Manufacturing method and device of high uniformity and high consistent optical glass

A technology of optical glass and manufacturing method, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of large refractive index fluctuation of optical glass, poor optical uniformity, poor refractive index consistency, etc., and shorten the production time. Cycle, saving melting cost, strong inclusive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

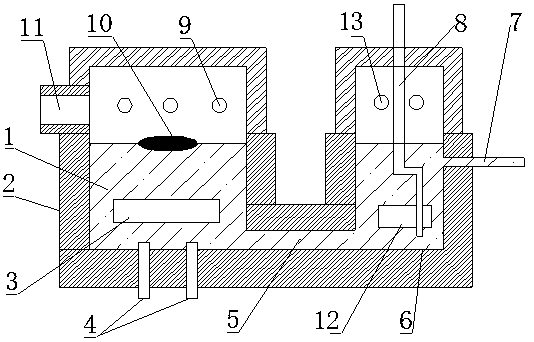

Image

Examples

Embodiment 1

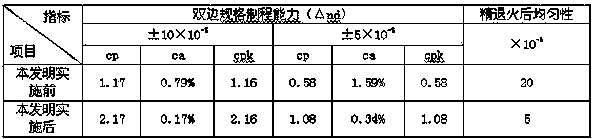

[0039] Select H-ZK21 glass (refractive index n d标准值 : 1.62299) as the implementation object, the data before and after the implementation of the present invention are compared, and the glass refractive index value in a certain production cycle before and after the present invention is statistically analyzed. Sampling rules: according to the requirements of the production process, take every 2 hours For one sample, the sample is quenched at -25°C / H quenching rate, and then the refractive index n of the sample is measured d The value is calculated based on the refractive index difference between two adjacent samples. In order to evaluate the consistency of the refractive index, Δn d (Δn d =n d后 -n d前 ) to evaluate the process capability cpk index. The uniformity of optical glass is calibrated by the maximum value of the measured value of uniformity after fine annealing of a single product. Its embodiment result contrast is shown in the following table:

[0040]

Embodiment 2

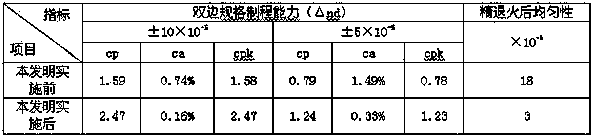

[0042] Select H-F4 glass (refractive index n d标准值 : 1.62005) as the implementation object, the data before and after the implementation of the present invention are compared. Statistically analyze the refractive index of the glass in a certain production cycle before and after the present invention, sampling rules: take a sample every 2 hours according to the requirements of the production process, quench the sample at a quenching rate of -25°C / H, and then measure the refractive index of the sample no d The value is calculated based on the refractive index difference between two adjacent samples. In order to evaluate the consistency of the refractive index, Δn is introduced d (Δn d =n d后 -n d前 ) to evaluate the process capability cpk index. The uniformity of optical glass is calibrated by the maximum value of the measured value of uniformity after fine annealing of a single product. Its embodiment result contrast is shown in the following table:

[0043]

[0044] Fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com