Siloxane-modified thermoplastic material and preparation method thereof

A thermoplastic material and siloxane modification technology, which is applied in the field of cross-linked siloxane modified thermoplastic material and its preparation, can solve problems such as poor heat resistance and aging resistance, and achieve enhanced performance and bright surface. , the effect of reducing the dispersion size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

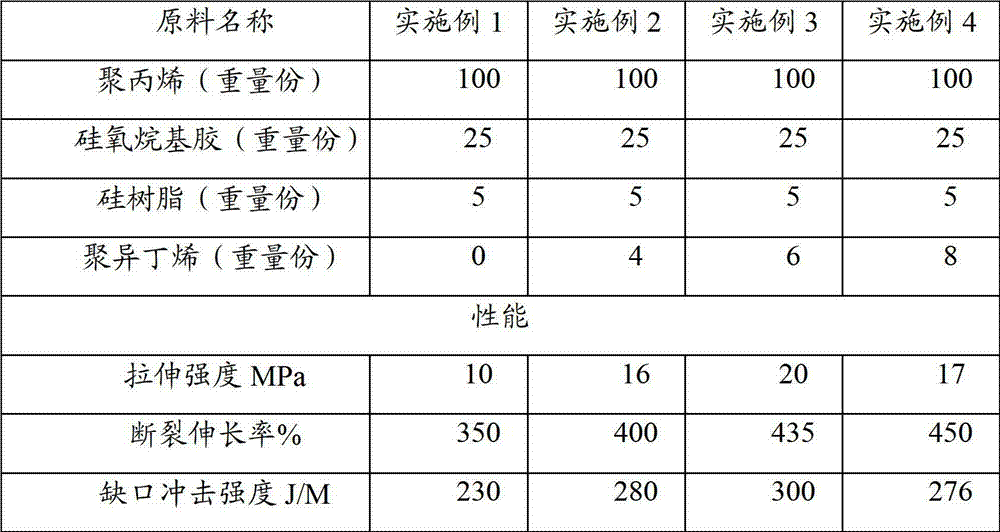

Examples

preparation example Construction

[0050] In order to promote the dispersion of siloxane, the preparation method of the present invention is divided into two steps, and the preparation method comprises the following steps:

[0051] Step 1, preparation of base material. Add a certain amount of thermoplastic material, high molecular weight siloxane, silicone resin, and compatibilizer into the high-speed mixer at the same time, and blend for 3 to 4 minutes, then add a crosslinking agent, and the catalyst reacts and blends for 3 to 5 minutes. Material is cooled to room temperature to obtain base material;

[0052] Step 2. Take 100 parts by mass of the base material in step 1 and mix them uniformly with 50-150 parts by mass of thermoplastic materials, and melt and blend them through an internal mixer or a twin-screw extruder to obtain the final product—siloxane-modified thermoplastic Material.

[0053] In the melt blending process of the second step, the high molecular weight organosiloxane reacts and cross-links ...

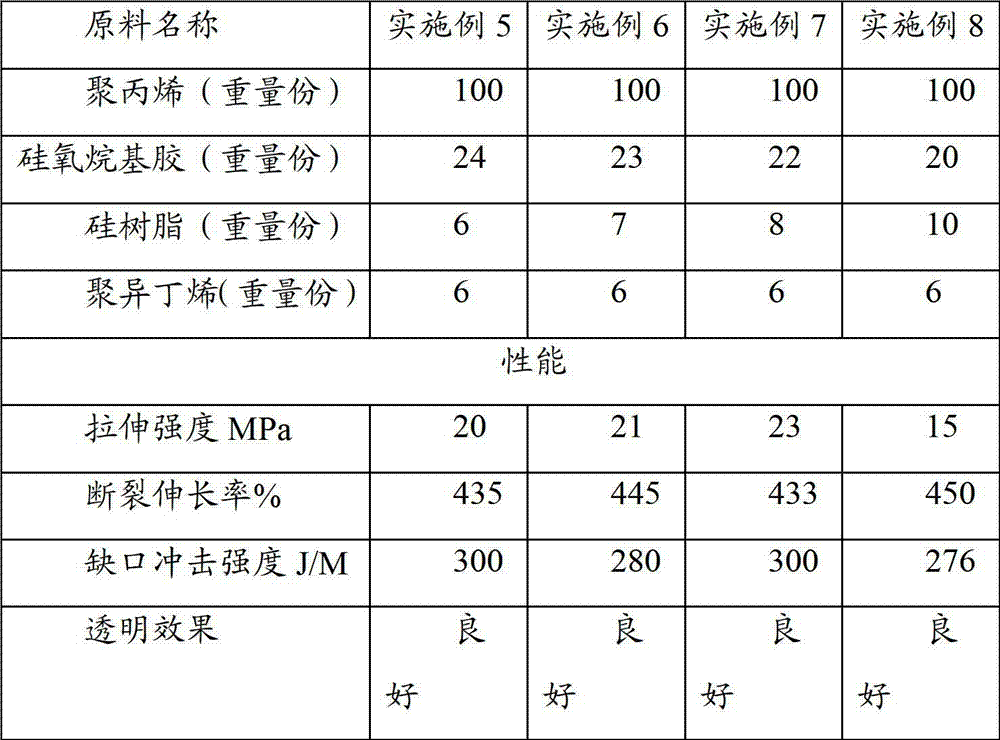

Embodiment 5~8

[0058] Embodiments 5-8: Add polysiloxane, silicone resin, polyisobutylene, and half of the PP into the blender and stir at high speed for 3 minutes in parts by weight, and add the mixture of the above-mentioned raw materials into a twin-screw extruder through melt extrusion, Granulation, the extrusion process is: first zone 170~180, second zone 180~190, third zone 190~200, fourth zone 180~190, screw speed 400r / min, vacuum degree -0.02~-0.04Mpa, high Concentrated siloxane dispersion masterbatch in PP. Melt the obtained dispersion masterbatch and remaining PP in a twin-screw extruder, extrude and granulate. The material ratio and properties are listed in Table 2.

[0059] Table 2

[0060]

[0061] The cross-linked siloxane modified thermoplastic material has the advantages of high heat resistance, excellent weather resistance, low coefficient of friction over time, bright surface, silky touch and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com