Stirrer device capable of efficiently homogenizing and clarifying

A stirrer and high-efficiency technology, which is applied in the field of stirring and homogenizing devices for batch-type crucible glass furnaces, can solve the problems of increased loss, adhesion of crucible walls, and large platinum consumption, so as to improve homogenization efficiency, reduce clarification time, Platinum's low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Various exemplary embodiments, features, and aspects of the invention will be described in detail below with reference to the accompanying drawings. The same reference numbers in the figures indicate functionally identical or similar elements. While various aspects of the embodiments are shown in drawings, the drawings are not necessarily drawn to scale unless specifically indicated.

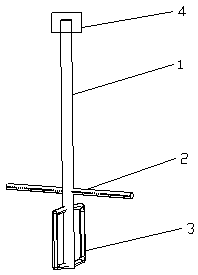

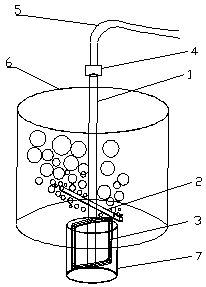

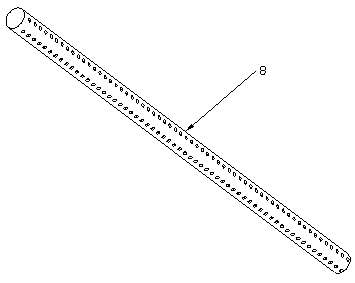

[0021] Embodiment 1 of a kind of high-efficiency homogenization and clarification agitator device provided by the present invention and its use status are as follows: Figure 1 to Figure 3 shown. Embodiment 1 includes a stirring shaft 1 , an air hole array tube 2 , a stirring frame 3 , a rotary ventilation joint 4 and an air pipe 5 . The stirring frame 3 is installed on the bottom of the stirring shaft 1, the stirring frame 3 is a rectangular outer frame, and the stirring frame 3 can also be a rectangular outer frame plus a cross-section in the rectangular outer frame, and the cross-sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com