Microcapsule and preparation method thereof, electrolyte and preparation method thereof and battery

A technology of microcapsules and electrolytes, applied in microcapsule preparations, non-aqueous electrolyte batteries, electrolyte battery manufacturing, etc., can solve the problems of negative impact of battery SEI film, increase electrolyte viscosity, reduce electrolyte activity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

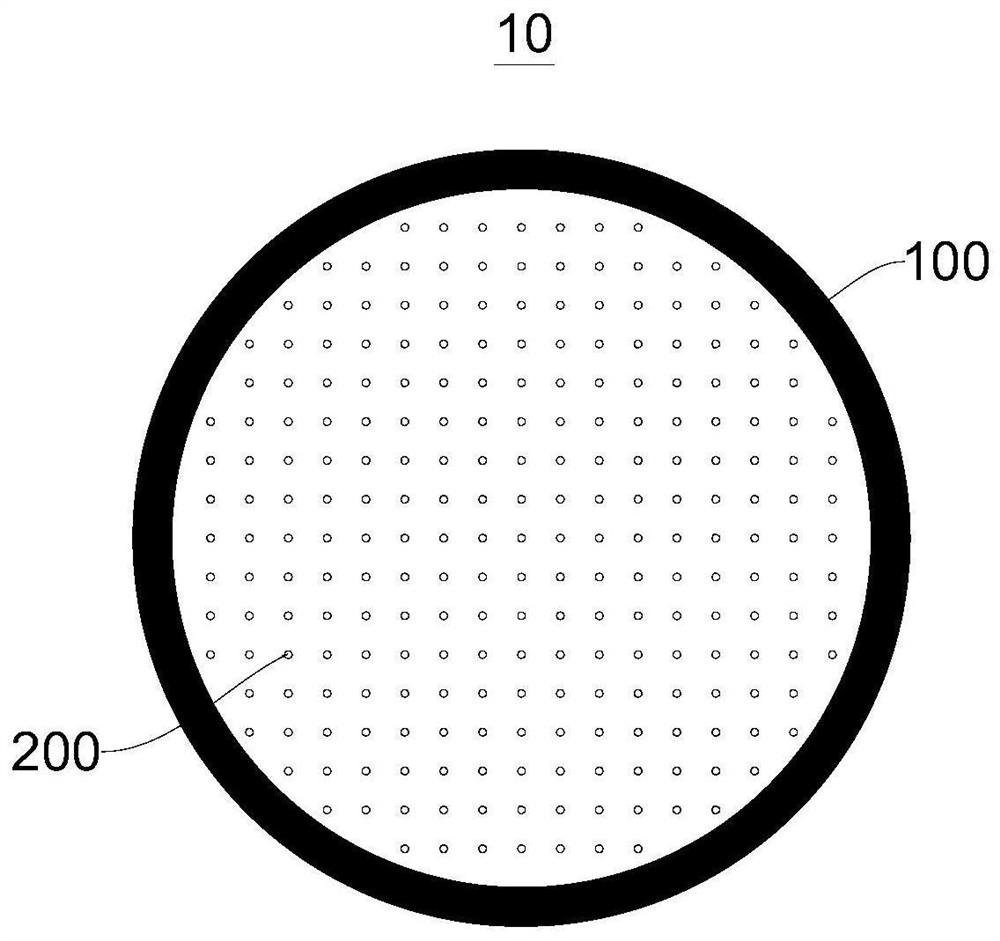

Image

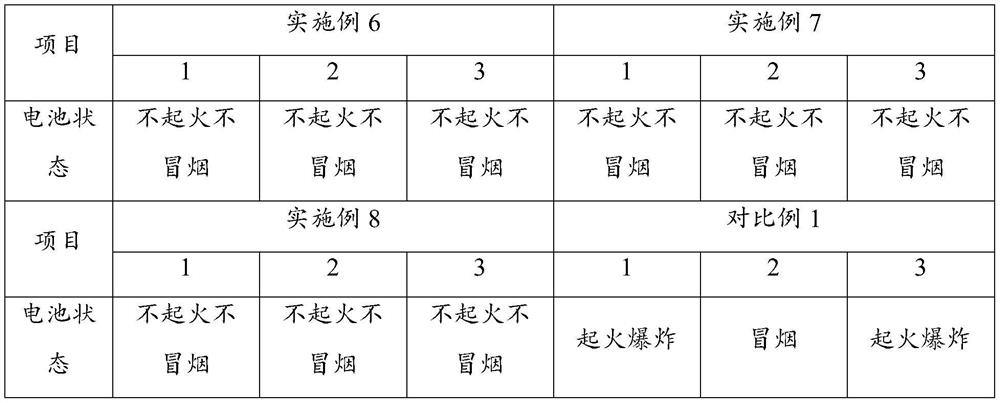

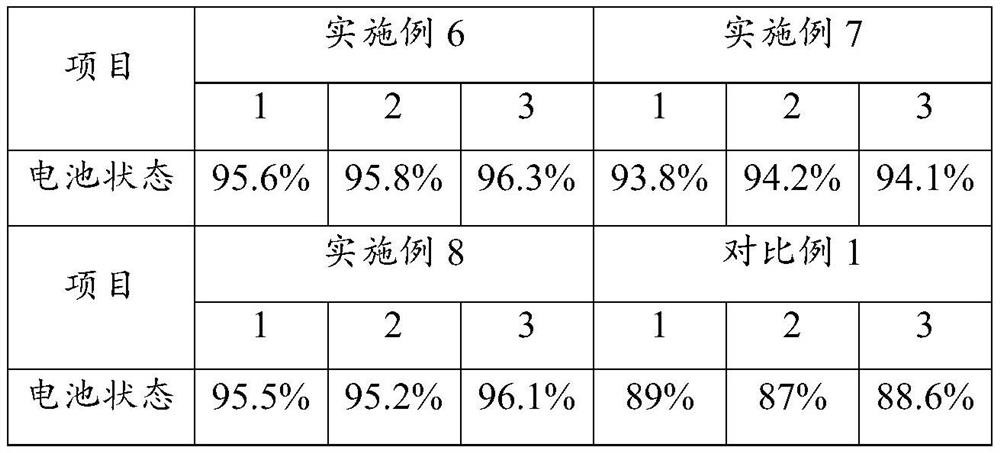

Examples

preparation example Construction

[0061] The present application provides a method for preparing microcapsules, which includes: mixing a first material and a first solvent to obtain a first mixed solution, mixing the first mixed solution with a second material to obtain a second mixed solution, and mixing the second mixed solution Mixing with the second solvent to obtain the third mixed liquid, drying the third mixed liquid to obtain microcapsules.

[0062] Wherein, the first solvent is a good solvent for the first material, and the second solvent is a poor solvent for the first material.

[0063] The microcapsules of the present application are prepared by coacervation phase separation. In the second mixed solution, the first material is the continuous phase, and the second material is the dispersed phase. After the second mixed solution is mixed with the second solvent, at this time, due to the first solvent to The solubility of the first material changes, and the continuous phase separation of the first mat...

Embodiment 1

[0096] The embodiment of the present application provides a kind of microcapsule and preparation method thereof, it comprises:

