Patents

Literature

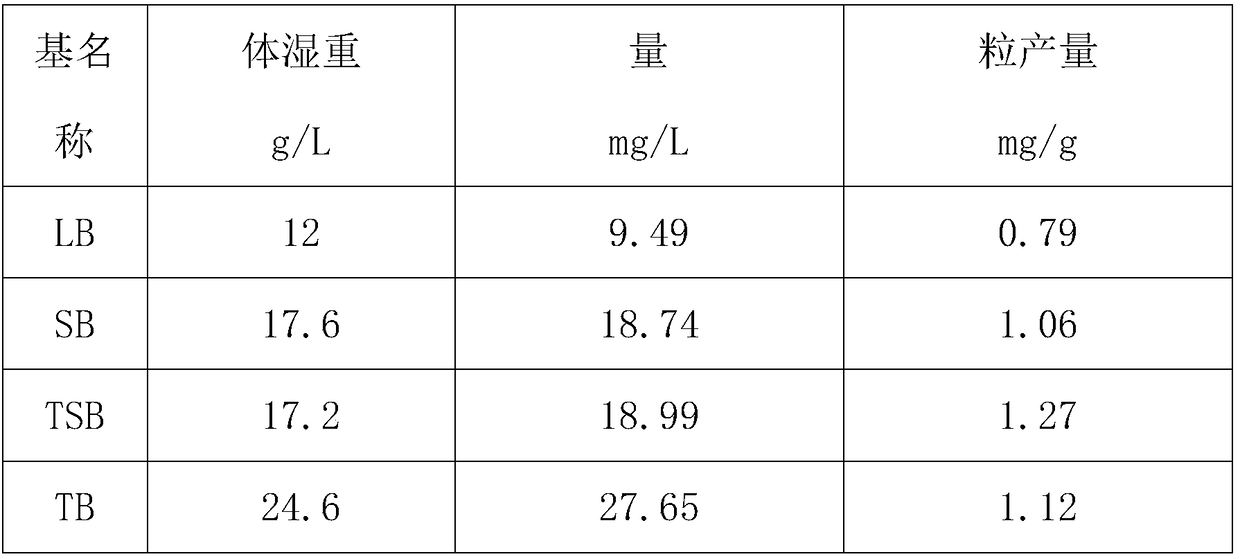

73 results about "Split product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Product Split. Use. This function allows you to replace a product with one or more products when it is released. This means that you can plan one product or product group in Demand Planning and use another product or products for further processing in SNP and PP/DS. There are several possible uses for this function, for example:

Method for preparing aromatic compounds employing catalytic cracking of industrial lignins

InactiveCN103508858AHigh selectivityImprove conversion rateOrganic compound preparationEther preparationSulfonateGuaiacol

The invention relates to a method for preparing aromatic compounds employing direct catalytic cracking of industrial lignins under a catalytic system with reducing capacity. The method comprises the following steps: selectively cracking industrial lignins such as sodium lignin sulfonate, alkali lignin, dealkalized lignin and the like as raw materials under combined action of a catalyst and a solvent with reducing capacity to obtain derived C6-C9 phenolic, guaiacol or syringyl aromatic compounds and the like by the effect of in-situ reduction of a poisoned catalyst, wherein the conversion rate of the raw materials can be over 50%; the content of guaiacol and syringyl aromatic compounds in a split product can be over 70%. By adopting the method related to the invention, the problem that the catalyst is poisoned by reaction materials is overcome, so that the catalytic process can be smoothly carried out; the method has the characteristics of low price and high conversion efficiency of raw materials, high yield of the aromatic compounds and mild reaction condition.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

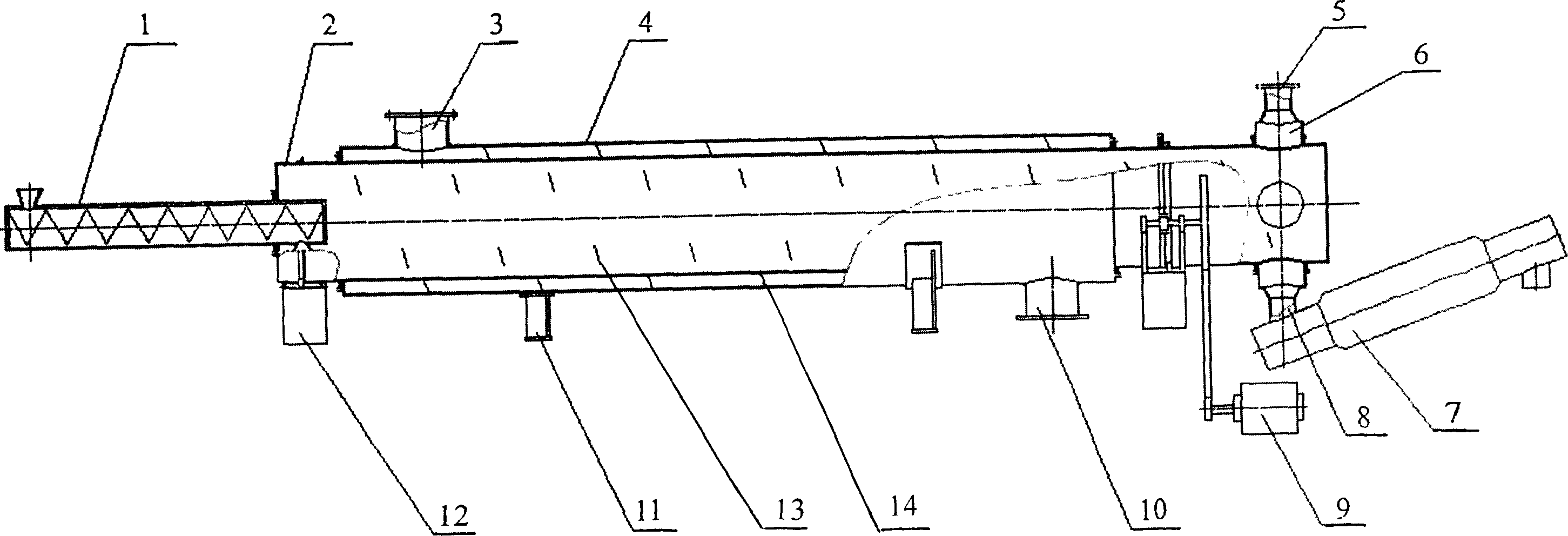

Horizontal type slew cylinder structure cracking furnace for waste steel wire blank continuous thermal cracking

InactiveCN1952045AAchieve self-sufficiencyThe cleavage reaction is fast and sufficientPigmenting treatmentLiquid hydrocarbon mixture productionEngineeringFlue

The invention disclosed a lying posture turnover cylinder cracking furnace which is used in the successive thermal cracking of a waste steel-wire tyre material. There's a below stack gas inlet and a top stack gas outlets on the outside tube of the cylinder; inside being positioned inner turning-over tube drived by transmission system; one side of the inner tube connects the tyre spiral feeder which can change the pitch, and the other side connects the static split product gathering trunk; on the top of the gathering trunk is the outlet of the gas hydrocracking product, while below the gathering trunk is outlet of the solid hydrocracking product, the gathering trunk also connects the spiral discharging device. The waste tyre material which is transferred by the spiral feeder is repeatedly grabbed by the grabbing plank located on the inner wall and pushed to the outlet. The high temperature stack gas counterflows in the passage between the outside and the inside tubes, during the process of the material's axial direction translation and circular direction rotation, the material absorbs the conducted calory from the tube wall to finish the splitting process. The gas product is pulped away by the blower while the solid product is discharged by the spiral discharging device through the bottom canal orifice.

Owner:ZHEJIANG UNIV

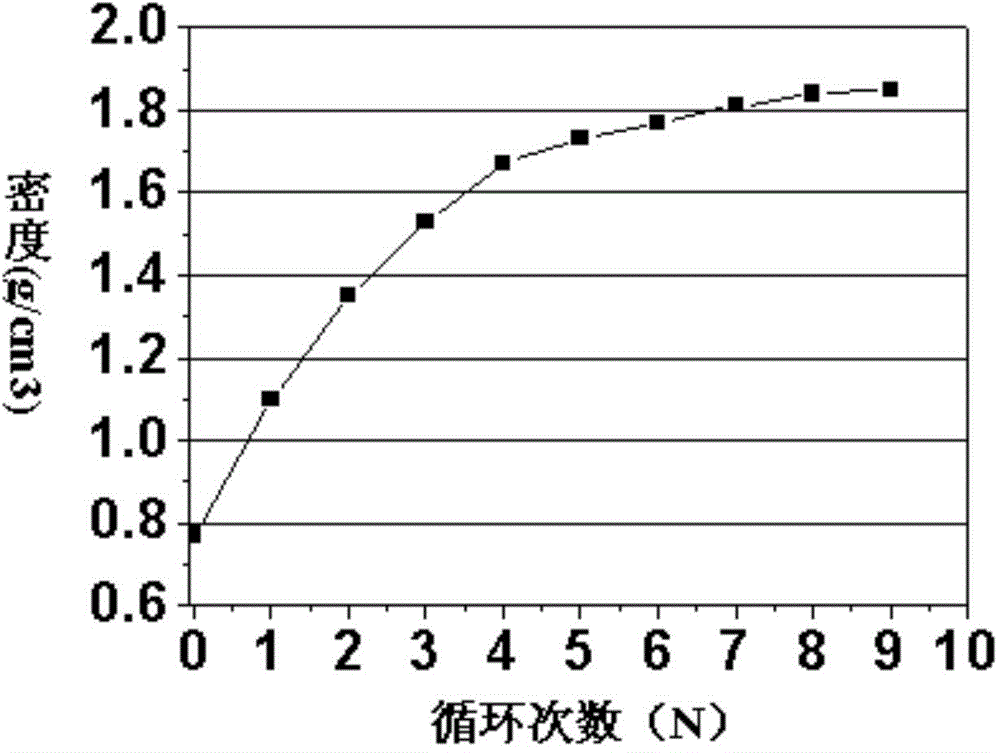

Preparation method for coal-based activated carbon for recovery of organic solvent

The invention relates to a preparation method for coal-based activated carbon for recovery of an organic solvent. The preparation method is characterized in that kneading, forming, carbonization,pre-activation and activation are performed on pulverized coal, coal tar, water and catalyst to obtain columnar activated carbon, wherein the adding amounts of the coal tar, the water and the catalyst are respectively 35-40 percent, 2-4 percent and 2-3 percent of the weight of the pulverized coal, and the catalyst is the hydroxide aqueous solution with the mass concentration of 13-17 percent. According to the invention, the hydroxide catalyst is added into the kneading process to achieve the purposes of splitting functional groups, expanding activated carbon pores, improving the absorption performance and neutralizing inorganic acidic compounds in the pulverized coal; then activation is performed twice to completely remove tar substances and split products accumulated in the pore structure in the carbonization process, some closed pores are opened, and under the action of the catalyst, the functional groups are further decomposed, pores are formed, and pore volume and specific surface area of the activated carbon are improved. According to the activated carbon prepared with the method, the adsorption rate of carbon tetrachloride is not less than 80 percent, the adsorption rate of iodine is not less than 1,050 mg / g, the bulk density is 400-450 g / l, and the mechanical strength is not less than 91 percent.

Owner:NINGXIA BAOTA PETROCHEM SCI & TECH IND DEV

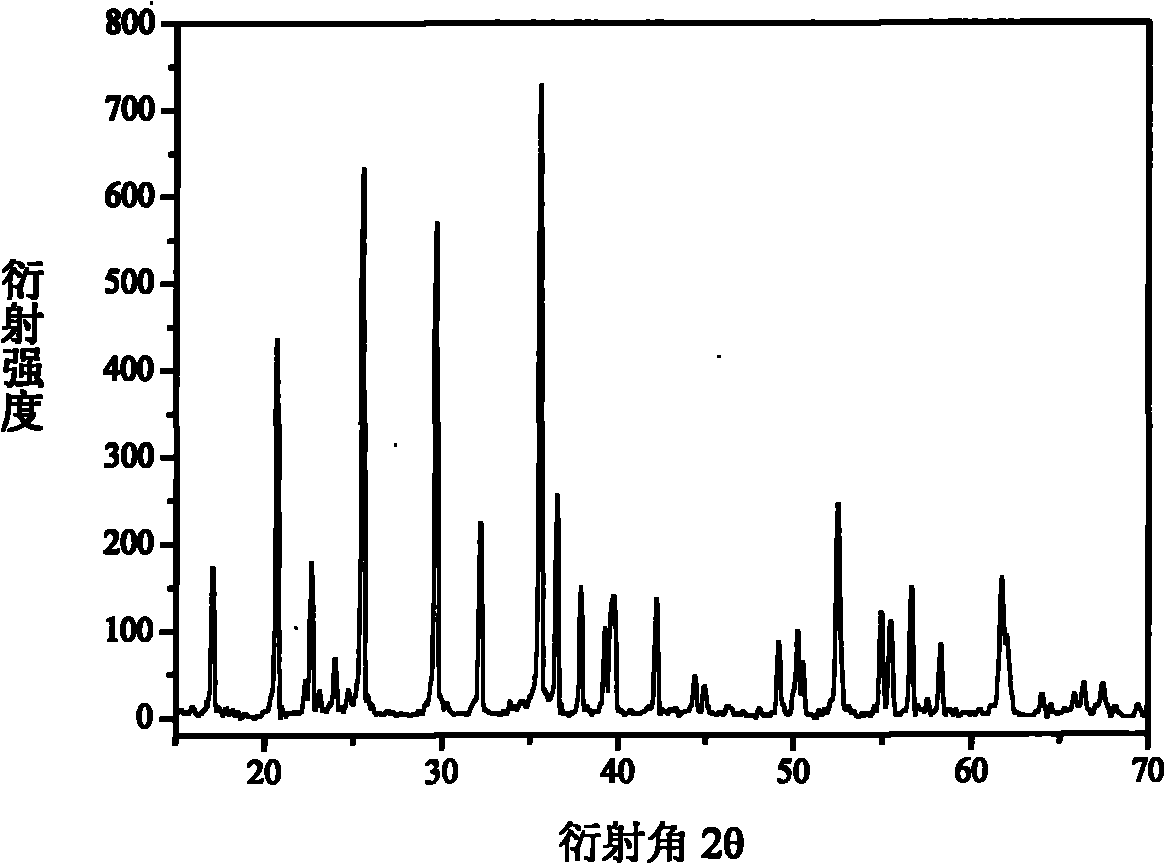

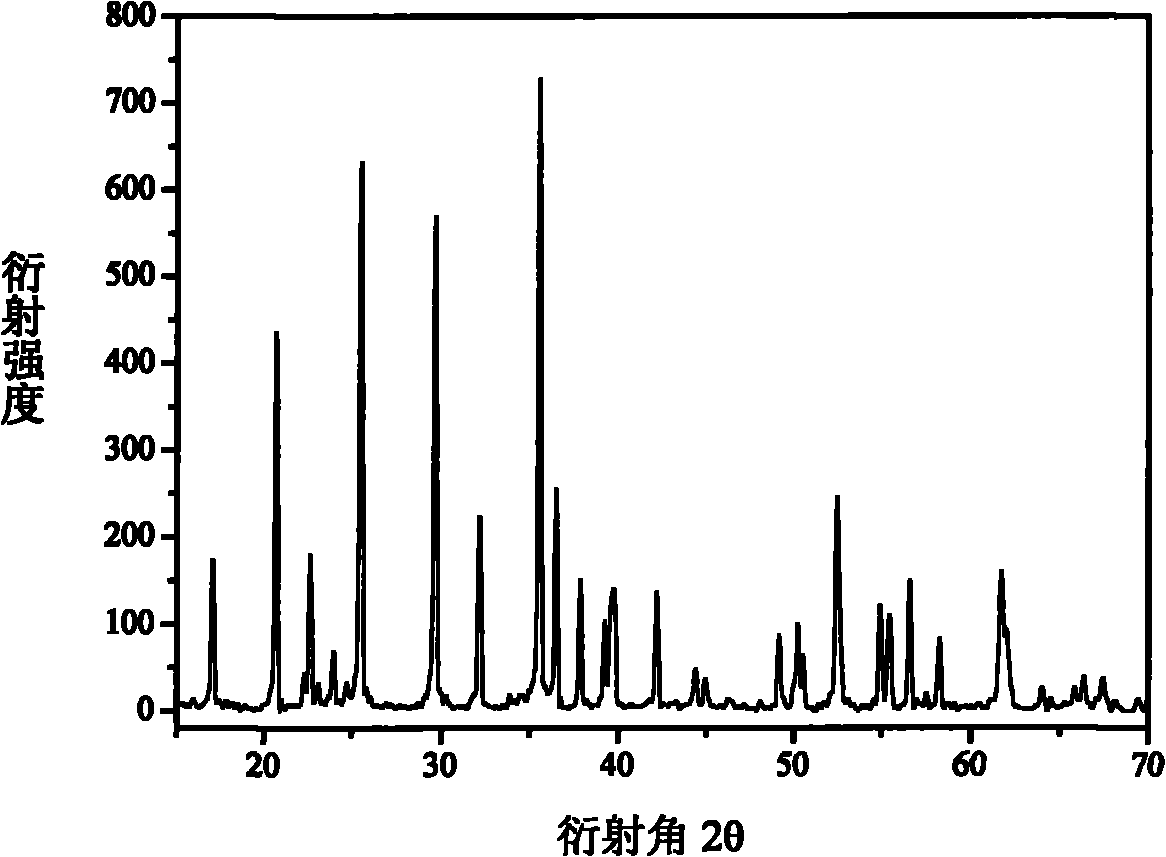

New method for preparing LixFeyPzO4 by using ferro phosphorus

The invention relates to a new method for preparing LixFeyPzO4 (particularly LiFePO4, LiFe2 / 3PO4 and Li4 / 7Fe4 / 7P8 / 7O4) by using ferro phosphorus, which comprises the following steps of: supplying an oxygen source for oxidizing P in the ferro phosphorus by only utilizing the oxygen in raw materials, proportioning in the mol ratio of the total phosphorus element to the total oxygen element of 1.0:(1.5-9.0), mixing the raw materials and then carrying out one-step reaction in a closed system at the temperature of 500-900 DEG C to obtain a product. The oxidation-reduction reacted material balance of the raw materials per se is realized in the closed system, without external oxygen sources, thereby solving a series of technical difficult problems caused by difficult oxygen quantity accurate control and oxygen introduction and eliminating the pollution of a large amount of waste gas during roasting by adopting an inert atmosphere or a carbide split product reducing atmosphere; the reaction is finished in the closed system, and the complete reaction is promoted by utilizing the pressure of the reaction per se, thereby reducing the volatilization of substances, such as lithium and the like in the raw materials, at high temperature and causing the product to be looser; and the method has no pollutant discharge in the preparation process, cleanness, environmental protection, short reaction flow, simple process, easy reaction operation, low requirement for equipment, low cost, less investment and good benefit and is easy to realize industrialization and suitable for producing high-performance LixFeyPzO4 by using the ferro phosphorus with low cost.

