Silicone mist suppressing agent

A silicone and mist technology, applied in thin material handling, transportation and packaging, coating, etc., can solve problems such as damage to peeling performance, and achieve sufficient mist suppression effect and excellent silicone mist suppression effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

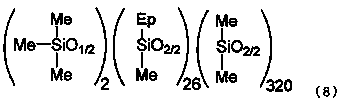

[0129] 98 parts by mass of polydimethylsiloxane (vinyl valence content: 0.02mol / 100g) with a viscosity of 400mPa·s at both ends containing vinyl groups at 25°C, 2.0 parts by mass of the following average formula (7) Represented polyorganohydrogensiloxane (SiH group / Vi group (molar ratio) = 1.8) having a viscosity of 20 mPa·s at 25°C,

[0130] [chemical formula 4]

[0131]

[0132] and 0.3 parts by mass of ethynylcyclohexanol were uniformly mixed. 3 parts of silicone mist inhibitor I and 2 parts by mass of a complex salt of chloroplatinic acid and vinylsiloxane (approximately 100 ppm in terms of platinum atoms) were added thereto, and uniformly mixed to obtain a silicone composition 1.

Embodiment 2

[0134] Except adding 3 parts of silicone mist inhibitor II, the operation of Example 1 was repeated to obtain silicone composition 2.

Embodiment 3

[0136] Except adding 3 parts of silicone mist inhibitor III, the operation of Example 1 was repeated to obtain silicone composition 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com