Technology utilizing waste solids to prepare ceramic particles used as soilless culture substrates

A technology for soilless culture substrate and solid waste is applied in the field of preparing soilless culture substrate ceramsite, which can solve the problems of unfavorable social sustainable development, low utilization rate of solid waste discharged from industrial and mining, environmental pollution, etc., and achieves ensuring chemical stability. and buffer capacity, the effect of protecting social and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

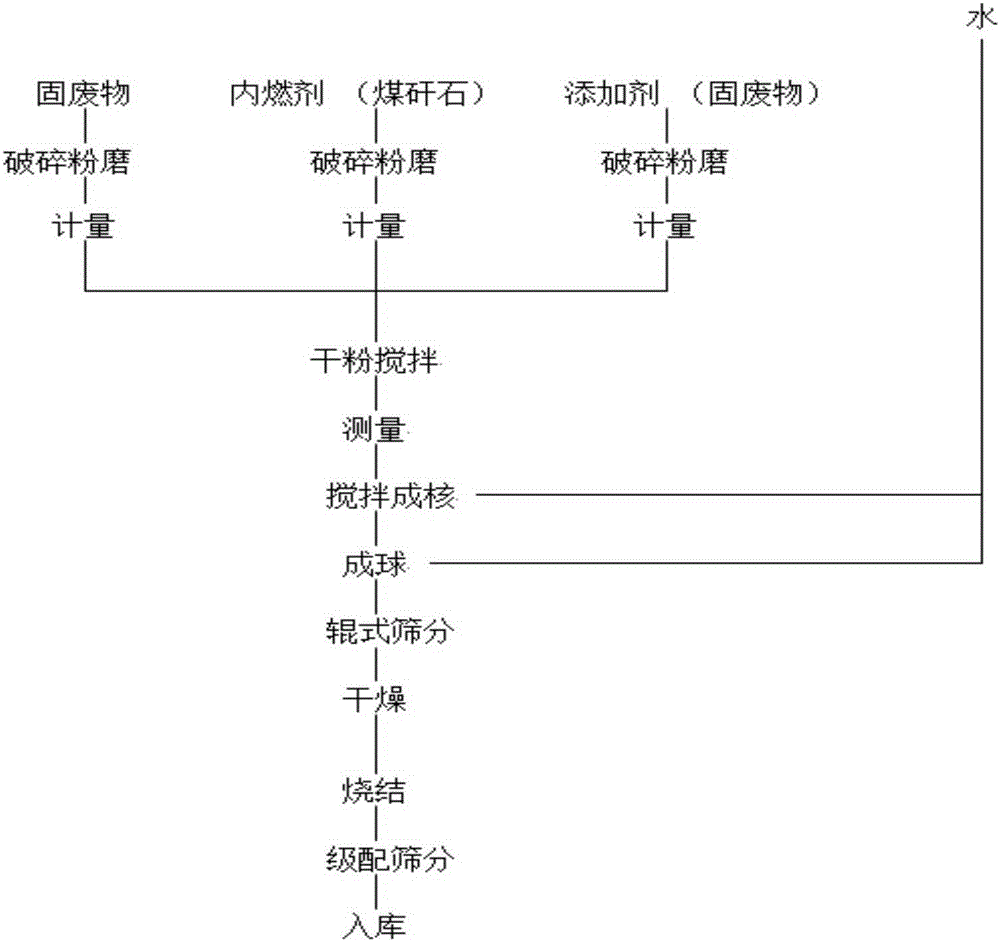

Method used

Image

Examples

Embodiment 1

[0029] The mixed-grade fly ash dry ash discharged from Donghua thermal power plant in Baotou City was taken, and its chemical composition was determined, which contained 56% SiO 2 , 32%Al 2 o 3 , 4.8% Fe 2 o 3 , 2.5% GaO, 0.7% Na 2 O, 0.5%K 2 O, 0.3%SO 3 , 0.7% loss on ignition. The coal gangue from the coal washing plant in the Shiguai Mining Area of Baotou City was taken, and its chemical determination showed that it contained 46% SiO 2 , 29%Al 2 o 3 , 5.2% Fe 2 o 3 , 1.7% CaO, 0.6% Na 2 O, 0.9%K 2 O, 0.7%SO 3 , 15% loss on ignition.

