Dry-type transfer-printed textile and preparation method thereof

A technology of transfer printing and textiles, which is applied in the direction of textiles, papermaking, dyeing, etc., to achieve the effects of ensuring stability, processing environment safety, and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

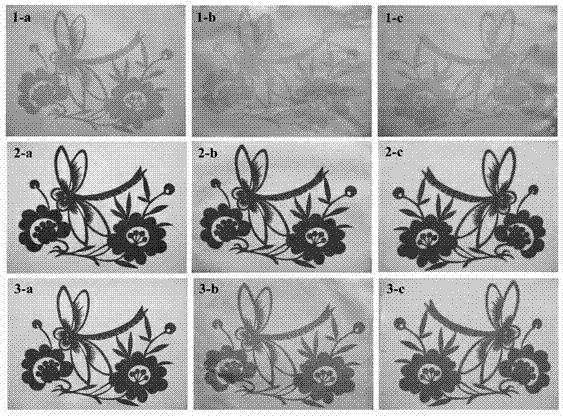

Image

Examples

Embodiment 1

[0031] Step 1: Evenly disperse polyester hot melt adhesive powder with a mesh number of 200 in water to form a suspension, then add sodium alginate to the above suspension to adjust the viscosity of the solution to 2000mPa.s, finally add sodium carbonate and urea, and stir Dissolve the sodium carbonate and urea evenly to prepare the paste for dry transfer printing. In this paste, the content of polyester hot melt adhesive is 10% (w / w), the content of sodium alginate is 6% (w / w), the content of sodium carbonate is 3% (w / w), and the content of urea is 7% %(w / w). The percentages in the examples mean the mass ratio of this component to the total amount of the paste.

[0032] Step 2: Coating the printing paste prepared above on the paper surface with a density of 45 g / cm2. The coating thickness is 0.4 mm, the drying temperature is 60°C, and the drying time is 20 minutes; the calendering temperature is 25°C, the calendering roll speed is 10 rpm, and the calendering pressure is 0.5...

Embodiment 2

[0037]Step 1: Evenly disperse polyurethane hot melt adhesive powder with a mesh number of 100 in water to form a suspension, then add starch ether to the above suspension to adjust the viscosity of the solution to 3000mPa.s, finally add trichloroacetic acid and glycerin, and stir well Fully dissolve the trichloroacetic acid and glycerin to prepare the paste for dry transfer printing. In this paste, the content of polyurethane hot melt adhesive is 8% (w / w), the content of starch ether is 12% (w / w), the content of trichloroacetic acid is 5% (w / w), and the content of glycerin is 10% (w / w).

[0038] Step 2: coating the printing paste prepared above on the surface of the PET film. The coating thickness is 0.3 mm, the drying temperature is 50° C., and the drying time is 30 minutes; the calendering temperature is 25° C., the calendering roll speed is 20 rpm, and the calendering pressure is 0.3 Mpa.

[0039] Step 3: Print the acid dye ink on the surface of the above-prepared film by...

Embodiment 3

[0043] Step 1: Evenly disperse the polyamide hot-melt adhesive powder with a mesh number of 300 and the polyester hot-melt adhesive powder with a mesh number of 200 in water to form a suspension, and then add sodium carboxymethylcellulose (belonging to Cellulose ether) to adjust the viscosity of the solution to 3500mPa.s, finally add sodium trichloroacetate and urea, stir evenly to fully dissolve the sodium trichloroacetate and urea, and prepare a paste for dry transfer printing. In this paste, polyamide hot melt adhesive content is 5% (w / w), polyester hot melt adhesive content is 5% (w / w), carboxymethyl cellulose sodium content is 3% (w / w ), the content of sodium trichloroacetate is 4% (w / w), and the content of urea is 9% (w / w).

[0044] Step 2: Coating the printing paste prepared above on the paper surface with a density of 44 g / cm2. The coating thickness is 0.5 mm, the drying temperature is 70°C, and the drying time is 20 minutes; the calendering temperature is 25°C, the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com