Biomass-plastic and preparation method thereof

A technology of bio-based plastics and raw materials, applied in the field of bio-based plastics and its preparation, can solve the problems of poisonous and harmful, unsuitable for daily consumables and agricultural film, etc., achieve good performance, good molding and processing performance, simple and effective method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

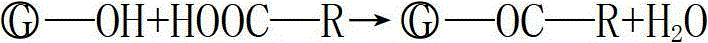

Method used

Image

Examples

Embodiment 1

[0035] The first step, the preparation of natural polymer modified materials:

[0036] First, add 75 parts of wheat starch, 10 parts of linoleic acid, 10 parts of xylitol, 3 parts of polyethylene wax, and 2 parts of antioxidant 1010 into a special high-speed mixer, and stir at 150 ° C for 20 minutes , mix evenly, cool down and discharge.

[0037] Then the above materials are added into a special twin-screw extruder, and reacted and extruded at 80°C to obtain natural polymer modified material pellets.

[0038] The second step, the preparation of the mixed material of natural polymer modified material and PVC:

[0039] Add 50 parts of natural polymer modified material pellets prepared in the first step, 35 parts of PVC, 5 parts of EAA, 5 parts of epoxy soybean oil, and 5 parts of calcium stearate into a special high-speed mixer , stirred at 150°C for 20 minutes, mixed evenly, cooled and discharged.

[0040] Then, the above materials are added into a special twin-screw extrude...

Embodiment 2-4

[0042] The step of embodiment 2-4 is the same as embodiment 1, and difference is that raw material ratio, processing condition are different, as shown in table 1 below:

[0043]

[0044]

[0045] The performance of the mixed material of embodiment 2-4 gained natural macromolecule modified material and PVC, sees the following table 2:

[0046]

Embodiment 5-7

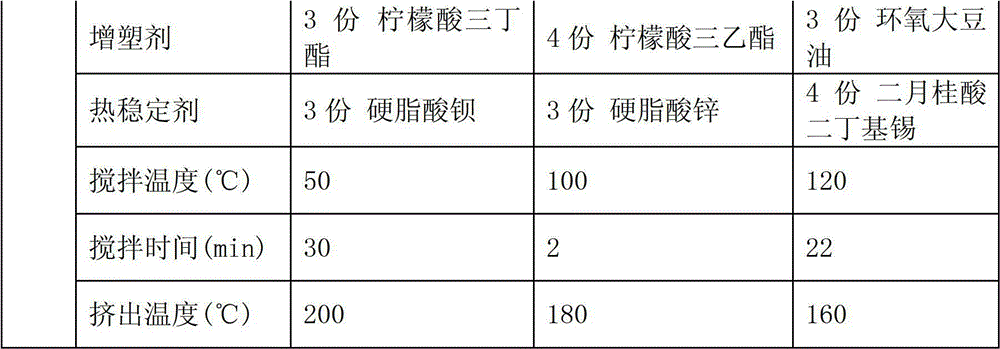

[0048] The step of embodiment 5-7 is the same as embodiment 1, and difference is that raw material ratio, processing condition are different, as shown in following table 3:

[0049]

[0050]

[0051] The performance of the mixed material of embodiment 5-7 gained natural macromolecule modified material and PVC, sees the following table 4:

[0052]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com