Culture medium prescription for the industrial production of rhamnolipid fermentation liquor

A medium formulation and a rhamnolipid technology are applied in the field of medium formulations for industrial production of rhamnolipid fermentation broth, and can solve problems such as failure to form an industrialized production scale, low rhamnolipid content, and optimized medium formulations. , to achieve the effect of shortening the fermentation cycle, increasing the amount of rhamnolipid, and shortening the cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

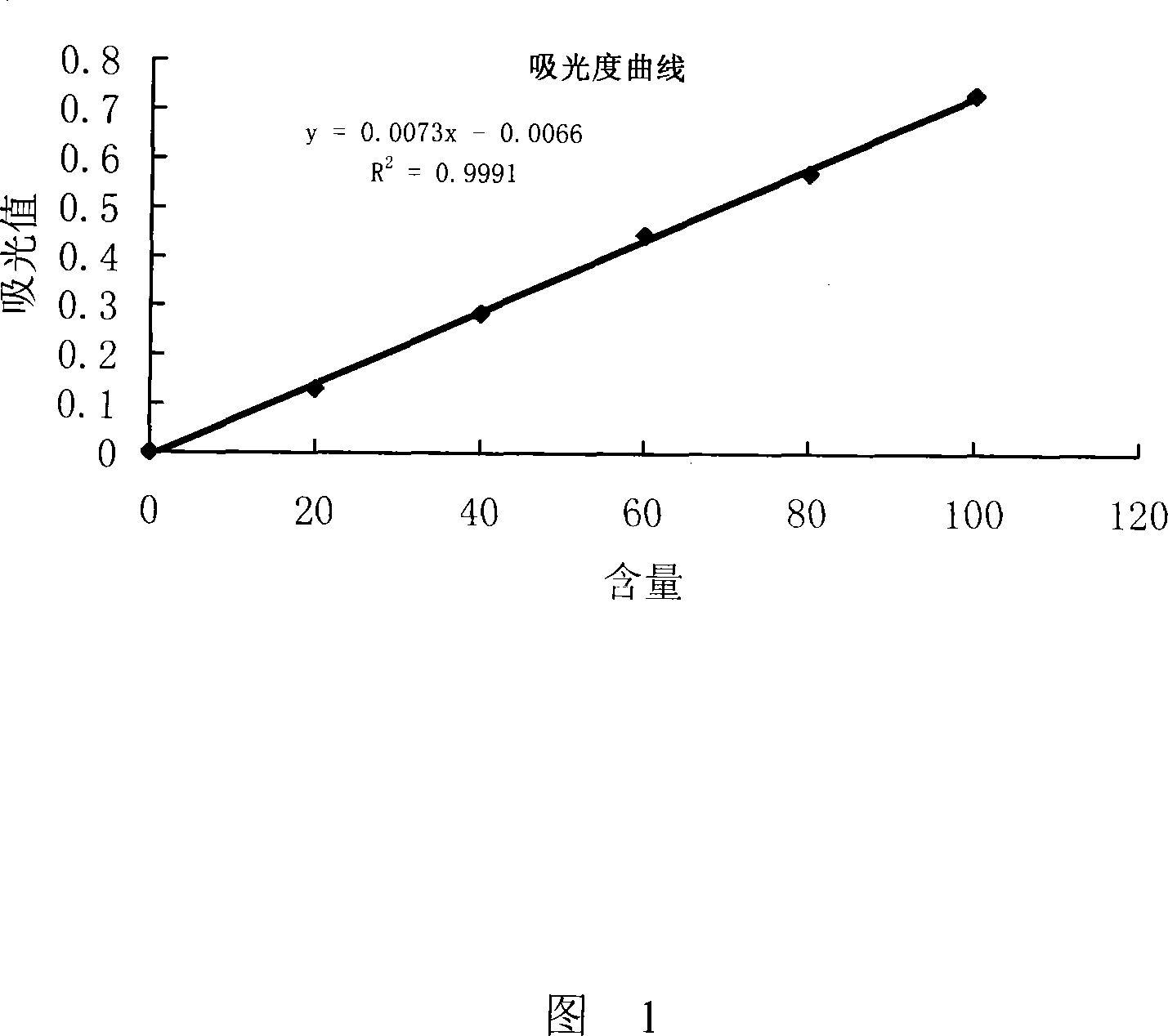

Image

Examples

Embodiment 1

[0009] Embodiment 1, industrialized method produces rhamnolipid biological fermentation liquid:

[0010] Shake flask and fermenter culture: Pseudomonas aeruginosa (Pseudomonas sp.VTS-1) was cultured for 30 hours, transferred to a 5L shake flask (loaded with 2L medium), and the inoculation amount was 5% (the concentration of the bacterial solution was at OD 600 =0.8~1.0), the temperature is 32±2°C, 120rpm cultivated for 12h, transferred to the 500-liter first-level fermenter, the filling coefficient is 75%, the inoculum size is 5%, the temperature is 32±2°C, and the ventilation ratio is 1:1, pH 6.5-7.5, stirring speed 100rpm, culture for 12 hours, transfer to a 3.5-ton secondary fermentation tank, the filling coefficient is 75%, the inoculum size is 5%, the temperature is 32±2°C, and the ventilation ratio is 1 : 1. The pH is 6.5-7.5, the stirring speed is 100rpm and cultivated for 12 hours, then transferred to a 30-ton three-stage fermenter with a loading capacity of 20 tons. T...

Embodiment 2

[0012] Embodiment 2, industrialized method produces rhamnolipid biological fermentation liquid:

[0013] Shake flask and fermenter culture: Pseudomonas sp.VTS-1 was cultured for 30 hours, transferred to a 5L shake flask (loaded with 2L medium), inoculated at 5%, 32±2°C, 120rpm and cultured for 12 hours , the 500 liters of first-class fermentation tanks that are transferred into, the filling coefficient is 65%, the inoculum size is 5%, the ventilation ratio is 1:1, the pH is 6.5~7.5, the stirring speed is 100rpm, and the inoculum size is 5%, and the stirring speed is 100rpm. Connect to a 3.5-ton secondary fermentation tank, with a filling factor of 65%, an inoculum size of 5%, 32±2°C, a ventilation ratio of 1:1, a pH of 6.5-7.5, and a stirring speed of 100-150rpm for 12 hours, transfer Enter a 30-ton three-stage fermenter with a loading capacity of 20 tons. The process parameters of the three-stage fermenter are: temperature 32±2°C, pH adjusted to about 6 before sterilization, ...

Embodiment 3

[0015] Embodiment 3, industrialized method produces rhamnolipid biological fermentation liquid:

[0016] Shake flask and fermenter culture: Pseudomonas sp.VTS-1 was cultured for 30 hours, transferred to a 5L shake flask (loaded with 2L medium), inoculated at 5%, 32±2°C, 120rpm and cultured for 14 hours , transferred to a 500-liter primary fermenter with a filling factor of 65%, an inoculum size of 5%, 32±2°C, a ventilation ratio of 1:1, a pH of 6.5 to 7.5, and a stirring speed of 100 to 150 rpm for 12 hours. , transferred to 3.5 tons of secondary fermenter (filling coefficient is 65-75%), inoculum size 5%, 32 ± 2 ℃, ventilation ratio is 1: 1, pH is 6.5-7.5, stirring speed is 100rpm to cultivate 12h , transferred to a 30-ton three-stage fermenter with a loading capacity of 18 tons. The process parameters of the three-stage fermenter are: temperature 32±2°C, pH adjusted to about 6 before sterilization, and pH control with 0.185 tons of NaOH in the later stage Above 6, the venti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com