Dairy product homogenizing processing device

A technology for processing devices and dairy products, applied in mixers with rotary stirring devices, transportation and packaging, dissolving and other directions, can solve the problems of general relative processing efficiency and difficulty in controlling the degree of homogenization of stirring and mixing, and achieve good fusion and guarantee. Taste, improve the effect of homogenization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

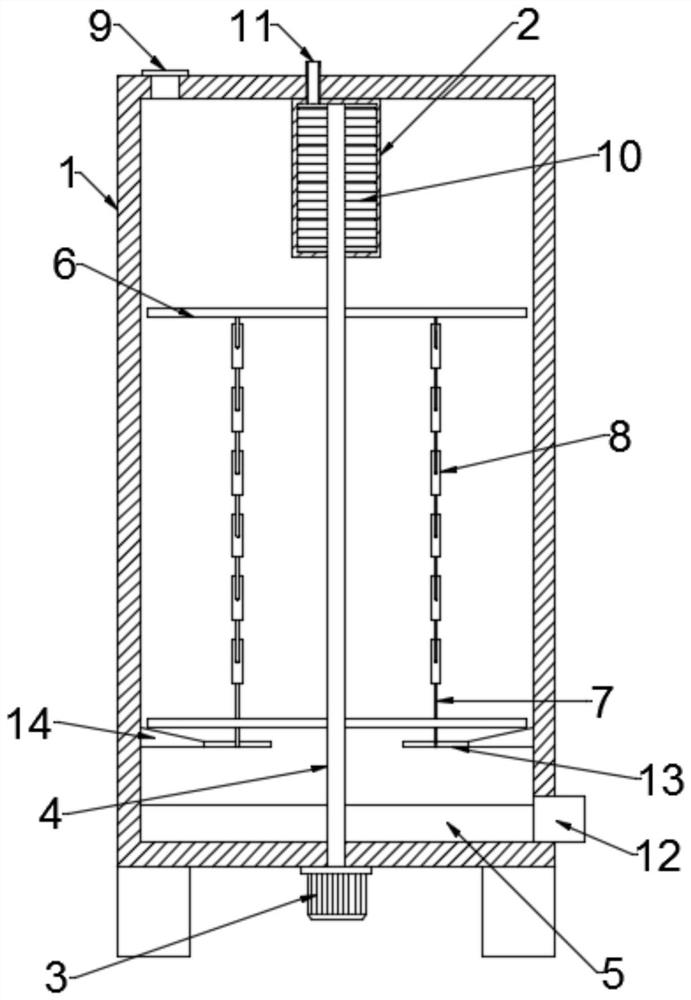

[0021] see figure 1 and 4 , in an embodiment of the present invention, a dairy product homogeneous processing device includes a housing 1, the top of the housing 1 is fixedly connected with an adding chamber 2, and the axis of the housing 1 and the adding chamber 2 Coincidentally, the surface and bottom of the adding chamber 2 are net-like structures, and the housing 1 is rotationally connected with a stirring shaft 4, and the stirring shaft 4 runs through the lower end of the adding chamber 2 and is rotationally connected with the adding chamber 2, so The outer bottom of the stirring shaft 4 is fixedly connected with a discharge stirring blade 5, the middle part of the outer periphery of the stirring shaft 4 is fixedly connected with a homogenizing mechanism, and the part of the stirring shaft 4 located in the adding chamber 2 is fixedly connected with multiple groups. A crushing blade 10, one end of the stirring shaft 4 passes through the bottom of the housing 1, and a moto...