[0097] At room temperature 25°C, dissolve polyethylene powder in toluene to obtain a polyethylene toluene solution. The mass volume ratio of polyethylene to toluene is 40g:350mL, and then add methylphenyl silicone resin to the polyethylene toluene solution. , stir evenly to obtain polyethylene as the continuous phase, methylphenyl silicone resin as the second mixed solution of the dispersed phase, the mass volume ratio of methylphenyl silicone resin and toluene is 8g: 350mL, and then add to the second mixed solution Acetone was added to obtain a third mixed solution, the volume ratio of acetone to toluene was 130mL:350mL, and finally the third mixed solution was dried at 90° C. for 11 h to obtain dry microcapsule powder.

Embodiment 2

[0099] The embodiment of the present application provides a kind of microcapsule and preparation method thereof, it comprises:

[0100] At room temperature 25°C, dissolve polyethylene powder in toluene to obtain a polyethylene toluene solution. The mass volume ratio of polyethylene to toluene is 30g:200mL, and then add methylphenyl silicone resin to the polyethylene toluene solution. , and stir evenly to obtain polyethylene as the continuous phase, and methylphenyl silicone resin as the second mixed solution of the dispersed phase. The mass volume ratio of methylphenyl silicone resin and toluene is 5g:200mL, and then add to the second mixed solution Acetone was added to obtain a third mixed solution, the volume ratio of acetone to toluene was 80mL:200mL, and finally the third mixed solution was dried at 80° C. for 12 hours to obtain dry microcapsule powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com