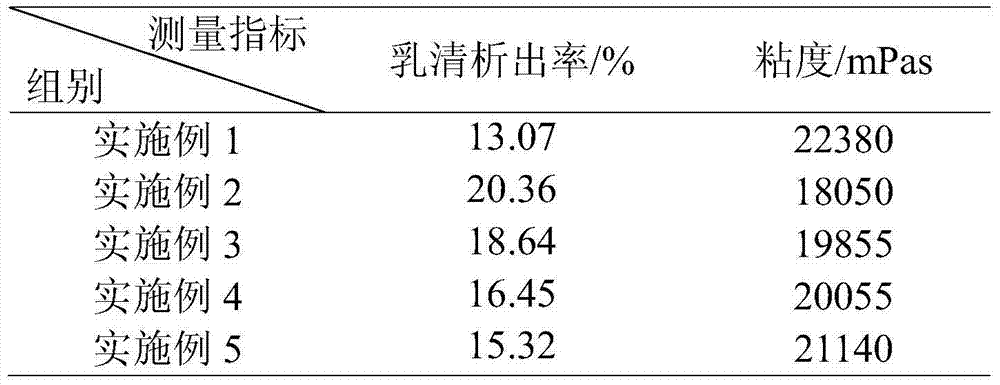

Preparation technology for set yogurt with high stability

The present invention relates to a preparation technology for set yogurt with high stability, and belongs to the field of dairy processing. The preparation technology for set yogurt with high stability comprises the following steps: adding 0.01-0.05 wt.% of casein protein powder into standardized and detected raw milk; homogenizing; pasteurizing; inoculating: adding 0.01-0.05 wt.% of beta-lactoglobulin into the pasteurized milk, inoculating lactic acid bacteria, and uniformly mixing the inoculated milk; and conducting fermentation. According to the preparation technology for set yogurt, the prepared set yogurt has good stability, does not contain any stabilizers, has thick and delicate mouth feel and pleasant aroma.

Owner:HANGZHOU NEW HOPE BIMODAL DAIRY CO LTD +1

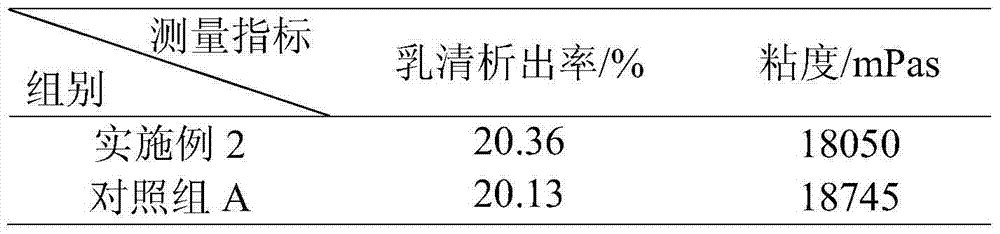

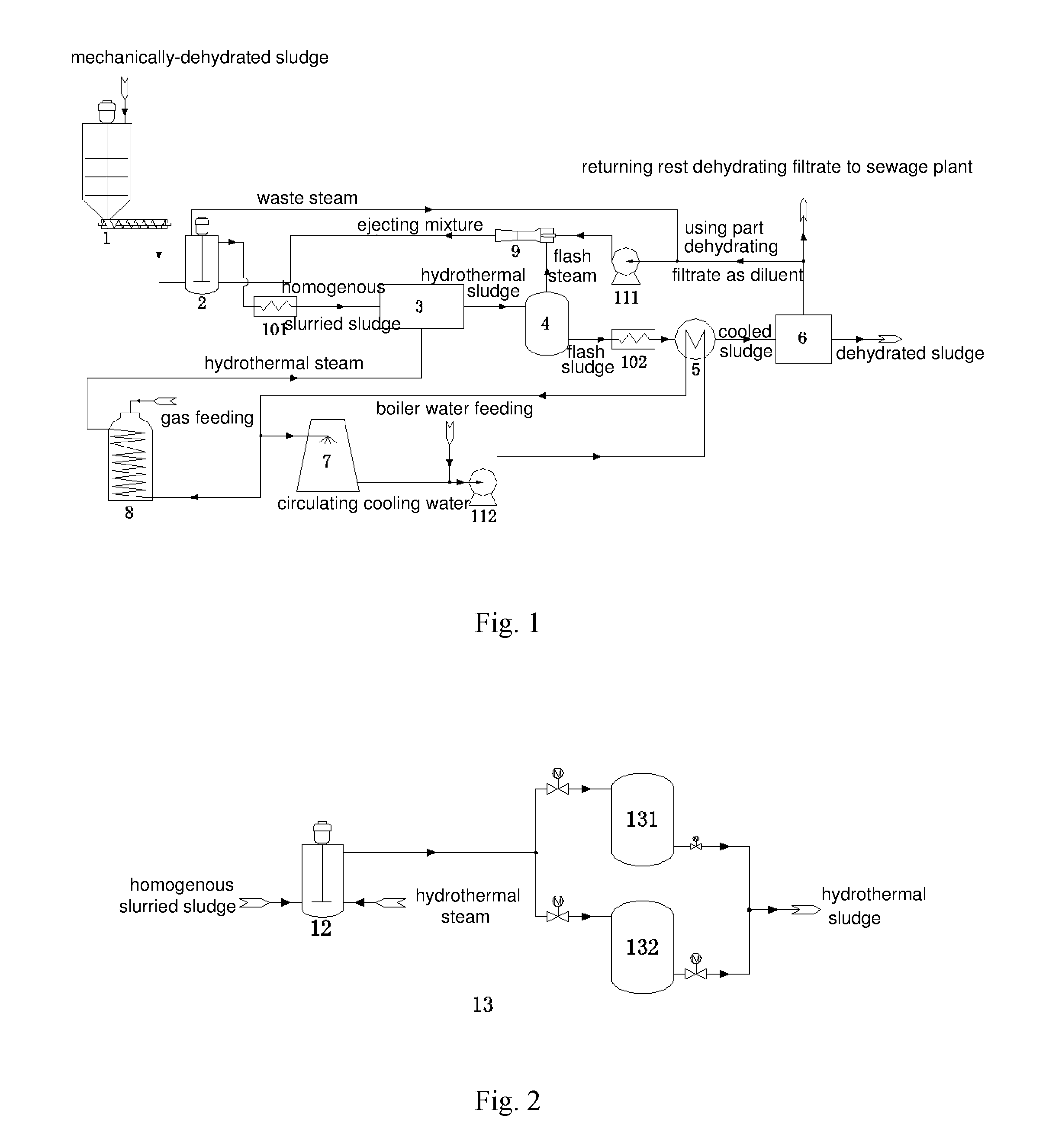

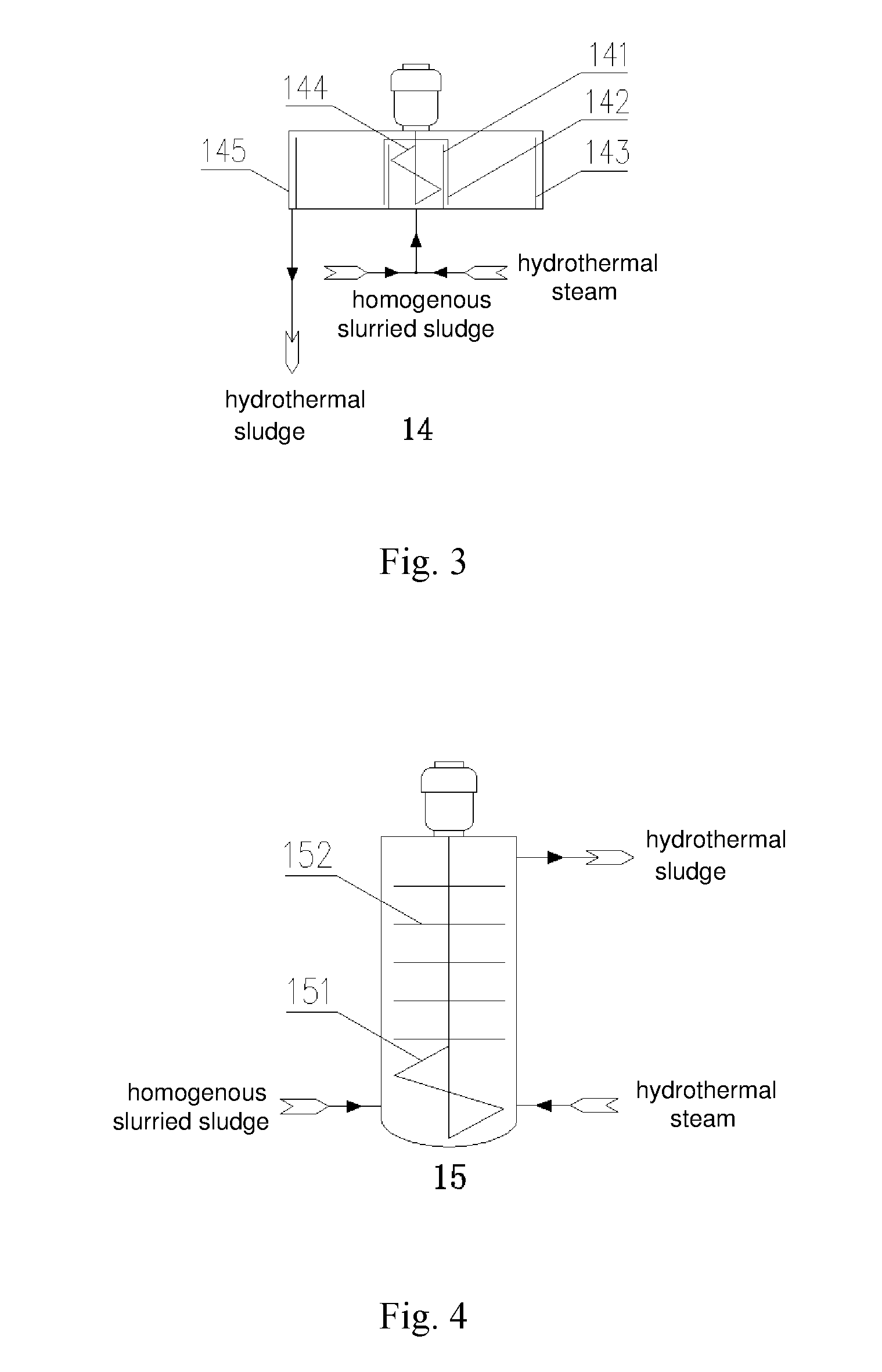

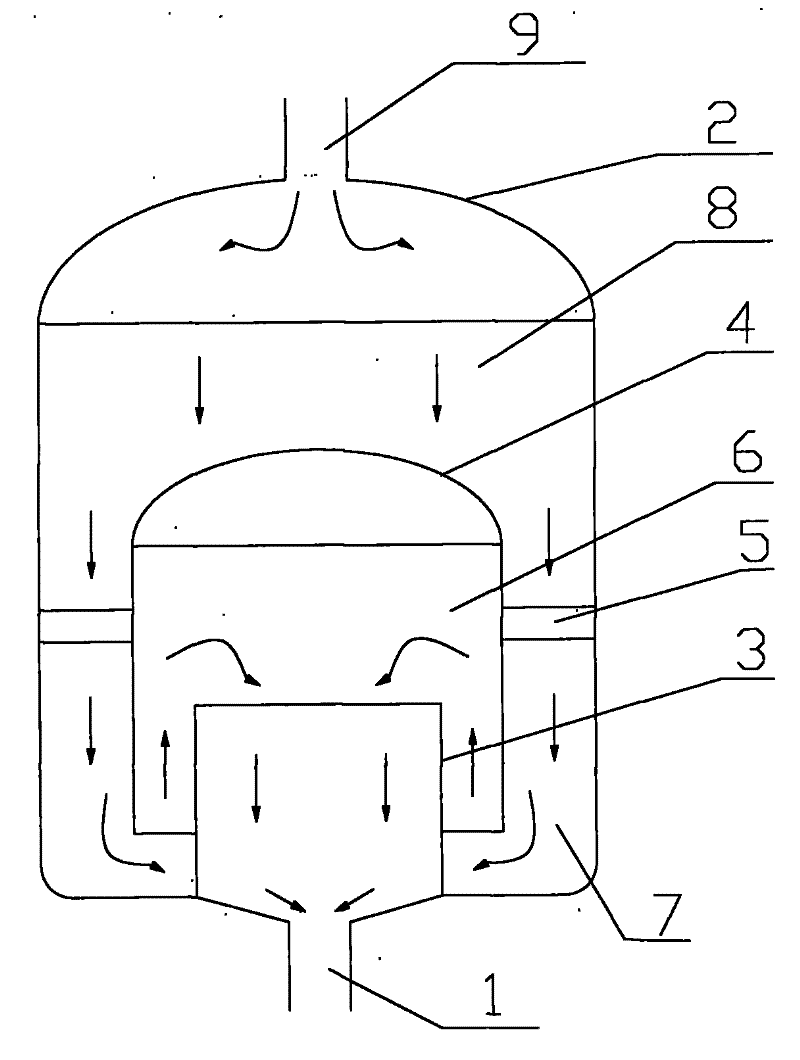

Sludge dehydrating system and method thereof based on thermal hydrolysis technology

InactiveUS20160194231A1Effectively water contentMeet the requirementsSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesWaste heat recovery unitDiluent

A sludge dehydrating system and a method thereof based on a thermal hydrolysis technology include: a homogeneous slurry unit, a hydrothermal unit, a flash reactor, a waste heat recovery unit, and a dehydrator; wherein a viscosity of sludge is lowered by homogenously slurrying before entering a pump, which is conducive to transportation; a sludge tank firstly crashes and then quantitatively transports for improving a homogenizing efficiency; a diluent is sludge dehydrated filtrate which is mixed with flash steam in an ejector, wherein an mixing efficiency is high; during homogenously slurrying, waste steam generated is added into a sludge diluent pipe for being absorbed; a hydrothermal unit include a variety of forms such as an intermittent form and a continuous form, in such a manner that reaction parameters, especially reaction time are effectively guaranteed; the flash steam enters the homogeneous slurry unit for heating the sludge.

Owner:XI AN JIAOTONG UNIV +1

Preparation method for lithium-ion button cell

InactiveCN106058292AImprove efficiencyImproved mixing uniformity and dispersionElectrode manufacturing processesFinal product manufactureSolventChemistry

The invention discloses a preparation method for a lithium-ion button cell. The preparation method comprises the following steps: preparation of positive and negative electrode slurry; coating of the slurry for preparation of pole pieces; cutting of the pole pieces; assembling of the cell; etc. The preparation of the slurry is realized through simultaneous addition of raw materials and step-by-step rotation and homogenization, and the process of rotation and homogenization is divided into three stages, i.e., low-speed rotation and homogenization, high-speed rotation and homogenization and medium-speed rotation and homogenization. According to the invention, in virtue of high-speed revolution and rotation of a container, high-speed collision and shearing occur among solid particles and between the particles and the container, all the solid particles are not aggregated any longer and are uniformly dispersed in a solvent; homogenization efficiency is improved, and manufacturing of a great number of button cells can be completed in one day, so research and development efficiency is improved and button cell manufacturing efficiency is enhanced; and the quality of the button cell is improved by improving uniformity and dispersibility of the slurry in mixing, so the battery can better reflect material performance and performance of the battery is improved.

Owner:WANXIANG 123 CO LTD +1

Ingredient stirring homogenizer used for cosmetic

InactiveCN106914184AImprove stirring efficiencyImprove homogenization efficiencyRotary stirring mixersTransportation and packagingElectric energyEngineering

The invention relates to an ingredient stirring homogenizer, and especially relates to an ingredient stirring homogenizer used for cosmetic. The ingredient stirring homogenizer comprises a support, a motor, a stirring device, a flexible pipe, a liquid-drawing pump, a non-return valve, and the homogenizer; the motor is arranged at the top in the support, the stirring device is arranged on the left side wall in the support, the motor and the stirring device are connected, the homogenizer is arranged at the front side of the right side wall of the support, the liquid-drawing pump is arranged on the right side wall of the stirring device, and the upper and lower sides of the liquid drawing pump are connected with the flexible pipe. The homogenizer has the advantages that stirring is full, the stirring efficiency is high, adherence of the ingredient on the inner wall of a stirring case and a homogenizing case can be prevented, utilization rate of the ingredient is increased, the ingredient homogenizing efficiency is high, electric energy is saved, and the ingredient can be used and collected in a quantitative mode.