[0030] Take fly ash about 1m 3 (According to bulk density 850~1000kg / m 3 ), coal gangue powder is 0.05m 3 , first crush it to a powder with a particle size of 60-80um and keep it dry. Use dry powder stirring to stir the raw material powder evenly, double-axis stirring to nucleate, roll into balls, pendulum cloth, roller sieving to obtain wet material balls with 5-10mm particle size gradation and surface finish that meet the...

Embodiment 2

[0033]Take 0.52m of mixed-grade fly ash from Baotou Donghua Thermal Power Plant 3 , coal gangue (clay ratio 5%) of coal washing plant in Shiguai mining area 0.05m 3 , the sludge of Baotou Donghe Water Purification Plant (45% after dehydration) 0.495m 3 , using the same dynamic sintering process as in Example 1 to prepare ceramsite with a particle size of 5-10 mm, the pH of the prepared ceramsite is 6.9, the bulk density is 1.0g / cm3, the total porosity is 82%, and the cylinder compressive strength is 5MPa.

Embodiment 3

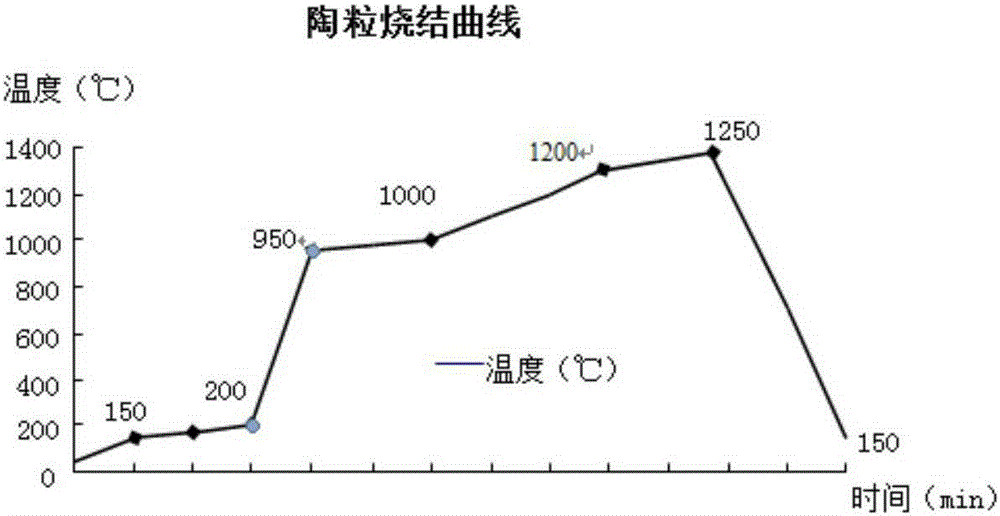

[0035] Take fly ash about 1m 3 (According to bulk density 850~1000kg / m 3 ), coal gangue powder is 0.05m 3 , first crush it to a powder with a particle size of 60-80um and keep it dry, then add 2-4% aluminum powder (such as crushed with aluminum scraps and ground into a particle size of 60-80 mesh sieve) as Foaming agent. Use dry powder stirring to stir the raw material powder evenly, biaxially stir to nucleate, and use a high-speed ball forming machine to generate wet material balls with a gradation of 2 to 5 mm. After being screened and transported to the rotary kiln drying preheating furnace (200-500°C) for drying and preheating, it is roasted in a two-section heating roasting furnace (500-1250°C). After constant temperature, it is finally pushed into the cooling furnace for slow cooling. During the sintering process, it rotates at a constant speed. During the process of rotary throwing, various gases accelerate volatilization and cause the volume of ceramsite to expand. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Cylinder compressive strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com