Preparation method of high-temperature high-density water-based drilling fluid filtrate reducer composition

A technology of water-based drilling fluid and fluid loss reducing agent, which is applied in the directions of drilling compositions, chemical instruments and methods, etc., can solve the problems of high temperature and high density drilling fluid, fluid loss reduction, viscosity increase and flocculation, and drilling fluid system. Limited and other problems, to achieve the effect of being beneficial to rheology, improving motion resistance, and preventing curling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

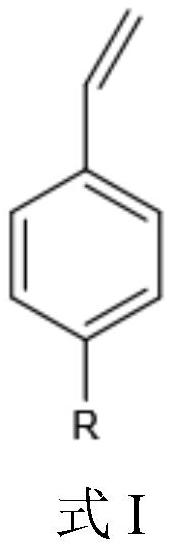

Method used

Image

Examples

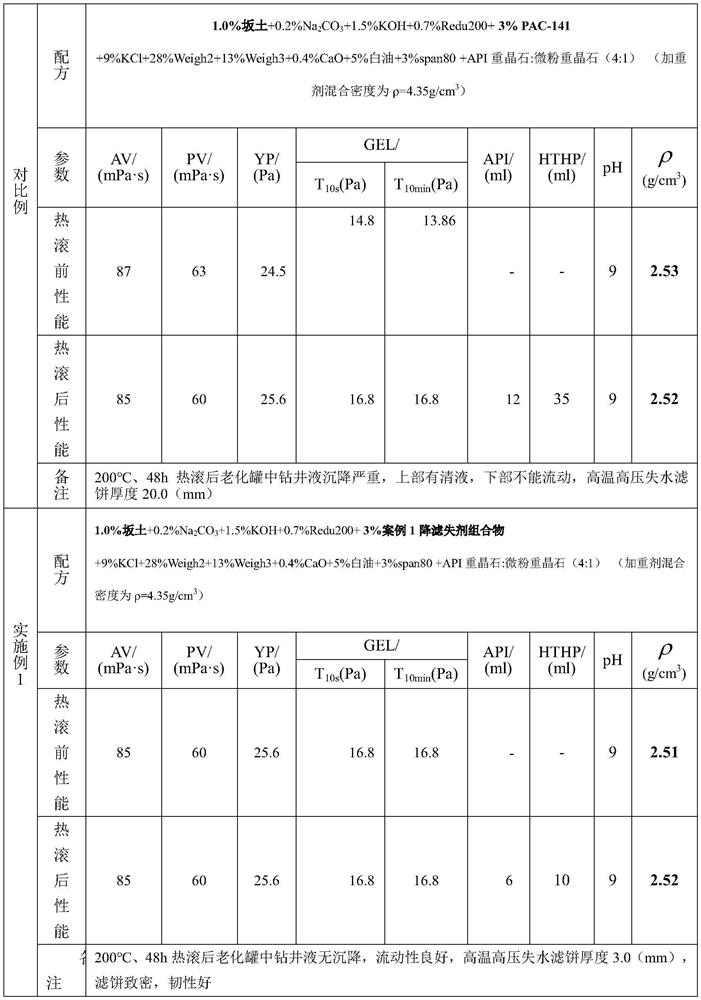

Embodiment 1

[0038] Embodiment 1: a kind of preparation method of high temperature and high density water-based drilling fluid fluid loss control agent composition, the steps are as follows:

[0039] S1, low molecular weight linear polymer preparation: respectively weigh 85 parts of acrylamide (AM), 5 parts of 2-acrylamide-2-methylpropanesulfonic acid (AMPS), 5 parts of N-vinylpyrrolidone, 5 parts of methyl Acryloyloxyethyltrimethylammonium chloride (DMC) (the total mass of the four monomers accounts for 30% of the mass of the reaction system), azobisisobutyronitrile (0.5% of the total mass of the monomers) (decomposition temperature 45~ 65°C), 5% isopropanol was used as the polymerization inhibitor, and the rest was deionized water.