Owner:SICHUAN UNIV

Ablation-resistant fire-retardant sealing adhesive and preparation method thereof

ActiveCN104232010AImprove sealingImprove adhesionNon-macromolecular adhesive additivesOther chemical processesSelf-healingAdhesive

The invention discloses an ablation-resistant fire-retardant sealing adhesive and a preparation method thereof. The ablation-resistant fire-retardant sealing adhesive comprises the following component in parts by weight: 35-60 parts of siloxane polymers, 20-40 parts of silicate mineral fillers, 1-2 parts of platinum complex catalysts, 2-5 parts of thickening agents, 1-5 parts of thixotropic agents, 5-20 parts of high-melting point metal compounds, 0.1-0.5 part of silane coupling agents and 5-10 parts of high-temperature-resistant whisker reinforcing materials. The ablation-resistant fire-retardant sealing adhesive disclosed by the invention has good sealability and adhesion at normal temperature, and has the advantage that a high-temperature split product can be subjected to ceramic reaction with an inorganic filler to form a ceramic sealing layer with adhesion and self healing properties, thus ensuring that the materials have good sealing and adhesion effect under the condition of high temperature. The ablation-resistant fire-retardant sealing adhesive disclosed by the invention is mainly applied to the fields of sealing, plugging and adhesion of a special position under the condition of high temperature.

Owner:WUHAN UNIV OF TECH

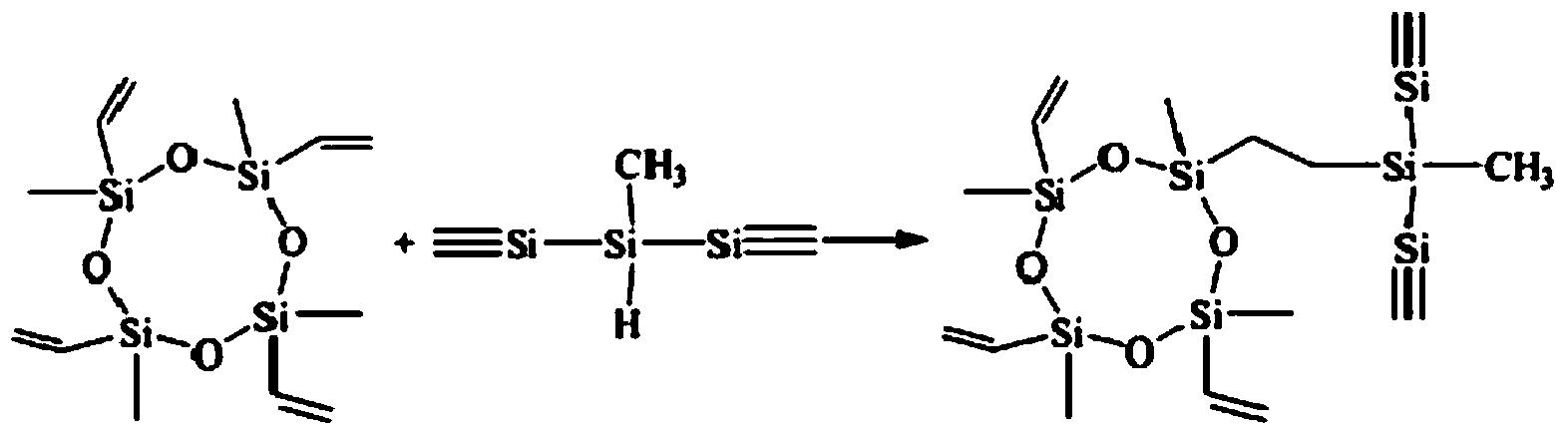

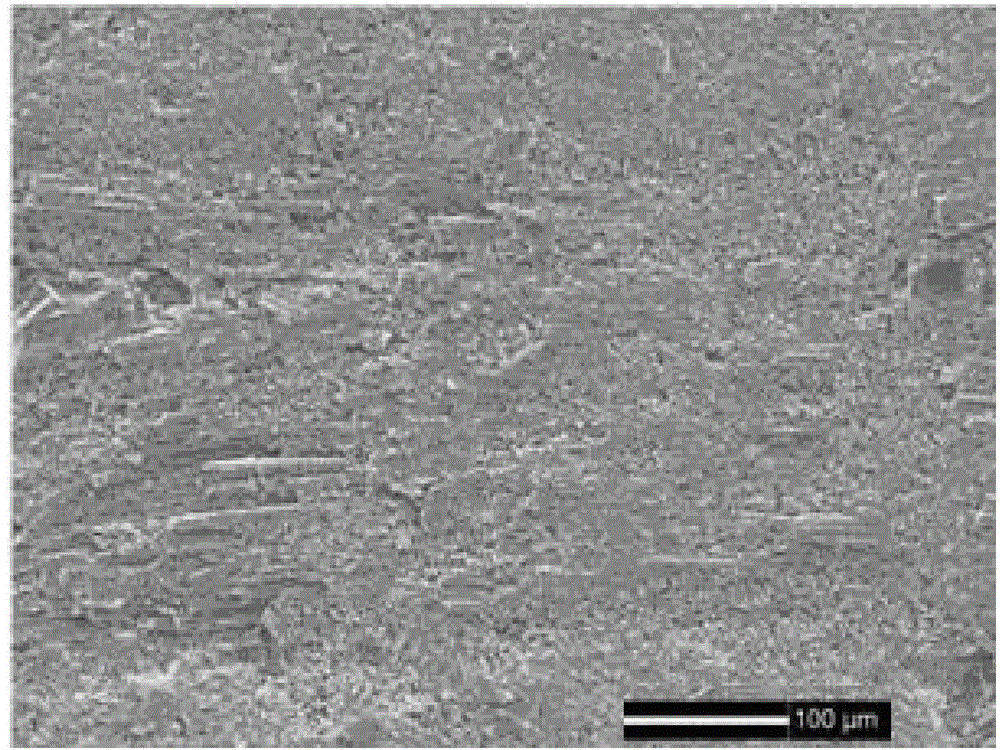

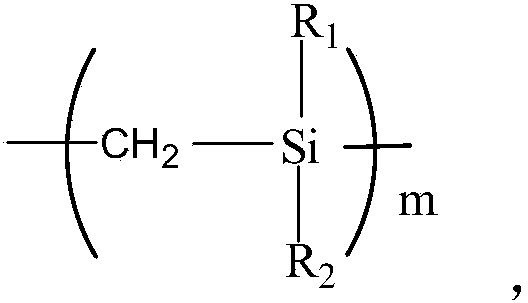

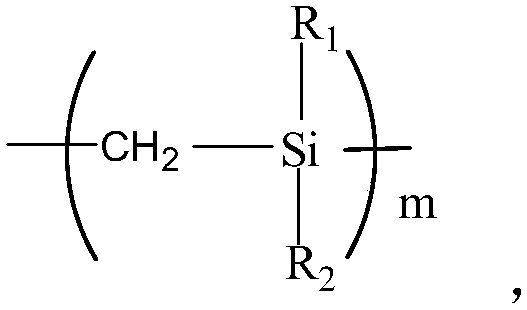

Ceramic matrix composite material employing silicon alkyne-modified SiBCN as precursor and preparation method of ceramic matrix composite material

The invention relates to a ceramic matrix composite material employing silicon alkyne-modified SiBCN as a precursor and a preparation method of the ceramic matrix composite material, and belongs to the technical field of ceramic materials. Polysilylacetylene is introduced into an SiBCN precursor in a molecular level to prepare a silicon alkyne-modified SiBCN precursor, so that the compactness of the composite material ceramic matrix can be effectively improved; the ceramic yield is increased; and meanwhile, a split product can have excellent high-temperature oxidation resistance. The silicon alkyne-modified SiBCN precursor is adopted as impregnation matrix; a carbon fiber is taken as a reinforcement body; and the novel SiBCN ceramic matrix composite material is prepared by an infiltration pyrolysis method. The composite material has good mechanical property and excellent oxidation resistance.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

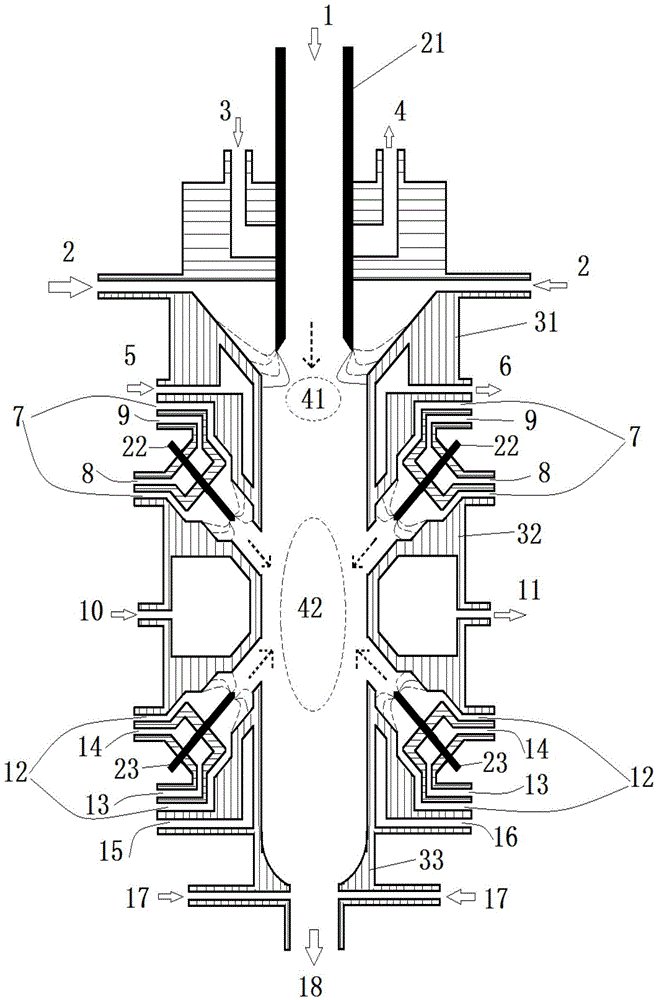

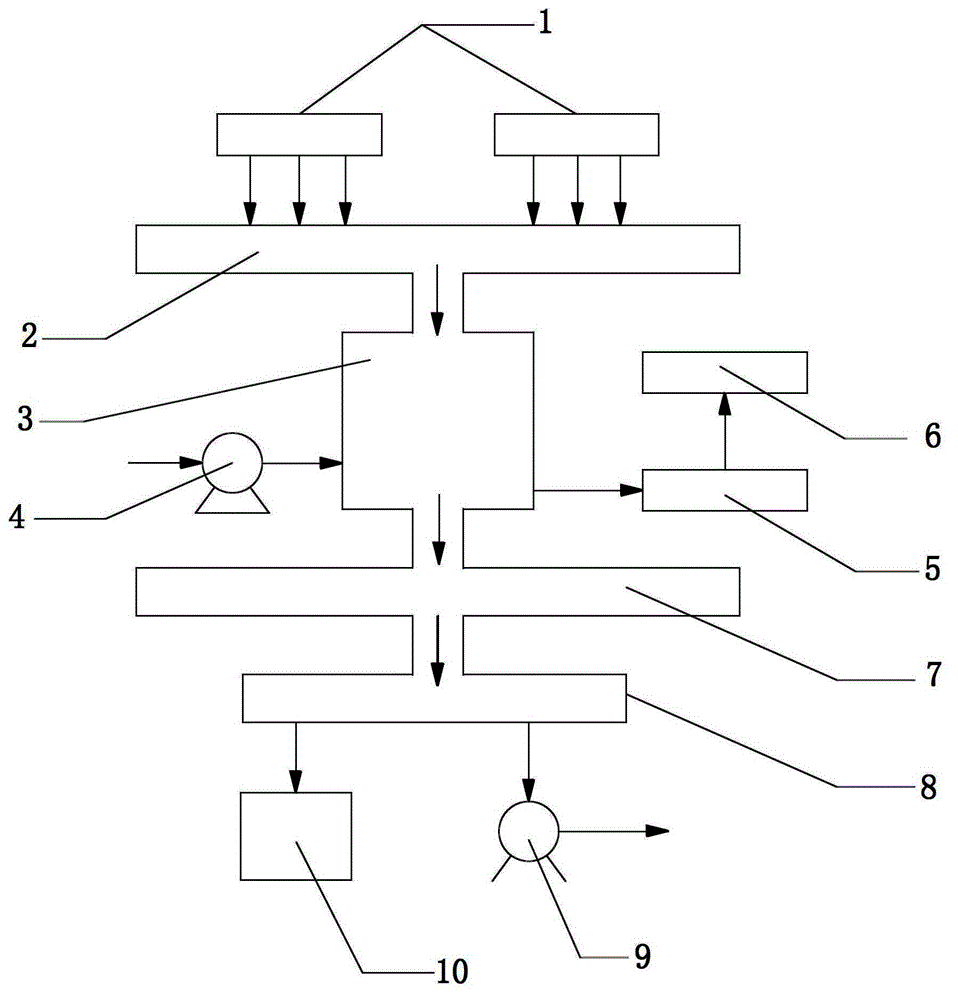

Multi-section plasma cracking carbonaceous material reactor system

The invention discloses a multi-section plasma cracking carbonaceous material reactor system which includes a preheating section, at least one hybrid reaction section, at least one chilling medium inlet and at least one chilling product outlet, wherein the preheating section includes a hollow cathode and an anode; carbonaceous material enters a reaction tube of the preheating section through a hollow passage of the hollow cathode; the at least one hybrid reaction section includes a plurality of cathode bars and anodes corresponding to the cathode bars; a plasma and or / arc forming region formed between the hollow cathode and the anode is positioned inside the reaction tube, and a plasma and or / arc forming region formed among the cathode bars and the anodes is positioned outside the reaction tube; a plurality of streams of plasma gas collides at the center of or near to the reaction tube of the preheating section, and is in convection contact with and intensely mixed with carbonaceous material and carrier gas, so that preheated carbonaceous material is heated, carbonaceous material is subjected to pyrolysis and cracking, and then carbonaceous material subjected to pyrolysis and cracking is subjected to volatile matter gas-phase reaction. The reactor system provided by the invention is excellent in carbon deposition prevention and thermal efficiency and higher in split product productivity.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

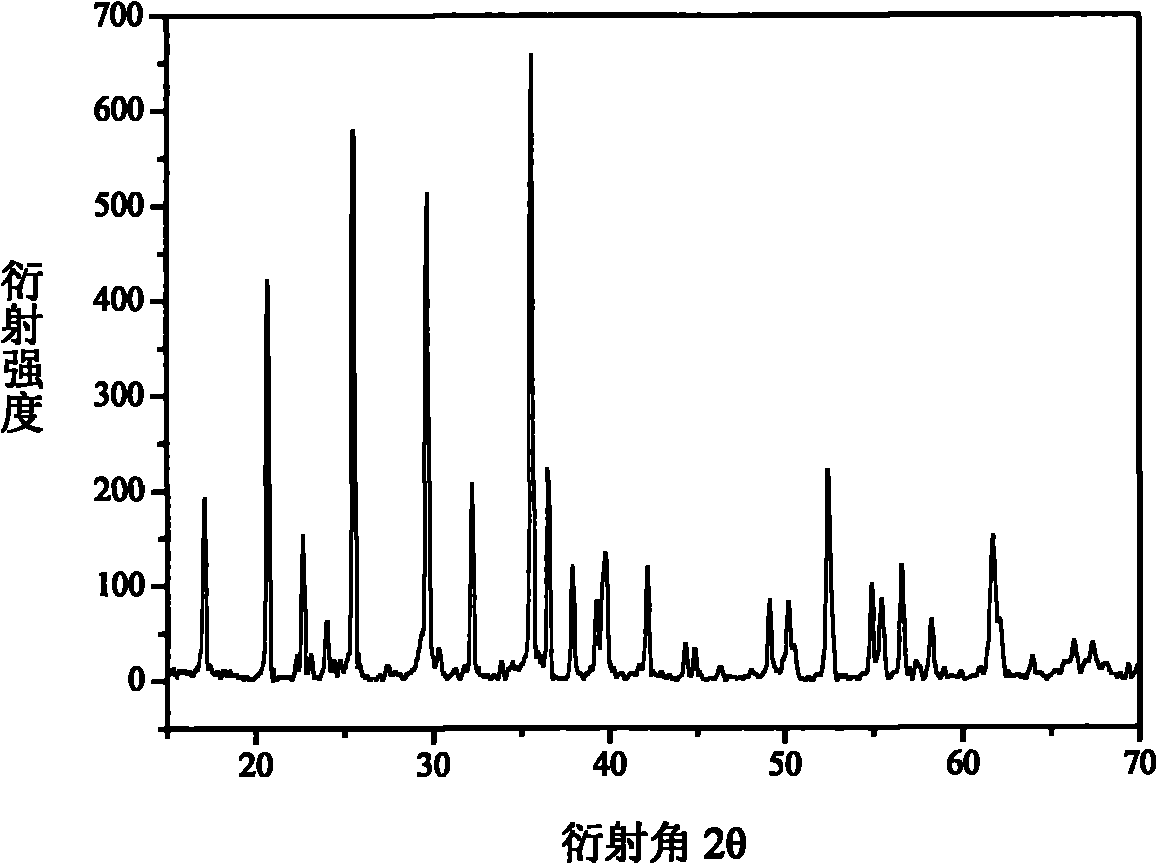

Lithium iron phosphate/carbon composite electrode material and preparation method thereof

ActiveCN101504981AGood coating effectImprove conductivityElectrode manufacturing processesCarbon compositesPhosphonium

The invention relates to a novel lithium iron phosphate / C composite electrode material and a method for preparing the same, which belong to the technical field of lithium ion secondary batteries. The lithium iron phosphate / C composite electrode material is prepared by using iron phosphate as an iron source and a phosphonium source, using a macromolecular carboxylic acid lithium salt as a lithium source, using a carbon skeleton split product of the macromolecular carboxylic acid lithium salt as a carbon source, and performing solid phase reaction on the mixture of the iron phosphate and the macromolecular carboxylic acid lithium salt at a temperature of between 500 and 900 DEG C, wherein the mol ratio of lithium to iron to phosphate radical is 1-1.5:1:1, and the C content is 1 to 10 percent in percentage by weight. The carbon in-situ doping generated by the thermal decomposition of the macromolecular carboxylic acid lithium salt improves the electrical conductivity of lithium iron phosphate, and simultaneously the high viscosity of the macromolecular carboxylic acid lithium salt and the framework barrier effect of a thermal decomposition product can prevent component segregation, inhibit crystal grain growth, and are advantageous for improving the multiplying factor and the discharge performance of the material. The preparation method is simple and has good reproduction quality, and the lithium iron phosphate / C composite electrode material prepared by the method is black powder and has even granularity and high electrical conductivity.