Owner:李良

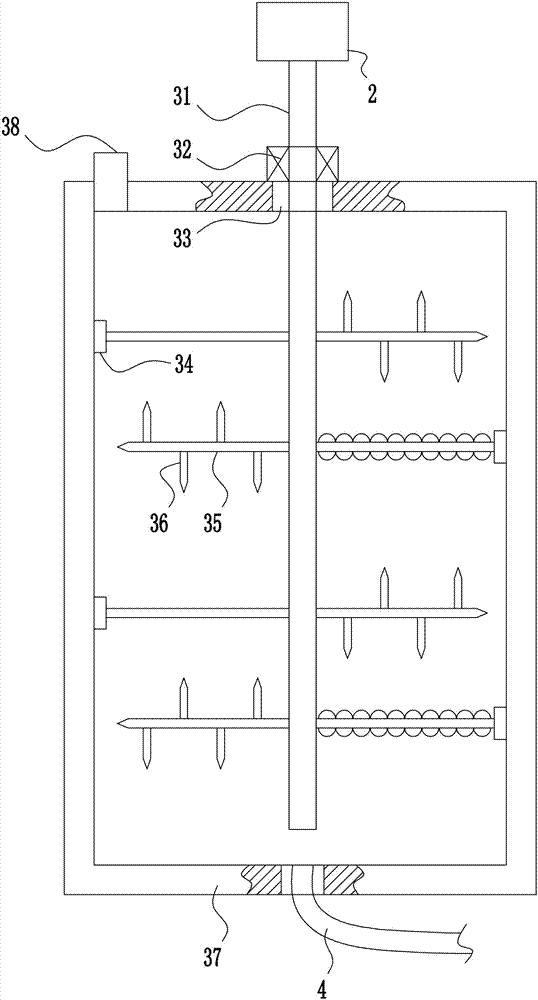

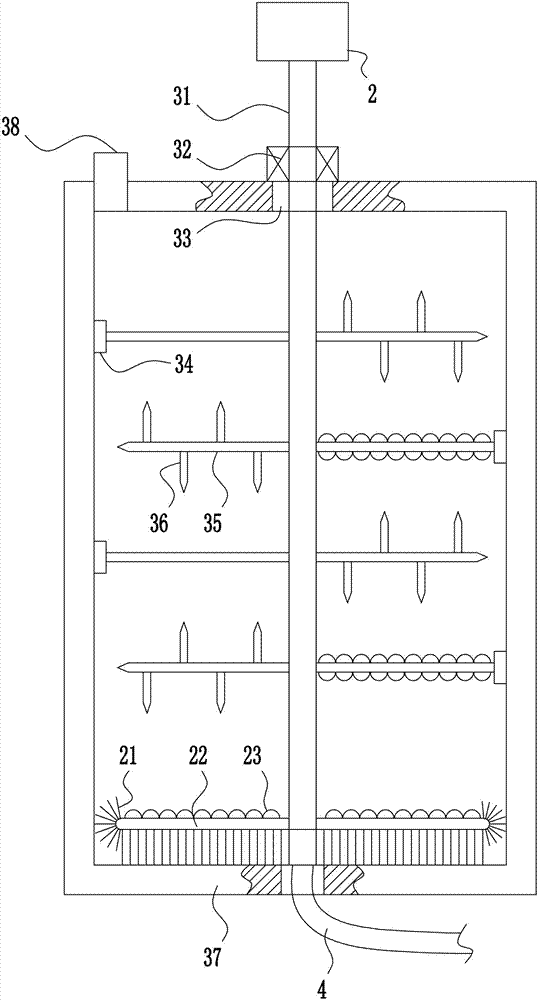

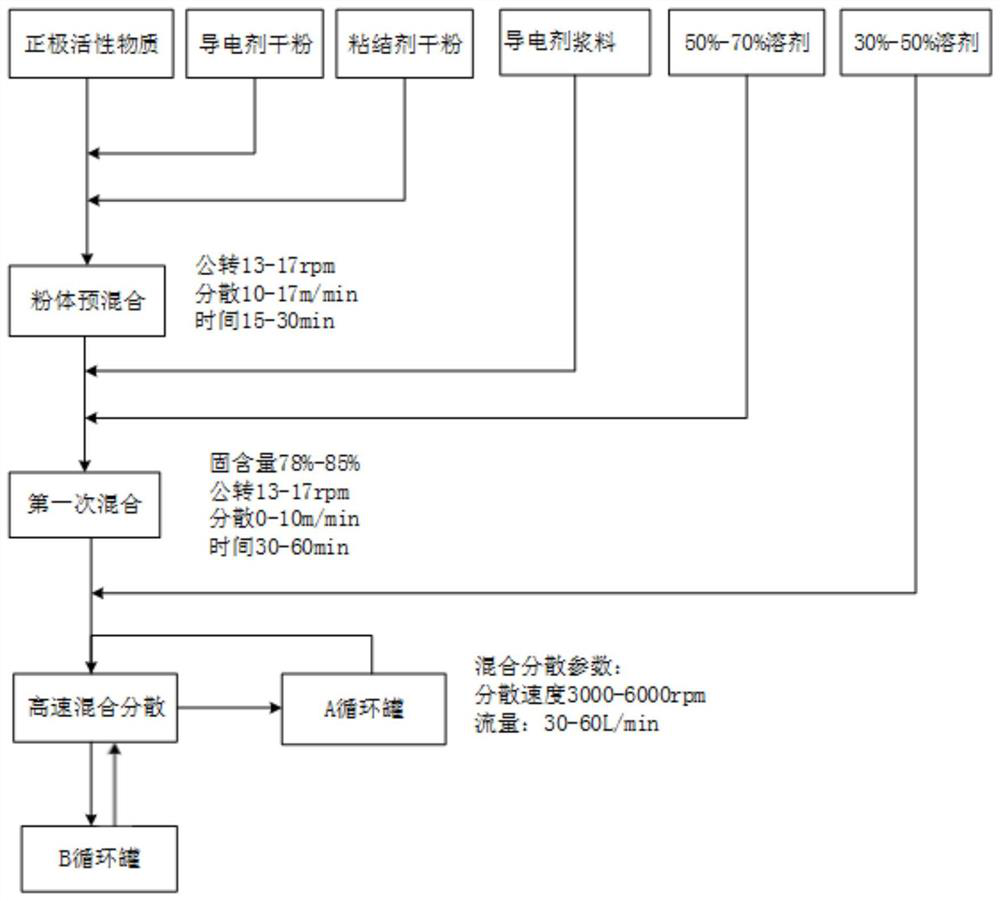

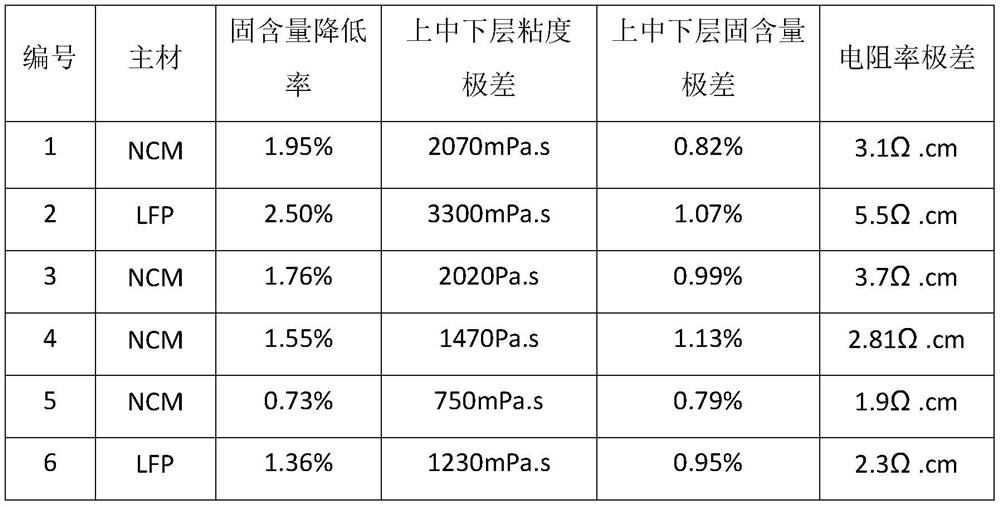

Homogenizing method of lithium ion battery positive electrode slurry

PendingCN111632509AImprove homogenization efficiencyReduce homogenization timeTransportation and packagingMixing methodsElectrically conductiveLithium electrode

The invention provides a homogenizing method of a lithium ion battery positive electrode slurry. The method comprises the following steps of: S1, feeding a positive active substance, conductive agentdry powder and binder dry powder into a double-planet stirrer one by one according to a ratio by using an automatic feeding system, and carrying out powder premixing to obtain a dry powder mixture; S2, dividing a solvent into two parts, adding a conductive agent slurry and one part of a solvent into the dry powder mixture prepared in S1 in proportion, and conducting first mixing to obtain a semi-finished product slurry; S3, starting a high-speed mixer, inputting the semi-finished product slurry obtained in S2 and another part of solvent into the high-speed mixer for high-speed mixing and dispersing, and pumping the mixed slurry into a circulation tank A; S4, inputting the slurry in the circulation tank A into the high-speed mixer again for high-speed mixing and dispersing, and pumping themixed slurry into a circulation tank B. The double-planet stirrer and the high-speed mixer are used at the same time, the slurry dispersion uniformity can be improved, and the slurry granularity consistency is better.

Owner:余姚市海泰贸易有限公司

Manufacturing method and device of high uniformity and high consistent optical glass

ActiveCN108409107AStrong toleranceEfficient separationGlass furnace apparatusGlass shaping apparatusMelting tankPhysical chemistry

The invention disclose a manufacturing method and device of high uniformity and high consistent optical glass and belongs to the technical field of manufacturing of optical glass. The device can remarkably improve the uniformity and consistency of optical glass and is mainly characterized in that bubblers are arranged at the bottom of a melting tank; a homogenization tank is arranged between the melting tank and a warming chamber; the homogenization tank is provided with a homogenization tank electrode, homogenization tank burners and a stirring rod; the manufacturing method is characterized by comprising the steps of S1, preparing a mixture material of the optical glass according to a formula of glass, uniformly mixing; S2, separately performing granulation on the mixture material according to a crucible batch to prepare into a granular mixture material; S3, taking different crucible batch granular mixture material according to a weight proportion to perform secondary mixing again; S4, bubbling in the melting tank and enhancing convective flow of glass liquid and the dissolving of material, the formula is shown in the description; S5, a stirring device in the homogenization tank is used for stirring and homogenizing the glass liquid, the formula is shown in the description; S6, after the glass liquid passes through the warming chamber, a clarifying chamber, a cooling chamber and a working chamber, injecting the glass liquid into a mold to be shaped into glass strip and precision annealing. The manufacturing method disclosed by the invention can obtain the high uniformity and high consistent optical glass through one step melting, and improve the efficiency of glass melting.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

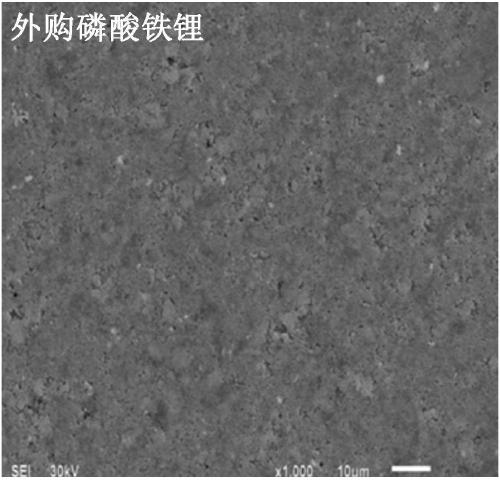

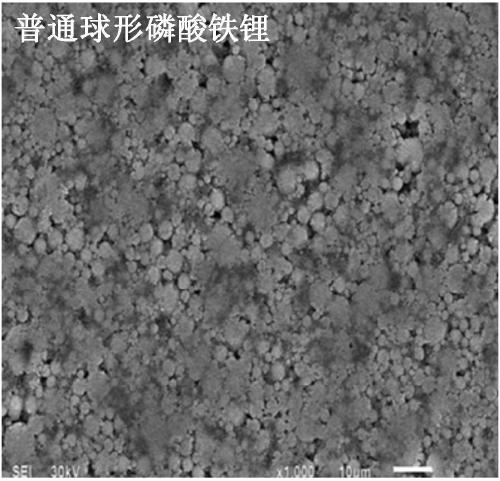

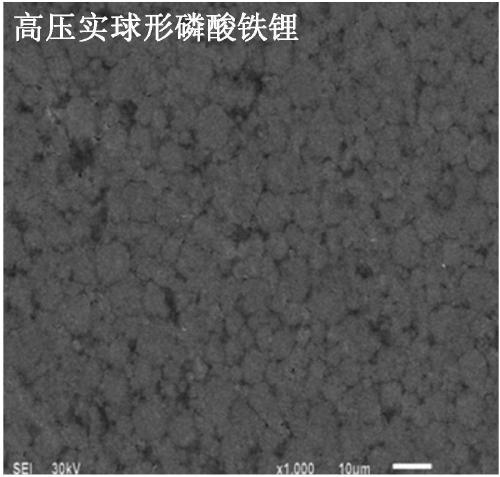

High-compaction spherical lithium iron phosphate, preparation method and lithium ion battery containing high-compaction spherical lithium iron phosphate

InactiveCN109502567AIncrease compaction densityImprove ductilityCell electrodesSecondary cellsCarbon filmPhosphate

The invention discloses high-compaction spherical lithium iron phosphate, a preparation method and a lithium ion battery containing the high-compaction spherical lithium iron phosphate. The method comprises the following steps that 1) a carbon source, iron salt, phosphate salt and lithium salt mixed aqueous solution is prepared, and sand grinding is carried out until D50 is equal to 0.5-1 microns,and D90 is equal to 1.2-2.3 microns; 2) obtained precursor slurry is dried and granulated in a pressure type spray drying device, and the particle size of granulation is controlled to be as follows:D50 is equal to 4-8 microns, and D90 is equal to 10-25 microns; and 3) sintering is carried out under the protection of inert gas so as to obtain the high-compaction spherical lithium iron phosphate.According to the high-compaction spherical lithium iron phosphate, the preparation method and the lithium ion battery containing the high-compaction spherical lithium iron phosphate, the high-compaction spherical lithium iron phosphate is good in ductility, the compaction density of a prepared pole piece is 2.45 g / cm<3> or above, the problems that in the prior art, lithium iron phosphate preparedthrough a crushing technology in the current market is not easy to disperse in the homogenizing process, the efficiency is low, the solid content is low, the energy consumption is high and the like can be solved, and meanwhile, the problems that the compaction density of common spherical lithium iron phosphate is relatively low, and the integrity of a coated carbon film in the prior art is poor and is liable to fall off can be solved.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

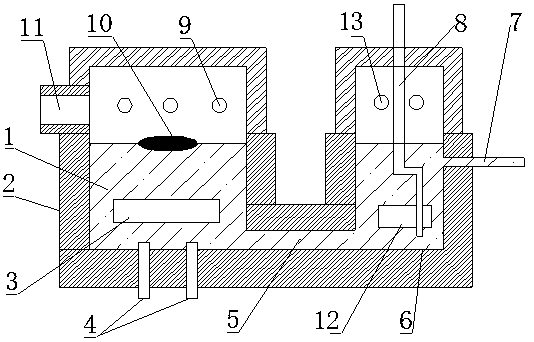

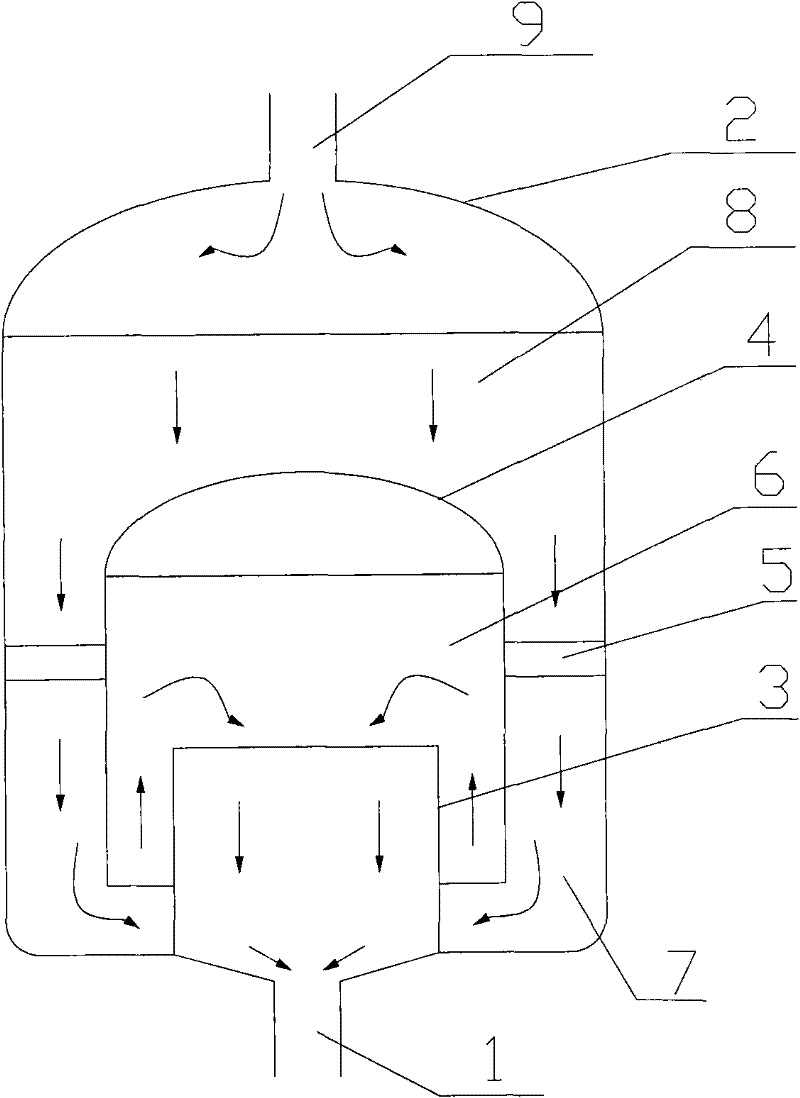

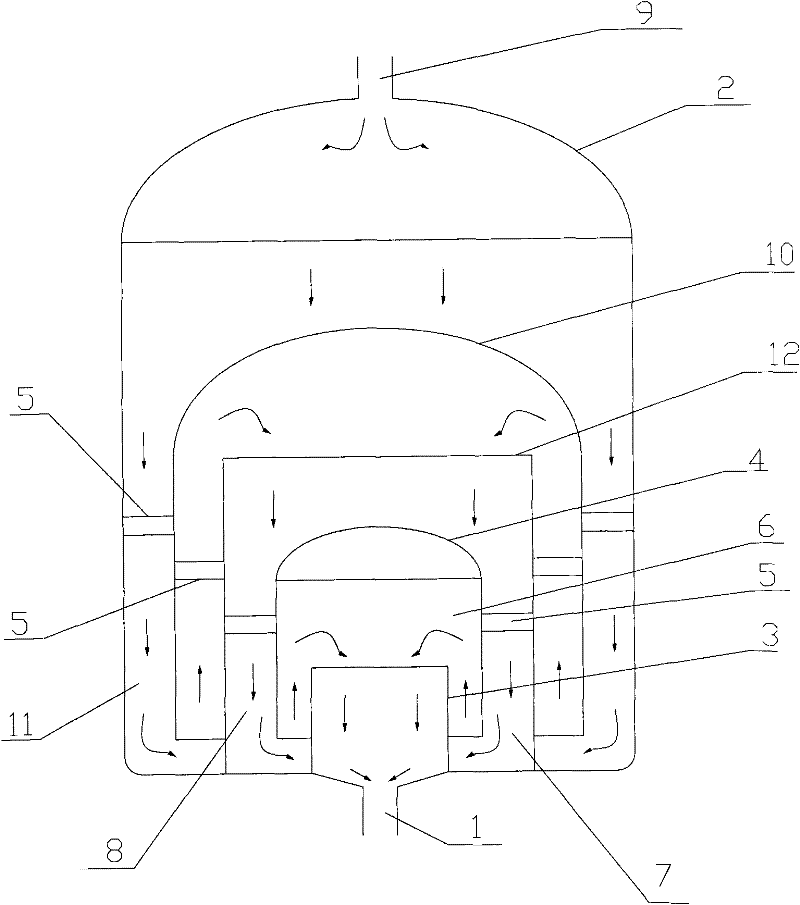

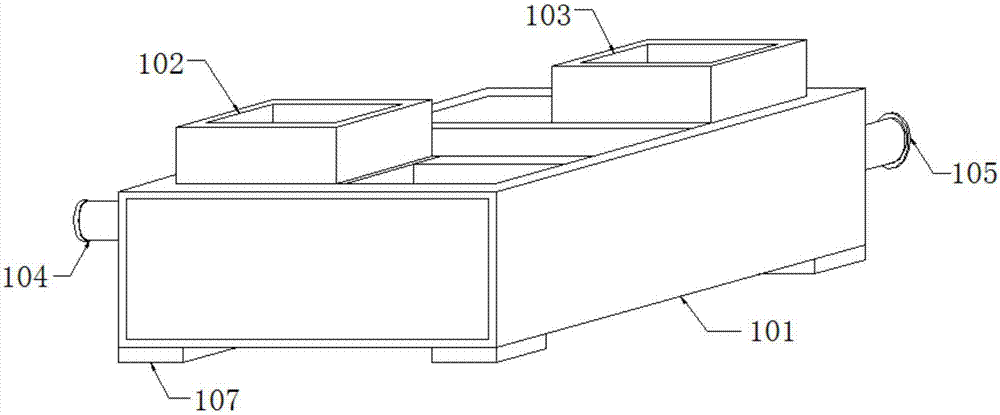

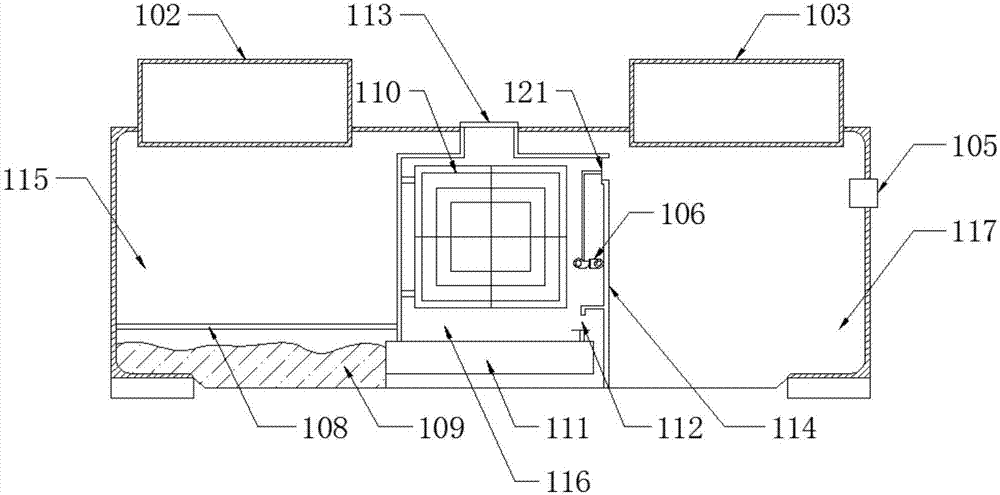

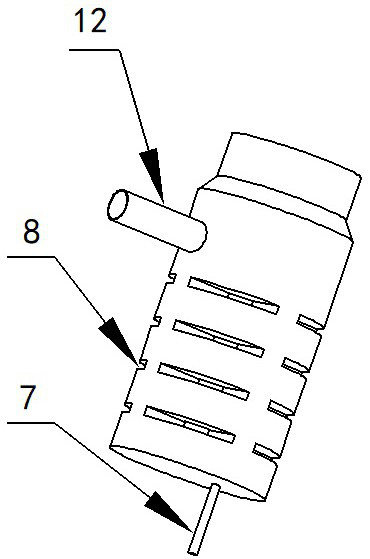

Homogenizer

InactiveCN101745331ASimple structureReduce processing costsFlow mixersEmulsificationEngineeringHomogenizer

The invention relates to a homogenizer comprises at least n first cylinders and at least n-1 second cylinders, which are sleeved together at intervals. The inmost cylinders and the outmost cylinders are both first cylinders; the top of the outmost first cylinder is closed and is provided with an opening which is communicated with the outside, and the bottom is provided with an opening which is communicated with the inside of the innermost first cylinder; the tops of other first cylinders are open; all the first cylinders share the bottom of the same homogenizer; the second cylinders are sleeved outside the first cylinders which are adjacent to the second cylinders at intervals; the tops of the second cylinders are open, and the bottoms are closed, thus a space in the homogenizer, where all the first cylinders are communicated with all the second cylinders, is formed; and the first cylinders and the second cylinders are fixed mutually by connecting parts.

