Preparation technology for set yogurt with high stability

A set-type yogurt, high-stability technology, applied in milk preparations, dairy products, applications, etc., can solve the problems of poor stability of set-type yogurt, achieve the effect of compact structure, good taste, and increased thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

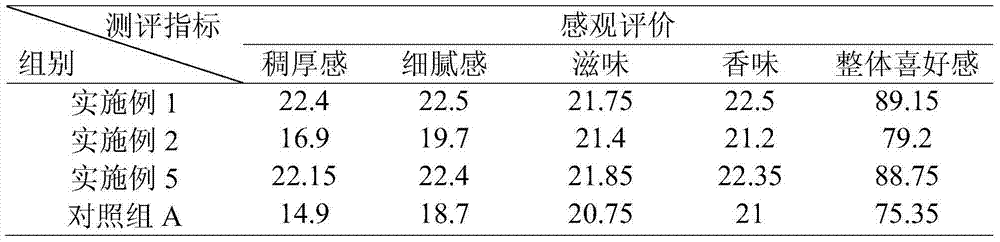

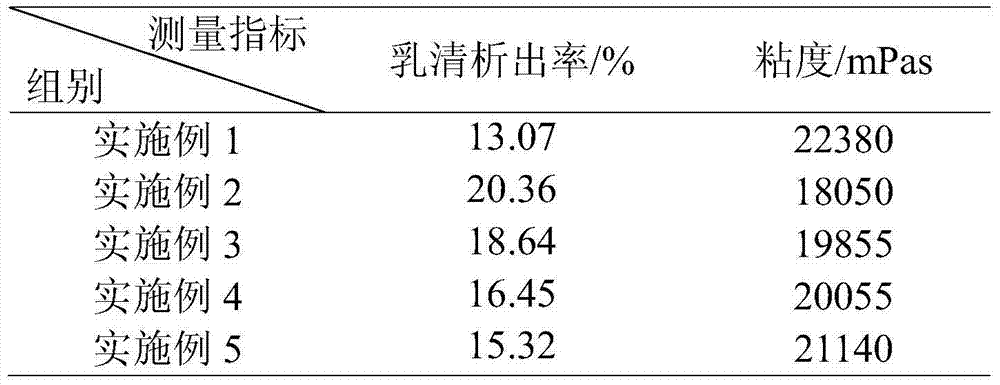

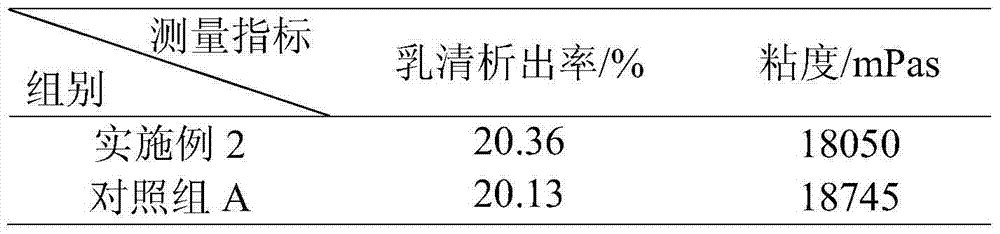

Examples

Embodiment 1

[0036] The raw material formula used in the preparation process of the high-stability set yogurt in this example is: raw milk 91.5 wt.%, white sugar content 8.5 wt.%. The concrete processing steps of the present embodiment are:

[0037] (1) Raw milk preparation: meet the inspection standards for fresh milk for yogurt process, non-fat milk solids should not be less than 8.5%, no antibiotics are required for raw milk, and the bacteriostatic factor lysozyme cannot be detected;

[0038] (2) Clean milk: Standard clean milk separator separates and standardizes raw milk;

[0039] (3) Mix standardized raw milk and white sugar, and add 0.05wt.% casein powder of raw milk to it;

[0040] (4) Preheating and homogenization: Preheat the milk prepared in step (3) to 60-70°C; homogenize the preheated milk with a homogenization pressure of 18MPa;

[0041] (5) Pasteurization: Sterilize at 85-95°C for 15 minutes, then cool;

[0042] (6) Inoculation: add 0.05wt.% β-lactoglobulin powder of raw ...

Embodiment 2

[0046] The raw material formula used in the preparation process of the high-stability solidified yoghurt in this example is: 91.5 wt.% of raw milk and 8.5 wt.% of white sugar. The concrete processing steps of the present embodiment are:

[0047] (1) Raw milk preparation: meet the inspection standards for fresh milk for yogurt process, non-fat milk solids should not be less than 8.5%, no antibiotics are required for raw milk, and the bacteriostatic factor lysozyme cannot be detected;

[0048] (2) Clean milk: Standard clean milk separator separates and standardizes the raw milk; the solid content of the standardized raw milk is 12%, and the protein content is 2.95%;

[0049] (3) Mix standardized raw milk and white sugar, and add 0.01wt.% casein powder of raw milk to it;

[0050] (4) Preheating and homogenization: Preheat the milk prepared in step (3) to 60-70°C; homogenize the preheated milk with a homogenization pressure of 18MPa;

[0051] (5) Pasteurization: Sterilize at 85-...

Embodiment 3

[0056] The raw material formula used in the preparation process of the high-stability solidified yoghurt in this example is: 91.5 wt.% of raw milk and 8.5 wt.% of white sugar. The concrete processing steps of the present embodiment are:

[0057] (1) Raw milk preparation: meet the inspection standards for fresh milk for yogurt process, non-fat milk solids should not be less than 8.5%, no antibiotics are required for raw milk, and the bacteriostatic factor lysozyme cannot be detected;

[0058] (2) Clean milk: Standard clean milk separator separates and standardizes raw milk;

[0059] (3) Mix standardized raw milk and white sugar, and add 0.05wt.% casein powder of raw milk to it;

[0060] (4) Preheating and homogenization: Preheat the milk prepared in step (3) to 60-70°C; homogenize the preheated milk with a homogenization pressure of 18MPa;

[0061] (5) Pasteurization: Sterilize at 85-95°C for 15 minutes, then cool;

[0062] (6) Inoculation: add 0.01wt.% β-lactoglobulin powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com