Owner:CHENGDU ZHONGKE LAIFANG POWER SCI & TECH CO LTD

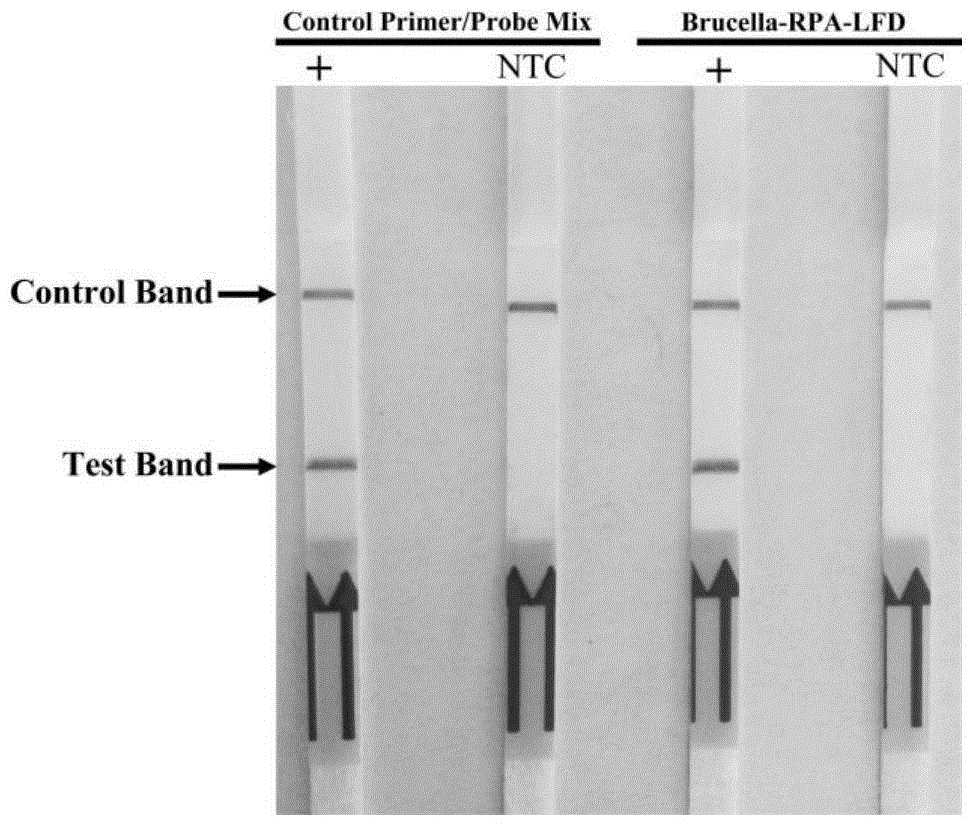

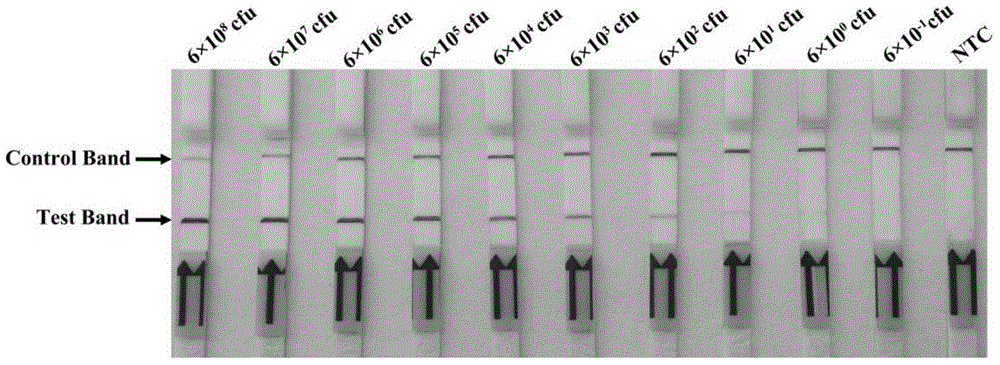

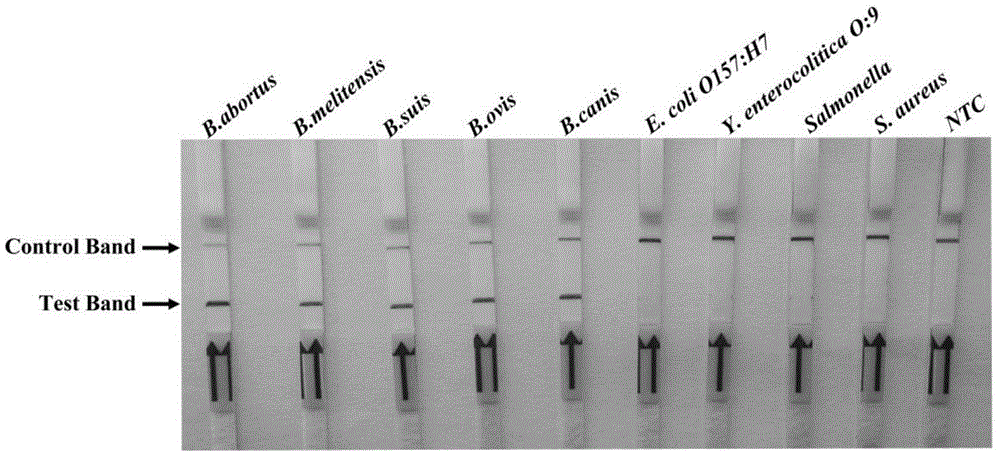

Universal primers and probe for on-site rapid detection of Brucella and kit

ActiveCN104946749AIncreased sensitivityStrong specificityMicrobiological testing/measurementMicroorganism based processesForward primerEscherichia coli

The invention discloses universal primers and a probe for on-site rapid detection of Brucella and a kit. The forward primer sequence is shown as SEQIDNo.1, the reverse primer sequence is shown as SEQIDNo.2, and the probe sequence is shown as SEQIDNo.3. The universal primers, the probe and the kit provided by the invention for detection of Brucella have high sensitivity and strong specificity, minimumly can detect 6.0*10<0>cfu Brucella, and have no cross reaction with Escherichia coli O157:H7, yersinia enterocolitica O:9, Salmonella, Staphylococcus aureus and other bacteria. The universal primers, the probe and the kit provided by the invention not only can be used for detection of Brucella strains, but also can be used for detection of clinical samples, which mainly include blood, milk samples, aerosol samples, and tissue samples, etc. The kit provided by the invention is convenient to use, has no need for special equipment, can carry out sensitive, specific and rapid detection of Brucella on the crude split product of a to-be-detected sample in 25min just at 38DEG C, and is suitable for field or grassroots brucellosis quarantine work.

