Lithium ion electrolyte containing grafted polysilane additive

An additive and polysilane technology, which is applied in the field of battery electrolyte and lithium battery electrolyte, can solve the problems of insufficient wide-temperature electrolyte rate performance and high-temperature safety performance, and achieve improved impedance phenomenon, high-temperature safety performance, and discharge performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

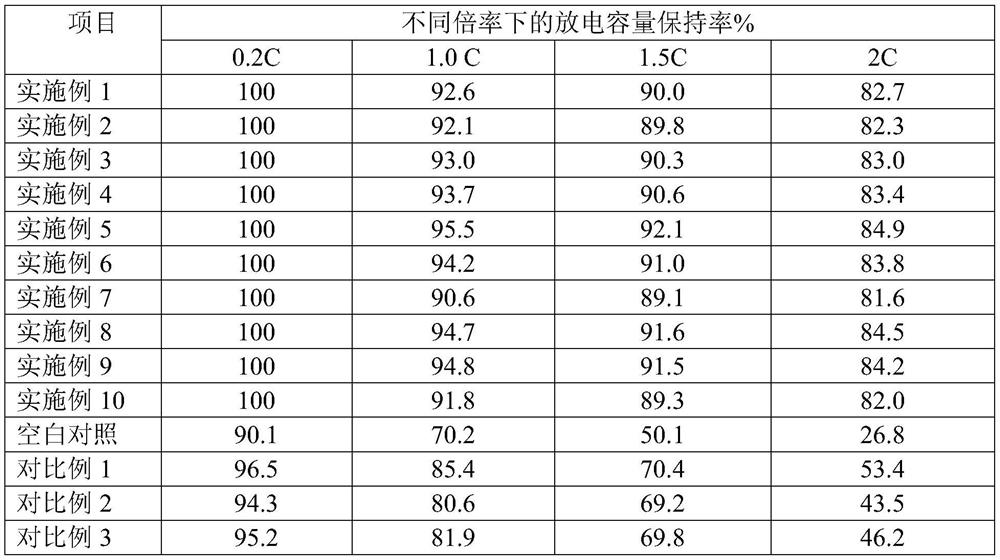

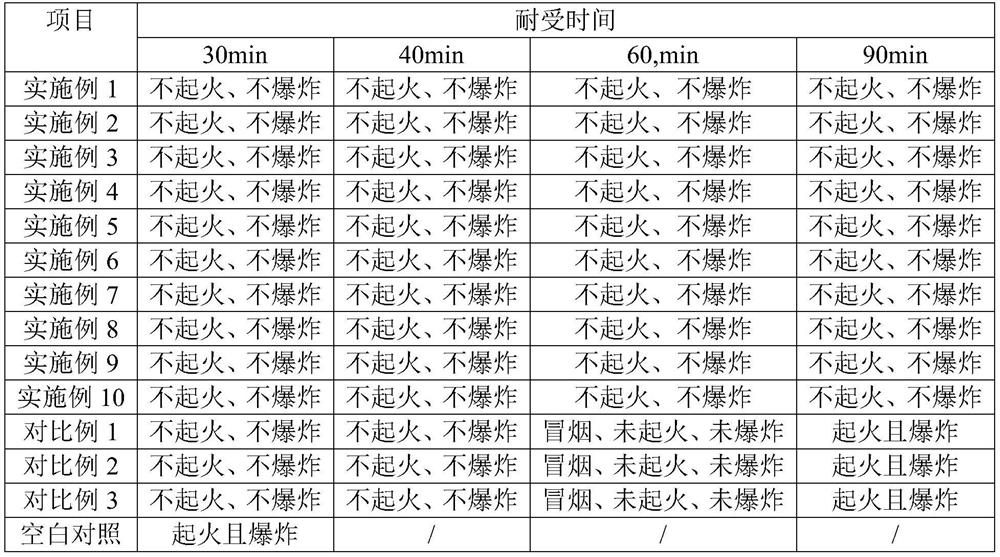

Examples

Embodiment 1

[0020] Lithium-ion battery wide-temperature electrolyte, including an organic solvent composed of ethylene carbonate, dimethyl carbonate, and diethyl carbonate with a volume ratio of 4:1:5; LiPF with an organic solvent concentration of 1mol / L 6 Lithium salt; an additive that accounts for 1% of the electrolyte mass, and the graft polysilane additive in the additive includes a vinylene carbonate-polymethylhydrogensilane graft polymer with a substitution rate of 0.05 and ethylene carbonate with a substitution rate of 0.6 Ethylene ester-polymethylhydrogensilane graft polymer, the mass ratio of the two is 1:1; the additive also includes trifluoropropyltriethoxysilane accounting for 0.04% of the mass of the grafted polysilane additive.

Embodiment 2

[0022] Lithium-ion battery wide temperature electrolyte, including an organic solvent composed of ethylene carbonate and methyl ethyl carbonate with a volume ratio of 4:6; LiBF with an organic solvent concentration of 1.5mol / L 4 Lithium salt; an additive that accounts for 2% of the mass of the electrolyte, and the grafted polysilane additive in the additive includes a vinylene carbonate-polymethylhydrosilane graft polymer with a substitution rate of 0.1 and ethylene carbonate with a substitution rate of 0.1 Ethylene ester-polymethylhydrogensilane graft polymer, the mass ratio of the two is 1:3; the additive also includes trifluoropropyltriethoxysilane accounting for 0.1% of the mass of the grafted polysilane additive.

Embodiment 3

[0024] Lithium-ion battery wide-temperature electrolyte, including an organic solvent composed of ethylene carbonate, dimethyl carbonate, and diethyl carbonate with a volume ratio of 3:3:4; Li(CF) with an organic solvent concentration of 1.1mol / L 3 SO 2 )N 2 Lithium salt; an additive that accounts for 1% of the mass of the electrolyte, and the grafted polysilane additive in the additive includes a vinylene carbonate-polymethylhydrosilane graft polymer with a substitution rate of 0.05 and ethylene carbonate with a substitution rate of 0.5 Ethylene ester-polymethylhydrogensilane graft polymer, the mass ratio of the two is 1:3; the additive also includes trifluoropropyltriethoxysilane accounting for 0.1% of the mass of the grafted polysilane additive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com