Owner:NANJING HAOYANG CHEM EQUIP

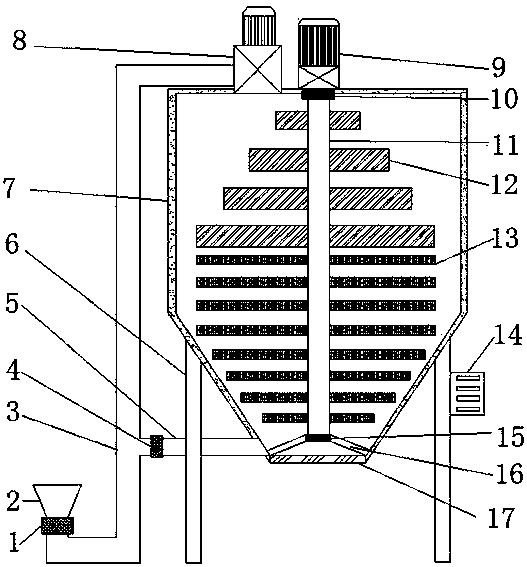

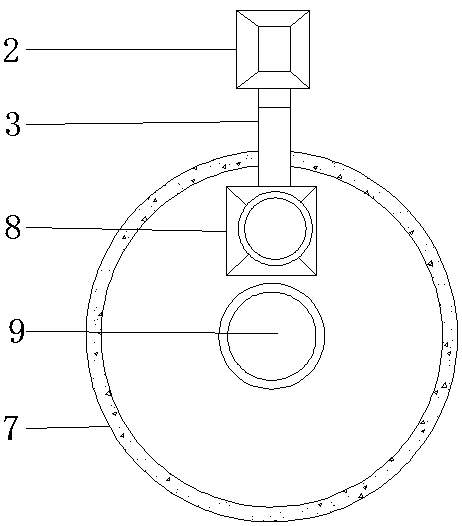

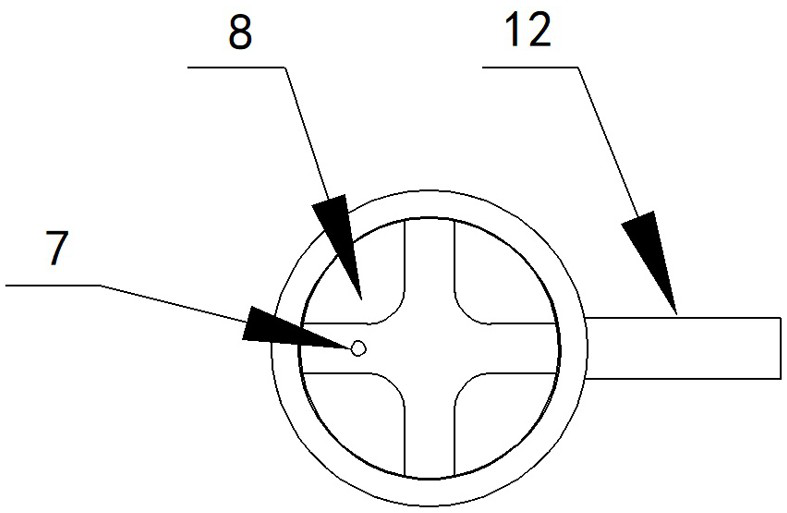

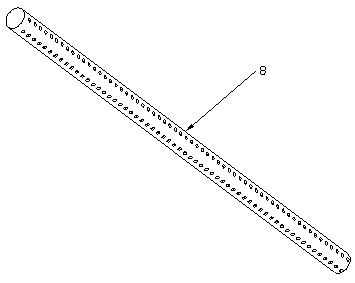

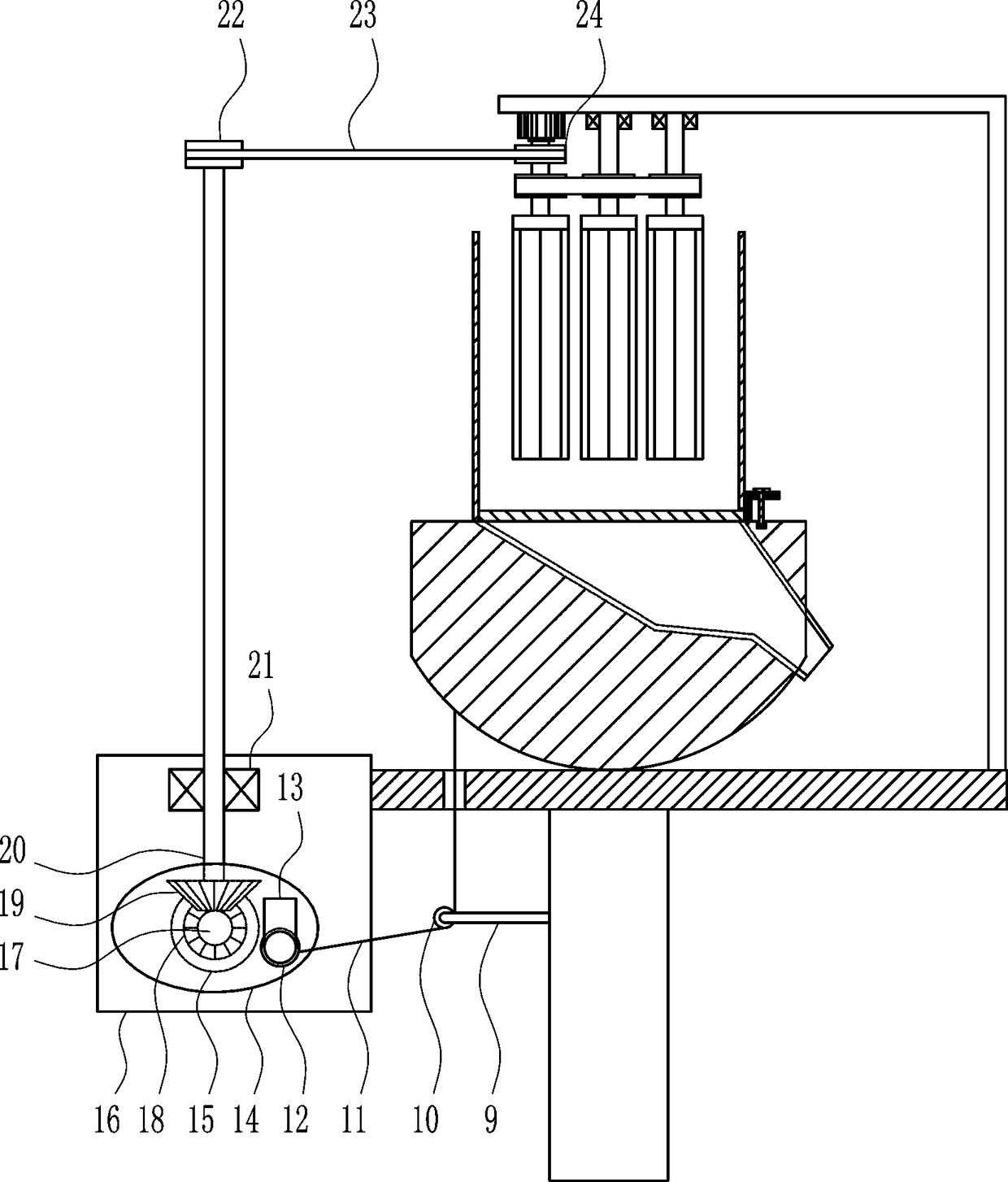

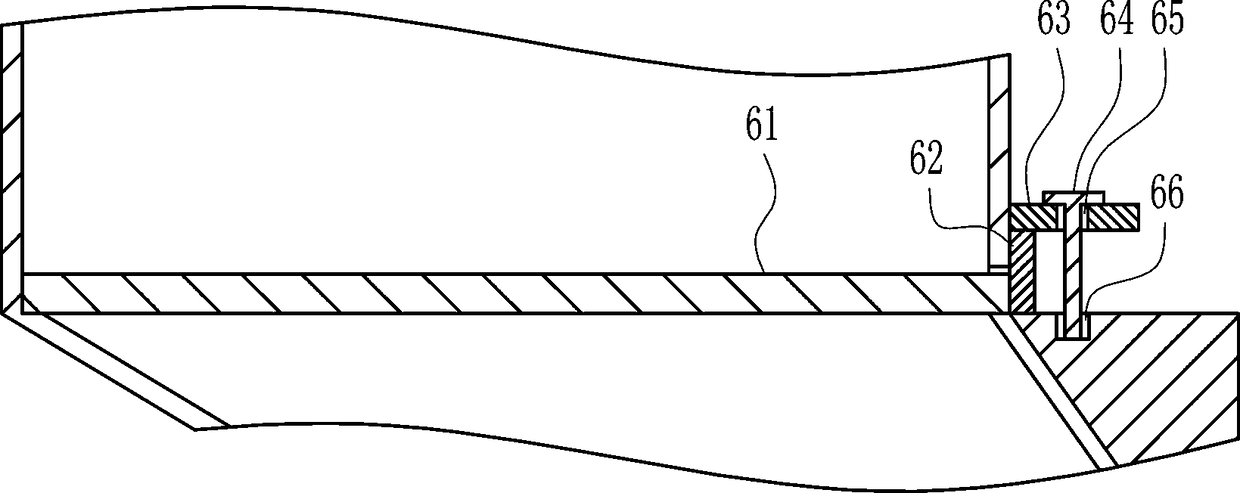

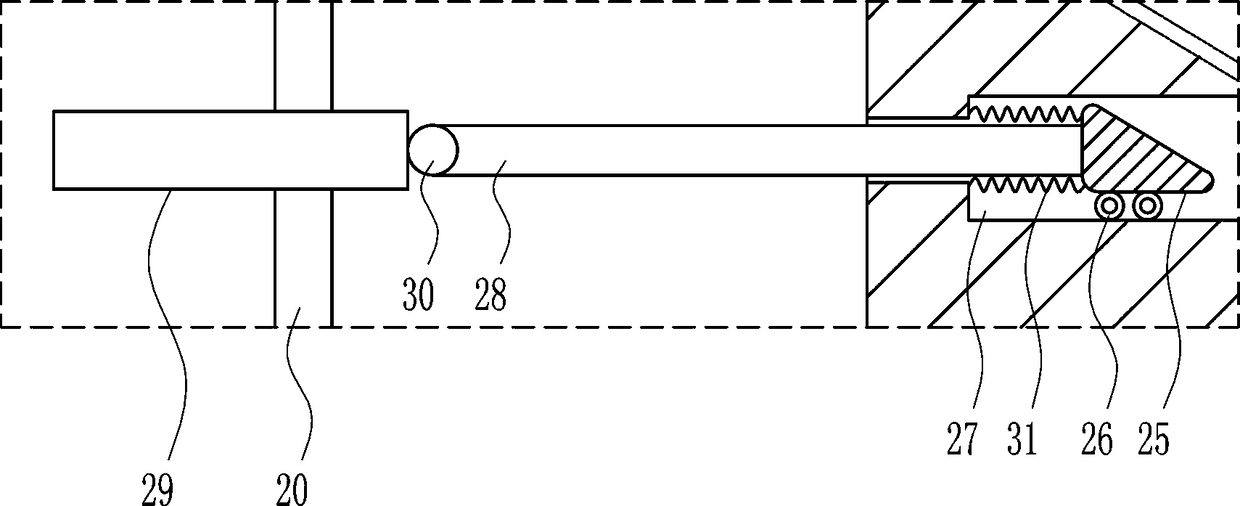

Stirrer device capable of efficiently homogenizing and clarifying

The invention disclosesa stirrer device capable of efficiently homogenizing and clarifying, belongs to the technical field of glass smelting, and aims to increase a glass transmittance by increasing the homogenizing efficiency and clarifying efficiency, and shortening the smelting time. The stirrer device is mainly characterized by comprising a stirring shaft, pore array tubes or the pore array tubes and a stirring frame and a rotary vent joint, wherein pore array tubes are arranged on a lower part of the stirring shaft; the stirring frame or the pore array tubes are arranged at a bottom end of the stirring shaft; the whole walls of the pore array tubes are provided with pores; the stirring shaft is provided with an inner cavity which is provided with an opening at an upper end; the inner cavity is in communication with inner cavities of the pore array tubes; the rotary vent joint is arranged at an upper end of the stirring shaft. The stirrer device has the characteristics that upper large-area molten glass and lower large-area molten glass are homogenized simultaneously, bubbles in the molten glass are gathered and eliminated by floating, the homogenizing time and the clarifying time are shortened, and the stirrer device is mainly applied to the preparation and production of small-batch or experimental clinkers by intermittent crucibles.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

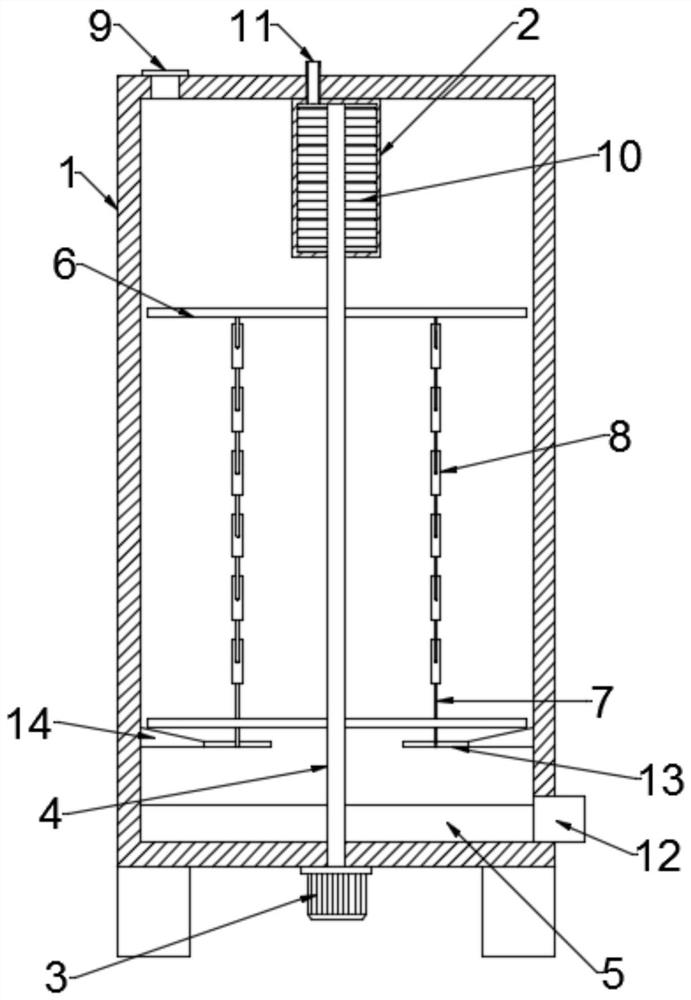

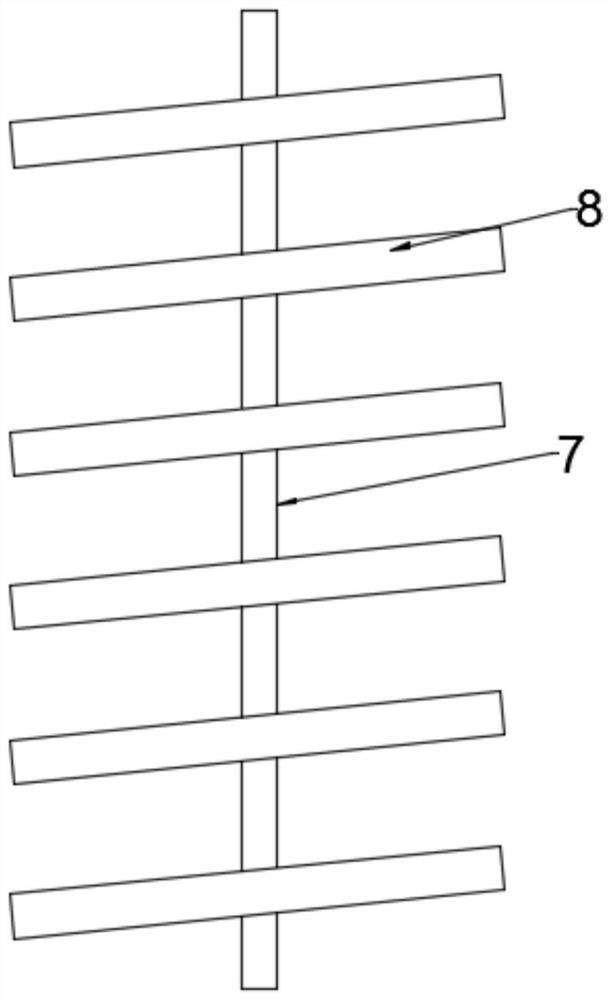

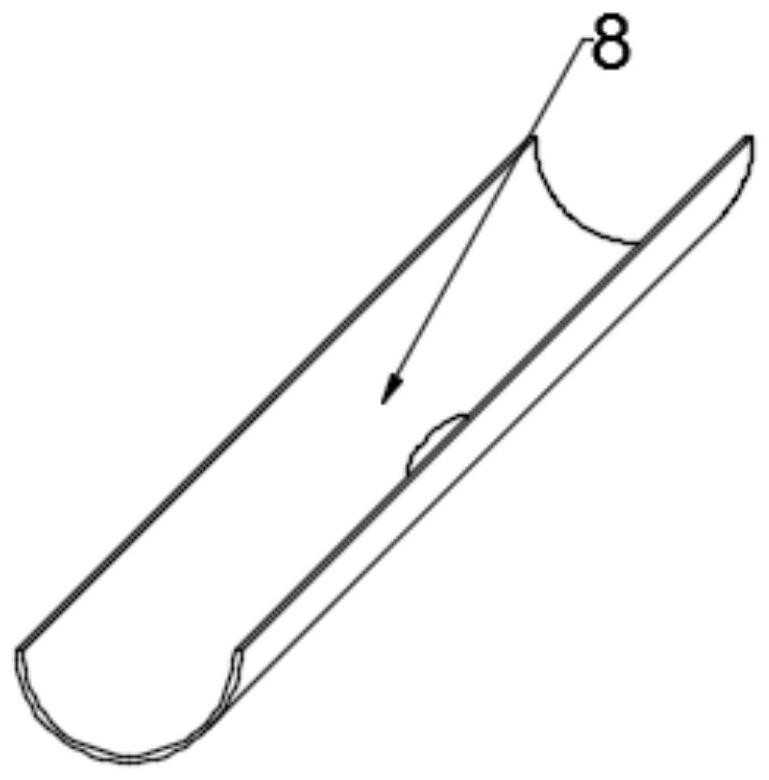

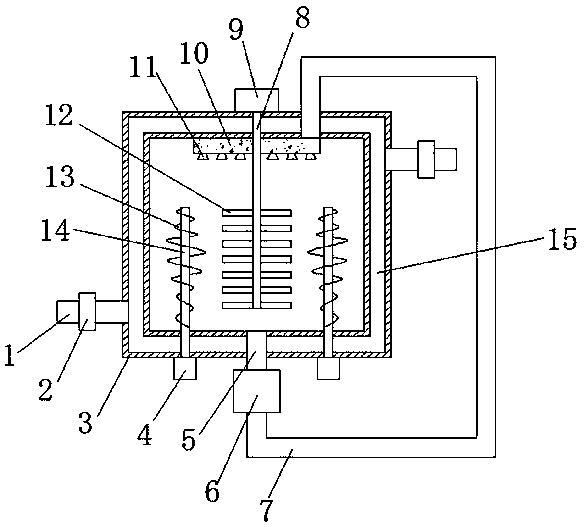

High-efficiency chemical production homogenization device

InactiveCN107551892AImprove efficiencyImprove the quality of homogenizationFlow mixersTransportation and packagingEngineeringRaw material