Owner:DAIRY CATTLE RES CENT SHANDONG ACADEMY OF AGRI SCI

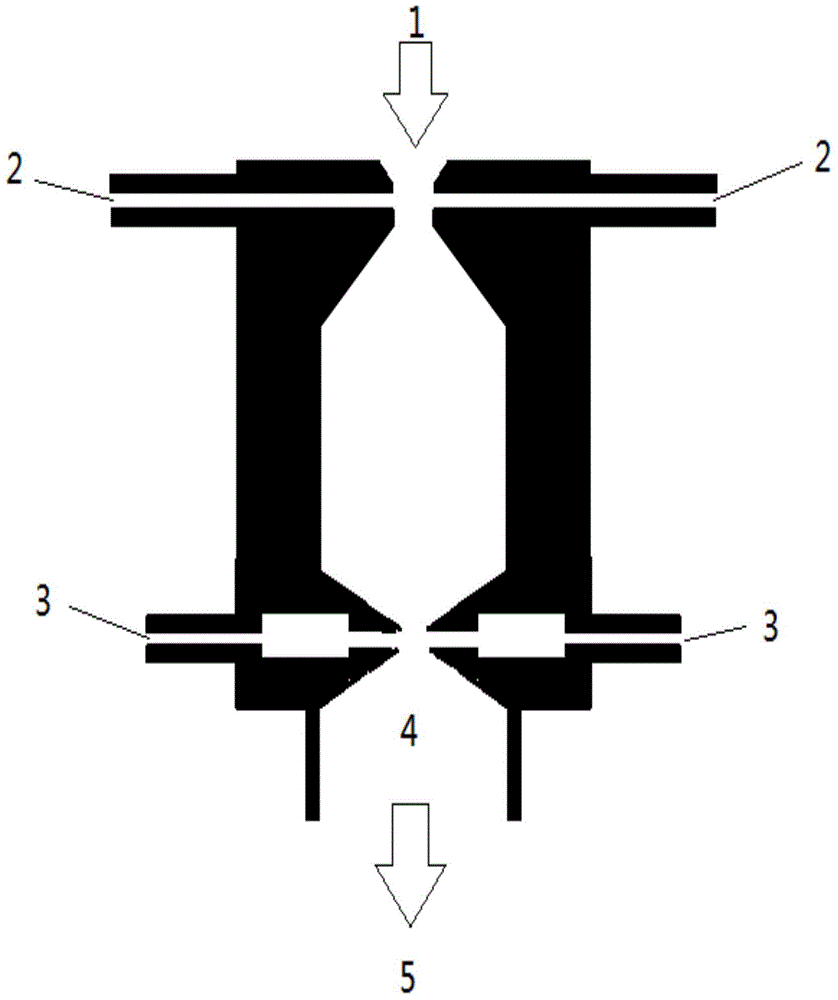

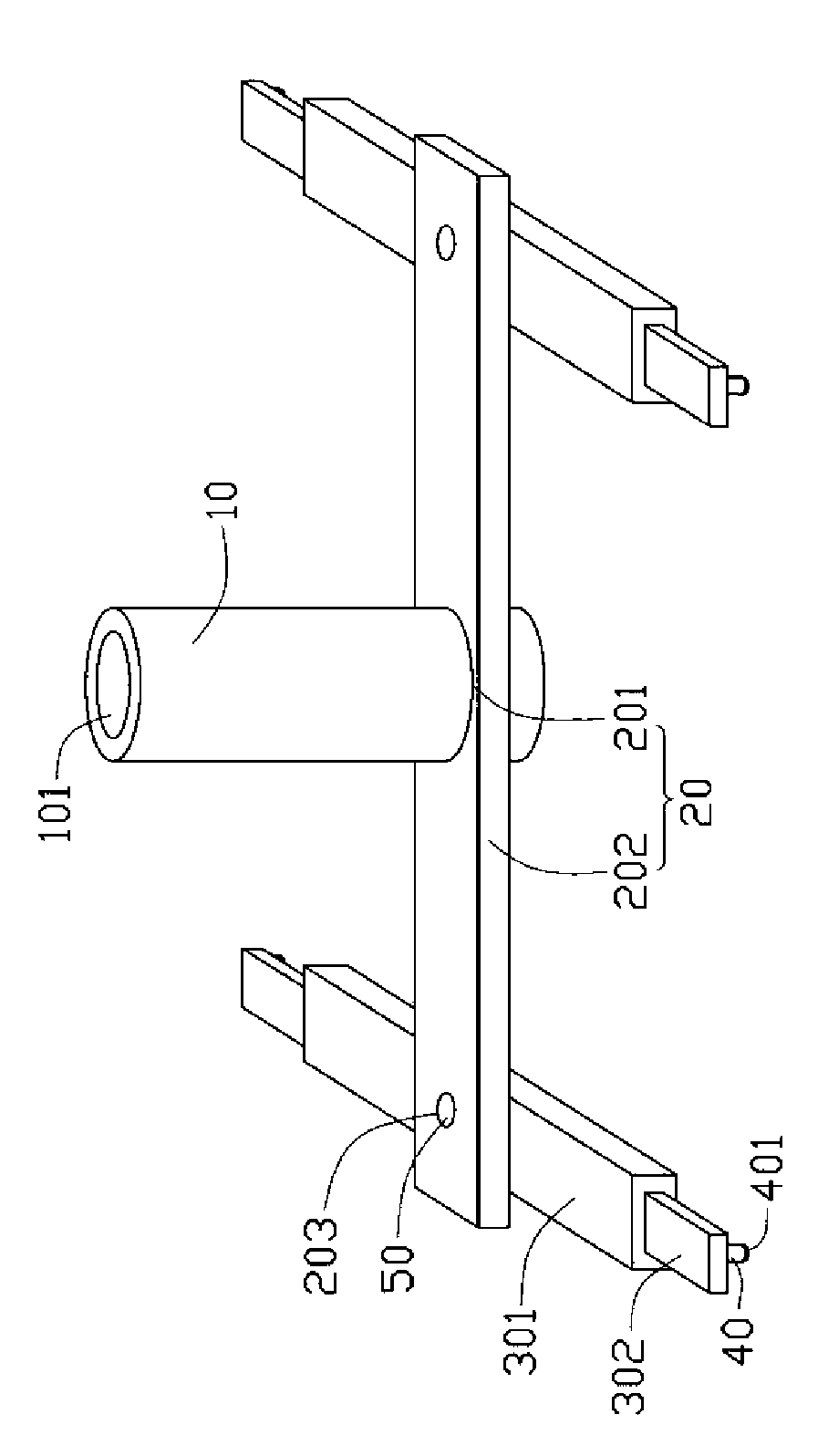

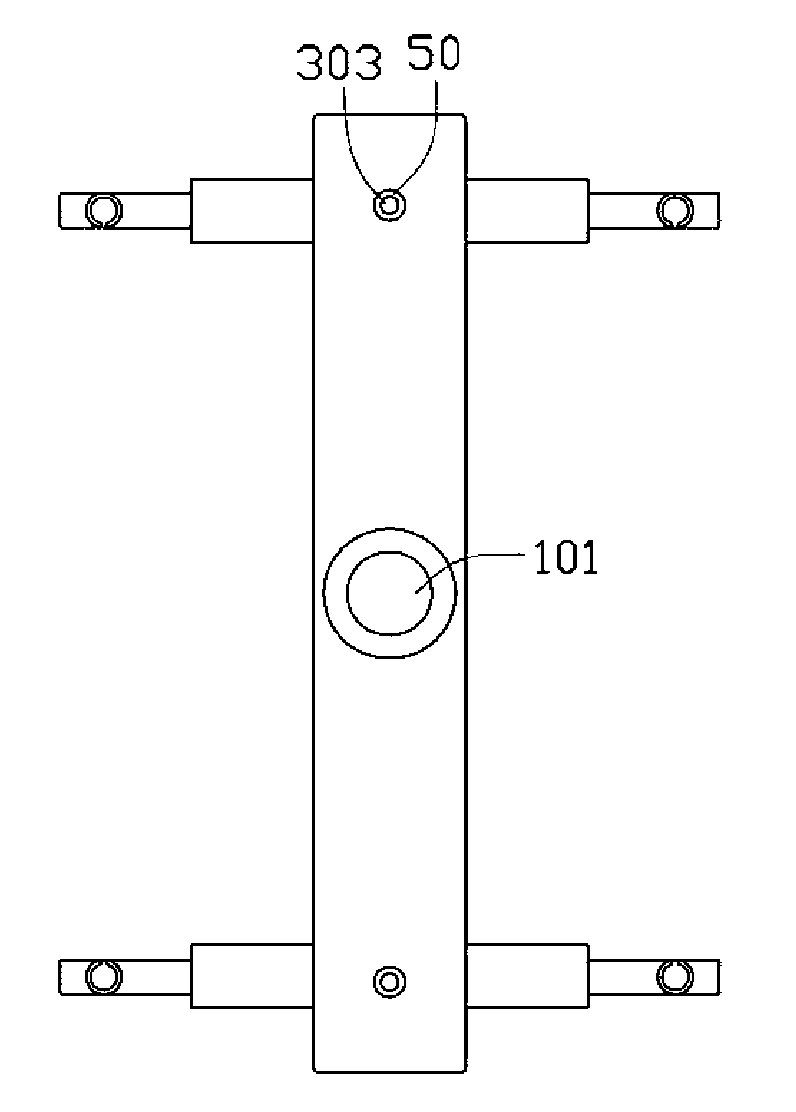

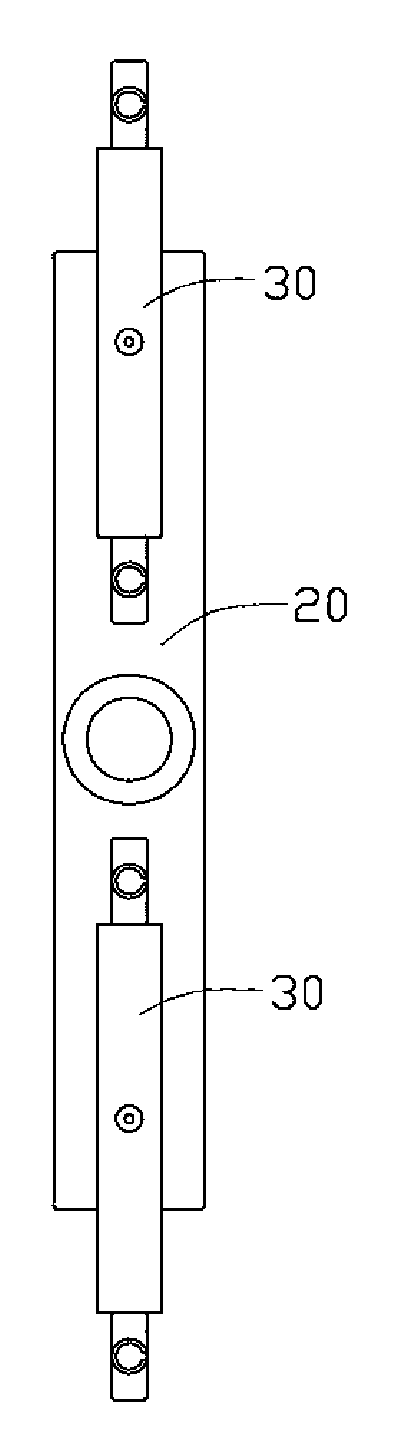

Cavity splitting device for injection forming mould

The invention relates to a cavity splitting device for an injection forming mould, which comprises a vertical rod, a cross rod of which the middle part is vertically fixed on the vertical rod, two telescopic rods which are respectively and rotatably arranged at two ends of the cross rod, and a plurality of adsorption devices which are positioned at the end part of the telescopic rod. The cavity splitting device for the injection forming mould adopts the structures with the vertical rod, the cross rod and the telescopic rod to adapt to moulds with different mould cavities; and meanwhile, the adsorption devices can split cavities and respectively split products in the mould cavities to corresponding product baskets, thereby omitting the procedures of distinguishing the products in the mouldcavities by artificial visual inspection, easily knowing the products in which mould cavities have flaws, correcting corresponding mould cavities, saving cavity splitting time, and improving the production efficiency. The cavity splitting device can save the time for splitting the cavities and labor force cost, and improve the production efficiency.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

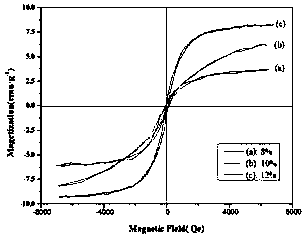

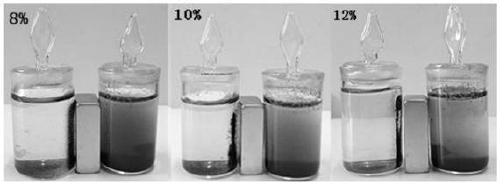

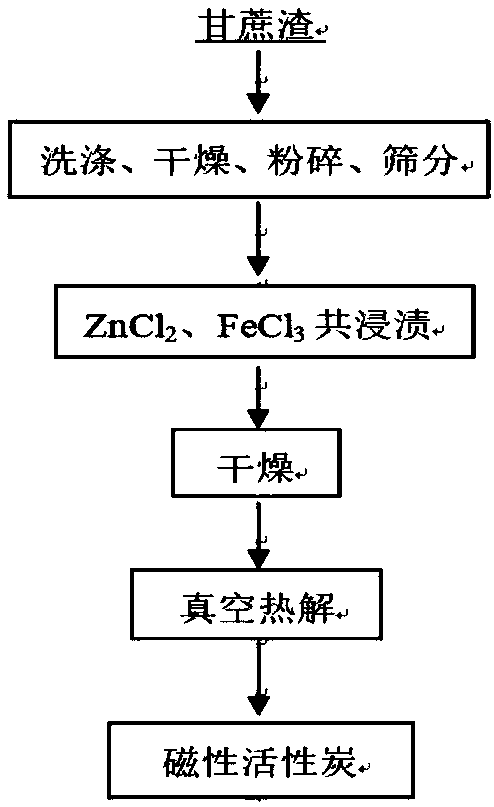

Simple and convenient method of preparing magnetic bagasse based active carbon by one step

InactiveCN109336110AProtect the pore structureImprove adsorption capacityCarbon compoundsMagnetizationSystem pressure

The invention discloses a simple and convenient method of preparing magnetic bagasse based active carbon by one step. The method comprises the steps of taking bagasse in loose texture as a raw material, directly dipping an activator zinc chloride and a magnetic additive ferric chloride into the raw material in an ion form, and regulating the quantity of the magnetic additive, a carbonization temperature and system pressure to prepare the magnetic active carbon. According to the method, a magnetic precursor is introduced into the biological raw material in an ion form; activation, carbonizationand magnetization are performed synchronously; the magnetic active carbon is prepared by one step; a technical flow is simple; the production cost is low; all split products are effectively collectedin a vacuum environment; the environmental pollution is low; the obtained product is large in specific surface area and excellent in absorbability; a magnetic compound is formed in the raw material and securely combined with the raw material; and a magnetic property of the product is stable.

Owner:CENT SOUTH UNIV

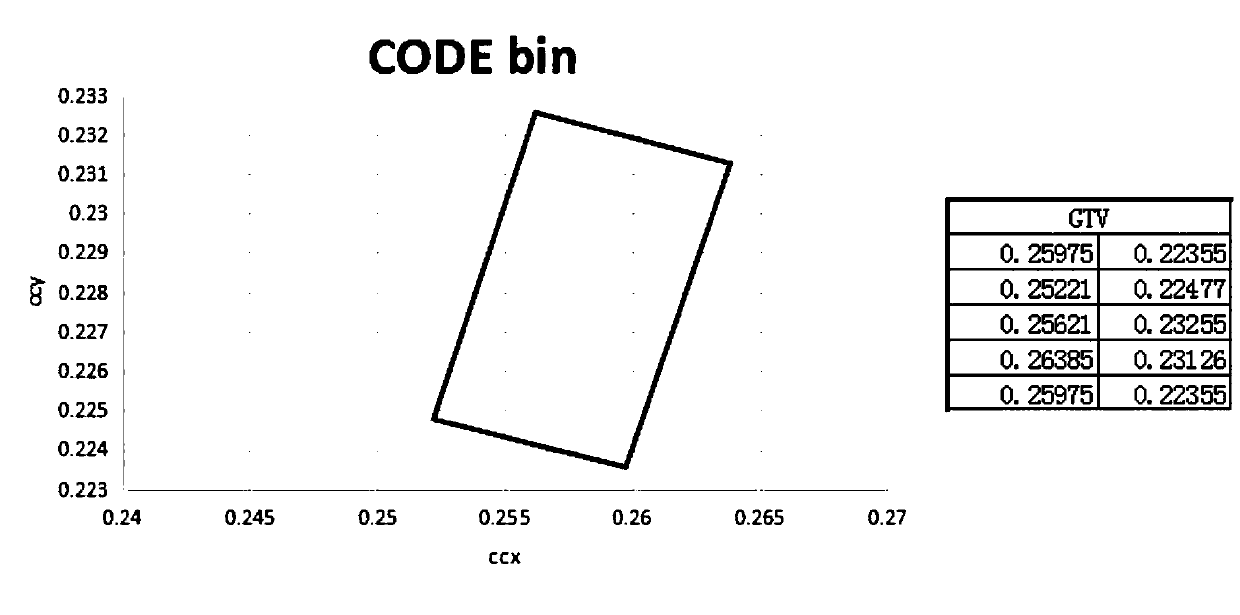

High-color gamut LED backlight source and processing method thereof

The present invention relates to a high-color gamut LED backlight source and a processing method thereof. The processing method comprises a step 1 of fixing a UV LED wafer and a plurality of blue light LED wafers on an SMC support via a die bonder for die bonding; a step 2 of adopting a gold wire bonding technology to connect the four LED wafers in series and then connect the positive and negativeelectrodes of the SMC support via a wire bounder; a step 3 of preparing a fluorescent glue solution, wherein the fluorescent glue solution is a mixture of the glue, the yellow green powder of which the emission wavelength is 537 nm and the KSF red powder; a step 4 of pouring the prepared fluorescent glue solution into a glue barrel of a glue dispenser, extruding the glue and the bubbles, and thendispensing according to the GTV color gamut requirements; a step 5 of carrying out the threshing processing on the dispensed and baked LED product and then using a splitting testing machine to splitaccording to the given GTV color gamut requirements, so that the split product satisfies the conditions that the NTSC color gamut is greater than 90%, a spectrum generates a peak wave at the 380-410 nm and has a plurality of peak waves at the 600-700 nm, and the color rendition degree of the LED backlight source is improved.

Owner:JIANGSU WENRUN OPTOELECTRONICS

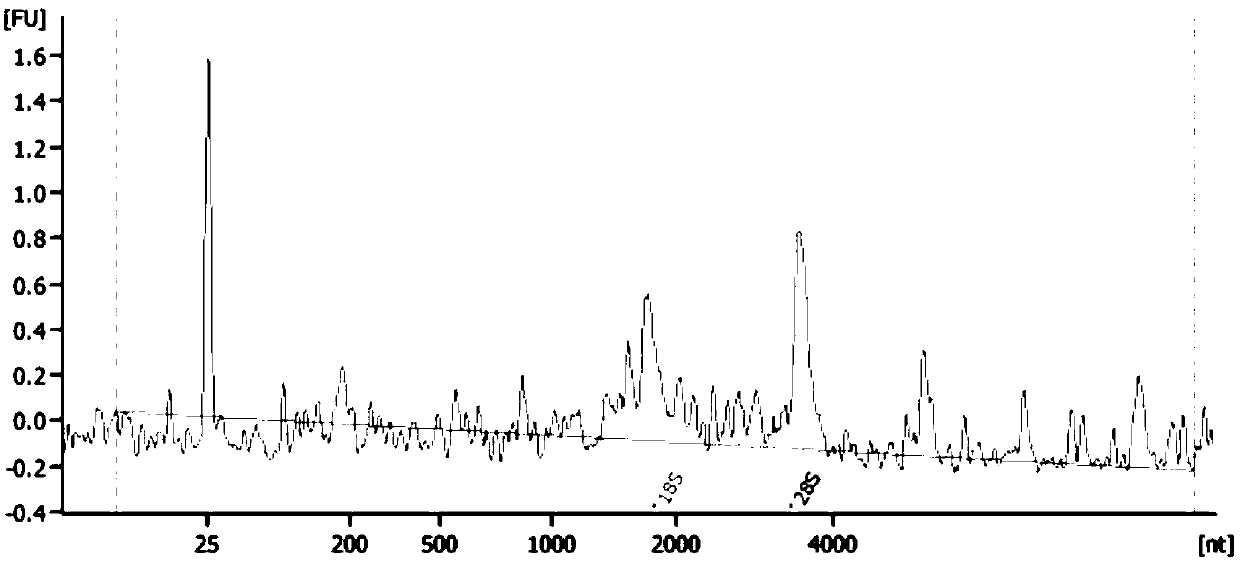

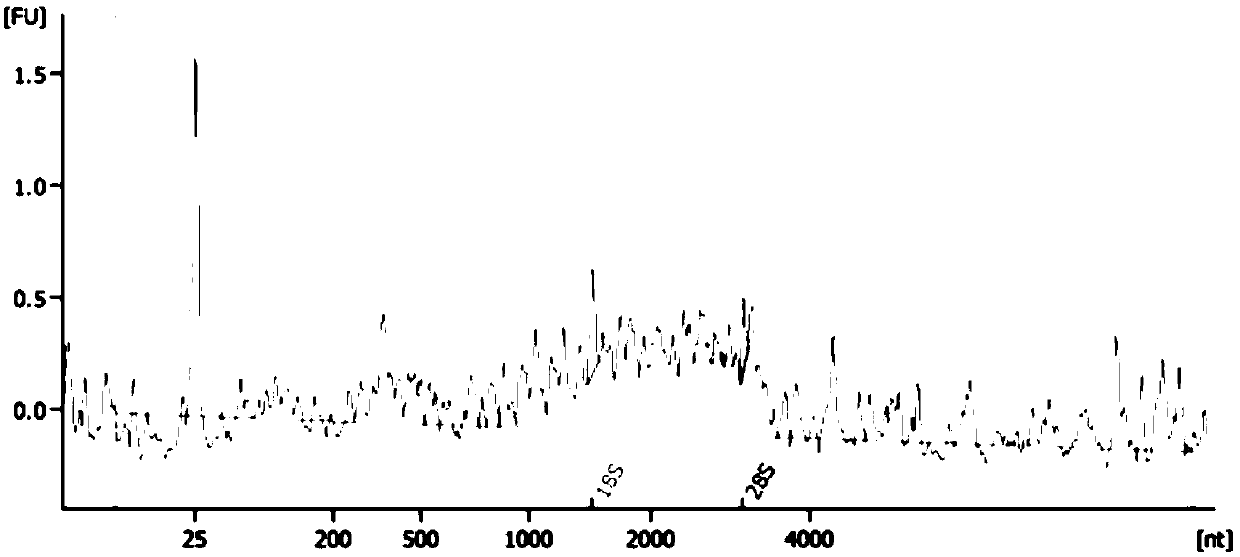

Method for separating cell nucleus from human frozen tumor tissue suitable for single cell sequencing

The invention discloses a method for separating a cell nucleus from a human frozen tumor tissue suitable for single cell sequencing and a method for extracting the cell nucleus. The method for extracting the cell nucleus comprises performing splitting treatment on a sample to be extracted in a first buffer solution; performing first centrifugation on a split product to obtain a cell nucleus precipitate; rinsing the cell nucleus and conducting resuspending treatment in a second buffer solution to obtain the cell nucleus; wherein the first buffer solution comprises: 116.8 mM of NaCl, 8 mM of Tris base at pH 7.8, 0.8 mM of CaCl2, 38 mM of MgCl2, 0.04% BSA, 0.16% Nonidet P-40, 1 mM of EDTA and 1 mg / mL of DAPI. The second buffer solution comprises 1*PBS, 1.0% BSA and 0.2U / [mu]L of RNase inhibitor. According to the method, only a simple reagent is required, no expensive separation equipment is required, and sufficient complete mononuclear can be obtained from the less frozen tumor tissue forsingle cell RNA sequencing.

