Homogenizing method of lithium ion battery positive electrode slurry

A lithium-ion battery, cathode slurry technology, applied in battery electrodes, positive electrodes, mixing methods, etc., can solve the problems of uneven mixing, cumbersome operation steps, large fluctuations in discharge viscosity, etc., to improve dispersion uniformity, Improve the homogenization efficiency and the effect of improving the homogenization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

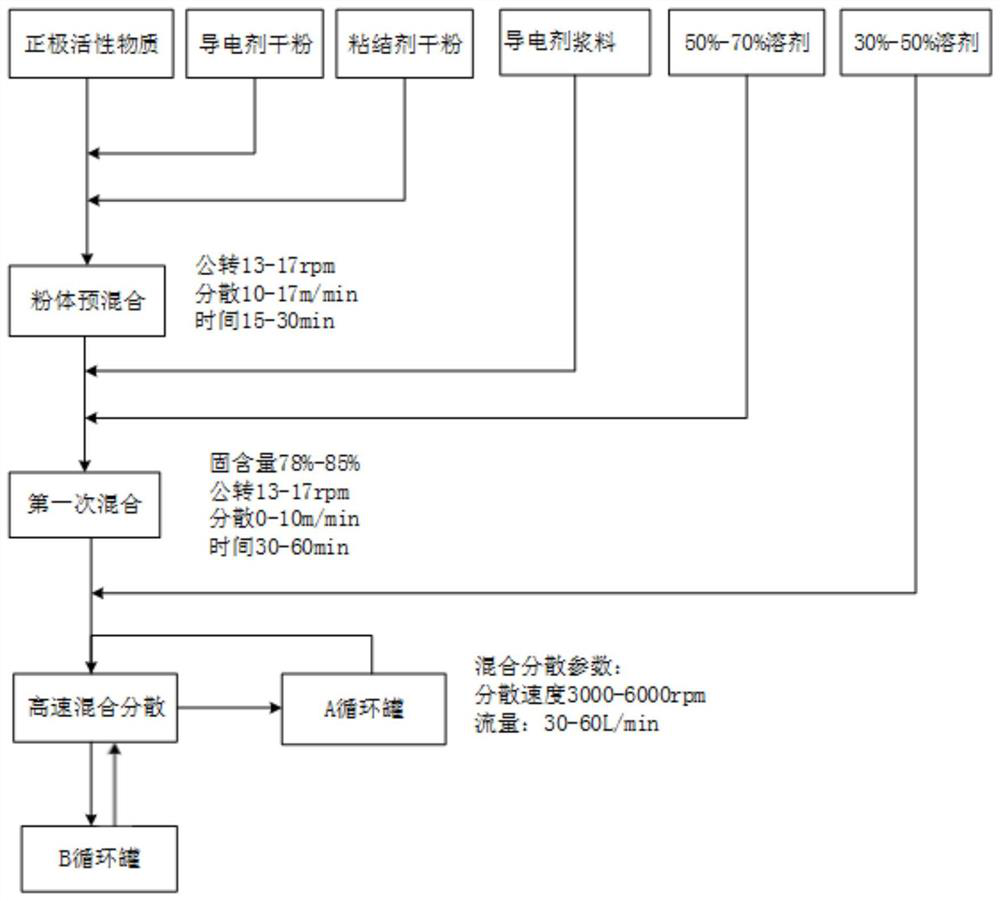

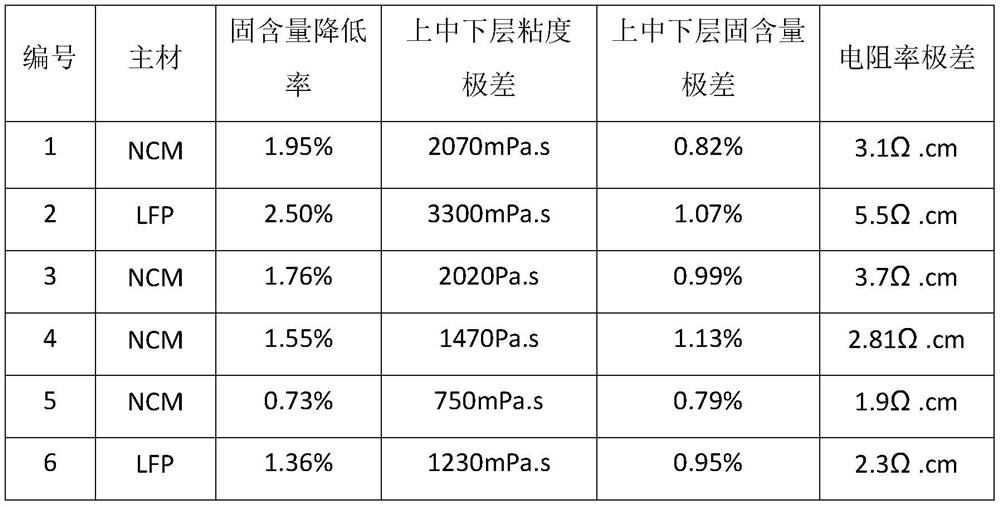

[0075] Take by weight 97 parts of NCM powder, 1 part of Super-P powder (as conductive agent), 1.5 parts of PVDF powder (as binder), 0.5 part of slurry containing CNT (as conductive agent), and adopt the present invention The batching process prepares the positive electrode slurry, and the specific steps are as follows:

[0076] Step 1: Add 97 parts of NCM powder, 1 part of Super-P powder, and 1.5 parts of PVDF powder into the double planetary mixer, turn on the revolution 13-17r / min, rotate 300-500r / min, and stir for 30min.

[0077] Step 2: Add the slurry containing 0.5 part of CNT and 50% NMP into the mixer, turn on the revolution at 15-17r / min, rotate at 300-500r / min, and stir for 60min.

[0078] Step 3: Transport the slurry in step 2 and 50% NMP to an impeller-type high-speed mixer with a rotation speed of 5000r / min by a screw according to a fixed flow rate. After mixing, put the slurry into the circulation tank A for 30-60 minutes.

[0079] Step 4: Turn on the mixer at a ...

Embodiment 2

[0082] Weigh 97 parts of LFP powder by mass fraction, 0.5 part of Super-P powder (as conductive agent), 1.8 parts of PVDF powder (as binder), 0.7 part of slurry containing CNT (as conductive agent), and adopt the present invention The batching process prepares the positive electrode slurry, and the specific steps are as follows:

[0083] Step 1: Add 97 parts of LFP powder, 0.5 parts of Super-P powder, and 1.8 parts of PVDF powder into the double planetary mixer, turn on the revolution 13-17r / min, rotate 300-500r / min, and stir for 30min.

[0084] Step 2: Add 0.7 parts of CNT-containing slurry and 70% NMP into the mixer, turn on the revolution at 15-17r / min, rotate at 300-500r / min, and stir for 60min.

[0085] Step 3: Transport the slurry in step 2 and 30% NMP to an impeller-type high-speed mixer with a rotation speed of 5000 r / min by a screw according to a fixed flow rate, and pour the slurry into the circulation tank A for 30-60 minutes.

[0086] Step 4: Turn on the mixer at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com