High-speed pump

A technology for high-speed pumps and pump shafts, applied in the field of hydraulic pumps, can solve problems affecting the pumping efficiency and service life of plunger pumps, uneven oil film on the distribution surface, and prone to cavitation, so as to eliminate partial wear and avoid gas Corrosion phenomenon, the effect of uniform oil film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

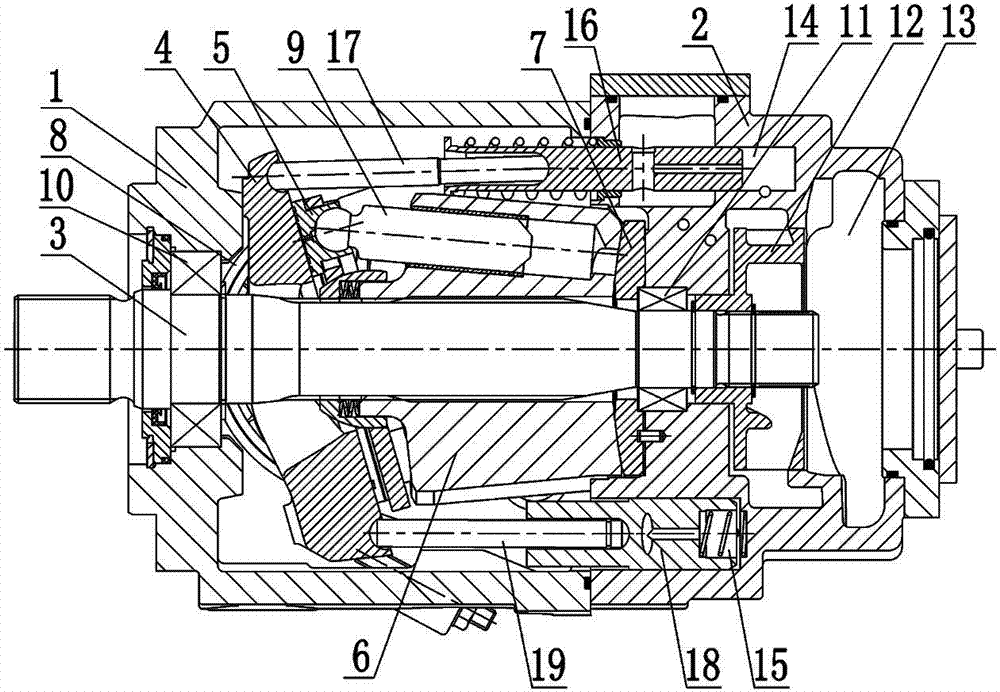

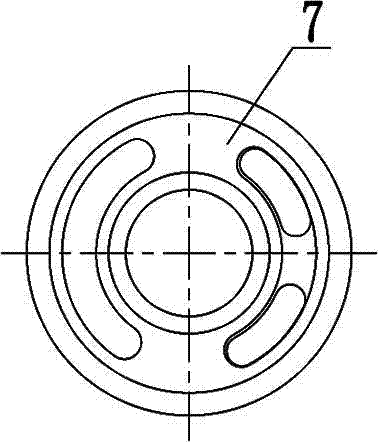

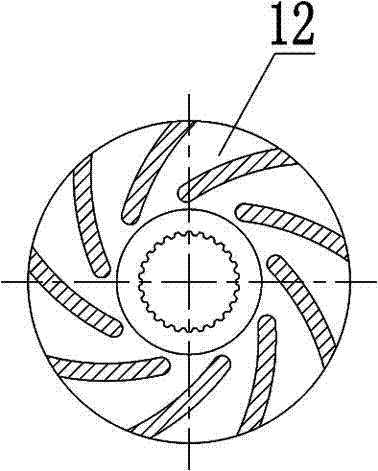

[0015] Such as figure 1 , figure 2 , image 3 As shown, a high-speed pump includes a casing 1, a pump cover 2, a pump shaft 3, a swash plate 4, a return plate, a sliding shoe 5, a cylinder body 6, a distribution plate 7, a split bearing 8, a plunger 9, a return Position piston rod 16, variable piston rod 18, last adjustment rod 17, lower adjustment rod 19, upper return spring, lower return spring and impeller 12.

[0016] The front part of the casing 1 has a shaft hole, the rear part of the casing 1 is connected to the pump cover 2, the pump shaft 3 extends into the inside of the casing 1 from the shaft hole, and one end is supported by the front bearing 10 outside the casing 1, and can be connected with external devices. Connection, liquid seal between the pump shaft 3 and the shaft hole; the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com