Owner:杭州瑞普基因科技有限公司

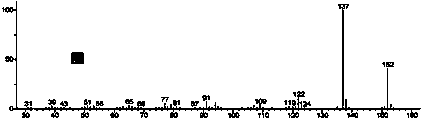

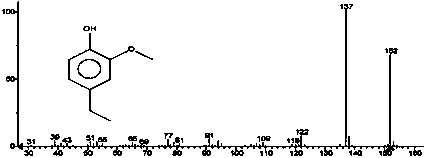

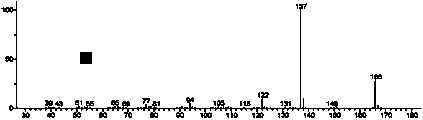

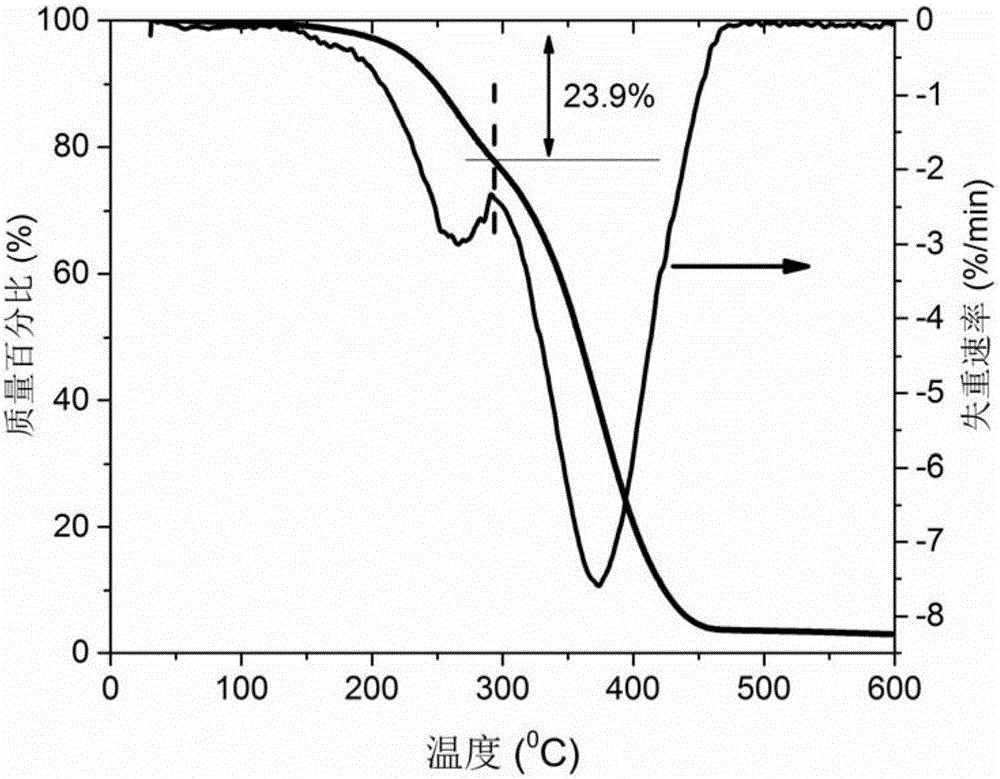

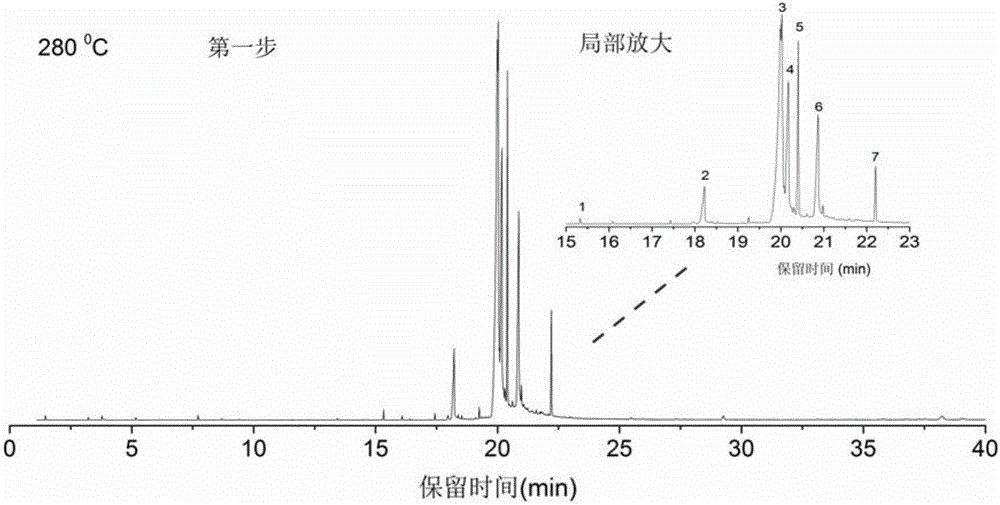

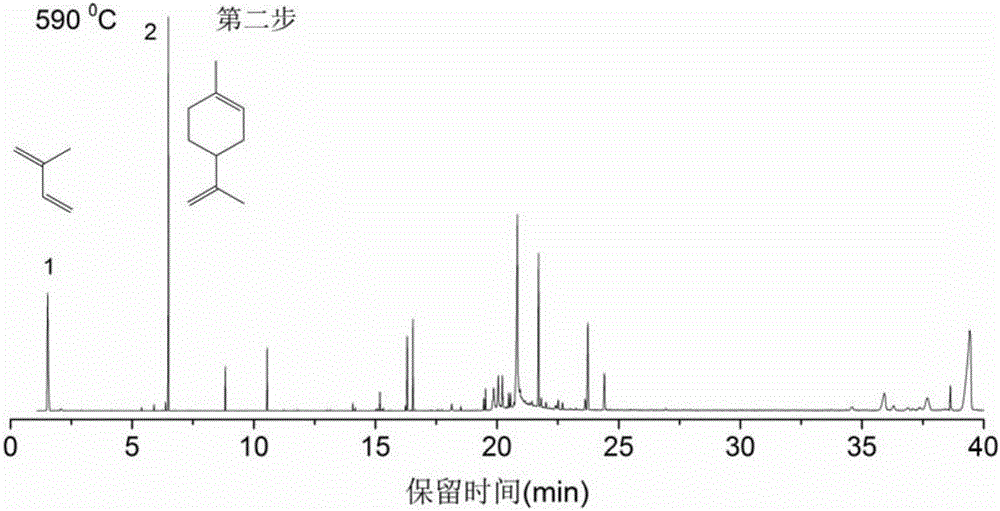

Method for identifying structure and composition of non-rubber component in natural rubber through thermogravimetry-PGC (pyrolysis gas chromatography)-MS (mass spectrum)

InactiveCN107525871ARich application of basic theoryQuick analysisComponent separationMaterial weighingChromatographic columnEvaluation system

The invention discloses a method for identifying a structure and composition of a non-rubber component in natural rubber through thermogravimetry-PGC (pyrolysis gas chromatography)-MS (mass spectrum). The method comprises the following steps: (1) concentrating and drying the non-rubber component obtained from the natural rubber; (2) making a thermogravimetry detection analysis on a sample obtained after drying; (3) analyzing the composition of the sample with a step-by-step cracking method according to a result of the thermogravimetry detection analysis, effectively separating a split product in each step by using a chromatographic column, obtaining corresponding molecular structure information of the split product by using mass spectrum search and primarily judging composition characteristics of substances in the original sample according to the strong and weak degree of signal peaks in a total ion chromatorgraphy. Through application of the method disclosed by the invention, the molecular structure and the composition of the non-rubber component in the natural rubber can be analyzed quickly and accurately, the basic application theory of the natural rubber is enriched, and the technical guidance is provided for perfection of planting, processing and quality evaluation systems of the natural rubber and product production.

Owner:SOUTH CHINA UNIV OF TECH

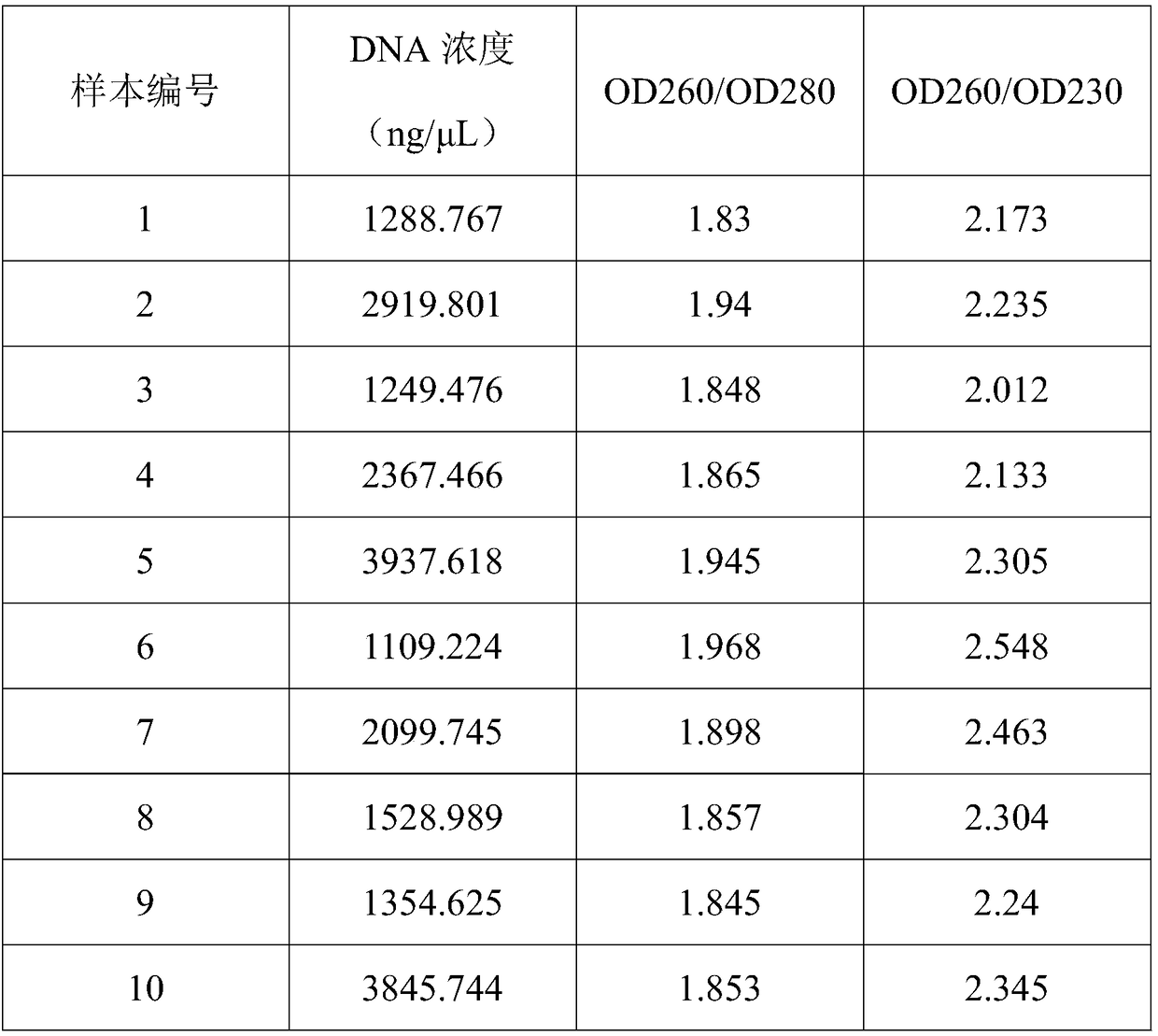

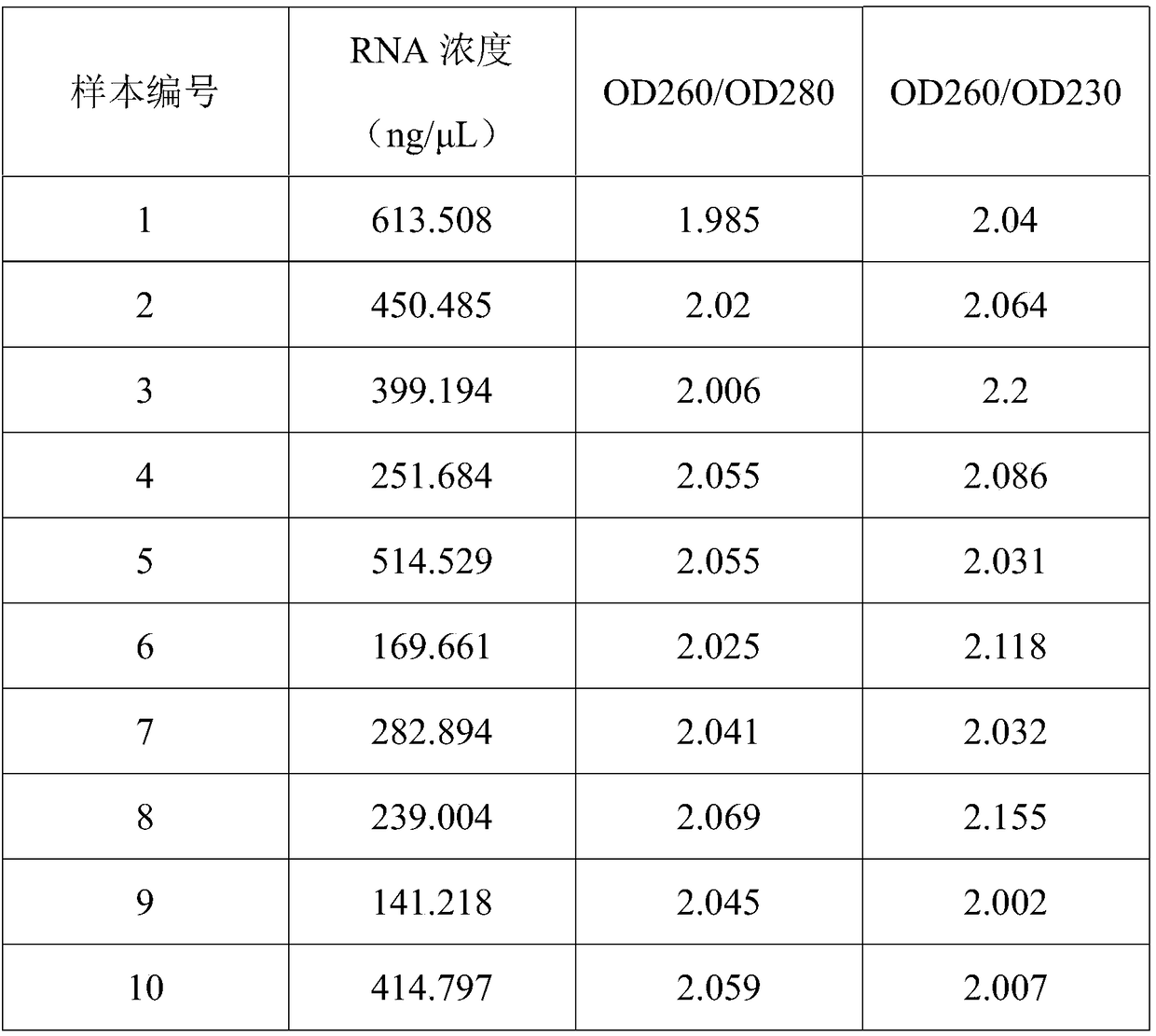

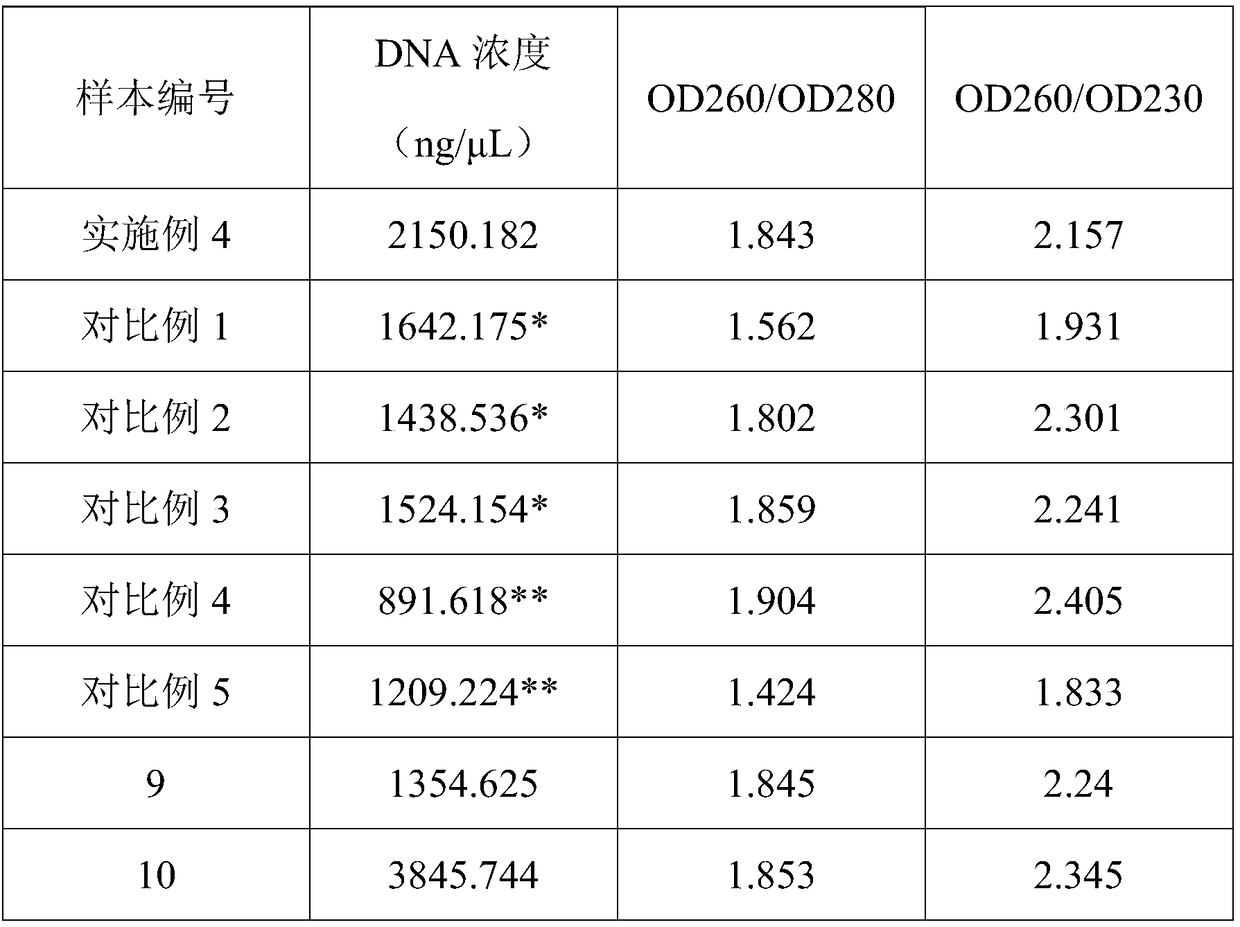

Method for separation and extraction of DNA and RNA in cells

The invention relates to the technical field of biology, in particular to a method for separation and extraction of DNA and RNA in cells. The method includes: a) adopting Trizol for splitting a cell sample to release nucleic acid to obtain a split product; b) contacting the split product with at least one organic extracting solvent, and centrifuging to layer the split product into an upper RNA aqueous phase layer, a middle DNA flocculent layer and a lower organic phase layer; c) respectively subjecting the RNA aqueous phase layer and the DNA flocculent layer to precipitation and washing, wherein a DNA precipitation agent for precipitation comprises 1,2-propanediol. By adoption of the method, problems of low yield and poor purity in simultaneous extraction of DNA and RNA can be effectivelyavoided.

