Front-rear material mixing type homogenizing device for compound fertilizer

A compound fertilizer and homogenization device technology, which is applied in the direction of mixers, transportation and packaging, chemical instruments and methods, etc., can solve the problems of inability to mix and homogenize compound fertilizers, low homogenization efficiency, and poor homogenization effect, and achieve easy Maintenance and repair, high homogenization efficiency, and cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

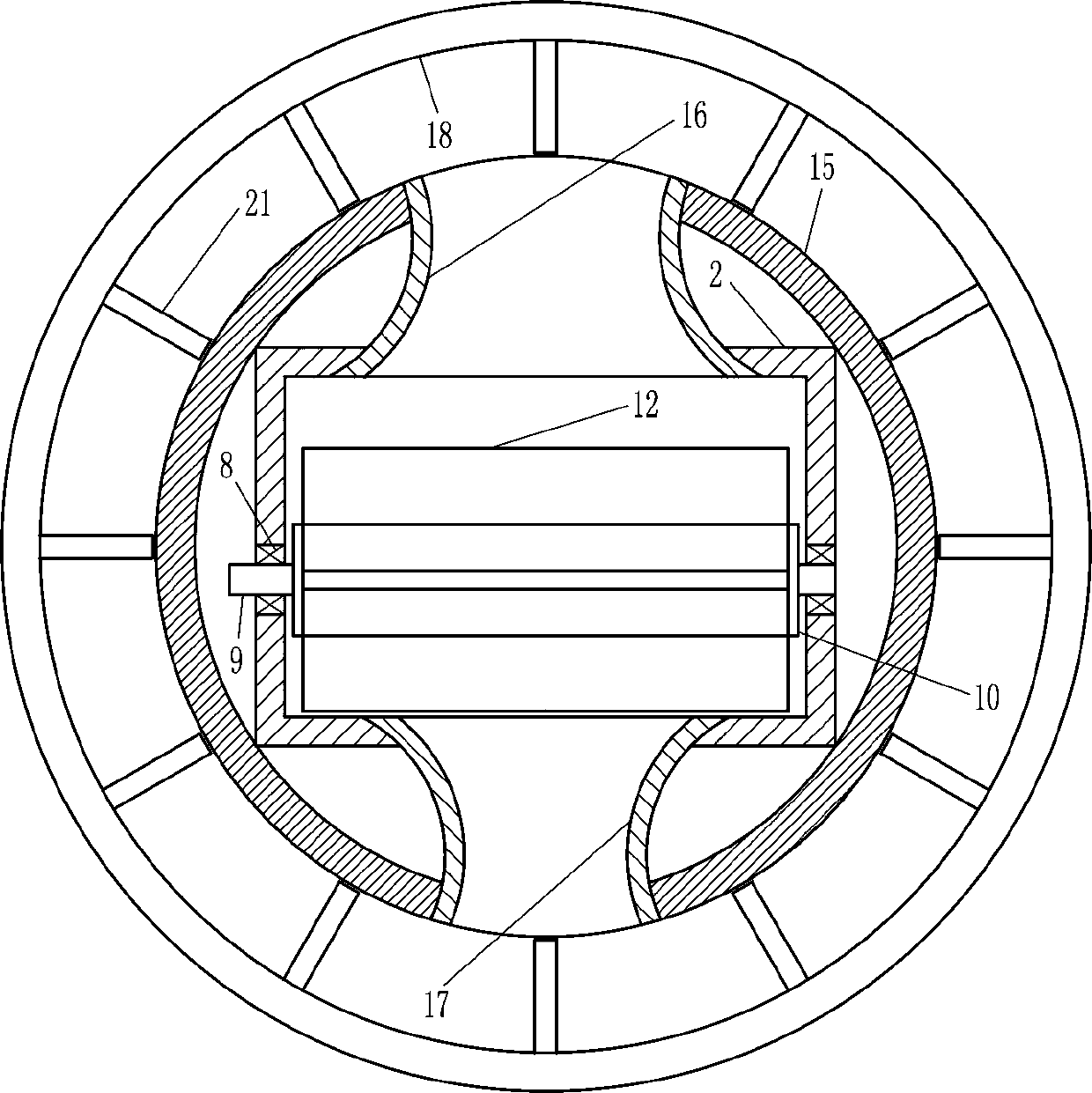

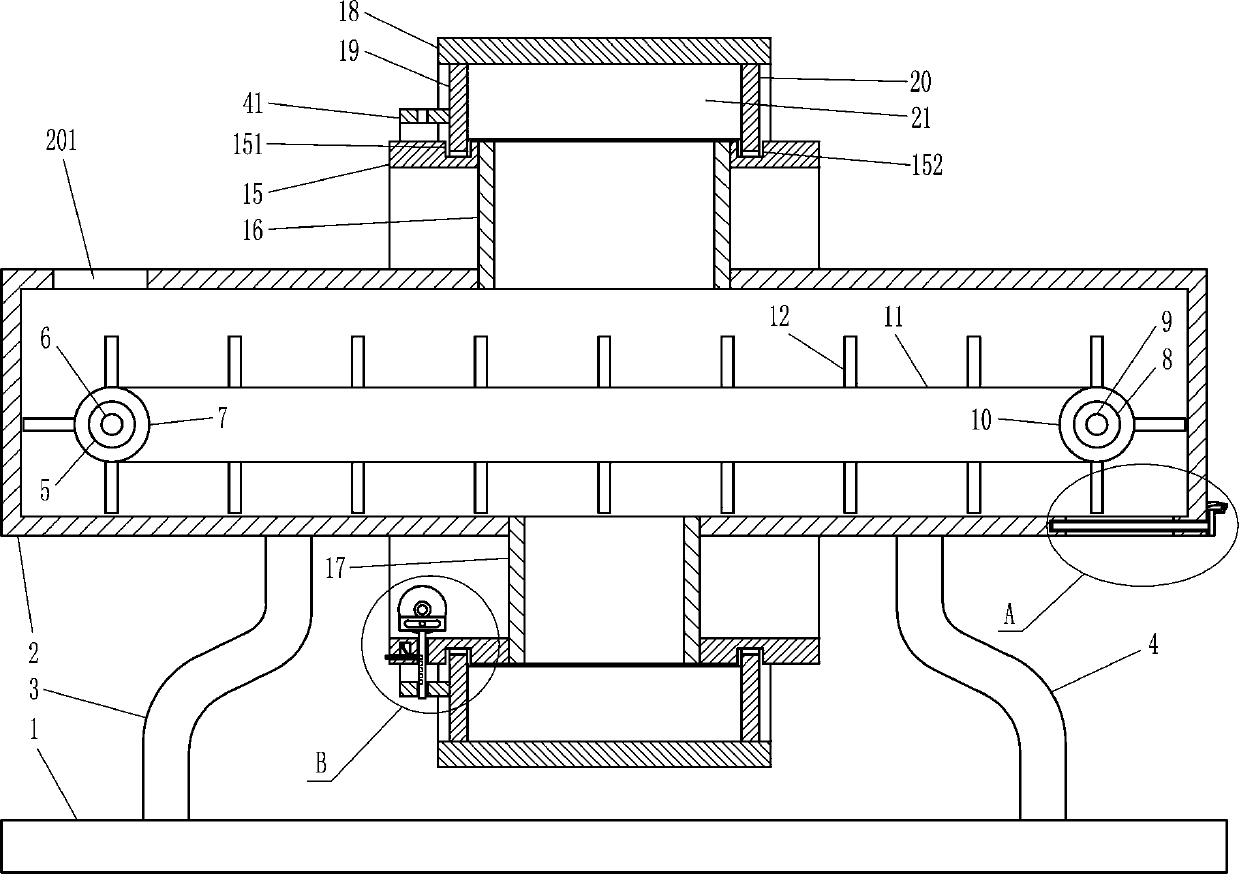

[0018] A front and rear mixing type homogenizing device for compound fertilizers, such as Figure 1-3As shown, it includes a base 1, a box body 2, a first bracket 3, a second bracket 4, a first bearing 5, a first rotating shaft 6, a first belt roller 7, a second bearing 8, a second rotating shaft 9, Second belt roller 10, endless belt 11, small scraper plate 12, baffle plate 13, movable plate 14, large round pipe 15, feed hopper 16, discharge hopper 17, large casing 18, first annular plate 19, second The ring plate 20 and the large scraper 21, the box body 2 is located directly above the base 1, the left side of the top of the box body 2 is vertically opened with a feed port 201, and the right side of the bottom of the box body 2 is vertically opened with a discharge port 202, the lower end of the right side of the box body 2 is horizontally provided with a large slot 203, the large slot 203 communicates with the discharge port 202, the left side of the top of the base 1 is co...

Embodiment 2

[0020] A front and rear mixing type homogenizing device for compound fertilizers, such as Figure 1-3 As shown, it includes a base 1, a box body 2, a first bracket 3, a second bracket 4, a first bearing 5, a first rotating shaft 6, a first belt roller 7, a second bearing 8, a second rotating shaft 9, Second belt roller 10, endless belt 11, small scraper plate 12, baffle plate 13, movable plate 14, large round pipe 15, feed hopper 16, discharge hopper 17, large casing 18, first annular plate 19, second The ring plate 20 and the large scraper 21, the box body 2 is located directly above the base 1, the left side of the top of the box body 2 is vertically opened with a feed port 201, and the right side of the bottom of the box body 2 is vertically opened with a discharge port 202, the lower end on the right side of the box body 2 is horizontally provided with a large slot 203, the large slot 203 communicates with the discharge port 202, the left side of the top of the base 1 is c...

