TPU alloy material production homogeneous equipment for engineering

An alloy material and engineering technology, which is applied in the field of engineering TPU alloy material production homogeneous equipment, can solve the problems of limiting production efficiency and low homogeneous efficiency, and achieves the effect of improving homogeneous efficiency, improving uniformity and improving mixing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

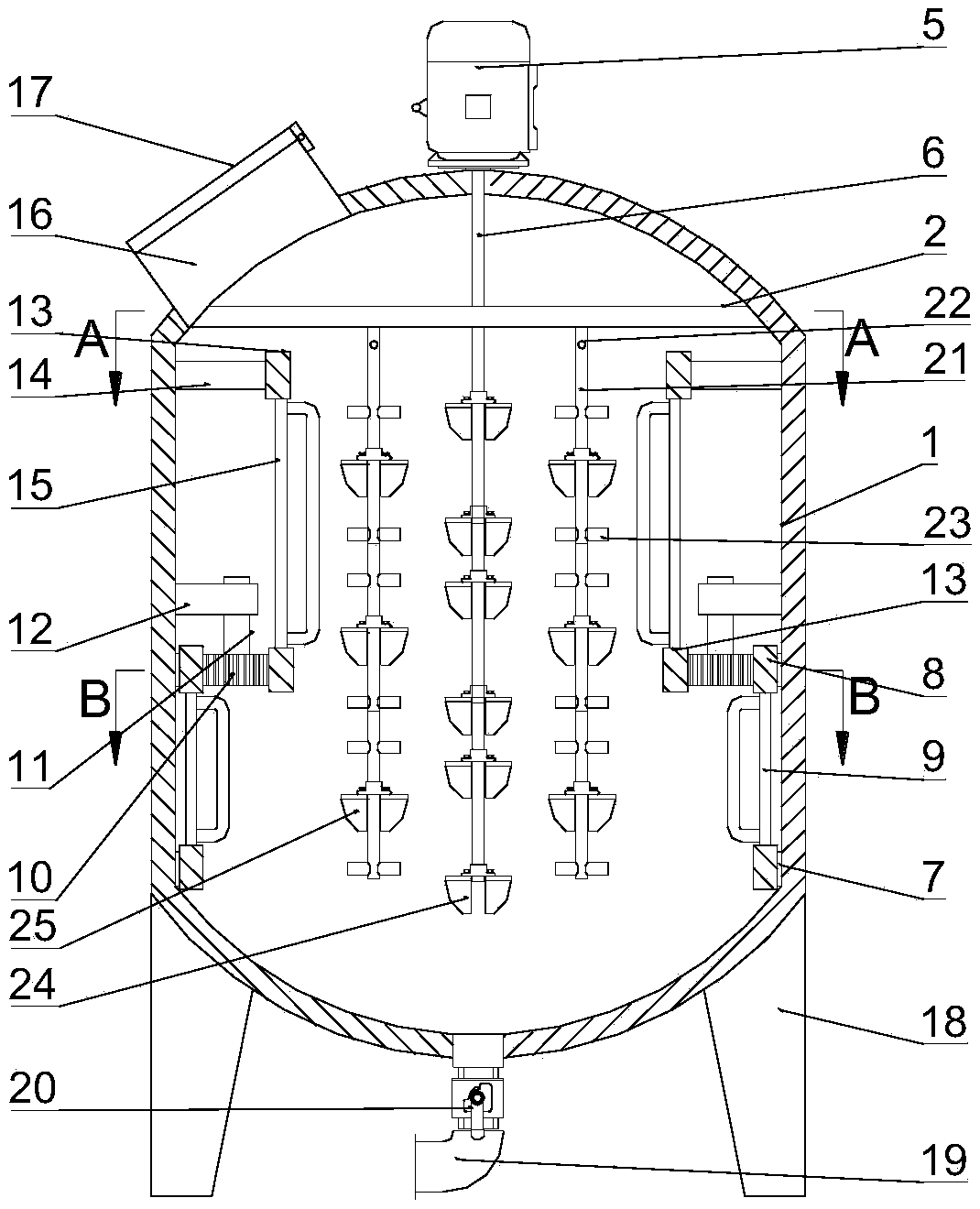

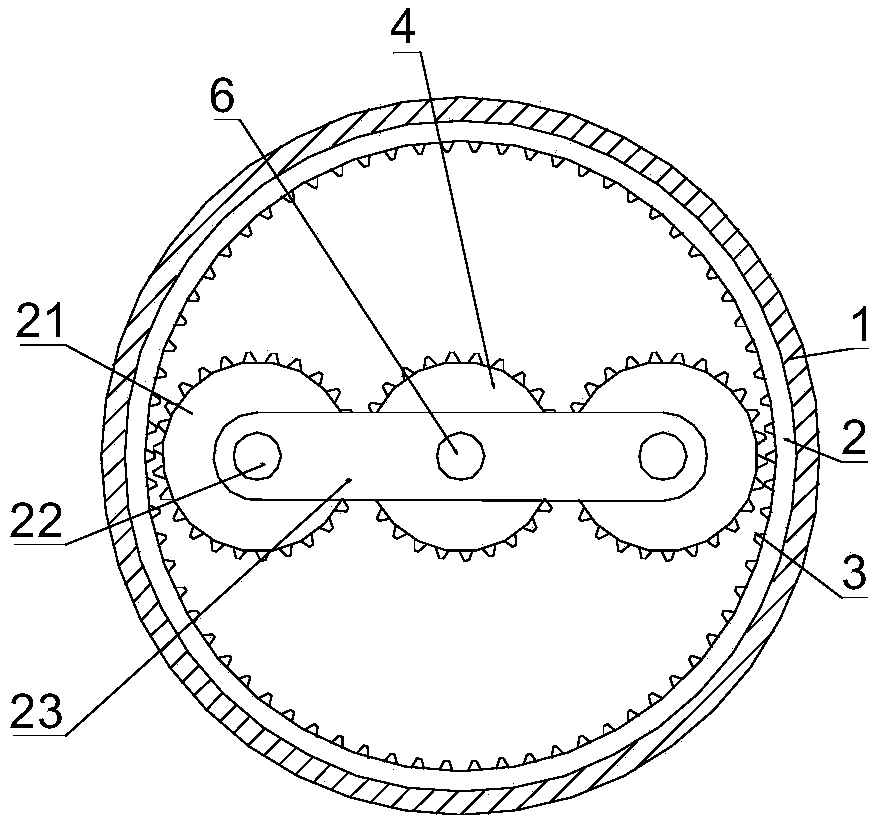

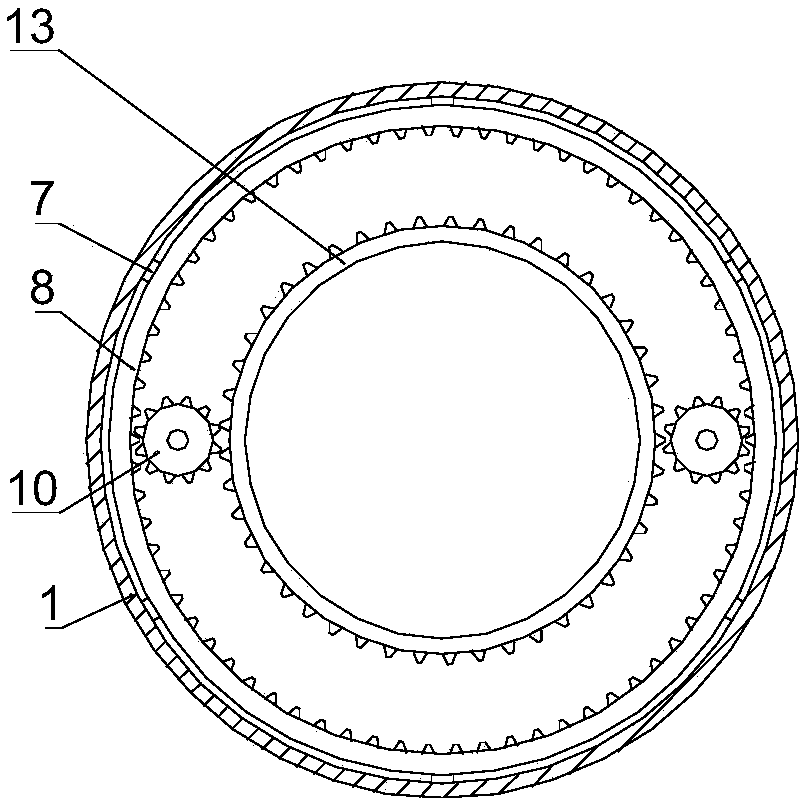

[0022] see figure 1 with 2 , a kind of homogeneous equipment for engineering TPU alloy material production, including a homogeneous box 1, the lower side of the inner wall of the homogenized box 1 is fixedly connected with two groups of moving blocks a7 arranged up and down, and the inner moving block a of the homogenized box 1 7 are respectively provided with a ring piece a8, the outer surface of the ring piece a8 is provided with a bar-shaped gap a that is slidably connected with the moving block a7, and the ring piece a8 on the upper and lower sides is fixedly connected through the baffle block a9, and the homogeneous box 1 The upper side of the inner wall is fixedly connected with a connecting ring 2, the inner wall of the connecting ring 2 is integrally formed with a number of uniformly distributed straight teeth, the inner middle of the conn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com