The invention discloses a high-efficiency chemical production homogenization device which comprises a homogenization tank, wherein the bottom end of the homogenization tank is in an open structure; abin gate is fixed on an outer wall of the bottom end of the homogenization tank by hinges; a rotating shaft bracket is welded on an inner wall of the bottom end of the homogenization tank, and is in an X-shaped structure; a bearing pedestal is welded in the center of the rotating shaft bracket; a second bearing is connected on an inner wall of the bearing pedestal in a sleeving manner; an openingis formed in a center point of the top end of the homogenization tank; a first bearing is connected on an inner wall of the opening in a sleeving manner; and a rotating shaft is connected between thefirst bearing and the second bearing in a sleeving manner. According to the homogenization device, the homogenization tank is additionally arranged, and two stirring blades in different sizes are additionally arranged in the homogenization tank, so that a raw material can be homogenized in layers; and a circulating pipe is additionally arranged at the bottom end, so that the precipitated and unhomogenized raw material can be conveyed to the top of the homogenization tank by a conveying pipe for homogenization again, and the homogenization efficiency and the homogenization quality can be improved.

Owner:新乡市巨能合成材料有限公司

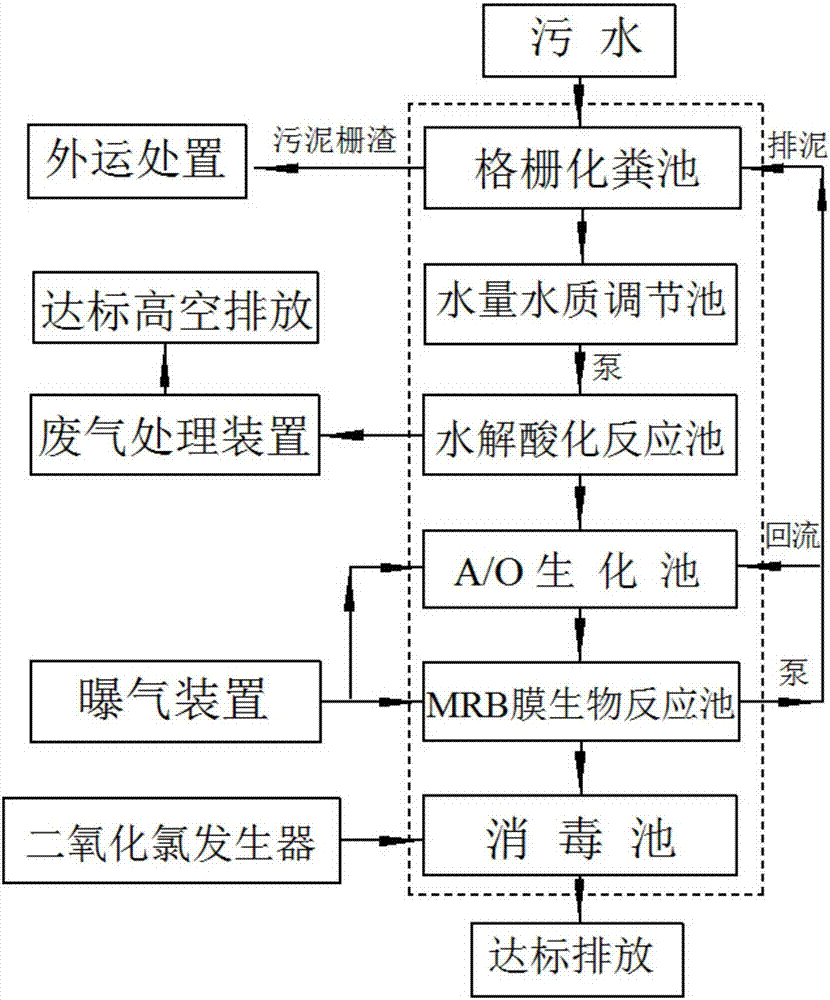

Sewage purifying treatment equipment for water conservancy and hydropower environment engineering

InactiveCN107986566AChange structureReduce moisture contentTreatment using aerobic processesTreatment involving filtrationSludgeWater quality

The invention discloses sewage purifying treatment equipment for water conservancy and hydropower environment engineering. Sewage is collected, is then converged in a main pipe and firstly enters a grid-type septic tank, and the sewage intercepted by grids automatically flows into a water quantity and water quality adjusting tank for water quantity adjustment and water quality homogenization; a three-dimensional elastic filler is mounted inside a hydrolyzing and acidifying reaction tank so as to increase the number of microorganisms per unit volume, and under the action of a large number of hydrolyzing bacteria and acidifying bacteria, high molecular non-degradable pollutants are hydrolyzed into easily-degradable small molecular substances, so that the biodegradability of the sewage is improved and a foundation is laid for a subsequent treatment technology; effluent water automatically flows into an A / O biochemical tank and is reduced into C, N and O in molecular states; effluent waterautomatically flows into a built-in MRB membrane bioreaction tank, and a filtrate flows through a water collecting pipe of an MRB membrane assembly and is converged into a disinfection tank; remaining sludge is discharged into the septic tank, regularly sucked by a fecal suction truck, externally transported and disposed; waste gas is deodorized by a waste gas treatment device and emitted at a high altitude. The sewage treatment efficiency is high, waste gas emission is up to the standard, and the harmless wastewater treatment performance is strong.

Owner:陈值英

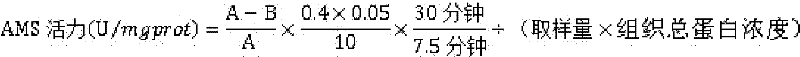

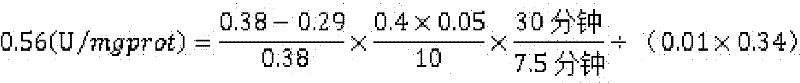

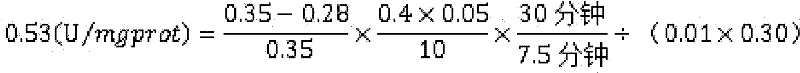

Method for measuring digestive enzyme activity of tissues of seahorse baby with enzyme linked immunosorbent assay

InactiveCN102213716AReduce dosageLow costPreparing sample for investigationColor/spectral properties measurementsAssayTotal protein

The invention relates to a method for measuring the digestive enzyme activity of tissues of a seahorse baby with enzyme linked immunosorbent assay. The method comprises the following steps of: (1) putting a frozen seahorse baby into a container, adding normal saline of NAC1 with the concentration of 0.7 percent or a homogenizing medium in an ice bath, homogenizing by using a multifunctional sample homogenizer, centrifuging with a centrifuge and taking supernatant fluid for later use; (2) measuring the total protein concentration of the tissues with a part of the supernatant fluid; (3) adding a substrate starch buffer solution into a container A and a container B respectively, adding the supernatant fluid obtained in the step (1) into the container B and adding iodine reaction liquid and distilled water into the containers A and B respectively; (4) sucking the solutions in the containers A and B, dripping the solutions into two holes of an enzyme label plate, putting the enzyme label plate into an enzyme label reader and detecting the absorbency of the solutions in the two holes simultaneously; and (5) calculating the amylase activity of a sample. The method disclosed by the invention is easy to operate, has low cost and high efficiency and is environment-friendly.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Glass continuous melting furnace and melting method

ActiveCN112028454AReduce solubilityImprove clarification efficiencyPot furnacesGlass furnace apparatusPlatinumCrucible

The invention discloses a glass continuous melting furnace and a melting method, and belongs to the technical field of optical glass melting production. The furance mainly solves the problem that theproduction efficiency is affected due to the fact that the stripe homogenization efficiency and the bubble clarification efficiency are limited in the continuous smelting process. The furance is mainly characterized by comprising a melting crucible, a homogenizing crucible, a clarification tank and a working crucible which are made of platinum, and a first communicating pipe, a second communicating pipe and a third communicating pipe which are connected amoung the melting crucible, the homogenizing crucible, the clarification tank and the working crucible, wherein the homogenizing crucible andthe working crucible are respectively provided with a homogenizing partition plate and a homogenizing rod which are made of platinum, a clarifying partition plate is arranged in the clarification tank, and a negative pressure stabilizer is arranged at the upper part of the clarification tank. The furnace has the characteristics that the stripe dissipation efficiency and the bubble floating efficiency in the optical glass smelting process can be effectively improved, and the comprehensive production efficiency is improved, and the furnace is mainly used for improving the production efficiencyof the optical glass continuous smelting furnace.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

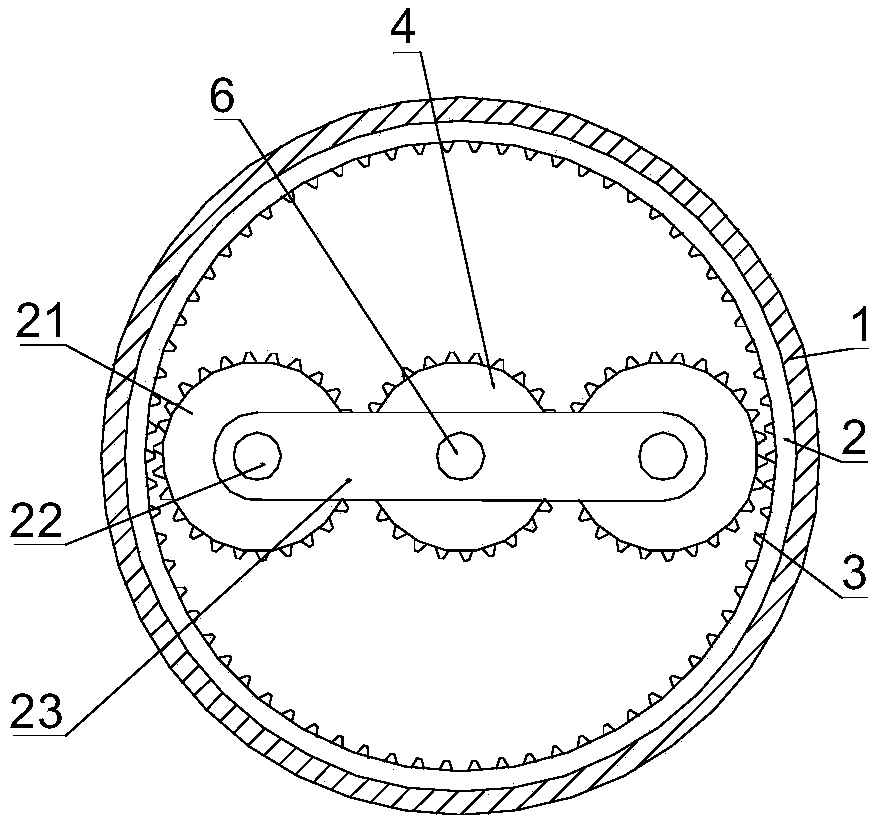

Dairy product homogenizing processing device

InactiveCN111905593AEffective stirringWell mixedRotary stirring mixersTransportation and packagingProcess engineeringMechanical engineering

The invention discloses a dairy product homogenizing processing device, which comprises a shell, an adding cavity is fixedly connected to the top in the shell, a stirring shaft is rotatably connectedto the interior of the shell, discharging stirring blades are fixedly connected to the bottom of the periphery of the stirring shaft, and a homogenizing mechanism is fixedly connected to the middle ofthe periphery of the stirring shaft; a plurality of sets of crushing blades are fixedly connected to the part, located in the adding cavity, of the stirring shaft, a material guide ring is fixedly connected to the inner wall of the shell, the material guide ring is of an annular structure, an inner gear is embedded and fixed to the inner ring, and the surface of the material guide ring inclines downwards from outside to inside; and the inner gear of the inner ring of the material guide ring is in engaged transmission with the homogenizing mechanism. According to the milk stirring device, additives can be crushed while materials are stirred, homogenized milk is efficiently stirred, mixed milk is better obtained, and the homogenizing efficiency is improved.

Owner:高贵真

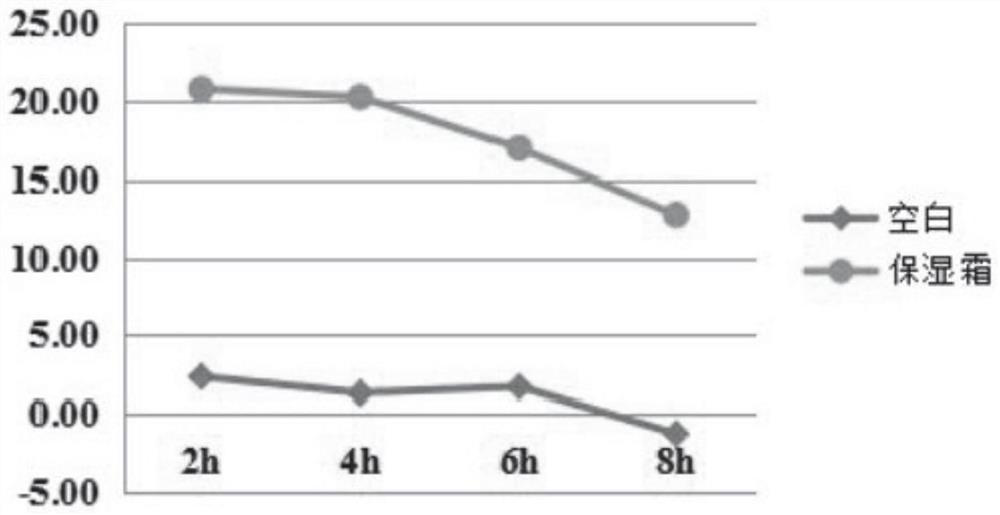

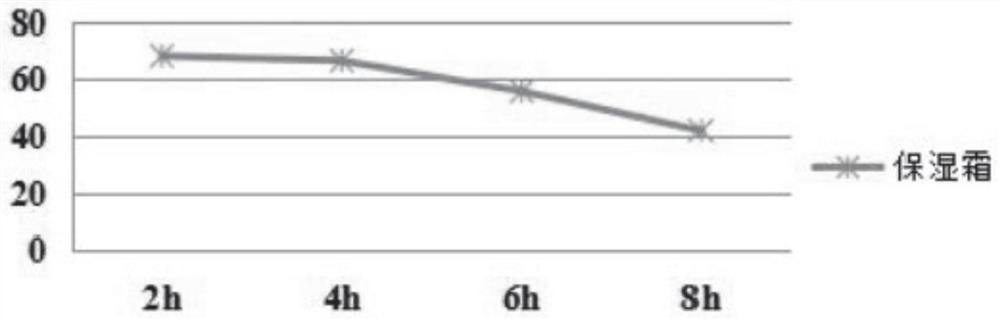

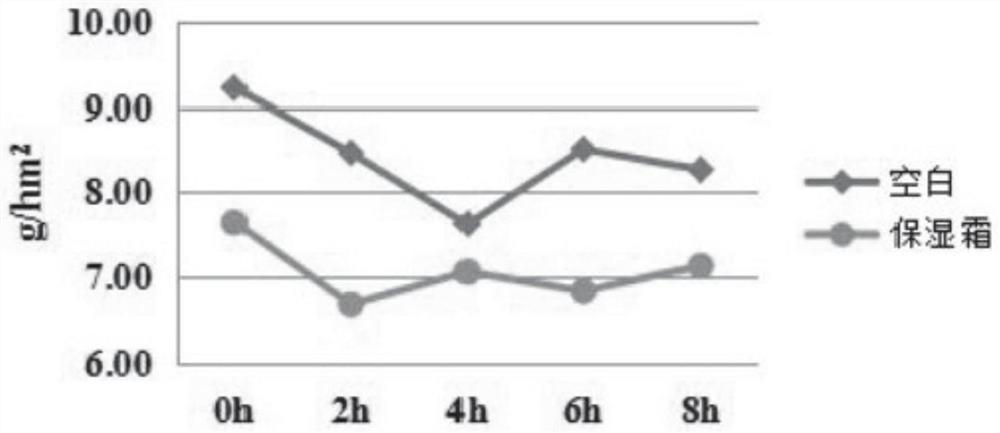

Moisturizing cream and preparation method thereof

PendingCN112957290AMild textureImprove dullnessCosmetic preparationsToilet preparationsGlycerolButyrospermum parkii

The invention discloses a moisturizing cream and a preparation method thereof. The moisturizing cream is prepared from polyglycerol-3 methyl glucose distearate, cetostearyl alcohol, butyrospermum parkii butter, stearic acid, beewax, C10-18 fatty acid triglyceride, wool fat, polydimethylsiloxane, phytosterol / octyldodecanol lauroyl glutamate, isononyl isononanoate, simmondsia chinensis seed oil, diisostearyl malate, pentaerythritol tetraisostearate, a ceramide compound, saccharomycetes / rice fermentation product filtrate, a dendrobium officinale stem extract, a radix ophiopogonis root extract, a poria cocos extract, a radix scrophulariae extract, a radix polygonati officinalis extract and the like. The moisturizing cream is safe in component, can make the face skin continuously moisturized and nourished, and relieves the dry and tight feeling of the face skin.

