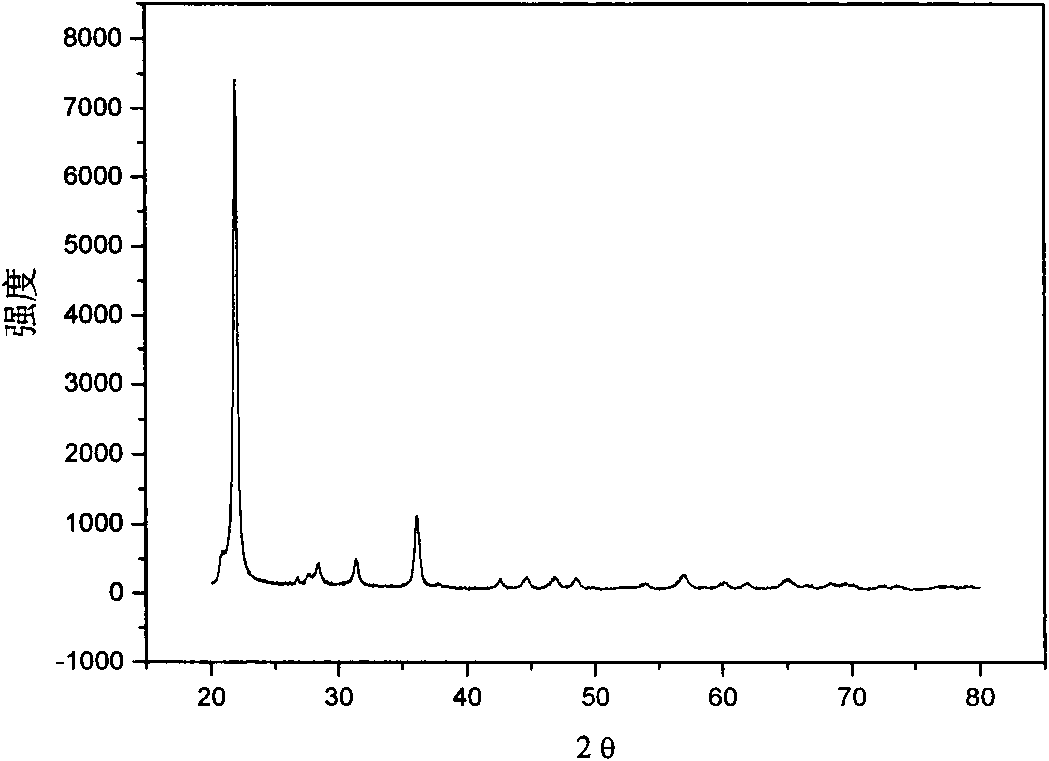

Preparation method of calcined diatomite flatting agent

A technology of calcined diatomite and matting agent, applied in chemical instruments and methods, inorganic pigment treatment, dyeing physical treatment, etc., can solve the problems of small bulk density, strong oil absorption of fumed silica, suspension (poor storage stability, etc.)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

