Environmentally-friendly casting mold-releasing agent and preparation method thereof

A release agent, an environmentally friendly technology, applied to casting molding equipment, casting molds, cores, etc., can solve the problems of large environmental pollution, poor oxidation stability, easy wax formation at low temperature, etc., to achieve pollution reduction, economical use, excellent quality The effect of the release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The preparation of embodiment 1 environment-friendly die-casting release agent

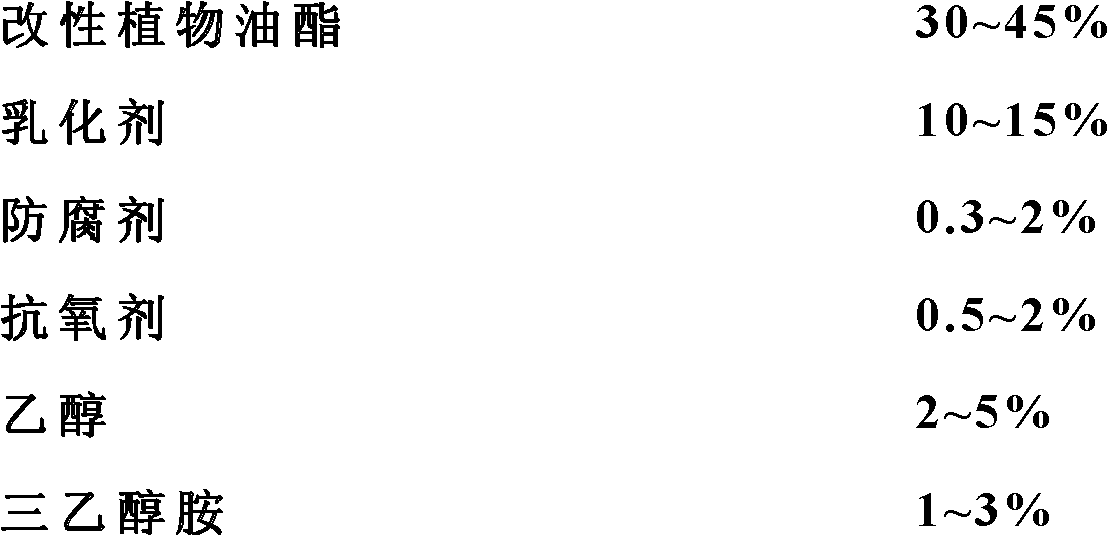

[0046] The raw material formula that present embodiment adopts is:

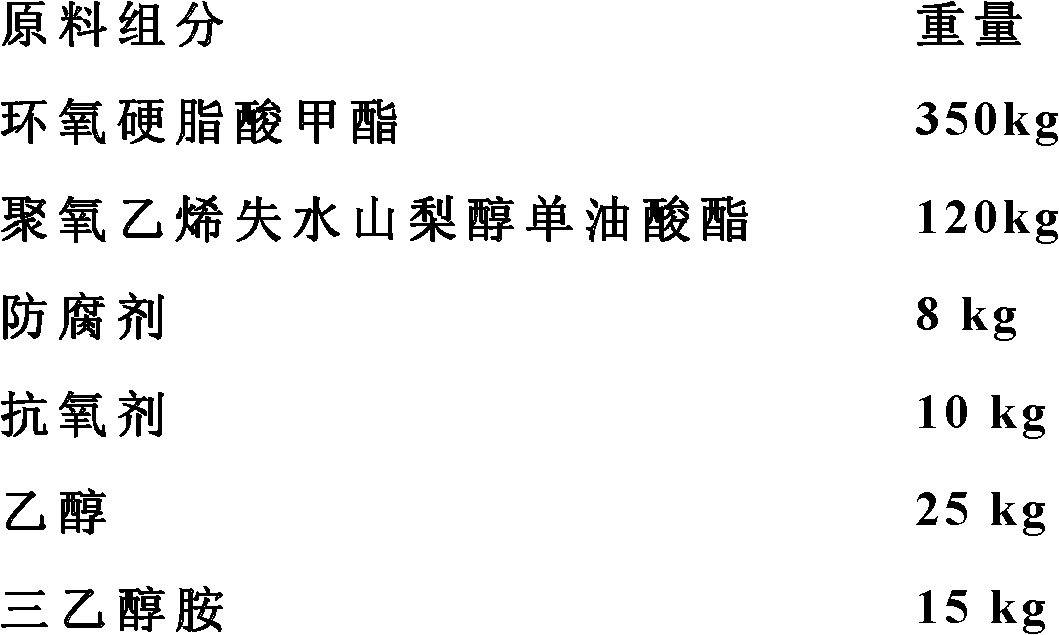

[0047]

[0048]

[0049] Concrete preparation steps:

[0050] (1) Add 350kg of epoxy methyl stearate into the emulsification tank, slowly heat to 70°C, then add 120kg of polyoxyethylene sorbitan monooleate, stir and disperse at 200 rpm for 1 hour.

[0051] (2) Add 79kg of water to the above system first, keep the condition of 70°C unchanged, stir and disperse at the speed of 1000-1500 rpm for 2 hours. Add deionized water slowly, in batches, and in small amounts under stirring. It is required that the added water must be fully miscible with the system before adding water. When the viscosity of the system suddenly becomes significantly smaller, you can add all the remaining deionized water at once, continue stirring for 30 minutes to make A, and cool to 30°C.

[0052](3) While stirring and dispersing, use a small am...

Embodiment 2

[0053] Embodiment 2 Preparation of environment-friendly die-casting release agent

[0054] The raw material formula that present embodiment adopts is:

[0055]

[0056] Concrete preparation steps:

[0057] (1) Add 300kg of epoxy ethyl stearate into the emulsification tank, slowly heat to 70°C, then add 100kg of polyoxyethylene sorbitan monooleate, stir and disperse at 200 rpm for 1 hour.

[0058] (2) Add 90kg of water to the above system first, keep the condition of 70°C unchanged, stir and disperse at the speed of 1000-1500 rpm for 2 hours. Add deionized water slowly, in batches, and in small amounts under stirring. It is required that the added water must be fully miscible with the system before adding water. When the viscosity of the system suddenly becomes significantly smaller, you can add all the remaining deionized water at once, continue stirring for 30 minutes to make A, and cool to 30°C.

[0059] (3) While stirring and dispersing, use a small amount of water to...

Embodiment 3

[0060] Embodiment 3 Preparation of environment-friendly die-casting release agent

[0061] The raw material formula that present embodiment adopts is:

[0062]

[0063] Concrete preparation steps:

[0064] (1) Add 400kg of ethyl formyl stearate into the emulsification tank, slowly heat to 70°C, then add 130kg of polyoxyethylene sorbitan monooleate, stir and disperse at 200 rpm for 1 hour.

[0065] (2) Add 68kg of water to the above system first, keep the condition of 70°C unchanged, stir and disperse at the speed of 1000-1500 rpm for 2 hours. Add deionized water slowly, in batches, and in small amounts under stirring. It is required that the added water must be fully miscible with the system before adding water. When the viscosity of the system suddenly becomes significantly smaller, you can add all the remaining deionized water at once, continue stirring for 30 minutes to make A, and cool to 30°C.

[0066] (3) While stirring and dispersing, use a small amount of water t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com