Owner:FUJIAN PIENTZEHUANG COSMETICS CO LTD

Material mixing device for concrete production

InactiveCN108972878AImprove homogeneityImprove homogenization efficiencyHollow article cleaningCement mixing apparatusEngineeringMoving parts

The invention discloses a material mixing device for concrete production, and relates to the technical field of concrete processing. The material mixing device comprises a mixing box; rotating blocksare arranged on the upper side of the interior of the mixing box; a rotating driving device is arranged on the outer surface of the mixing box; and the output end of the rotating driving device is fixedly connected to the centers of the side surfaces of the rotating blocks. According to the material mixing device, the rotating blocks rotate, through the cooperative effect of moving parts and strip-shaped gaps, free columns can move up and down in a reciprocating mode, due to the magnetic attraction action of magnets and iron sheets, rotating sheets can move in a reciprocating mode, and therefore the homogenization effect of concrete raw materials is improved; the elastic coefficients of the different pressure springs a are different, so that the moving range of the different rotating sheets is different, and therefore the homogenizing effect of the concrete raw materials is further improved; and the free columns drive stirring paddles to move, so that the concrete raw materials are turned over, and therefore the homogenization efficiency of the concrete raw materials is improved.

Owner:EAST CHINA JIAOTONG UNIVERSITY

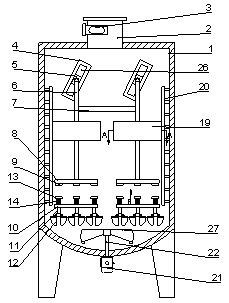

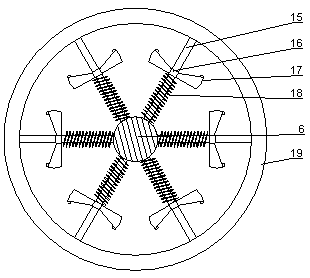

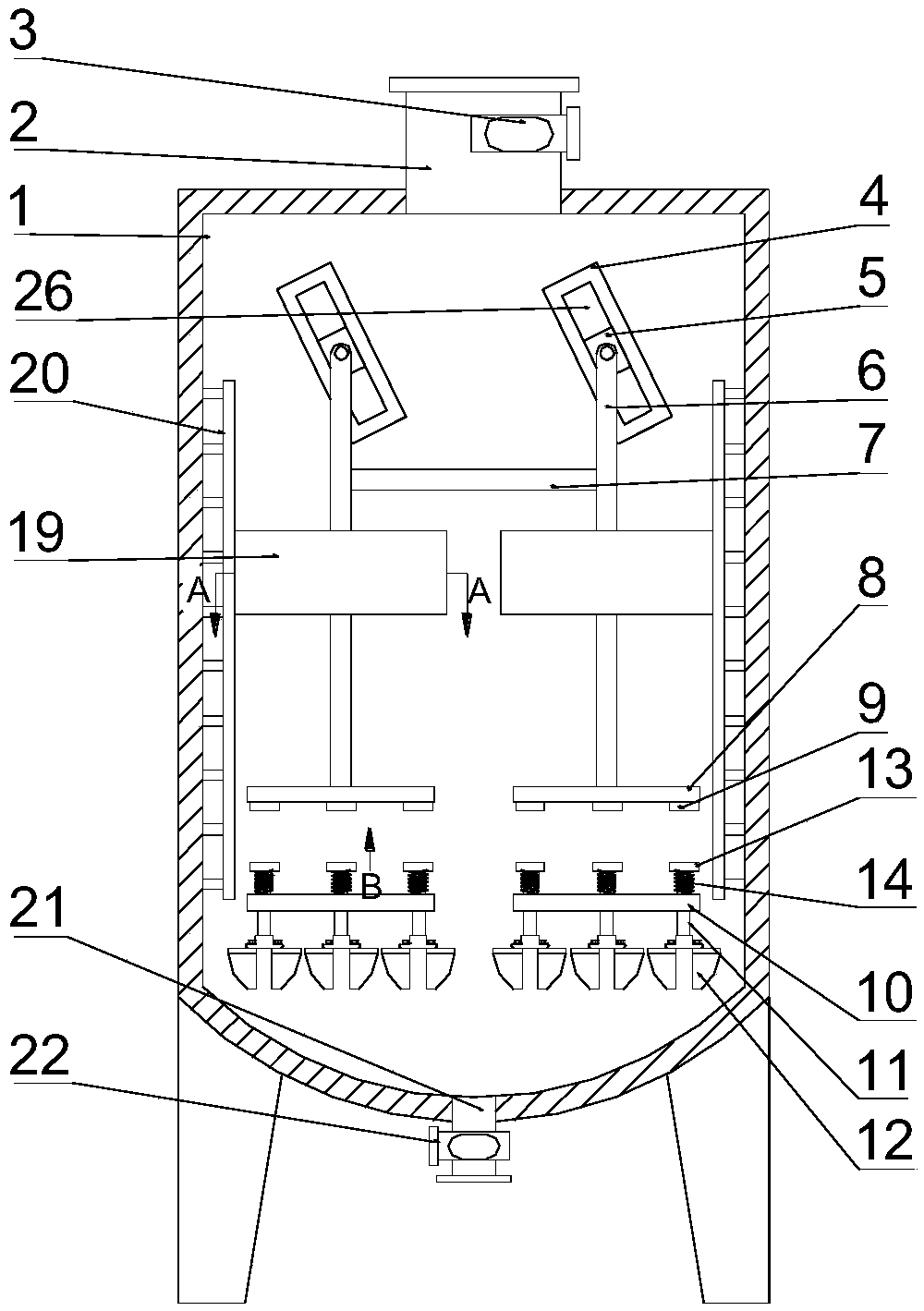

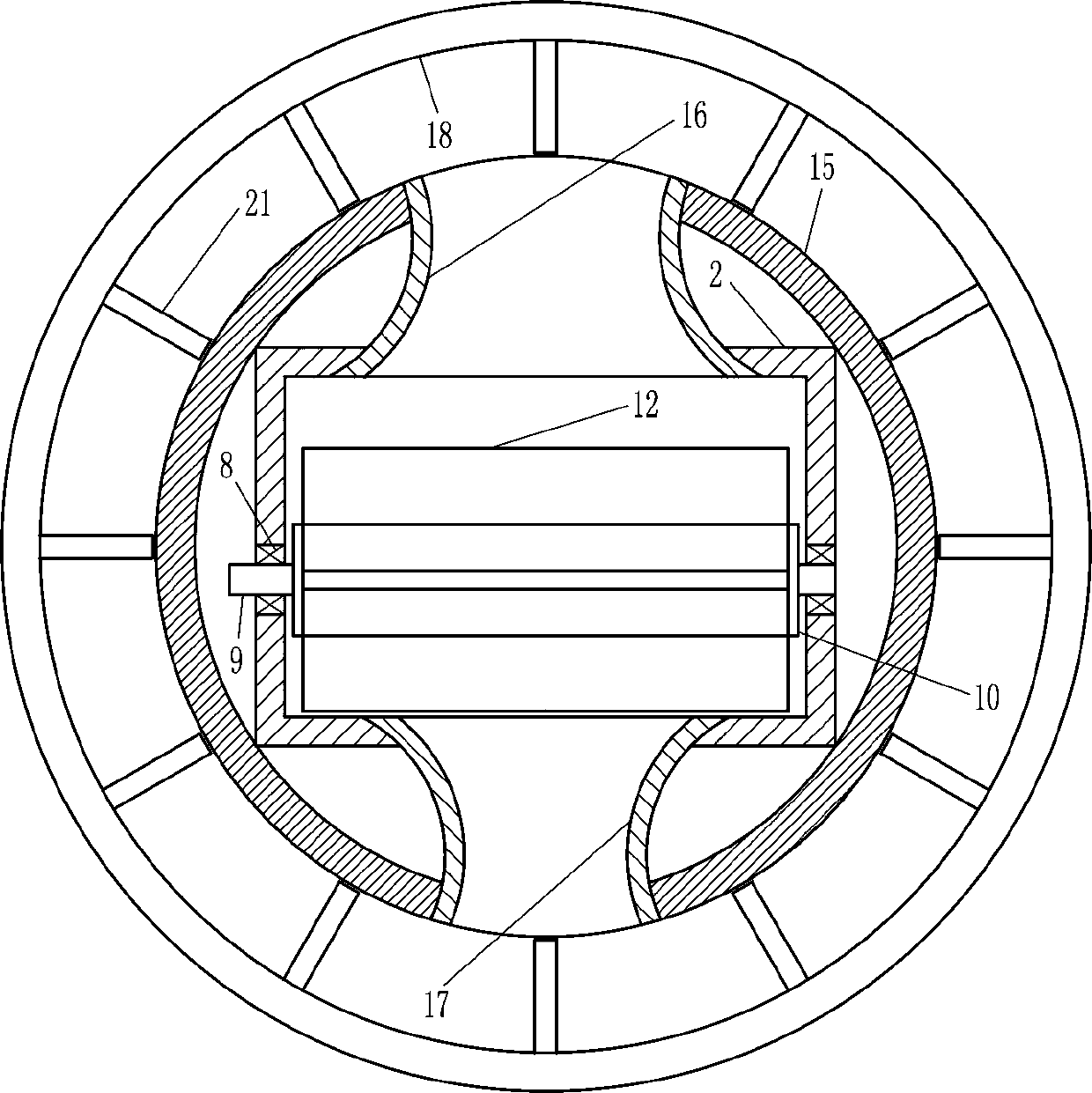

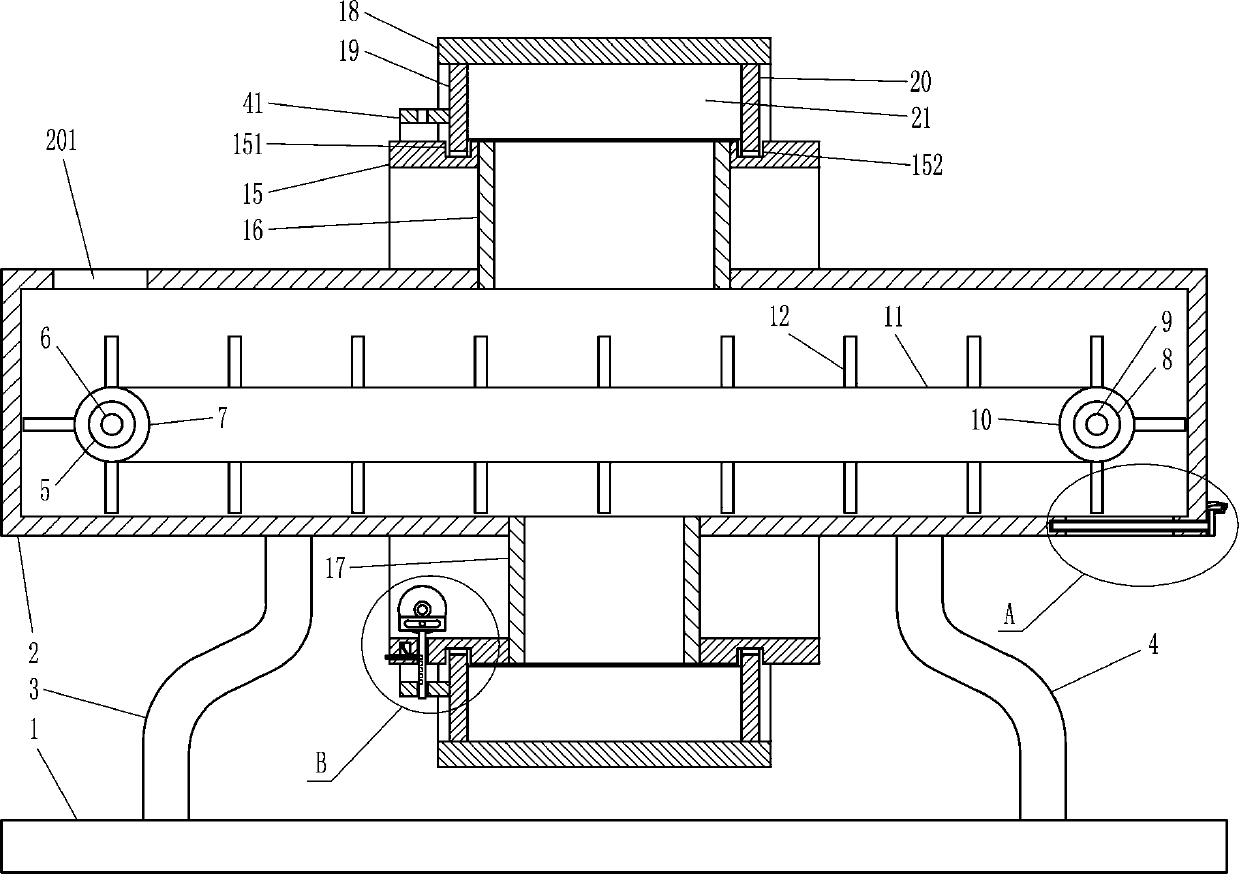

Nanocrystallization homogenizing and sterilizing all-in-one machine

ActiveCN111318204AEnergeticImprove transmission efficiencyRotary stirring mixersTransportation and packagingHydraulic cylinderEngineering

The invention discloses a nanocrystallization homogenizing and sterilizing all-in-one machine, which belongs to the field of homogenizing devices and comprises a homogenizing part, a transfer cylinderand an output part. The homogenizing part comprises a plurality of pressing pumps and a driving device, the pressing pumps are horizontally arranged, each pressing pump comprises a pressing cylinderand a pressing rod, the pressing rods penetrate through the pressing rods and extend into the pressing rods, and the driving device comprises a hydraulic cylinder, a first ejector rod, a second ejector rod, a third ejector rod, a fourth ejector rod, a rotary disc, a first abutting plate and a second abutting plate. The driving device is controlled through the hydraulic cylinder, more abundant power can be provided, meanwhile, the driving device makes the hydraulic cylinder provide power for driving the corresponding pressure pumps in the reciprocating two-end displacement process through matching of the multiple ejector rods and the rotary disc, the transmission efficiency is greatly improved, and the homogenization efficiency is also improved. Meanwhile, the condenser and the pressurizingpump arranged on the device can perform low-temperature pressurizing disinfection and sterilization on the materials while homogenizing, so that the trouble of later disinfection is reduced, and theproduction efficiency is improved.