Embodiment 2

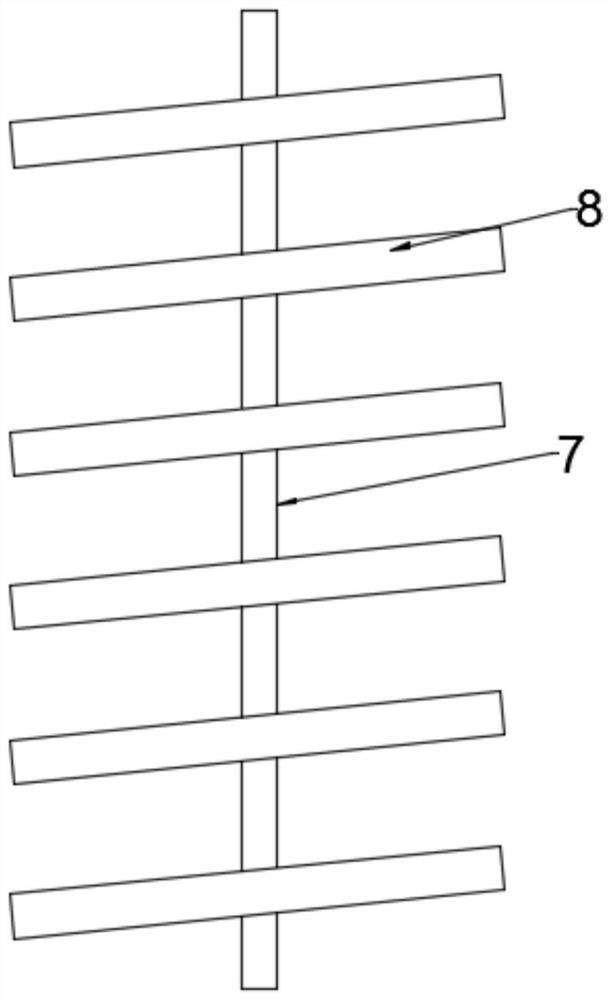

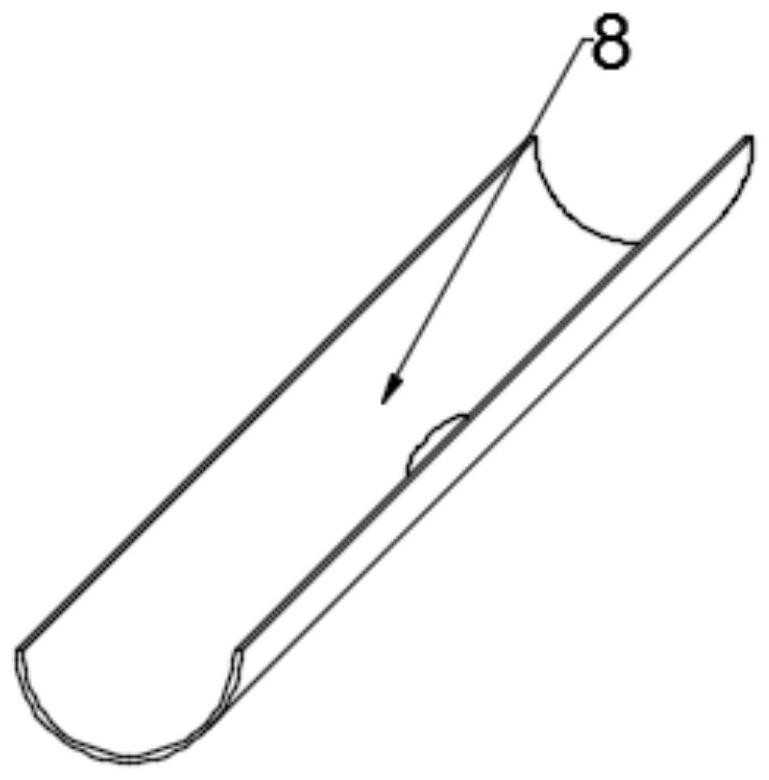

[0025] see Figure 1~3 , in the embodiment of the present invention, a dairy product homogeneous processing device, on the basis of embodiment 1, the homogeneous mechanism includes two sets of stirring rods 6 fixed on the periphery of the stirring shaft 4, the stirring rods 6 are composed of multiple The groups of thin rods are fixed on the periphery of the stirring shaft 4 at equal angles, and the two groups of stirring rods 6 are aligned in the vertical direction, and a rotating shaft 7 is installed between the corresponding thin rods in the two groups of stirring rods 6, and the rotating shaft 7 The bottom moves through the thin rod and is fixedly connected with a transmission gear 13. The transmission gear 13 and the inner gear of the inner ring of the guide ring 14 are meshed for transmission. The rotating shaft 7 is fixedly connected with multiple groups of homogeneous plates 8. The homogeneous plate 8 is a strip-shaped arc-shaped plate with a semicircular cross-section....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com