Owner:苏州呼呼健康科技有限公司

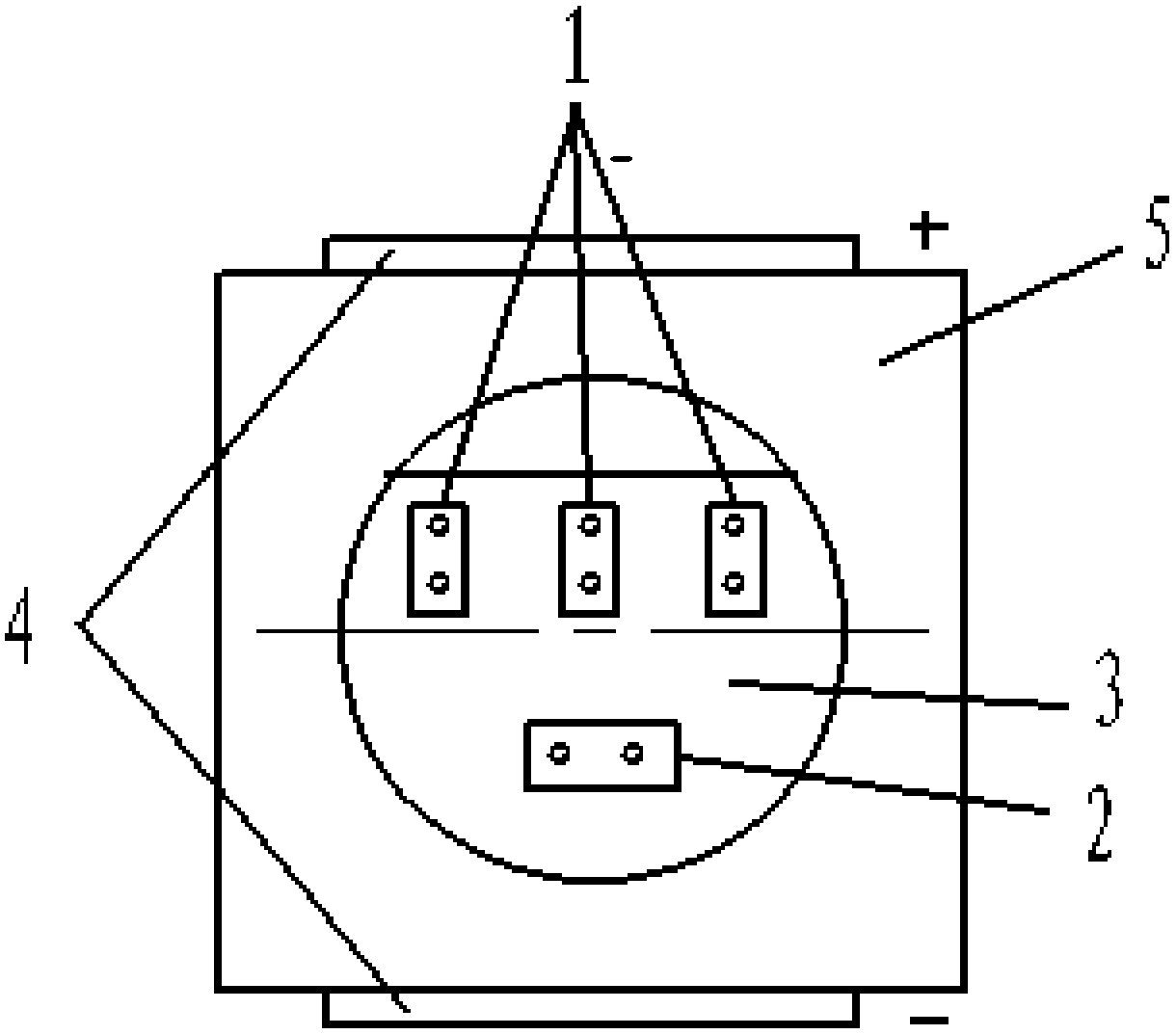

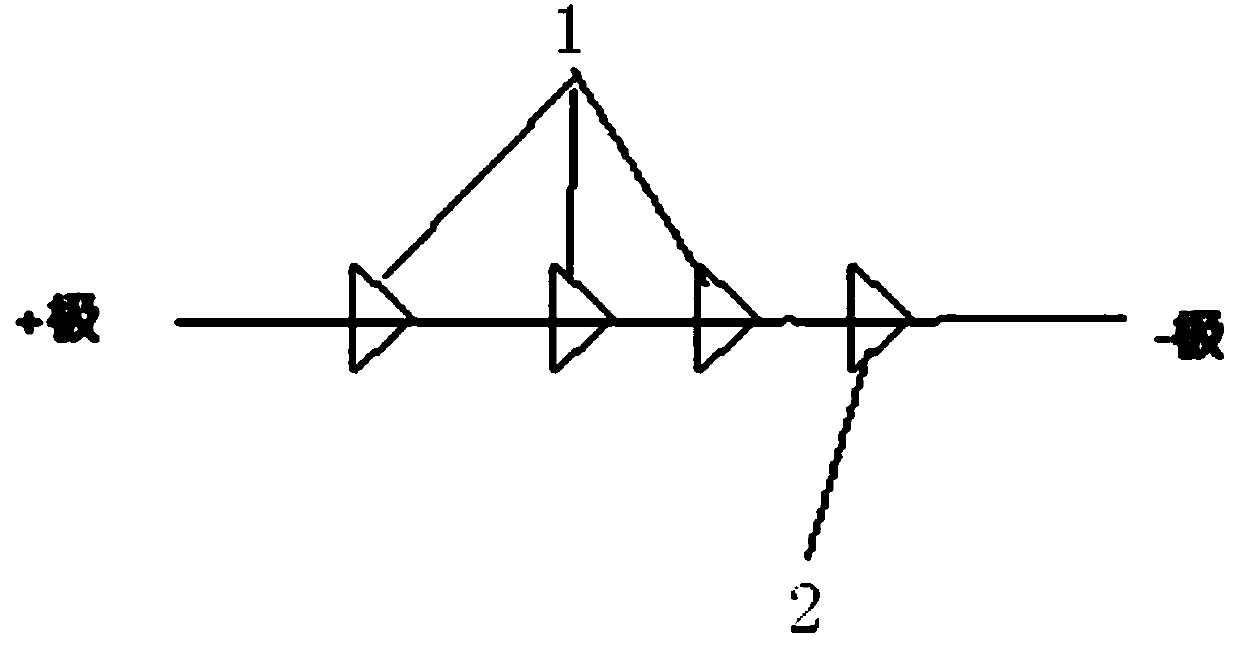

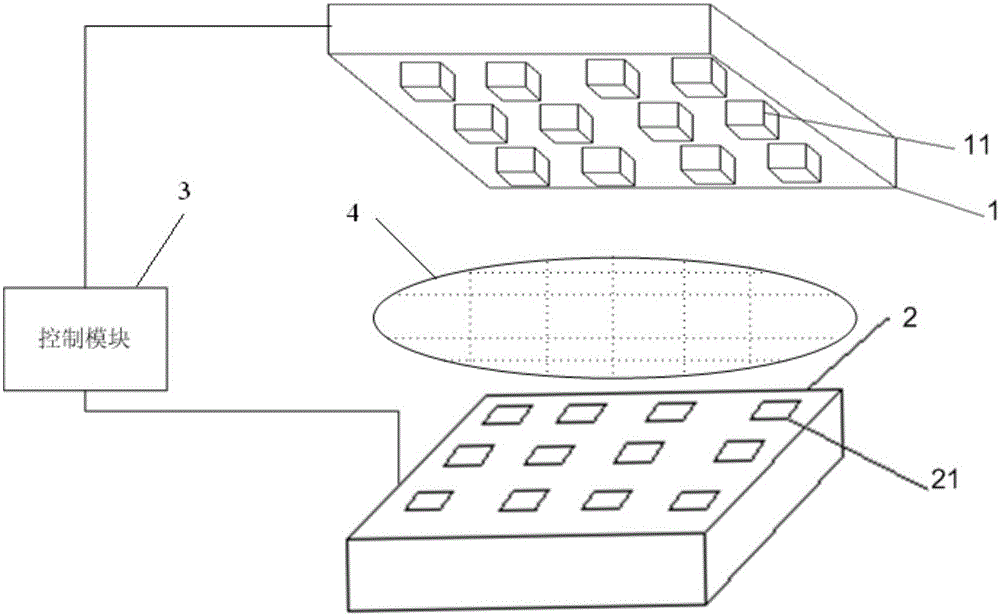

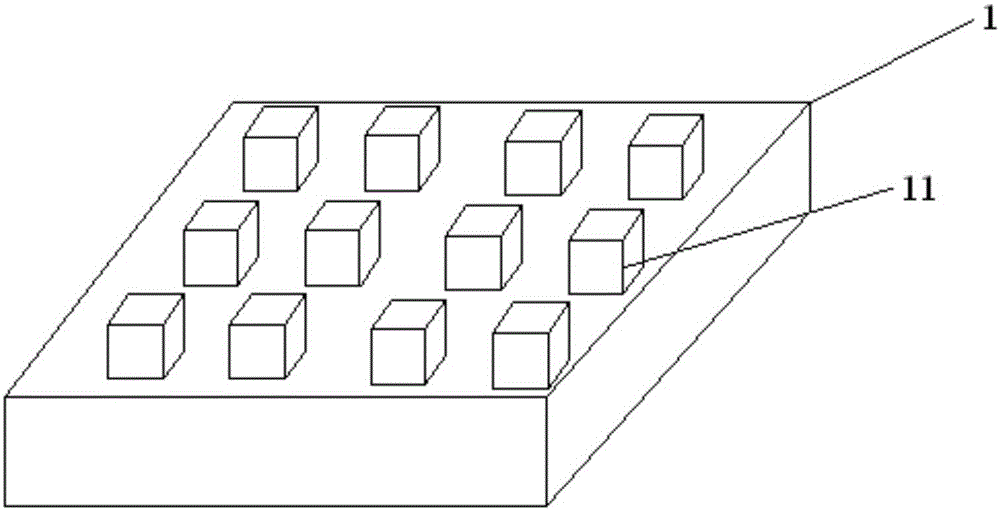

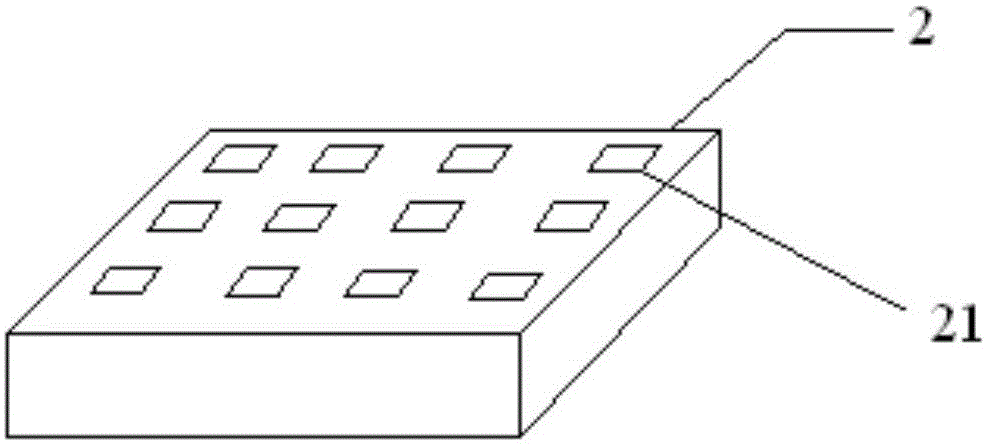

Ram-type splitting system

ActiveCN105161461AIncrease productivityImprove yieldSemiconductor/solid-state device manufacturingEngineeringCrystallite

The invention provides a ram-type splitting system, which comprises an impact plate, a groove plate and a control module, wherein at least one impact head for impacting to-be-divided wafers is arranged on the impact plate; the impact heads are evenly distributed on the impact plate; at least one groove matched with the impact heads is formed in the groove plate; the grooves are evenly distributed in the groove plate; the number of the impact heads and the number of the grooves are the same as that of crystal particles on the to-be-divided wafers; and the control module is used for controlling the impact heads on the impact plate to impact the to-be-divided wafers on the groove plate and controlling the impact heads to impact the to-be-divided wafers into the grooves in the groove plate. According to the ram-type splitting system provided by the invention, the splitting production efficiency can be improved, so that the split product yield is improved.

Owner:EPITOP PHOTOELECTRIC TECH

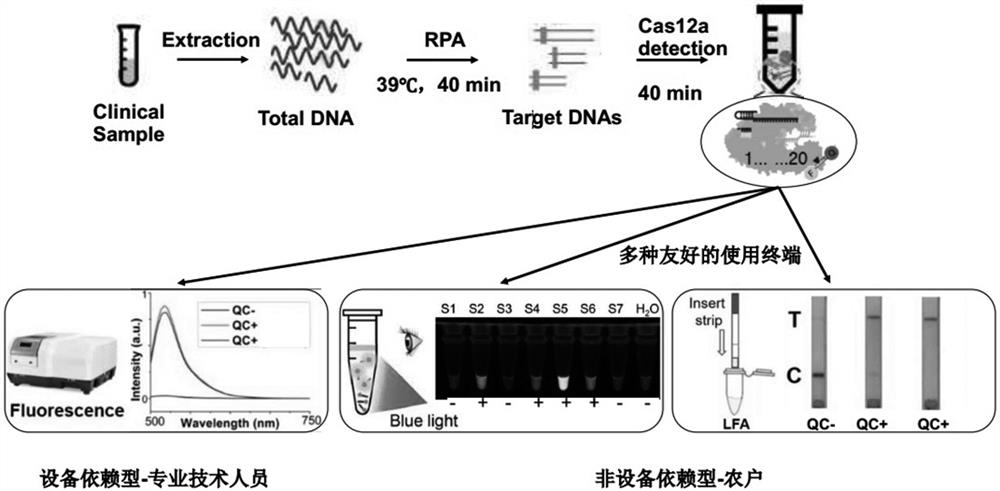

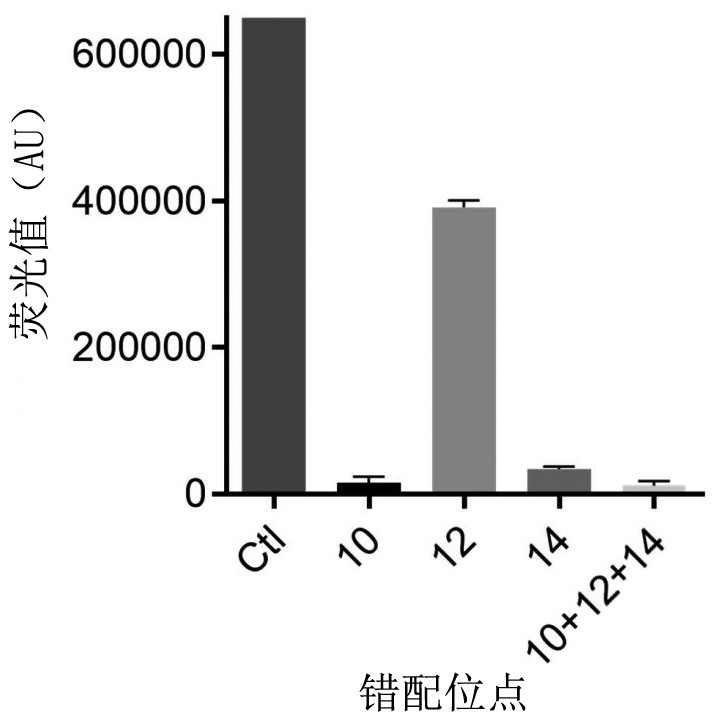

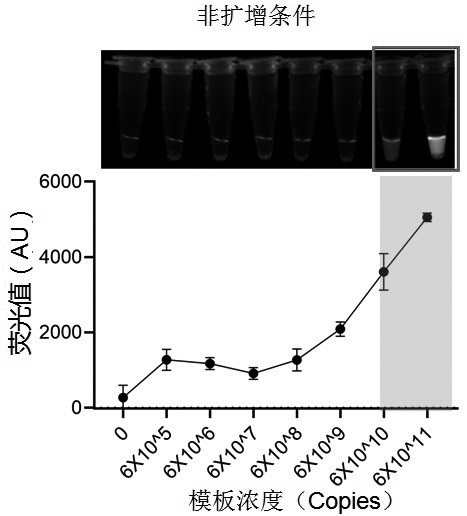

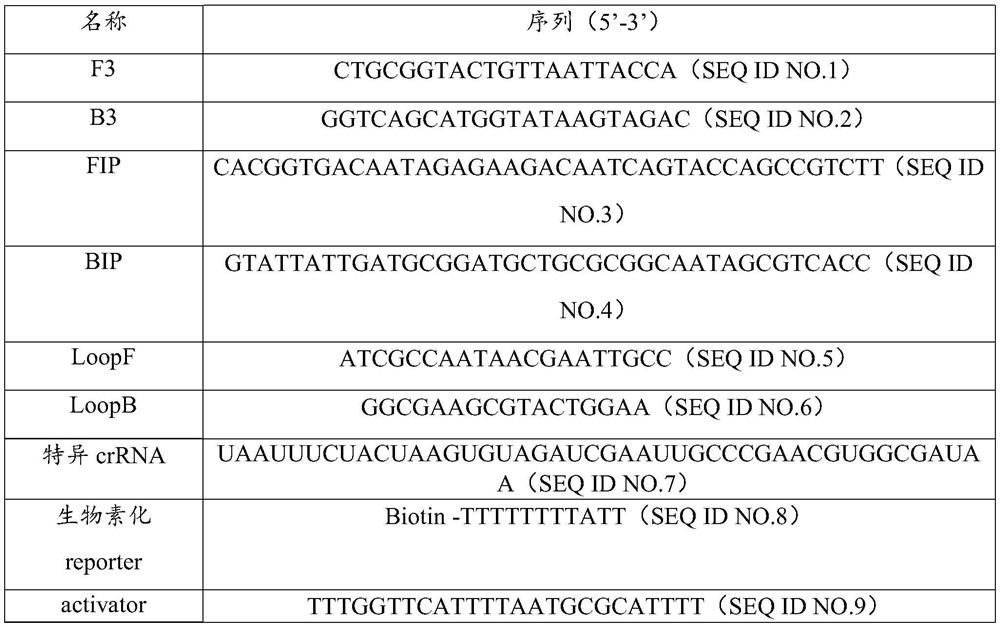

Kit and method for visual detection of citrus huanglongbing based on RPA-CRISPR-Cas12a system

ActiveCN114045356AOut of dependenceStrong specificityMicrobiological testing/measurementMicroorganism based processesBiotechnologyFluoProbes

The invention discloses a kit and a method for visual detection of citrus huanglongbing on the basis of an RPA-CRISPR-Cas12a system. The kit comprises an RPA primer and a crRNA guide sequence. The method comprises the following steps: carrying out RPA amplification on a to-be-detected sample, guiding a CRISPR-Cas12a system to carry out recognition combination on an RPA amplification product under the mediation of a crRNA sequence, cutting target double-stranded DNA to activate a non-specific nuclease function, randomly cutting an ssDNA fluorescent probe in the system to obtain a split product, and finally carrying out judgment through color development detection of the split product. The citrus huanglongbing can be duplexly and specifically detected through RPA amplification and crRNA recognition, high specificity is realized, sensitivity can be as low as 2 copies / [mu]L, plants infected with the citrus huanglongbing can be found earlier, and the citrus huanglongbing can be prevented and treated.