Owner:NANJING ZELANG AGRI DEV

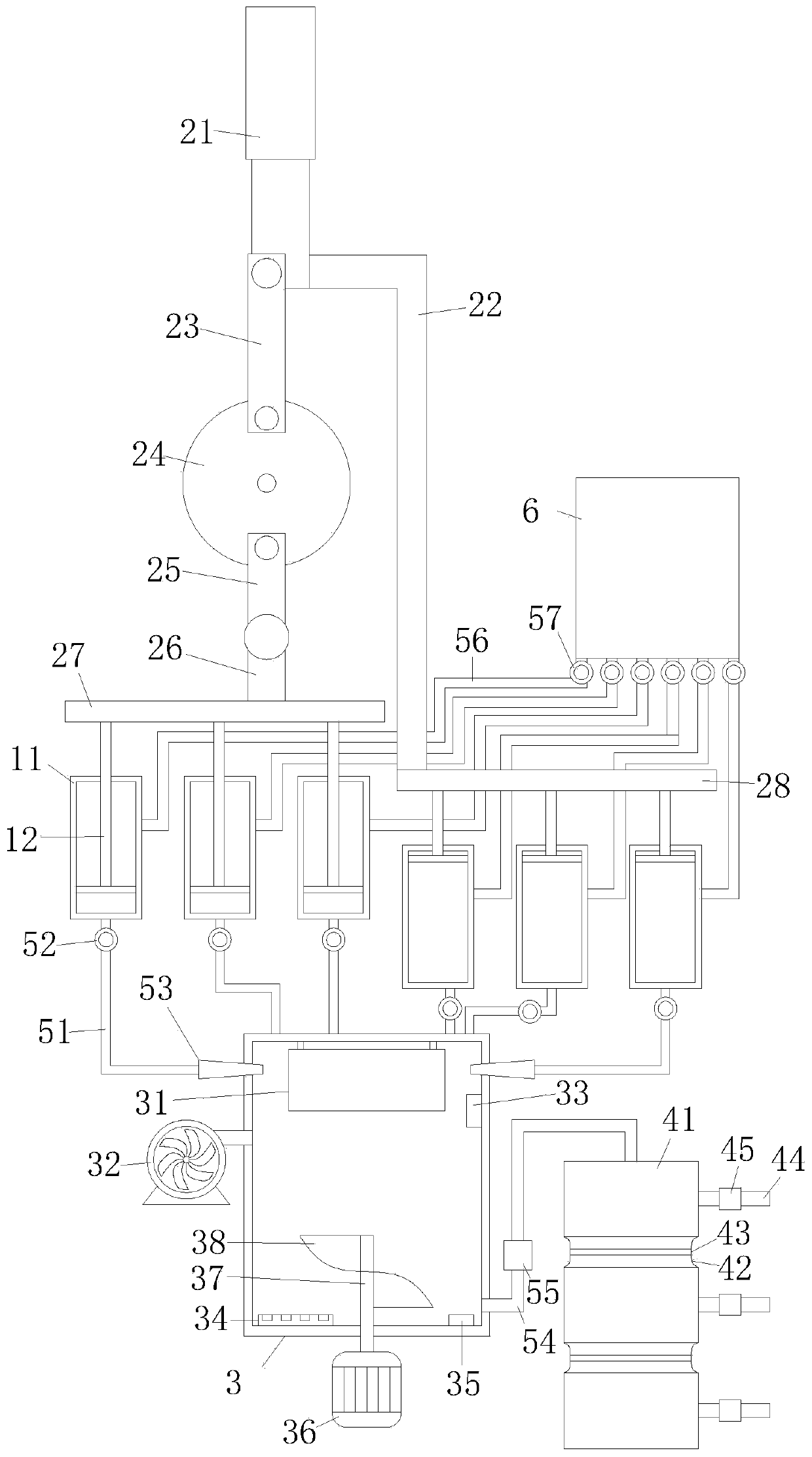

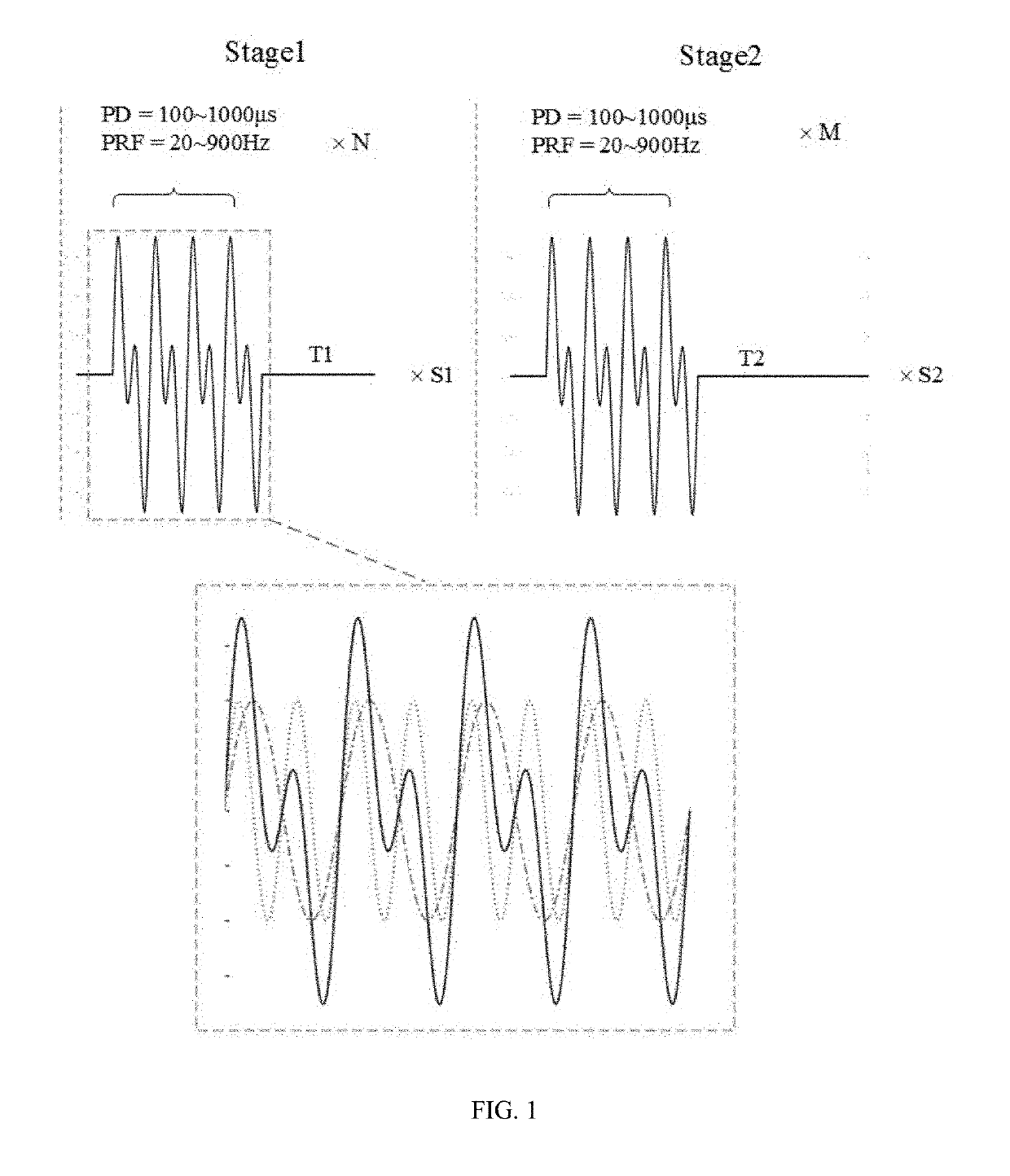

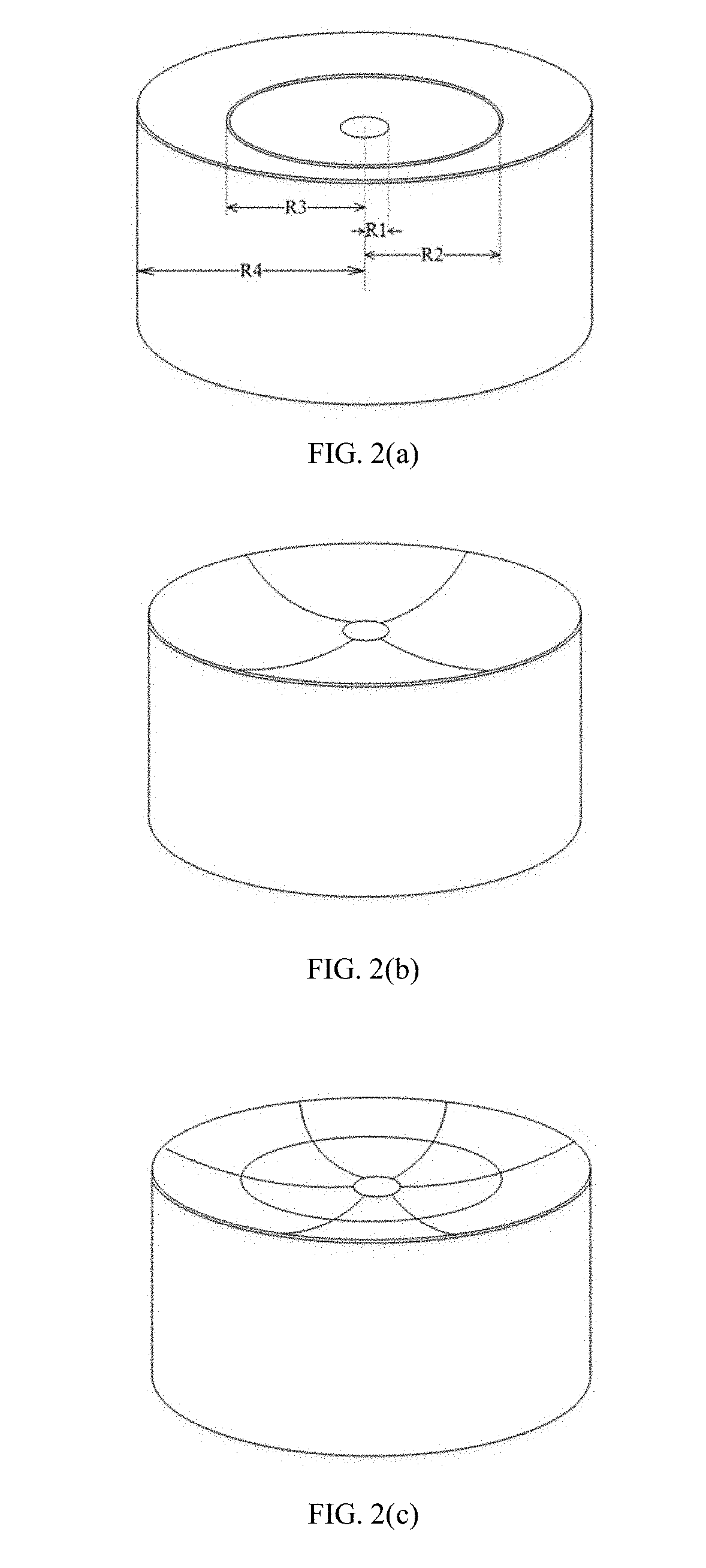

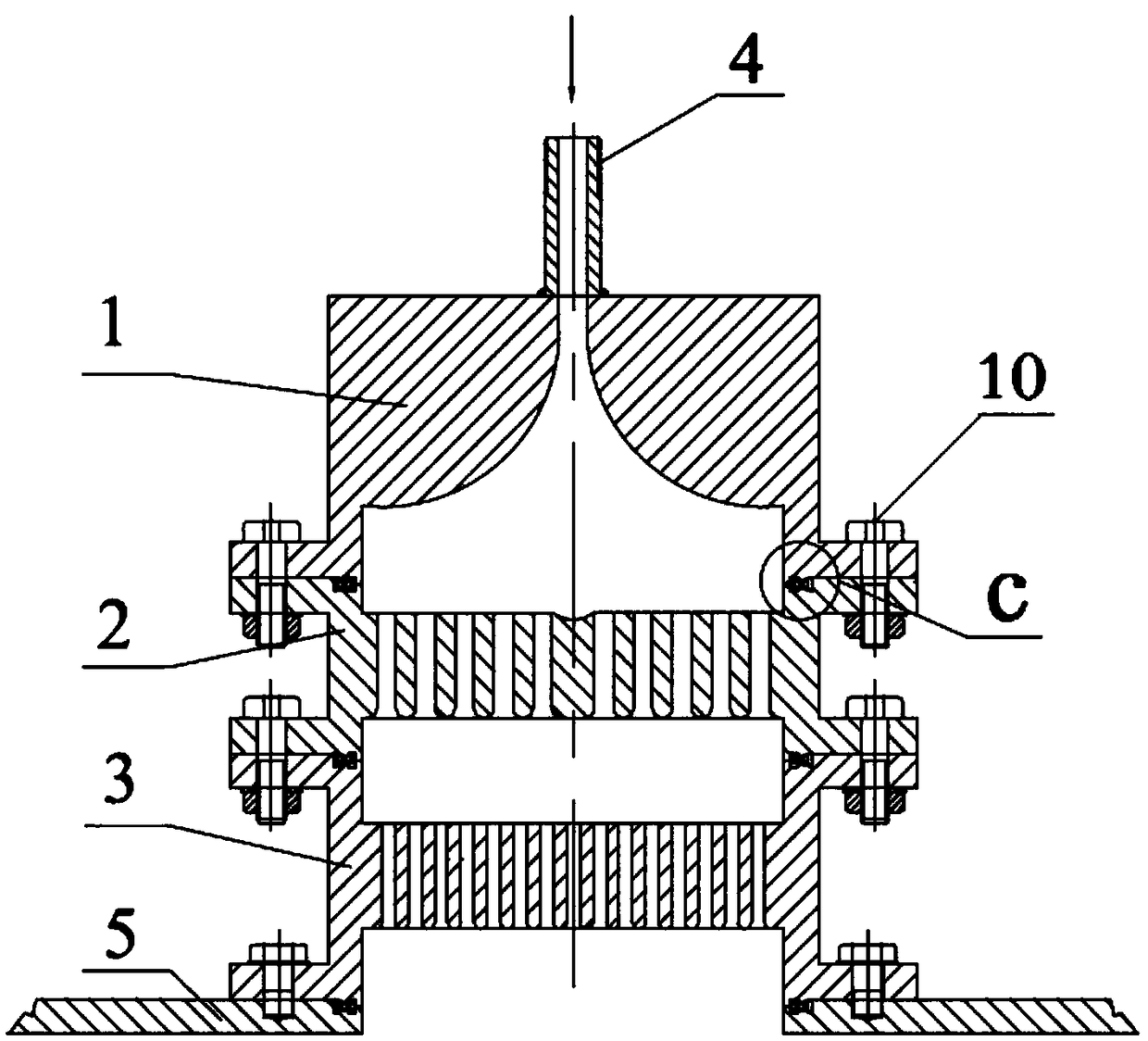

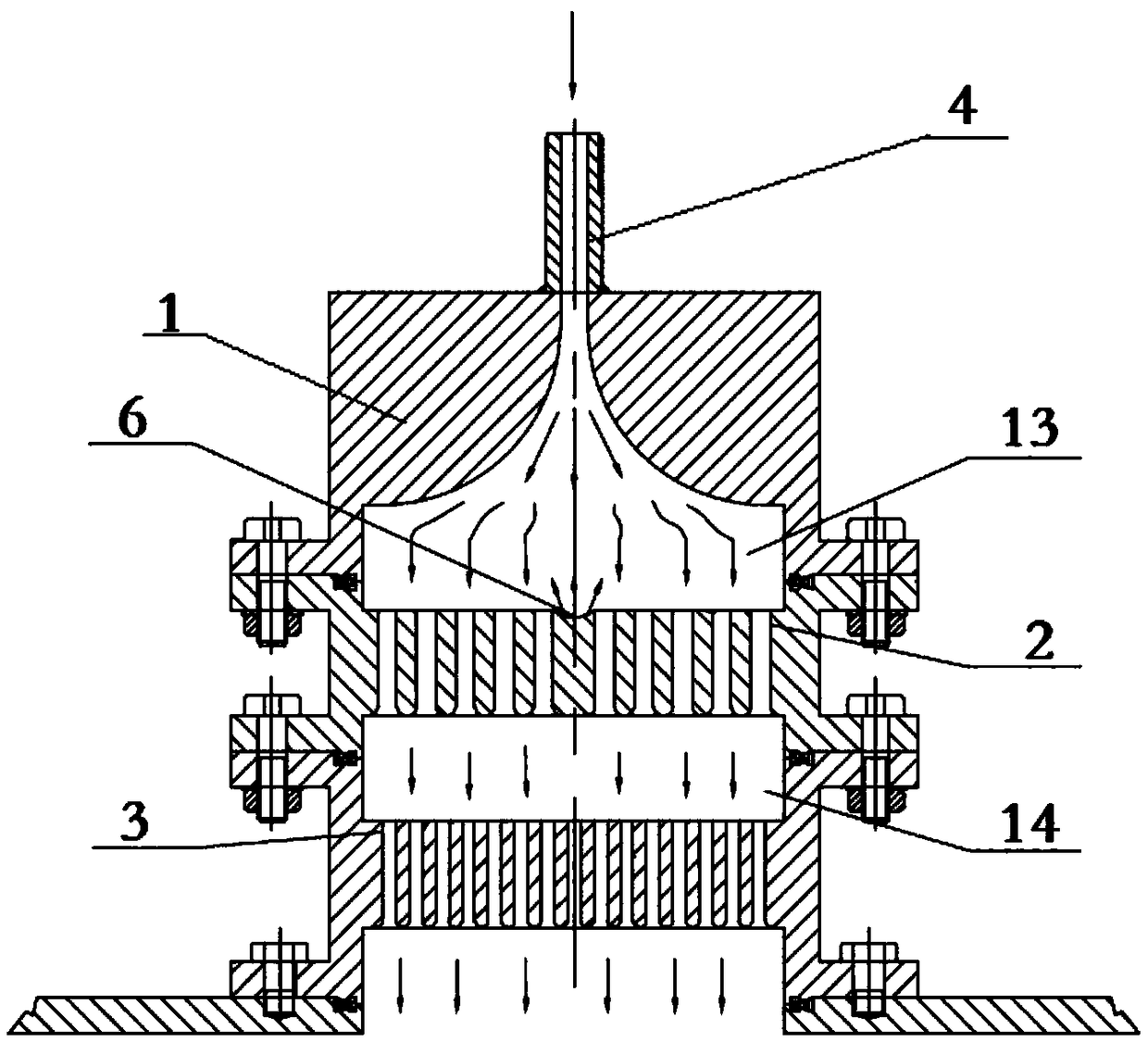

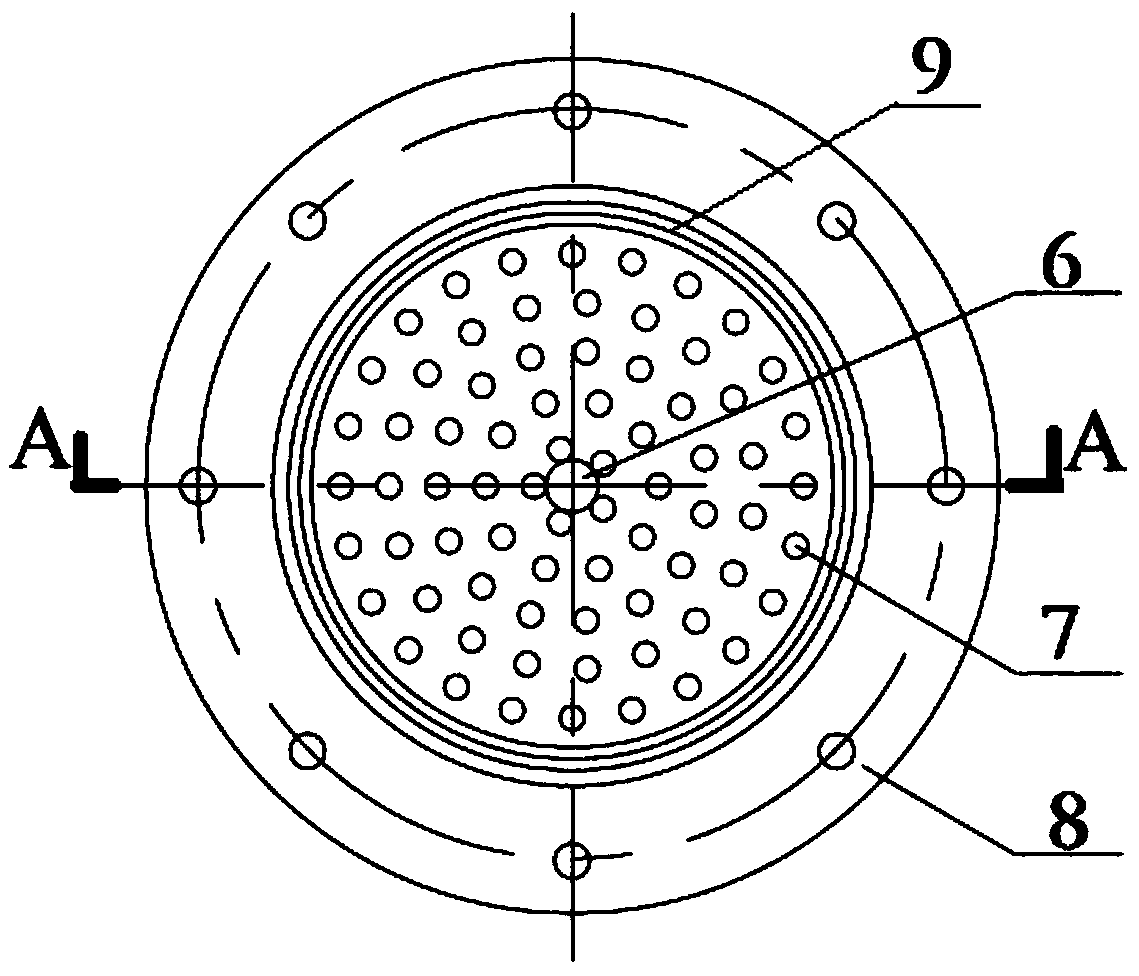

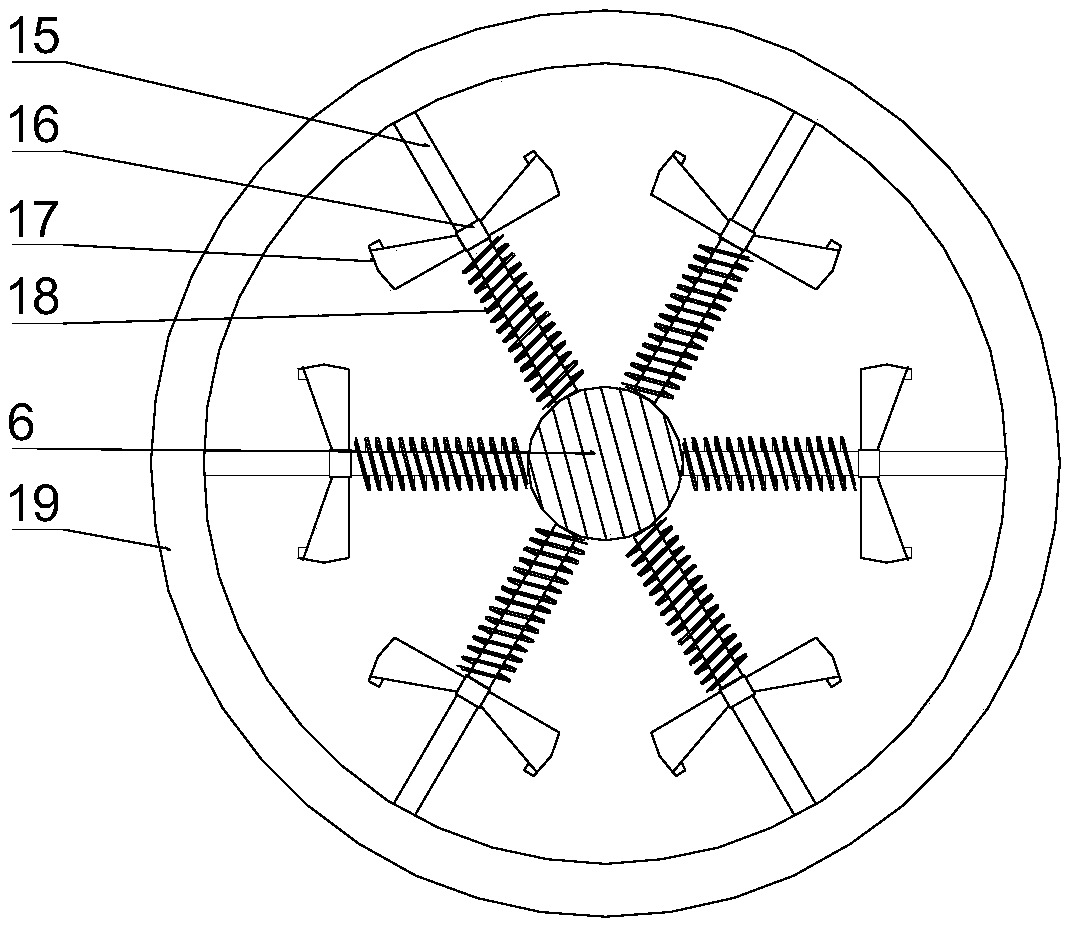

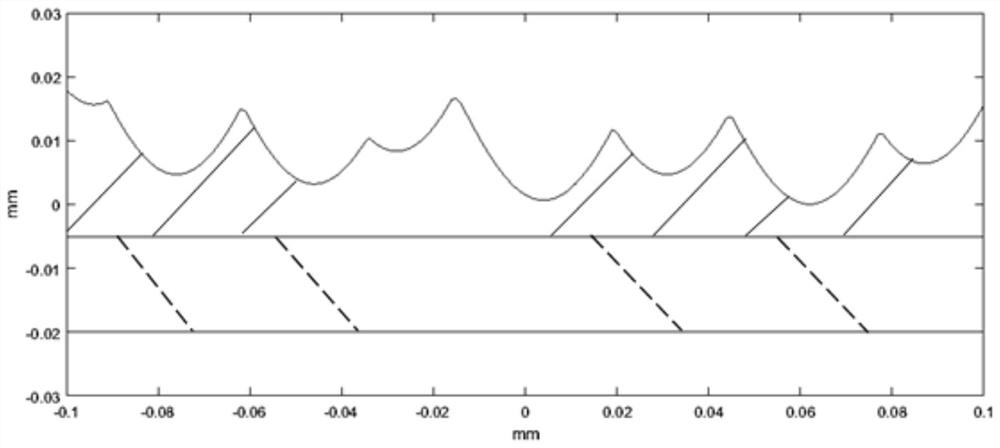

Method for controlling histotripsy using confocal fundamental and harmonic superposition combined with hundred-microsecond ultrasound pulses