Embodiment 3

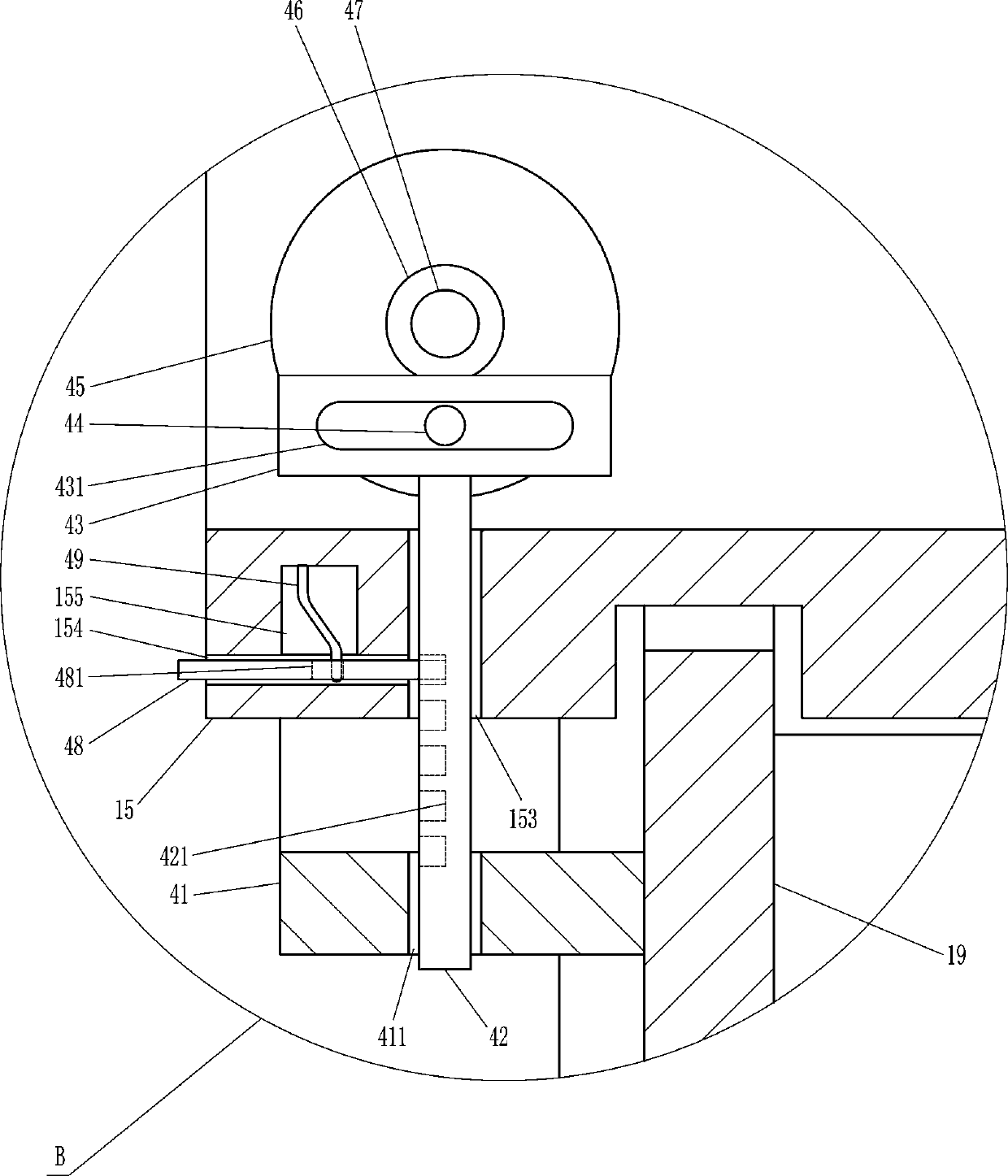

[0023] A front and rear mixing type homogenizing device for compound fertilizers, such as Figure 1-4 As shown, it includes a base 1, a box body 2, a first bracket 3, a second bracket 4, a first bearing 5, a first rotating shaft 6, a first belt roller 7, a second bearing 8, a second rotating shaft 9, Second belt roller 10, endless belt 11, small scraper plate 12, baffle plate 13, movable plate 14, large round pipe 15, feed hopper 16, discharge hopper 17, large casing 18, first annular plate 19, second The ring plate 20 and the large scraper 21, the box body 2 is located directly above the base 1, the left side of the top of the box body 2 is vertically opened with a feed port 201, and the right side of the bottom of the box body 2 is vertically opened with a discharge port 202, the lower end on the right side of the box body 2 is horizontally provided with a large slot 203, the large slot 203 communicates with the discharge port 202, the left side of the top of the base 1 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com