Owner:ZHONGKAI UNIV OF AGRI & ENG

High molecular weight polycarbosilane and preparation method thereof

The invention relates to high molecular weight polycarbosilane and a preparation method thereof. The method comprises the following steps: distilling polydimethylsilane, mixing the distilled polydimethylsilane with reducing metal powder, then heating up to 320-360 DEG C and carrying out heat preservation for 3.8-4.2h, and then cooling to room temperature to obtain a liquid split product-polysilane; adding divinyl benzene and polymetylhydrosiloxane, heating up to 320-360 DEG C, and carrying out heat preservation for 1.8-2.2h; then, heating up to 420-460 DEG C, carrying out heat preservation for5-7h, and then cooling to room temperature to obtain a polycarbosilane crude product; dissolving the crude product in xylene, filtering, and then introducing nitrogen; after that, heating up to 420-460 DEG C, carrying out heat preservation for 1.8-2.2h, and then cooling to 320-360 DEG C to obtain the high molecular weight polycarbosilane. The preparation method provided by the invention is simplein technology, low in requirements for equipment and easy in implementation of batch synthesis; the product is high in molecular weight and purity, and the synthetic yield reaches 70 or above.

Owner:南昌嘉捷天剑新材料有限公司

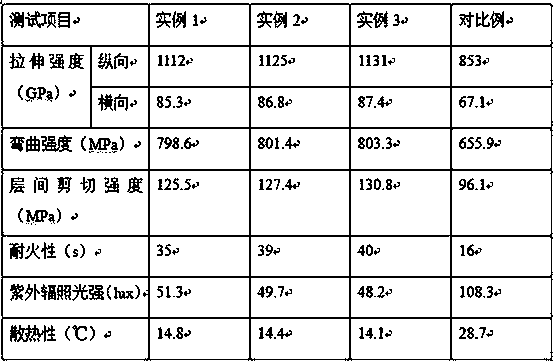

Preparation method of high-temperature pressure-resistant heat-insulation carbon fiber sheet

InactiveCN109133723ARapid absorption of heat of fusionRapid absorption of heat of evaporationBorideFiber

The invention belongs to the technical field of processing and preparation of textiles, and particularly relates to a preparation method of a high-temperature pressure-resistant heat-insulation carbonfiber sheet. The preparation method comprises the steps of taking methyl silicone oil is taken as a raw material to obtain a split product; blending the split product with dimethylbenzene to obtain aconcentrated solution; taking zirconium boride powder and the concentrated solution a as raw materials to prepare a binding agent; finally mixing raw materials such as white corundum and sodium polyacrylate, and then blending the binding agent to obtain fireproof porcelain powder; dissolving a mixed polymer in N-N dimethyl sulfoxide to obtain a blended spinning stock solution; sintering pre-oxidized wires to obtain a carbon fiber sheet preform; and coating the carbon fiber sheet preform with a high-temperature-resistant solution to obtain the high-temperature-resistant carbon fiber sheet. Expandable graphite can rapidly absorb melting heat and evaporation heat which are released from a resin carbon layer, therefore, the heat insulation property of the carbon fiber sheet is improved, air pores which can be reduced in the carbon fiber sheet can be filled with silicon carbide whiskers, the pressure resistance of the carbon fiber sheet at a high temperature is further improved, and the application prospect is wide.

Owner:黄勇

Large-scale preparation technology of endotoxin-free plasmid

InactiveCN108148831APurification method linear scale-upDNA preparationBiotechnologyPolyethylene glycol

The invention belongs to the technical field of biology, and specifically discloses a large-scale extracting technology of an endotoxin-free plasmid. The large-scale extracting technology is characterized by comprising the following steps: strain fermentation, collection of bacterial cells, splitting of bacteria, solid-liquid separation of a bacteria splitting product, collection of a liquid part,and purification of a liquid part of the bacteria splitting product, wherein the purification comprises the following steps: adding an endotoxin removing buffer solution, removing impurities and other plasmids through low-temperature treatment and ionization chromatography, and collecting target plasmids, wherein the pH (Potential of Hydrogen) of the endotoxin removing buffer solution is 7.0, andthe endotoxin removing buffer solution is prepared from 3-(N-morpholine)propanesulfonic acid, sodium chloride and polyethylene glycol octylphenol ether. A method disclosed by the invention does not use RNase A and protease K which are derived from animals and phenol and chloroform which have toxic and side effects on human bodies and animals; all indexes can achieve or approach the quality standard of FDA (U.S Food and Drug Administration) in related field; meanwhile, linear amplification can be realized; an important technological means is provided for industrial production of eukaryote products and development of gene therapy industry.

Owner:NANJING IASO BIOTHERAPEUTICS CO LTD

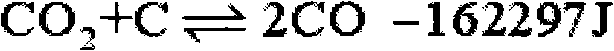

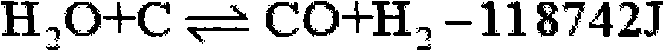

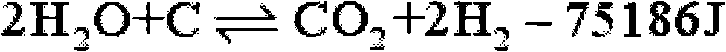

High-low temperature cycling four-layer separation decoking method during biomass gasification process

InactiveCN101928607AReduce contentQuality improvementCombustible gas productionWater vaporOxidation zone

The invention relates to a high-low temperature cycling four-layer separation decoking method during the biomass gasification process. The method comprises the following steps: (1) materials are ignited and air is introduced; (2) the air enters an oxidation zone in a gasification furnace after being heated; (3) the air is subjected to combustion reaction with carbon generated after fuel combustion in the oxidation zone; (4) the gas obtained in step (3) enters a reduction zone in the gasification furnace to carry out reduction reaction with the carbon and water vapor; (5) the gas generated in the oxidation zone and the reduction zone enters a cracking layer for cracking reaction to generate a split product; (6) the gas in the split product enters a drying zone in the gasification furnace for exchanging heat with the materials to obtain dried materials, water vapor and flammable gas; (7) the flammable gas is subjected to cracking through a dolomite catalytic cracking layer and a charcoal catalytic cracking layer to obtain gas containing remaining tar; and (8) the gas containing the remaining tar is heated at a furnace end for fully cracking and burning the remaining tar. By adoptingthe high-low temperature cycling four-layer separation decoking method, the tar content during the biomass gasification process is effectively lowered.

Owner:JIUQUAN LVJU ENERGY TECH DEV

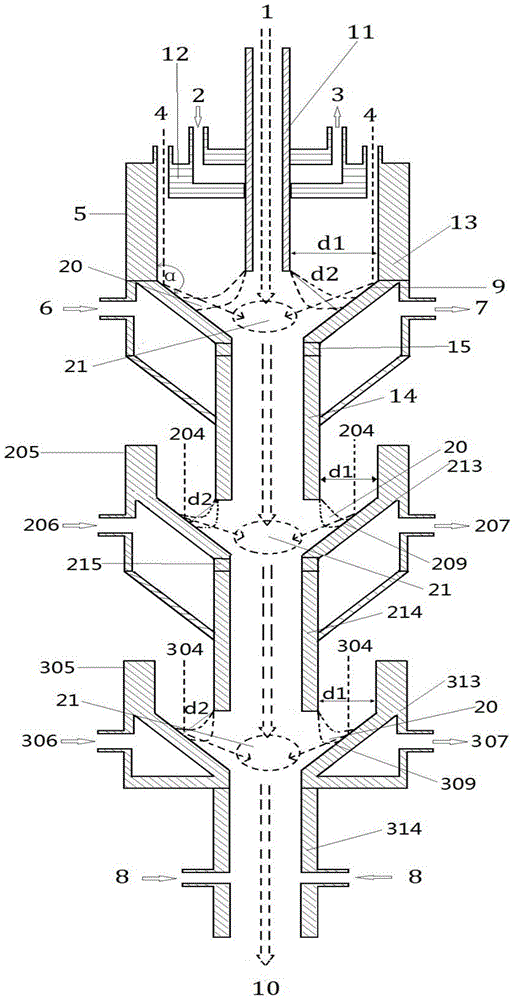

Method for preparing n-butene

ActiveCN105152833AImprove conversion rateHigh purityHydrocarbonsHydrocarbon preparationOrganic acidButene

The invention relates to the technical field of organic synthesis, particularly a method for preparing n-butene. The method comprises: by using process parameters disclosed by the invention, splitting monoprotic organic acid butanol acetate to prepare n-butene; splitting the monoprotic organic acid butanol acetate with high selectivity to monoacid and n-butene; discharging a part of monoprotic organic acid and unsplit raw materials from the bottom of a reactor; and discharging n-butene and the other part of monoprotic organic acid from the tower top and feeding the mixture to a rectifying tower so as to separate high purity n-butene. By using monoprotic organic acid butanol acetate as the raw material and matching a proper catalyst, splitting reaction at certain temperature, pressure and air speed is carried out to obtain organic acid and n-butene, wherein the obtained split product is rectified to prepare high purity n-butene. The conversion rate of monoprotic organic acid butanol acetate can reach up to 95%. Unreacted raw materials can be recycled, so that the material loss can be avoided.

Owner:ZHUHAI FEIYANG NOVEL MATERIALS

Method for preparing hydrocarbon liquid products

ActiveCN103361102AReduce consumptionEasy to operateLiquid hydrocarbon mixture productionBio-feedstockLiquid productMolten state

The invention relates to a method for preparing hydrocarbon liquid products. The method is characterized by comprising the following steps of: adding an organic solvent in the mass equal to 1.5 times of that of grease into the grease, heating to 120-200 DEG C, adding powder-type solid sodium hydroxide, and fast stirring to carry out saponification; carrying out subcooling on a product, separating out soda soap from the solution; and in a splitting stage, taking molten alkali as a heating and reacting medium, putting alkaline substances into a reactor, introducing shielding gas into the reactor, setting the reaction temperature at 350-600 DEG C, changing the alkaline substances into a molten state, and continuously adding the beforehand prepared soda soap into the reactor to generate a decarboxylic reaction on soap under the action of the molten alkaline, wherein the split products comprise liquid, solid substances and splitting gas. The method has the advantages that the preparation method is simple in operation process, mild in condition, concise in device and strong in controllability, and a prepared liquid product is low in acid value, high in aliphatic hydrocarbon content and low in oxygenated compound content and viscosity.

Owner:林清

A testability verification index evaluation method for airborne equipment of an aircraft

InactiveCN109033564AIntegrity guaranteedGuarantee sufficiencyGeometric CADResourcesData sourceComputer science

A testability verification index evaluation method for airborne equipment of an aircraft is provided. The method comprises the steps of: first, according to the FMEA report of the product, determiningthe failure mode set F of the product, and then analyzing all the failure modes in the failure mode set F of the product to determine a failure mode set that can be physically injected and a failuremode set that cannot be physically injected by the laboratory,; when determining that the failure mode is the failure mode set that can be physically injected completely, making a test scheme, carrying out the testability verification test, and completing the testability evaluation; if the determined failure mode has a failure mode that cannot be physically injected, splitting the product failuremode set F, and redetermining the failure mode set of the split product, and carrying out the corresponding analysis and evaluation. By synthetically weighting testability verification and fusing multi-faceted information, the integrity and adequacy of experimental data sources can be ensured and the accuracy of testability evaluation can be effectively improved.

Owner:JIANGXI HONGDU AVIATION IND GRP

Preparation method using bacterial lysate as inactivated vaccine adjuvant

PendingCN114028558ABiosafetyImprove immunityRotary stirring mixersTransportation and packagingBiotechnologyBacilli

The invention relates to a preparation method using bacterial lysate as inactivated vaccine adjuvant. The preparation method comprises the following steps: step 1, respectively putting corynebacterium pseudotuberculosis and rhodococcus equi into an LB culture medium for culturing at 37 DEG C, and harvesting thalli through a centrifugal machine; step 2, diluting each thallus to 8.0* 10<9> cfu / mL by using sterilized normal saline, and crushing the bacterial liquid by using a high-pressure homogenizer; and step 3, after sterility test, mixing the split products of corynebacterium pseudotuberculosis and rhodococcus equi with the two bacteria inactivated by formaldehyde according to a ratio of 1: 1 to obtain the inactivated vaccine added with the adjuvant. The preparation method has the characteristics of safety, high efficiency, strong immune enhancement capability and low cost, and is suitable for producing various bacterial inactivated vaccines.

Owner:ZHANGZHOU PIEN TZE HUANG PHARM +1

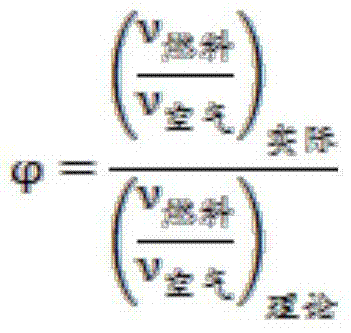

Analytical method and analytical device for simulating cigarette burning and smoking based on controllable equivalence ratio method

ActiveCN103926342ASimulation is accurateAccurate control of oxygen concentrationComponent separationEquivalence ratioEngineering