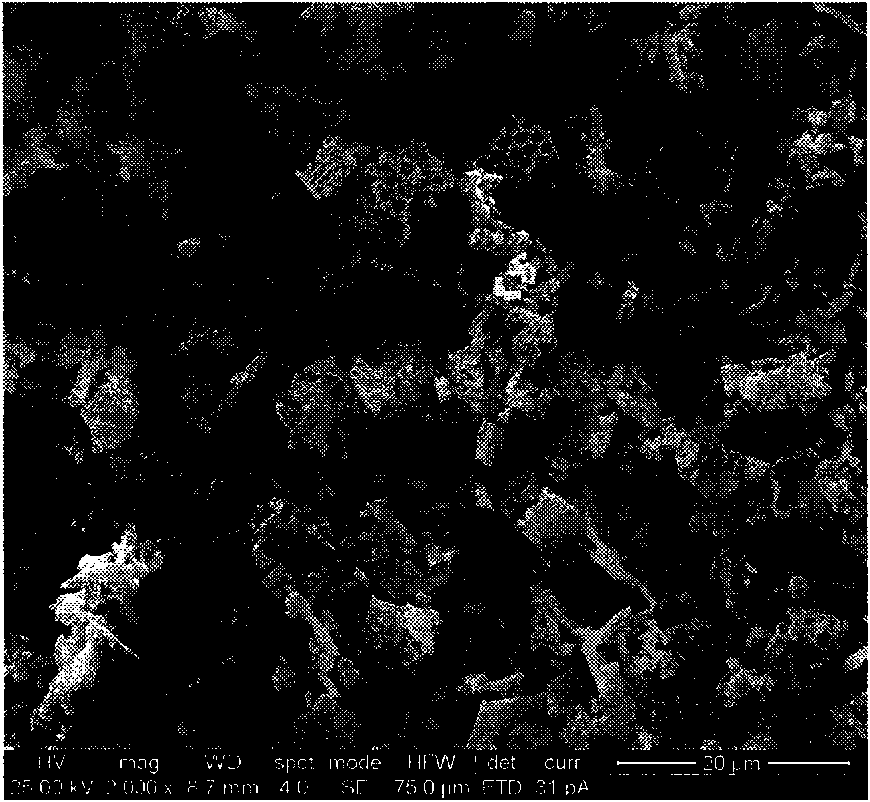

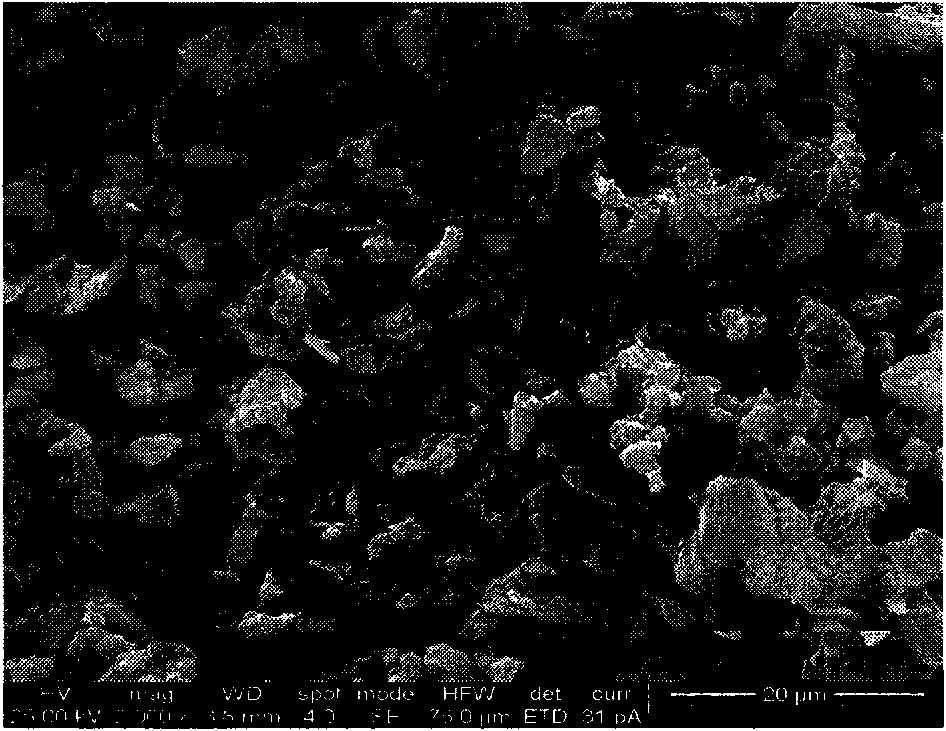

Embodiment 1

[0019] Example 1: Add 2wt% NaCl and 6wt% starch (diatomaceous earth is 100%) to diatomite, calcined at 850°C for 2 hours, and naturally cool down to obtain calcined material, which is air-jet crushed and gravity classified , named Y-1. Use styrene-acrylic emulsion paint, do a group of blank experiment, measure the coating glossiness that the incident angle is 20 °, 60 ° and 85 ° are respectively 2.6, 5.7 and 8.9; Sample Y-1 (accounting for 4wt% of coating weight ) (as shown in Table 1) was added in the above-mentioned styrene-acrylic emulsion paint, and the paint was painted according to the normal construction procedure, and the recorded incident angle was 20 °, and the coating gloss of 60 ° and 85 ° was respectively 1.3, 2.8 and 3.1, The glossiness of 60° and 85° is very close, and the extinction rate is 51% and 65% respectively.

Embodiment 2

[0020] Example 2: Add 3wt% NaCl and 7wt% starch (100% diatomaceous earth) to diatomite, calcined at 900°C for 2.5 hours, and naturally lower the temperature to obtain calcined material, which is air-flow pulverized and flotation Graded, designated Y-2. Use styrene-acrylic emulsion paint, do a group of blank experiments, measure that the coating glossiness of 20 °, 60 ° and 85 ° is respectively 2.6, 5.7 and 8.9 at incident angle; Sample Y-2 (accounting for 4wt% of coating weight ) (as shown in Table 1) was added in the above-mentioned styrene-acrylic emulsion paint, and the paint was painted according to the normal construction procedure, and the recorded incident angle was 20 °, and the coating gloss of 60 ° and 85 ° was respectively 1.3, 2.7 and 2.8, When the incident angle is 60° and 85°, the extinction rate is 53% and 68%, respectively.

Embodiment 3

[0021] Example 3: Add 4wt% NaCl and 8wt% starch (100% diatomaceous earth) to diatomite, calcined at 950°C for 3 hours, and naturally lower the temperature to obtain calcined material, which is jet-pulverized and centrifugally classified , named Y-3. Use pure acrylic emulsion paint, do a group of blank experiment, measure that incident angle is 20 °, the coating glossiness of 60 ° and 85 ° is respectively 2.6, 5.7 and 8.9; Sample Y-3 (accounting for 4wt% of coating weight ) (as shown in Table 1) was added in the above-mentioned pure acrylic emulsion paint, and the paint was painted according to the normal construction procedure, and the recorded incident angle was 20 °, and the coating gloss of 60 ° and 85 ° was respectively 1.3, 2.7 and 3.0, When the incident angle is 60° and 85°, the extinction rate is 53% and 66%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oil absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com