ActiveUS20190307472A1Good effectReduce peak acoustic pressureUltrasound therapyDiagnosticsShock waveSonification

A method for controlling a histotripsy using a confocal fundamental and harmonic superposition combined with hundred-microsecond ultrasound pulses, including: 1) positioning a target tissue by a monitoring and guiding system and adjusting a position of the target tissue to a focal point of a transducer; 2) first stage: controlling the confocal fundamental and harmonic superposition combined with hundred-microsecond ultrasound pulses to form a shock wave in a focal zone; wherein a negative acoustic pressure exceeds a cavitation threshold; an inertial cavitation occurs to generate boiling bubbles; the boiling bubbles collapse and achieve partial homogenization of the target tissue; 3) second stage: controlling the confocal fundamental and harmonic superposition combined with hundred-microsecond pulsed-ultrasound sequences to simultaneously irradiate a target zone and further mechanically disintegrate and homogenize the target tissue.

Owner:XI AN JIAOTONG UNIV

Gas shower device

PendingCN109402609AImprove homogenization efficiencyImprove spatial distribution uniformityChemical vapor deposition coatingProcess engineeringAir tightness

The invention discloses a gas shower device which comprises a gas intake buffer structure, a first gas homogenization structure and a second gas homogenization structure which are sequentially connected, and a gas inlet of the gas intake buffer structure is used for being connected with a gas inlet duct. A gas outlet of the gas intake buffer structure is communicated to the first gas homogenization structure, the first gas homogenization structure and the second gas homogenization structure are provided with gas shower holes communicated with each other, and the bottom of the second gas homogenization structure is used for being connected to the vacuum chamber wall of an atomic layer deposition coating machine. The gas intake buffer structure can achieve initial decompression and divergence of the intake gas, and the double-layer gas homogenization structures are adopted to improve the distribution uniformity of the shower gas at a substrate. Components are connected through flanges with knife edge grooves, the air tightness is good, and the device is suitable for use under corrosive gas and high temperature working conditions. After connection with the metal sealing structure, thebuffer space in certain height is formed between the three structures to further improve the gas homogenization efficiency.

Owner:CHENGDU JIANGYE OPTOELECTRONICS TECH

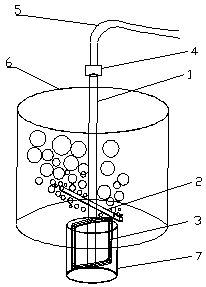

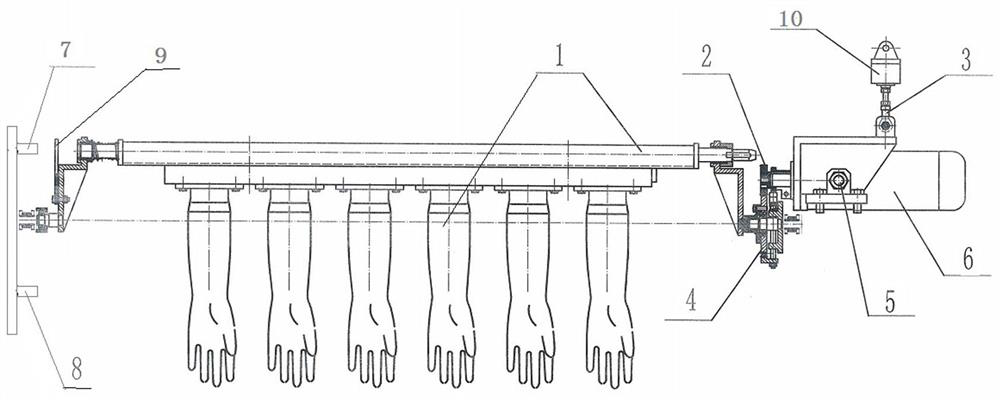

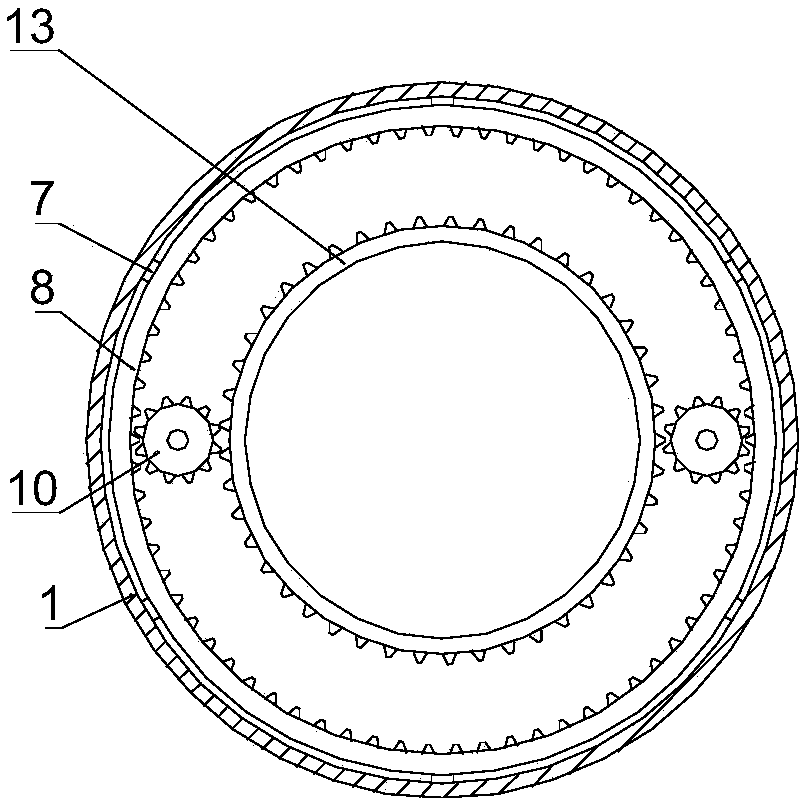

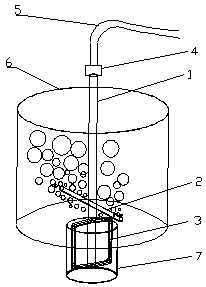

Circular homogenizing device for lubricating grease raw materials

PendingCN107551875AWell mixedImprove homogenization efficiencyRotary stirring mixersMixer accessoriesWater flowEngineering

The invention discloses a circular homogenizing device for lubricating grease raw materials. The circular homogenizing device comprises a homogenizing barrel, wherein a clamping cavity is formed between the inner wall and the outer wall of the homogenizing barrel; a first connecting pipe is inserted in the middle position of the bottom inner wall of the homogenizing barrel; a conveying pump is connected to one end, away from the homogenizing barrel, of the first connecting pipe through a flange; a conveying pipe is connected to one end, away from the first connecting pipe, of the conveying pump, through a flange; a second connecting pipe is connected to one end, away from the conveying pump, of the conveying pipe; equidistantly-distributed spray heads are connected to the outer wall of thebottom of the second connecting pipe through a fastening bolt. The circular homogenizing device is provided with a water pipe which can be used for injecting flowing warm water with proper temperature into the clamping cavity, so that the homogenizing efficiency is improved; the circular homogenizing device is provided with a first motor and a second motor which can be used for effectively and sufficiently mixing and homogenizing raw materials of the lubricating grease; the circular homogenizing device is also provided with the conveying pump, the conveying pipe and the spray heads by which homogenized circulation of the raw materials of the lubricating grease is facilitated and the homogenization efficiency is improved.

Owner:XINXIANG HENGXING TECH CO LTD

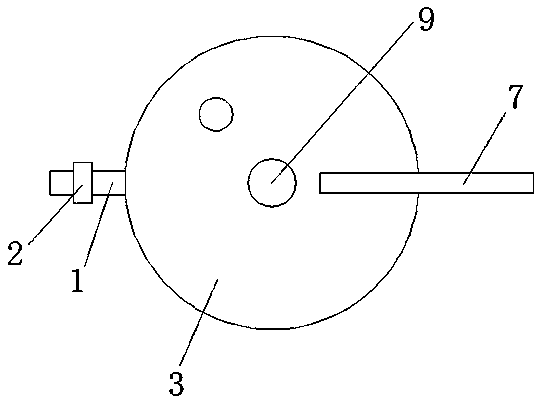

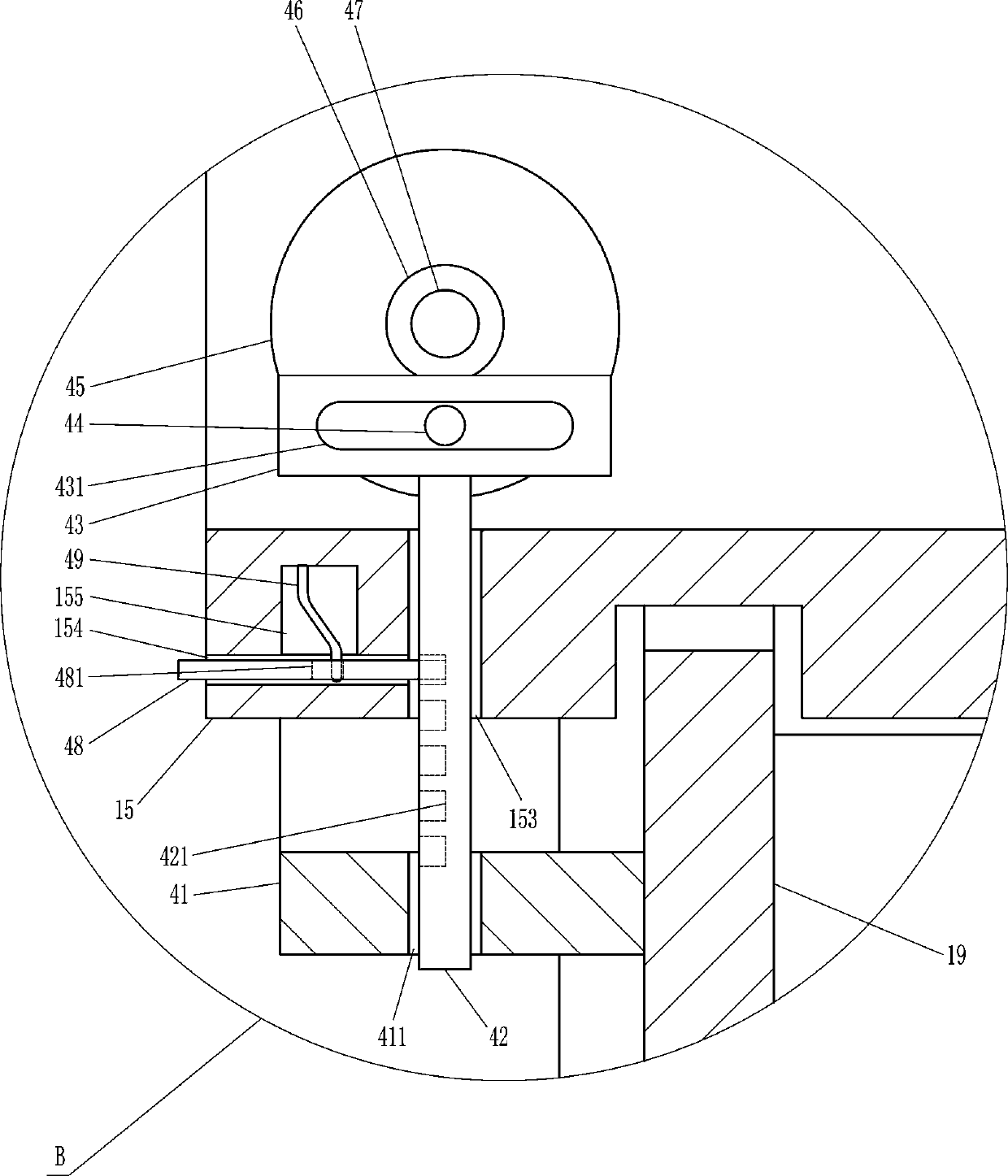

Plate overturning device in rubber latex glove production interlocking machine

PendingCN112238559AImprove homogenization efficiencyShorten the lengthDomestic articlesCoatingsLatex gloveGear drive

The invention discloses a plate overturning device in a rubber latex glove production interlocking machine. The plate overturning device comprises a transversely arranged glove template and is characterized in that the plate overturning device further comprises a sensor, a limiter, an air cylinder, a motor, a connecting rod, a transmission gear, a transmission shaft and a PLC control system, and the limiter is arranged on the left side of the glove template and connected with the sensor. The air cylinder is connected with the motor through the connecting rod, the air cylinder drives the connecting rod to lift, the motor moves with the transmission shaft as the center, the transmission gear is engaged with a gear of the glove template, the motor drives the transmission gear to rotate and drives the gear of the glove template to rotate, and the glove template overturns accordingly. After the plate overturning device is additionally mounted in the glove production interlocking machine, the homogenizing efficiency of gloves impregnated with latex is improved, the length of a glove impregnation tank can be effectively reduced, the mechanical maintenance difficulty is reduced, the spaceoccupied by a homogenizing device in the interlocking machine is also reduced, and the phenomena of uneven glove thickness, glove surface flow marks and fingertip cap-shaped rubber blocks can be wellsolved.

Owner:GUILIN ZIZHU LATEX PROD

TPU alloy material production homogeneous equipment for engineering

The invention discloses TPU alloy material production homogeneous equipment for engineering, and relates to the technical field of engineering alloy materials. A rotating column drives a gear a to rotate to enable a gear b to rotate, in the rotation process of a hollow column, negative pressure is formed at the stopping end of a hollow overflow column on the hollow column due to the action of centrifugal force, gas above a TPU alloy material is drawn into the hollow column through a through hole and discharged through the hollow overflow column to enter into a reaction TPU alloy material, andsufficient homogenization is performed again. Since the hollow column rotates and revolves around the rotating column, the homogenization efficiency is improved, and a turning over plate a and a turning over plate b are arranged in a staggered mode to further improves the uniformity of homogenization. When the rotated TPU alloy material flows through a baffling block a and a baffling block b, themixing effect is improved. The baffling block a rotates forward to cut the TPU alloy material, and meanwhile, the baffling block b rotates backward, and the cutting efficiency of the TPU alloy material is improved.

Owner:苏州荔记得机械工程科技有限公司

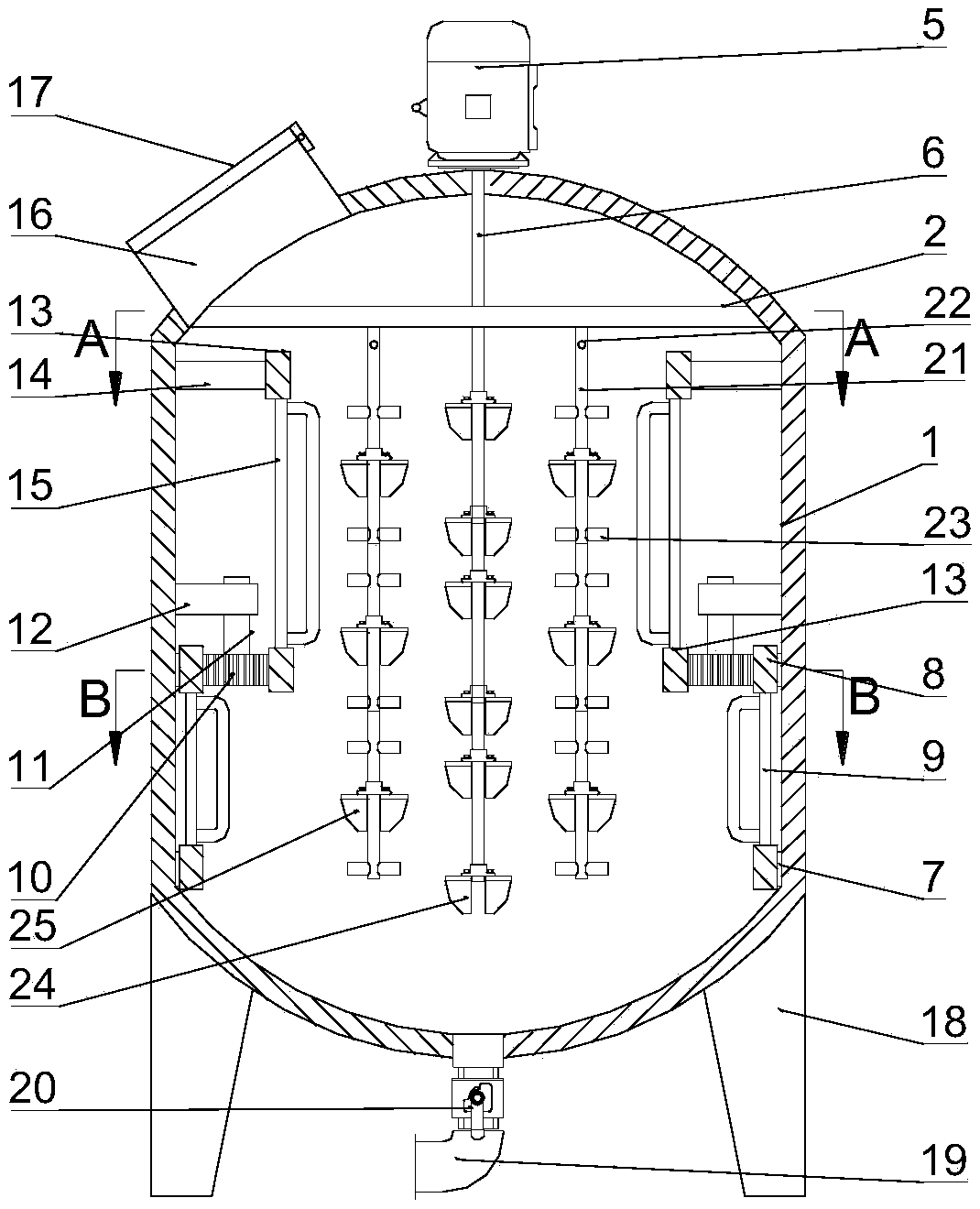

Homogenizer for preparing oil anti-foaming agent for electric power

ActiveCN108854797AImprove the homogenization effectImprove homogenization efficiencyShaking/oscillating/vibrating mixersTransportation and packagingMagnetCoil spring

The invention discloses a homogenizer for preparing oil anti-foaming agent for electric power, which relates to the technical field of electric power apparatus articles. The homogenizer comprises a homogenizing tank, wherein a bar-shaped block is installed on the inner upper side of the homogenizing tank, the outer surface of the homogenizing tank is provided with a driving mechanism, and an output end of the driving mechanism is fixedly connected with the center of the side surface of the bar-shaped block; the bar-shaped block rotates, by virtue of the cooperation effect of a sliding block and a rectangular groove, a movable rod moves up and down in a reciprocating manner, due to the magnetic suction effect of magnets and iron block, the pushing plate moves in a reciprocating manner, so that the homogenizing effect of the oil anti-foaming agent raw material is improved; due to the different elastic coefficients of different first spiral springs, the moving range of different pushing plates is different, so that the homogenizing effect of the oil anti-foaming agent raw material is further improved; the movable rod drives an overturning plate to move, so that the oil anti-foaming agent raw material is turned, and the homogenizing efficiency of the oil anti-foaming agent raw material is improved; and a fixed ring drives a brushing plate to move, so that raw material is unlikely to adhere to the homogenizing tank.