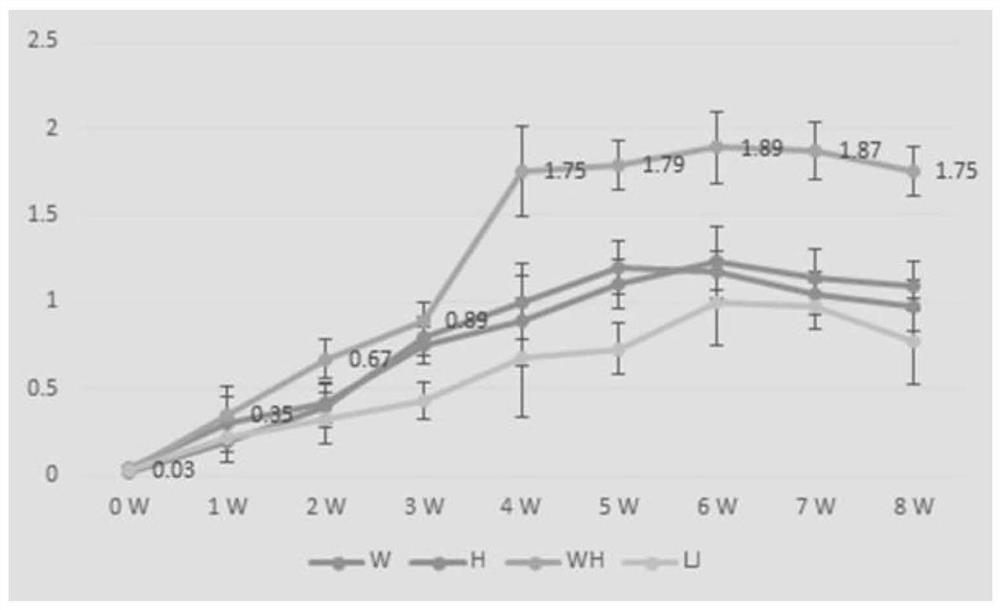

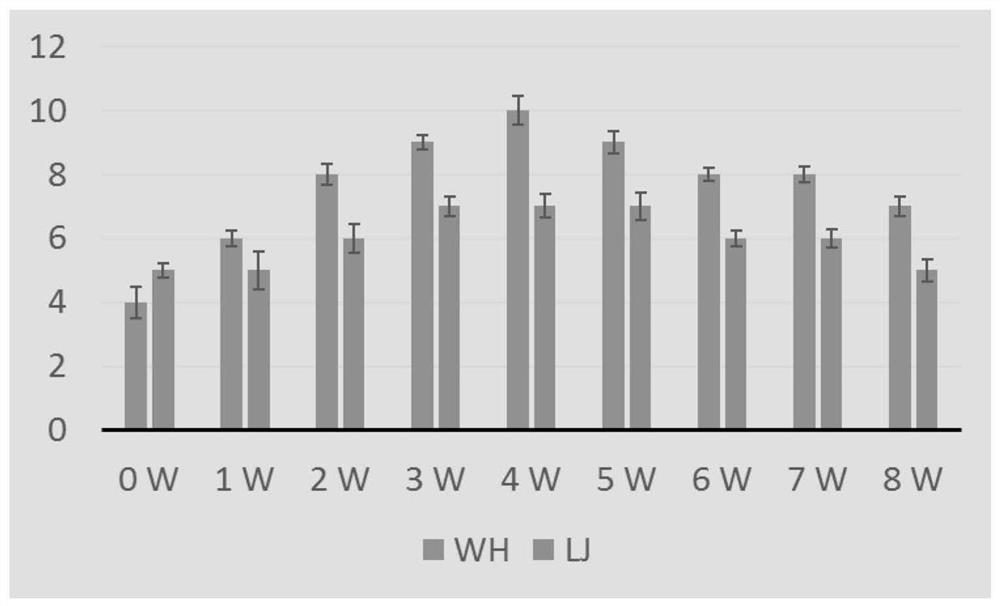

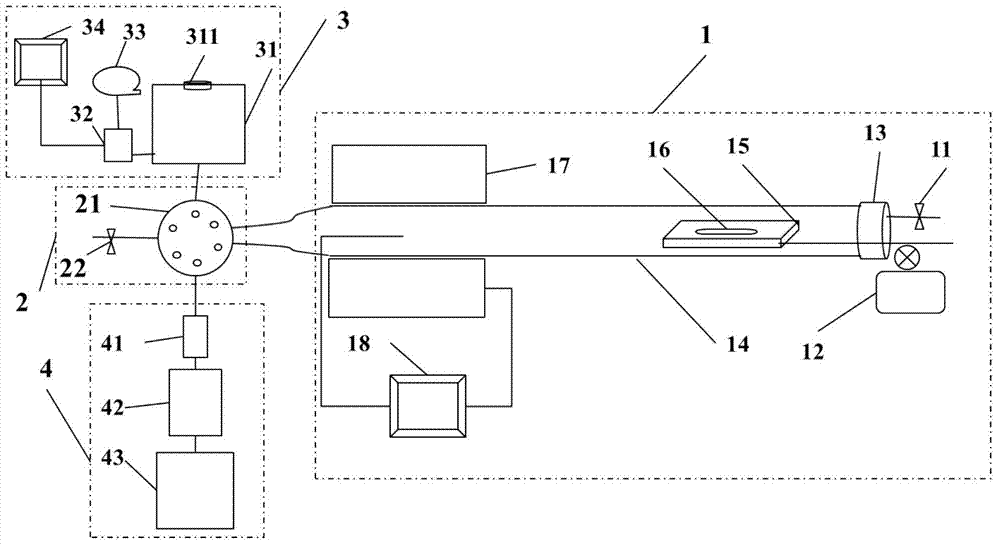

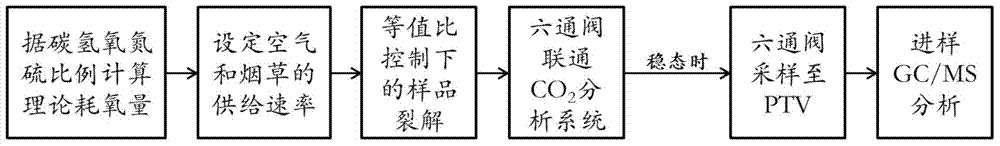

The invention discloses an analytical method and an analytical device for simulating cigarette burning and smoking based on a controllable equivalence ratio method, wherein actual air supply quantity and tobacco sample advancing speed are calculated according to equivalence ratio, then under the condition of the calculated air supply quantity, a sample loader uniformly paved with a tobacco sample is propelled into a tubular furnace with certain temperature according to calculation speed, a six-way valve guides a combustion product to a carbon dioxide analytical system, after the concentration fluctuation is small, a split product is guided to a PTV sample injector by the six-way valve and is condensed and enriched by liquid nitrogen, and after sampling is carried out for a period of time, the six-way valve is connected to the carbon dioxide analytical system; after a sample in the PTV sample injector is subjected to temperature programming and enters a gas chromatography (GC) for separation, a mass spectrum (MS) is adopted for carrying out qualitative and quantitative analysis. Compared with methods for simulating burning and smoking of cigarettes in the prior art, the method disclosed by the invention can accurately simulate the cigarette burning environment, is large in sample loading quantity, does not need preparation of cigarettes for experiment and the like, and can accurately measure chemical components in the smoke.

Owner:CHINA TOBACCO ANHUI IND CO LTD

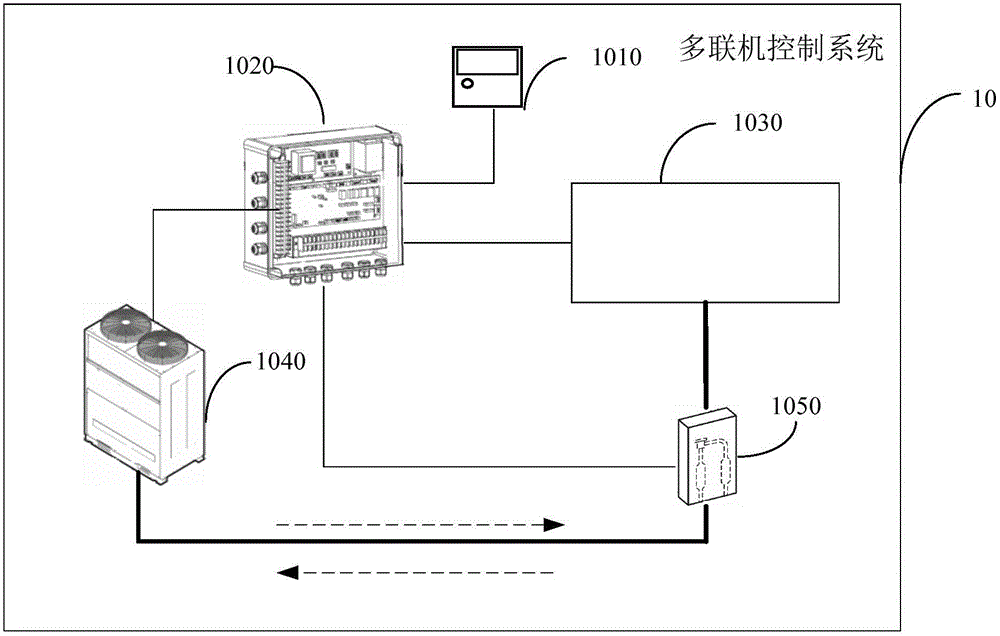

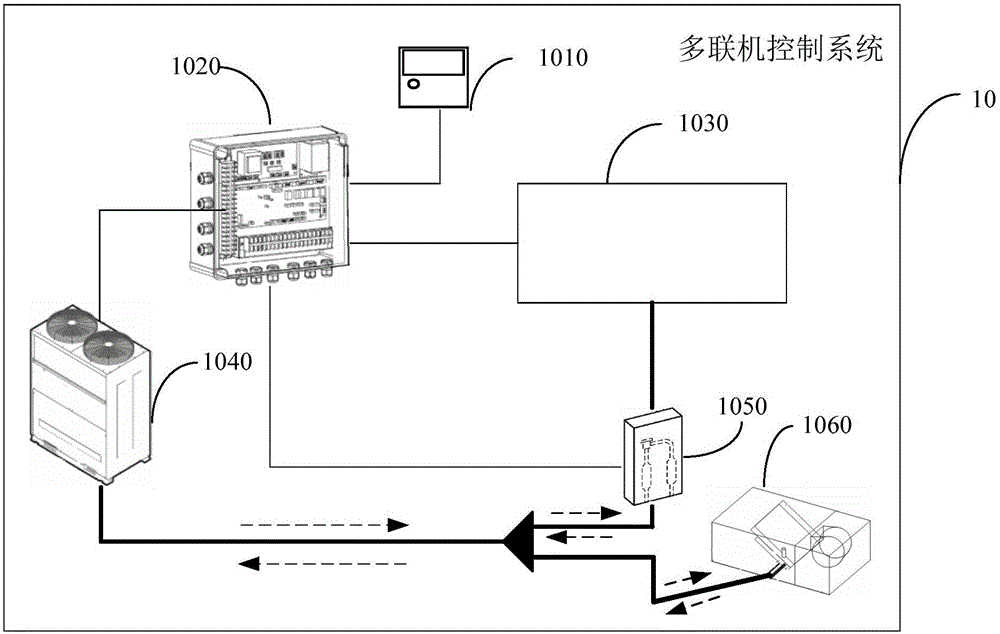

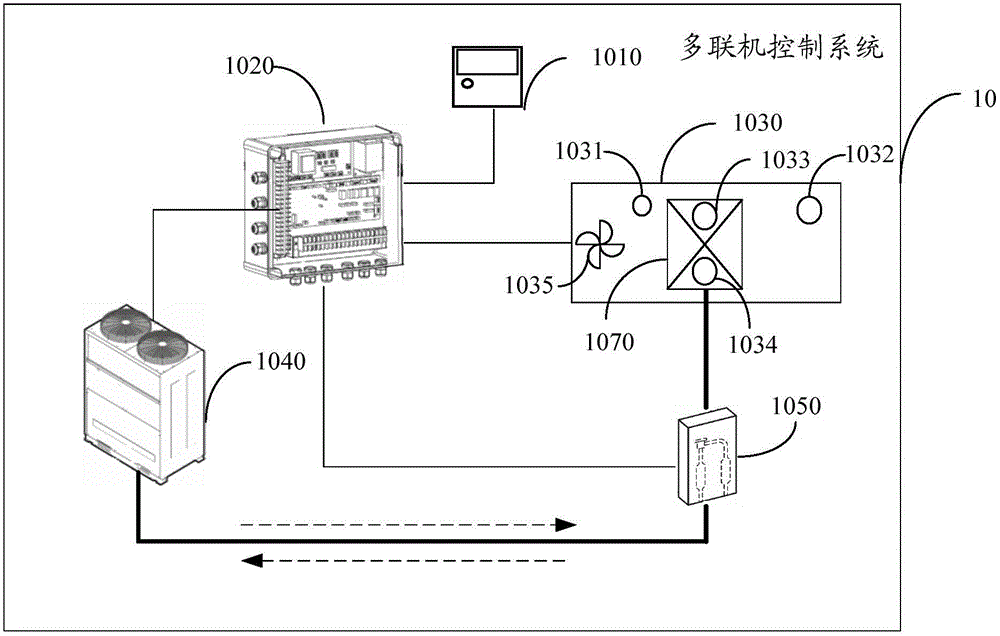

Multi-split control system

ActiveCN106765741ASolve the problem of not being able to match each otherMechanical apparatusSpace heating and ventilation safety systemsControl systemEngineering

The invention provides a multi-split control system, relates to the technical field of air conditioners, and solves the problem that in the prior art, a conventional AHU and a conventional multi-split product cannot be matched mutually when being used simultaneously. The multi-split control system comprises an external controller, at least one linkage controller, an air processor, an outdoor machine set and at least one throttling device, wherein the linkage controller is connected with the external controller; the air processor, the outdoor machine set and the throttling device are connected with the linkage controller; the throttling device is arranged between the outdoor machine set and the air processor; and the outdoor machine set at least comprises an outdoor machine. The multi-split control system provided by the embodiment of the invention is applied to the linkage control of a multi-split system.

Owner:QINGDAO HISENSE HITACHI AIR CONDITIONING SYST

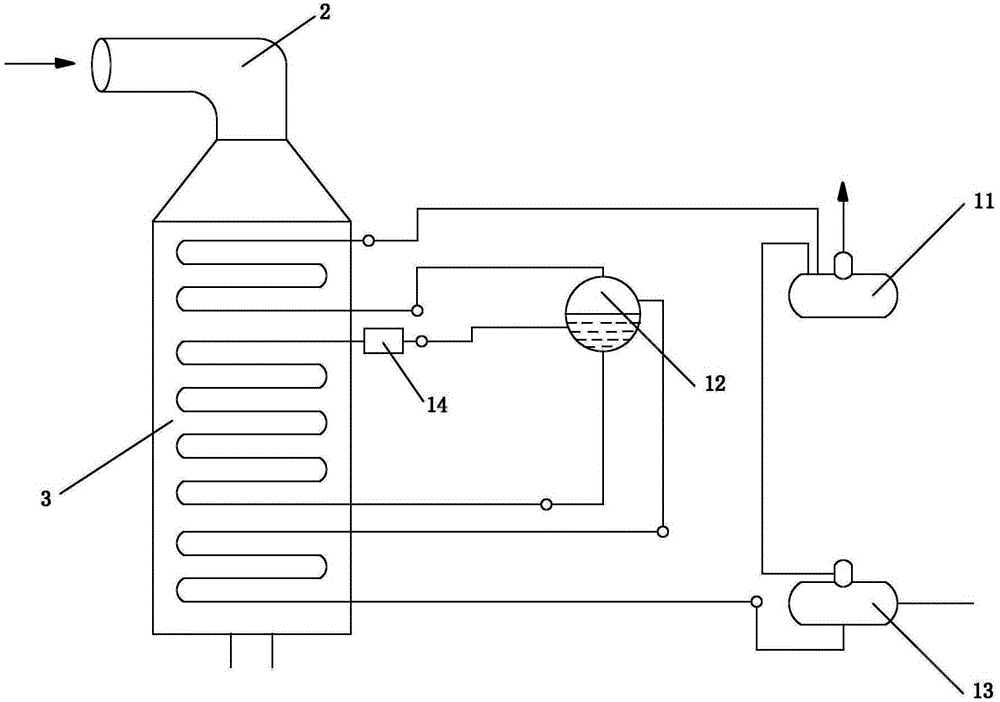

Power generation system using waste heat of coke oven crude gas

The invention provides a power generation system using waste heat of coke oven crude gas, and solves the problems that the waste of conventional coke oven heat energy is larger, and a large amount of split products in the crude gas are consumed without return. The power generation system comprises a waste heat gas passage, a waste heat boiler, a turboset and a generator set which are connected in sequence; the waste heat gas passage is connected with a coke oven rising pipeline; a superheater, an evaporimeter and an economizer are arranged in the waste heat boiler in the gas flowing direction in sequence; the economizer is connected with a softened water pump outlet; and the superheater is connected with the turboset through a steam pipeline. The power generation system is simpler, equipment is easy to arrange, the occupied area is small, the temperature of the raw coke oven gas is reduced from 650-750 DEG C to 82-86 DEG C since the crude gas is cooled, and meanwhile, about 60% of tar is cooled and collected in a mechanization slot for recycling.

Owner:青岛中拓科技有限公司

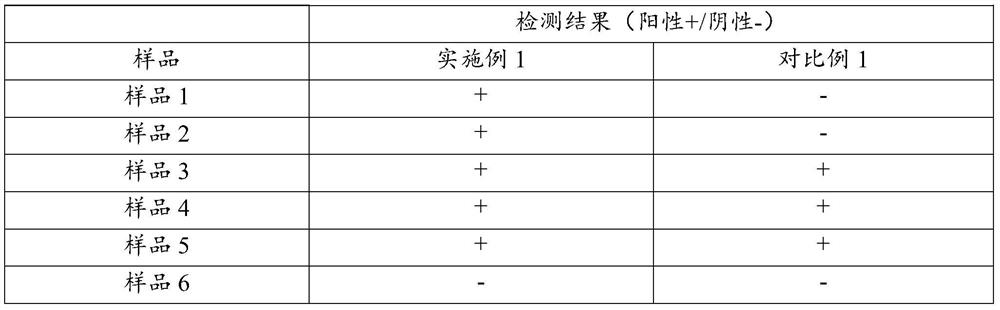

Method for detecting salmonella

PendingCN111961705AImprove accuracyIncreased sensitivityMicrobiological testing/measurementAgainst vector-borne diseasesSalmonella frintropColloidal au

The invention provides a method for detecting salmonella. The method comprises the following steps: (1) taking nucleic acid of a sample to be detected as a template, and carrying out amplification bya loop-mediated isothermal amplification technique by using specific primers of the salmonella, so as to obtain an amplified product; (2) under mediation of specific crRNA, subjecting the amplified product obtained in the step (1) to a cracking reaction by using a CRISPR system, so as to obtain a cracked product; and (3) carrying out chromogenic detection on the cracked product obtained in the step (2) by using a colloidal gold test paper strip. The method has very good sensitivity and accuracy.

Owner:FOSHAN UNIVERSITY

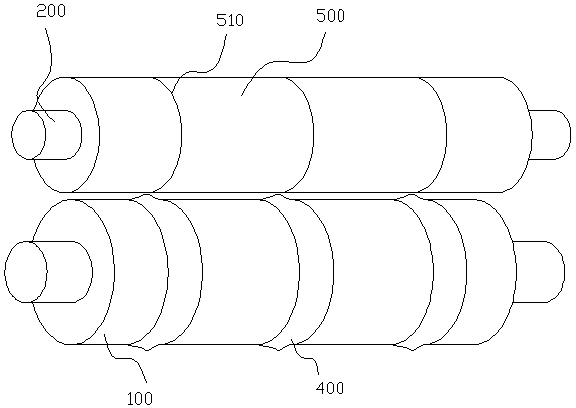

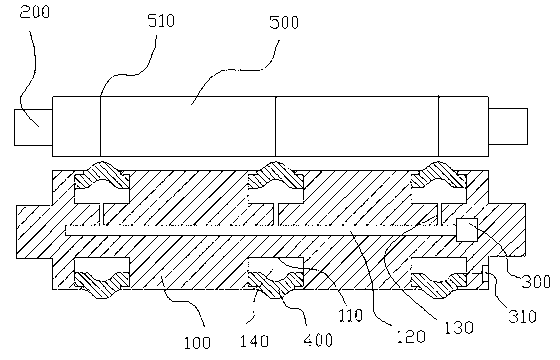

Compression roller of splitting machine rewinding shaft

Owner:深圳市宜美特科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com