Non-staining wall discoloring device for preparing epoxidizedepoxy soybean oil

An epoxy soybean oil decolorization technology, which is applied in the direction of fat oil/fat refining and fat production, etc., can solve the problem that the raw materials are easy to adhere to the inner wall of the box, the decolorization effect of epoxy soybean oil is poor, and the pigment cannot be fundamentally removed and other problems, to achieve the effect of simple structure, convenient cleaning and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of this patent will be described in further detail below in conjunction with specific embodiments.

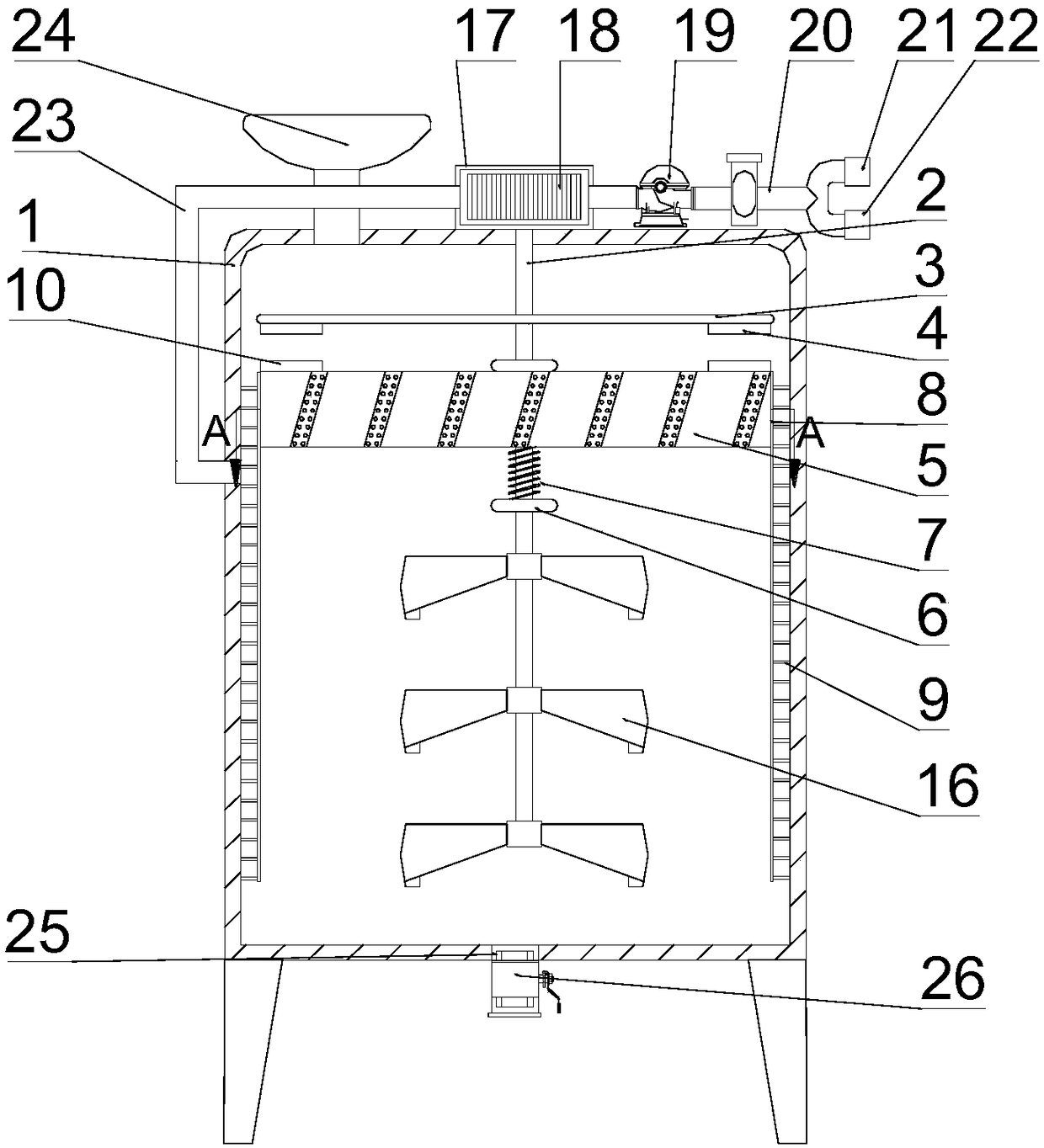

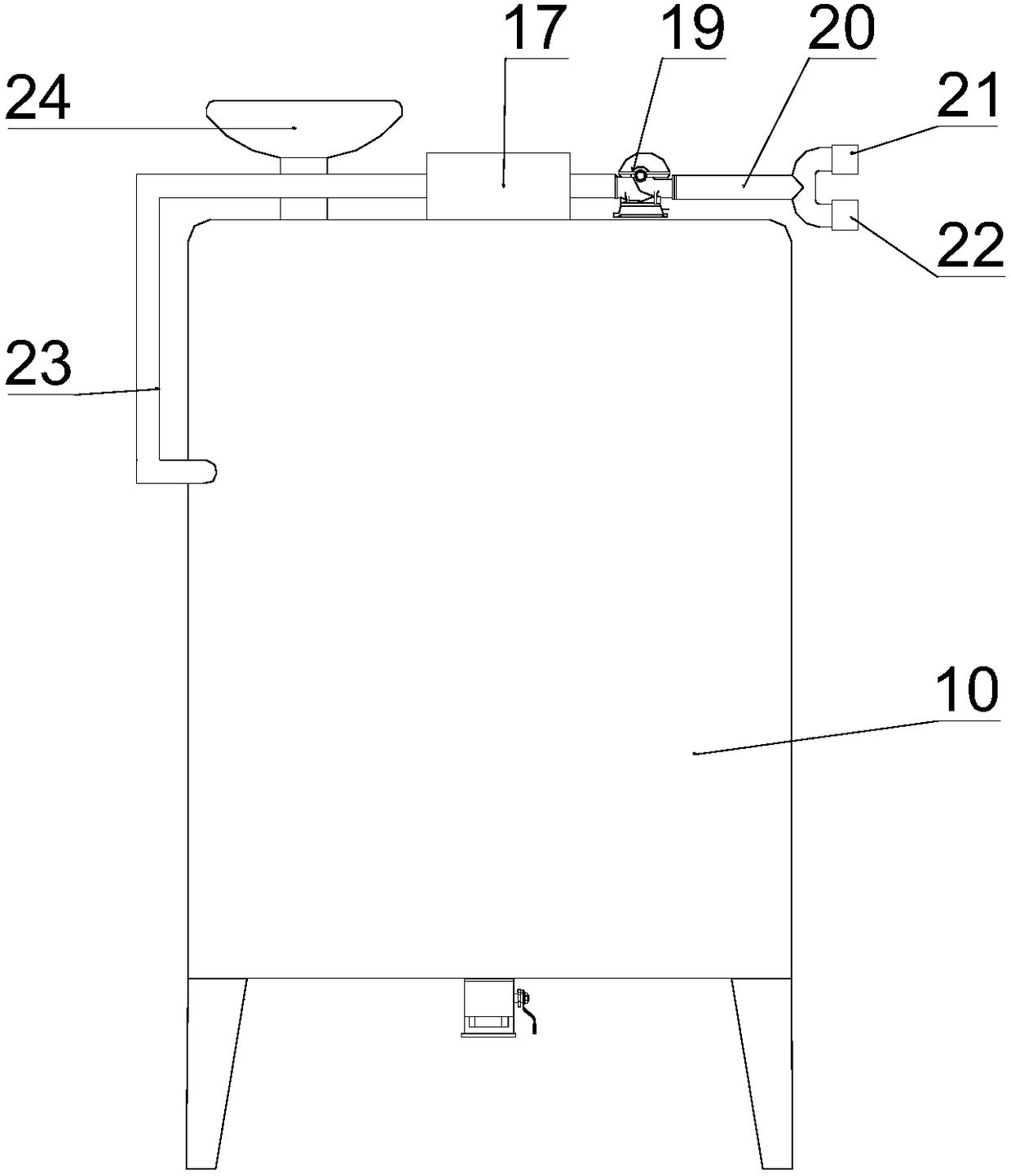

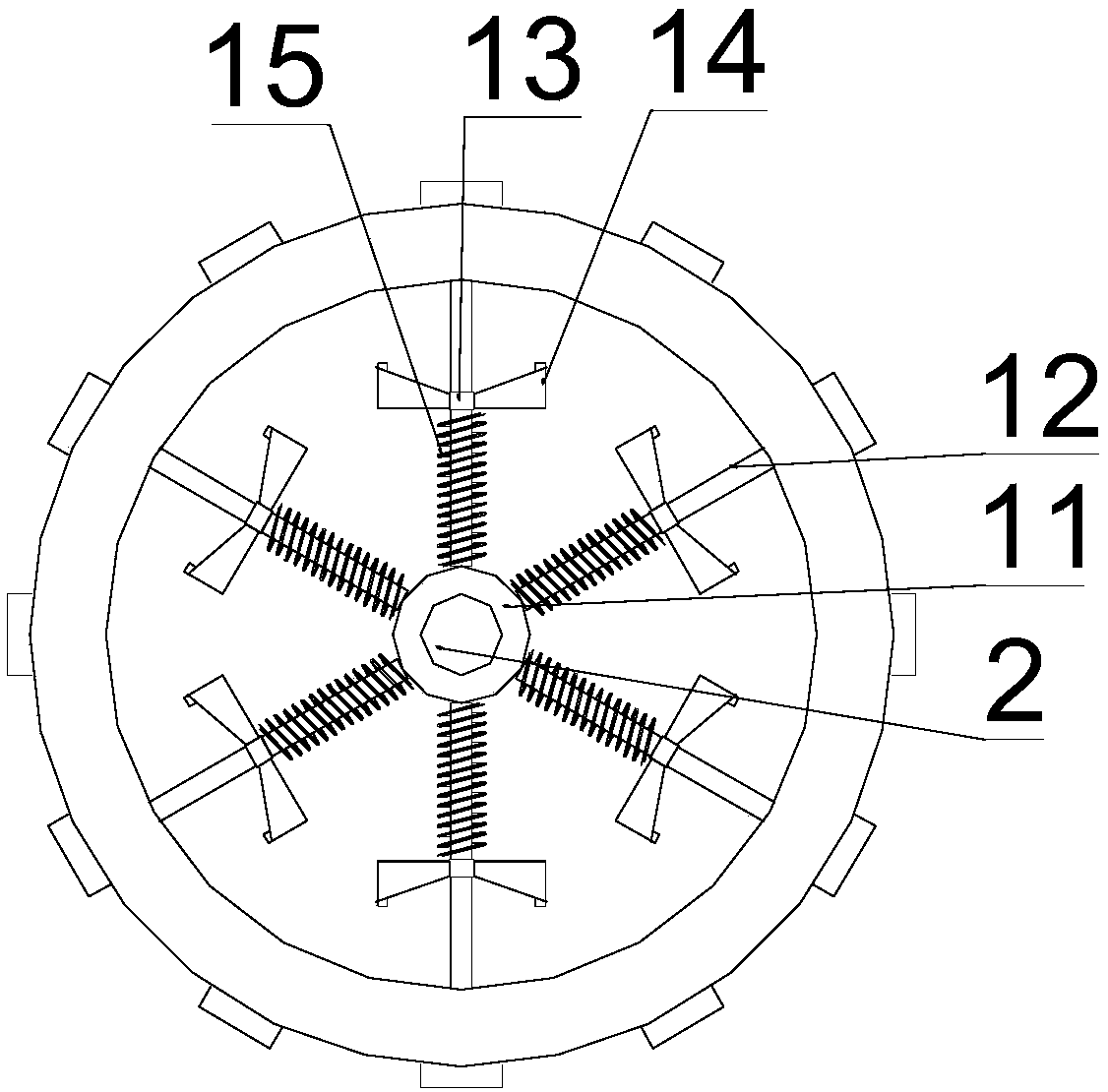

[0026] See Figure 1-2 , A non-stick wall decoloring device for the preparation of epoxidized soybean oil, comprising a decolorizing box 1. A rotating column 2 is arranged in the middle of the decolorizing box 1, and a plurality of stirring paddles 16 are fixedly connected to the lower surface of the rotating column 2 , The upper surface of the rotating column 2 is fixedly connected with a rotating rod 3, and the lower surface of the rotating rod 3 is symmetrically fixedly connected with a pair of first magnets 4, the magnetic south pole and the magnetic north pole of the pair of first magnets 4 are opposite and located on the rotating rod 3 The surface of the lower side of the rotating column 2 is fixedly connected with a pair of fixed blocks 6, a pair of fixed blocks 6 is provided with a sliding sleeve 11, the rotating column 2 passes through the sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com