Glass continuous melting furnace and melting method

A continuous melting furnace and glass technology, applied in glass furnace equipment, glass manufacturing equipment, glass production, etc., can solve problems such as melting, clarification, and homogenization efficiency deterioration, shorten melting time, improve streak dissipation efficiency and gas, and uniformity The effect of improving chemical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

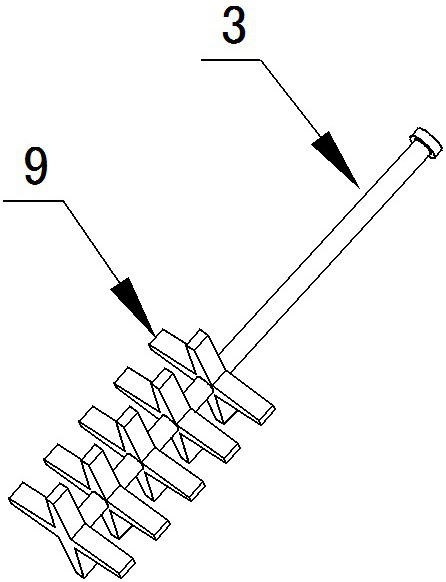

[0043] The homogenizing crucible homogenizing rod 3 and the working crucible homogenizing rod 14 made of wedge shape and 4 sets of paddles, the homogenizing crucible homogenizing rod 3 rotates at 60 rpm, the working crucible homogenizing rod 14 rotates at 40 rpm, melting The drop between the crucible low level liquid level 1 and the high level liquid level 5 is 22cm. After the implementation, the standard output of the product has been increased from 560kg / day in a common continuous furnace with the same volume to 690kg / day, the production efficiency has increased by 23.2%, and the 420nm internal transmittance τ10 of the same brand product has increased by 2.6%.

Embodiment B

[0045] The homogenizing crucible homogenizing rod and the working crucible homogenizing rod are made of cylindrical shape and 6 sets of blades. The drop between the surface and the high liquid level is 16cm. After the implementation, the standard output of the product has increased from 560kg / day of a common continuous furnace with the same volume to 710kg / day, the production efficiency has increased by 26.7%, and the 420nm internal transmittance τ10 of the same brand product has increased by 3.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com