Owner:郑全祥

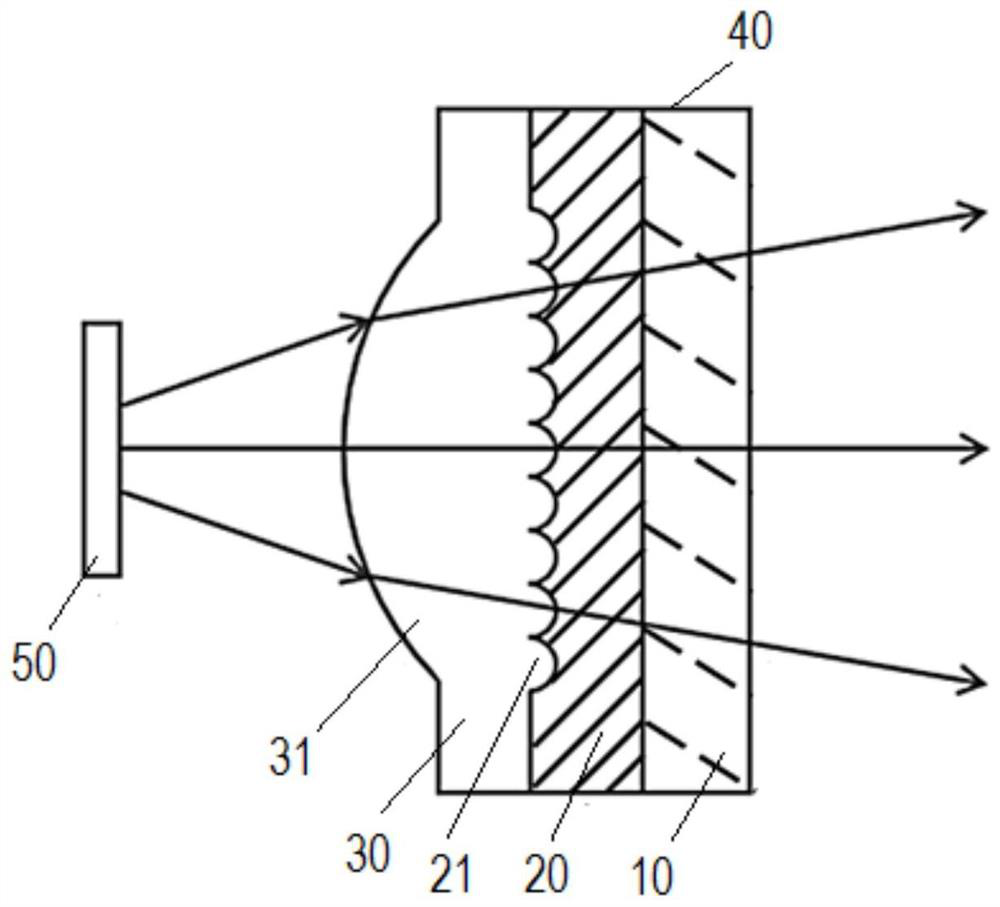

Light homogenizing sheet and TOF module

PendingCN111856631AImprove homogenization efficiencyEnsure dodging effectLensEngineeringMaterials science

The invention provides a light homogenizing sheet and a TOF module. The light homogenizing sheet comprises a substrate layer, a microstructure layer and a collimating mirror layer. The microstructurelayer is connected to the surface of one side of the substrate layer, the surface of the side, away from the substrate layer, of the microstructure layer is provided with a microstructure area, and the microstructure area is provided with a plurality of micro lenses. The collimating mirror layer is connected to the surface of the side, away from the substrate layer, of the microstructure layer, araised collimating mirror is arranged on the surface of the side, away from the microstructure layer, of the collimating mirror layer, and the projection of the collimating mirror to the microstructure layer coincides with at least one part of the microstructure area. According to the invention, the problem of poor light homogenizing effect of a light homogenizing sheet in the prior art is solved.

Owner:宁波舜宇奥来技术有限公司

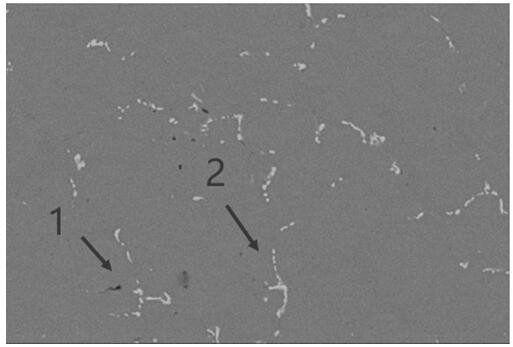

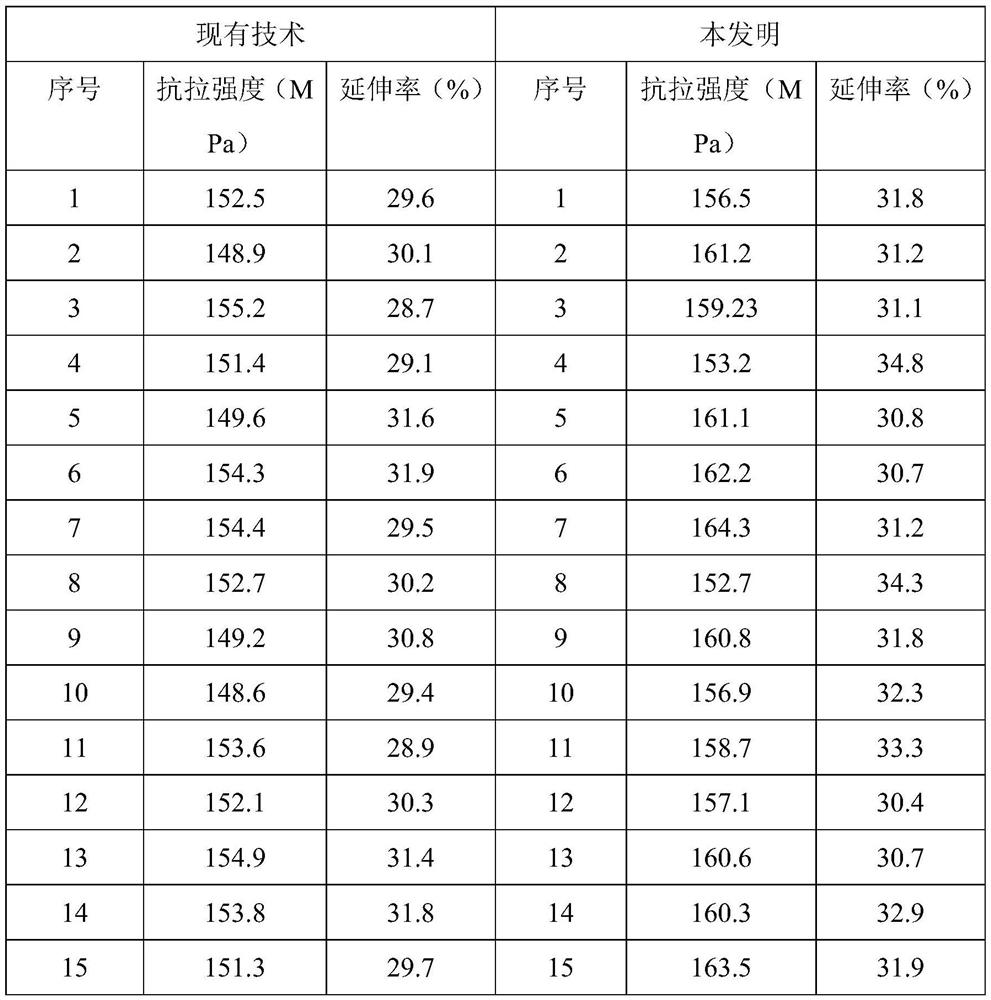

Homogenizing heat treatment process for 6-series aluminum-magnesium-silicon alloy bar

PendingCN114774814AHigh strengthImprove plasticityFurnace typesHeat treatment furnacesSilicon alloyHeat conservation

The invention relates to a homogeneous heat treatment process for a 6-series aluminum-magnesium-silicon alloy bar, and belongs to the technical field of 6-series aluminum-magnesium-silicon alloy heat treatment. The heat treatment process adopts three-section temperature type treatment, and specifically comprises the following steps: the first-section temperature is 347-353 DEG C, and the heat preservation time is 2.4-2.6 hours; the temperature of the second stage is 487-493 DEG C, and the heat preservation time is 2.9-3.1 h; and the temperature of the third stage is 557-563 DEG C, and the heat preservation time is 9.8-10.2 h. Compared with a traditional homogenizing heat treatment process, the method has the advantages that the structure segregation of the product is improved, dendritic crystals in an as-cast structure are basically eliminated, a non-equilibrium eutectic structure at a grain boundary is dissolved in a matrix or is changed into particles, and the eutectic phase area fraction is reduced. Component segregation does not exist in the product, and all alloy elements are evenly distributed. The improvement of the structure inevitably improves the alloy performance, the strength and plasticity of the alloy after heat treatment are improved, and the hardness and conductivity are reduced.

Owner:云南云铝泽鑫铝业有限公司

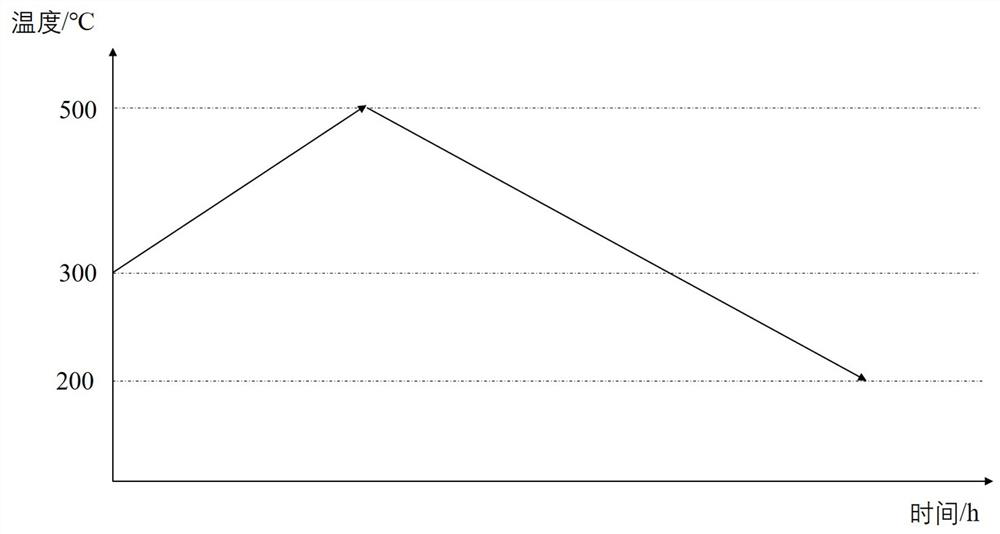

Method for improving homogenizing efficiency of 7000 series aluminum alloy cast ingots

The invention provides a homogenizing annealing method for 7000 series aluminum alloy cast ingots, and particularly relates to a method for improving the homogenizing efficiency of the 7000 series aluminum alloy cast ingots. The whole process of the method is completed in a variable-temperature environment, and the method is suitable for flat cast ingots with the thickness larger than 200 mm. Research finds that the key factor of coarse primary phase dissolution is temperature, the higher the temperature is, the more thorough the coarse primary phase dissolution is, traditional homogenizing treatment is performed at a constant temperature for a certain time, and in order to avoid overburning, the temperature far lower than the temperature of coarse primary phase dissolution is often selected, and the homogenizing effect is achieved by prolonging the time. However, the inventor of the invention surprisingly discovers that by adopting the method disclosed by the invention, not only the coarse primary phase dissolution can be quickly realized, but also the overburning of the cast ingots at a high temperature can be effectively avoided, and on the premise of obtaining the same homogenizing treatment effect, the time of the homogenizing treatment process can be remarkably shortened, and the production cost is greatly reduced.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Front-rear material mixing type homogenizing device for compound fertilizer

InactiveCN110639406AQuality improvementUniform qualityTransportation and packagingMixersAgricultural engineeringMechanical engineering

The invention relates to a homogenizing device for a compound fertilizer, particularly to a front-rear material mixing type homogenizing device for a compound fertilizer. The technical problem to be solved by the invention is to provide a front-rear material mixing type homogenizing device having characteristics of time saving, labor saving and cost saving and used for a compound fertilizer. The device comprises a base, a box body, a first bracket, a second bracket, a first bearing, a first rotating shaft, a first belt roller, a second bearing and the like, wherein the box body is located overthe base, a material inlet is vertically formed in the left side of the top of the box body, and a material discharging port is vertically formed in the right side of the bottom of the box body. According to the invention, with the front-rear material mixing type homogenizing device, a large amount of the compound fertilizer can be subjected to front-rear mixing homogenizing, and can be subjectedto cyclic and reciprocating homogenizing, so that the homogenizing efficiency is high, the time and the labor are saved, the homogenizing effect is good, the cost is saved, the quality of the compound fertilizer can be improved, and the nutrients of the compound fertilizer are uniform and consistent.

Owner:王涌

A mixer device for homogenization and clarification

The title of the invention is a homogenizing and clarifying agitator device. The invention belongs to the technical field of glass smelting. It mainly achieves the purpose of increasing the glass transmittance by improving the homogenization and clarification efficiency and shortening the melting time. Its main features are: including the stirring shaft, the air hole array tube or the air hole array tube and the stirring frame, and the rotating ventilation joint; among them, the air hole array tube is installed at the bottom of the stirring shaft, and the stirring frame or air hole array tube is installed at the bottom of the stirring shaft; the air hole Air holes are provided on the entire tube wall of the array tube; the stirring shaft is provided with an inner cavity with an open upper end, and the inner cavity communicates with the inner cavity of the air hole array tube; the upper end of the stirring shaft is provided with a rotary ventilation joint. The invention has the characteristics of simultaneously homogenizing the large-area upper and lower parts of the glass liquid in the crucible, gathering and floating the bubbles in the glass liquid, shortening the time of homogenization and clarification, and is mainly used for small batches or intermittent crucible clinker for experiments Preparation and production.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

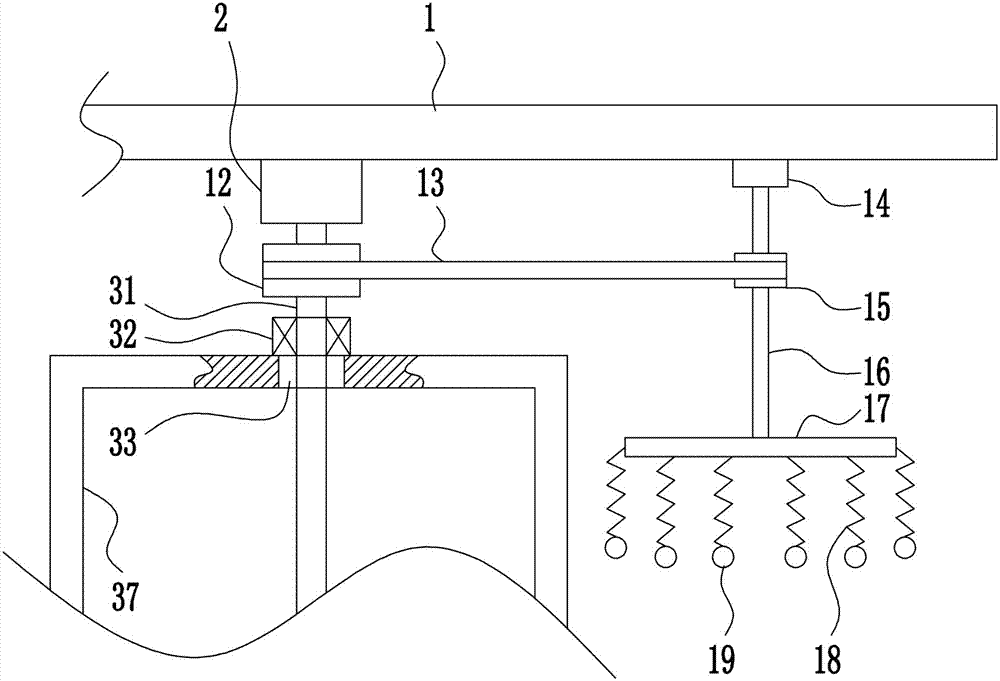

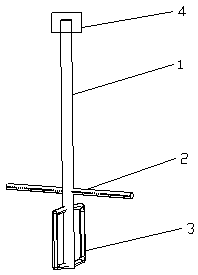

Lithium battery slurry dispersing homogenizer

ActiveCN109158005AGood dispersionImprove efficiencyShaking/oscillating/vibrating mixersRotary stirring mixersPulp and paper industrySlurry

The invention relates to a homogenizer, in particular to a lithium battery slurry dispersing homogenizer. In order to solve the technical problem, the invention provides the lithium battery slurry dispersing homogenizer with high homogenizing efficiency and uniform dispersion. The technical scheme is as follows: the lithium battery slurry dispersing homogenizer comprises a supporting column, a horizontal plate, a 7-shaped stand, a material outlet pipe, a mounting seat body, a material outlet mechanism and the like; the horizontal plate is mounted at the top of the supporting column; the rightend of the top of the horizontal plate is connected with the 7-shaped stand; a homogenizing mechanism is mounted at the inner top of the 7-shaped stand; the mounting seat body is placed on the left side of the top of the horizontal plate; a dispersing drum is mounted at the top of the top of the mounting seat body; and the homogenizing mechanism extends into the dispersing drum. The lithium battery slurry dispersing homogenizer disclosed by the invention achieves effects of high homogenizing efficiency and uniform dispersion; a turntable and a homogenizing stick rotate; the homogenizing stickcontinuously stir slurry to enable the slurry to be fully homogenized; and the dispersing drum swings left and right, so that the slurry swings left and right, and the dispersing and homogenizing effect and efficiency are improved.

Owner:广西东来新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com