[0040] First, acrylamide (AM), 2-acrylamide-2-methylpropanesulfonic acid (AMPS), N-vinylpyrrolidone, methacryloyloxyethyltrimethylammonium chloride (DMC) were added to the condenser pipe, mechanical stirring and constant pressure dropping funnel; then add dei...

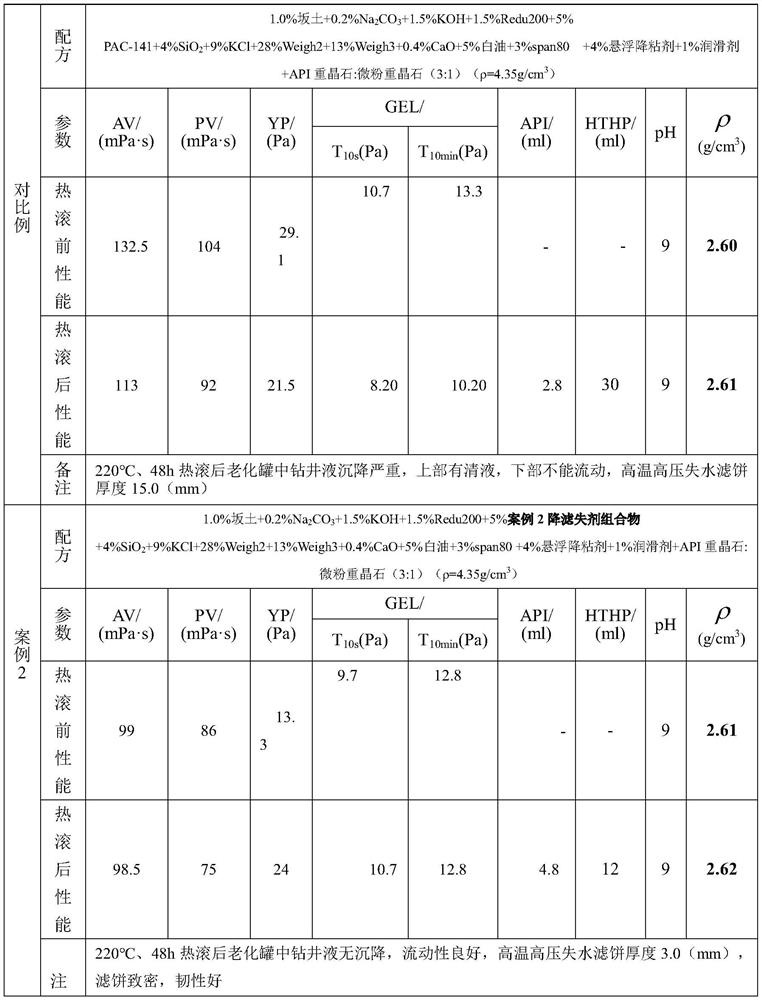

Embodiment 2

[0046] Embodiment 2: a kind of preparation method of high temperature and high density water-based drilling fluid fluid loss control agent composition, the steps are as follows:

[0047] S1. Preparation of low molecular weight linear polymer: Weigh 90 parts of acrylic acid, 5 parts of 2-acrylamide-2-methylpropanesulfonic acid (AMPS), 5 parts of divinylpyridine, 5 parts of dimethyldiallyl respectively Ammonium chloride (DMDAAC) (the total mass of the four monomers accounts for 40% of the mass of the reaction system), the dibenzoyl peroxide initiator accounts for 0.5% of the mass of the reaction system, the polymerization inhibitor is 10% of ethanol, and the rest is deionized water.

[0048] First, acrylic acid, 2-acrylamido-2-methylpropanesulfonic acid (AMPS), divinylpyridine, and dimethyldiallylammonium chloride (DMDAAC) were added to the equipment equipped with a condenser, mechanical stirring and constant pressure. Add it to the three-necked flask of the dropping funnel, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com