Material mixing device for concrete production

A technology for mixing materials and concrete, used in clay preparation devices, cement mixing devices, cleaning hollow objects, etc., can solve the problems of cleaning the inner wall of the non-mixing chamber, affecting the processing quality, and concrete adhering to the inner wall, etc., to improve the uniformity. Quality efficiency, the effect of improving the homogenization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

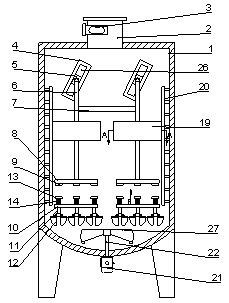

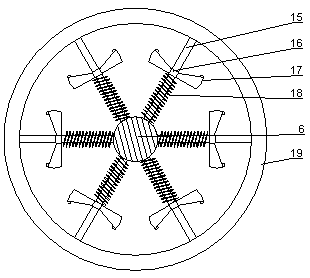

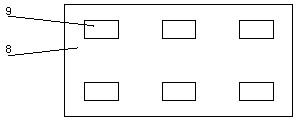

[0025] see Figure 1-2 , a mixing material device for concrete production, comprising a mixing box 1, a rotating block 4 is installed on the inner upper side of the mixing box 1, a rotating drive device is installed on the outer surface of the mixing box 1, and the output end of the rotating drive device is connected to the rotating block 4 The center of the side of the rotating block 4 is fixedly connected, and the other side of the rotating block 4 is provided with a bar-shaped gap 26, and the moving part 5 is slidably connected in the bar-shaped notch 26, and the free column 6 is hinged on the moving part 5, and the two sides located on the left and right sides The free columns 6 are arranged in parallel and two free columns 6 are fixedly connected by a fixed column 7. The bottom end of the free columns 6 is fixedly connected with a lifting bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com