Plate overturning device in rubber latex glove production interlocking machine

A technology of rubber latex and linkage machine, which is applied to household components, household appliances, and other household appliances. It can solve the problems of low production efficiency, poor uniformity of glove film thickness, and easy air in the dipping, so as to reduce occupancy The space of the linkage machine, the effect of solving the uneven thickness of gloves and reducing the difficulty of mechanical maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

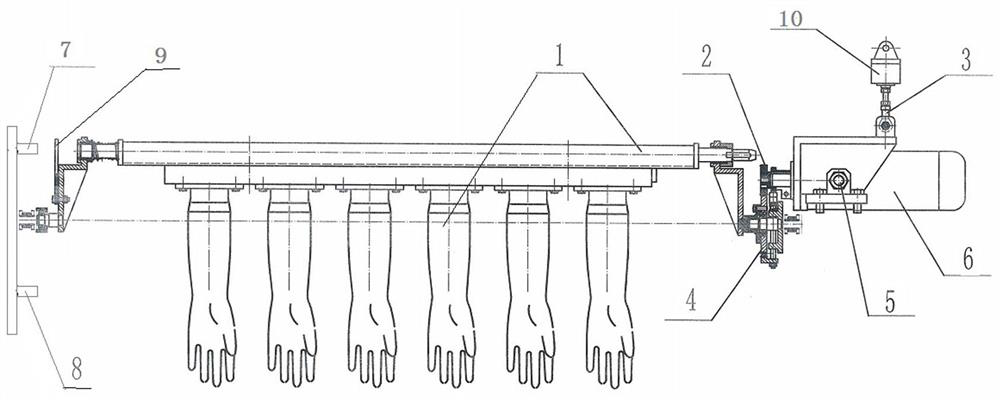

[0018] Such as figure 1 Shown, the turnover device in a kind of rubber latex glove production linkage machine of the present invention is made of glove template 1, transmission gear 2, connecting rod 3, glove template gear 4, transmission shaft 5, motor 6, first sensor 7, the first The second sensor 8, the stopper 9, the cylinder 10 and the PLC control system are composed of the first sensor 7 and the second sensor 8 respectively arranged on the upper and lower ends of the left side of the glove template 1, and the stopper 9 is arranged on the glove template 1 The left side is respectively connected with the first sensor 7 and the second sensor 8; the cylinder 10 is connected with the motor 6 through the connecting rod 3, and the connecting rod 3 is driven by the cylinder 10 to lift, and the motor 6 moves around the transmission shaft 3, and the transmission gear 2 and the The glove formwork gear 4 meshes, drives the transmission gear 2 to rotate through the motor 6, and drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com