Ablation-resistant fire-retardant sealing adhesive and preparation method thereof

A fire-retardant and sealant technology, which is applied in chemical instruments and methods, adhesives, and other chemical processes, can solve the problems of cracking, degumming, loss of bonding performance and sealing performance, and achieve the goal of increasing the viscosity of the system and reducing free movement. Effect of space, good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

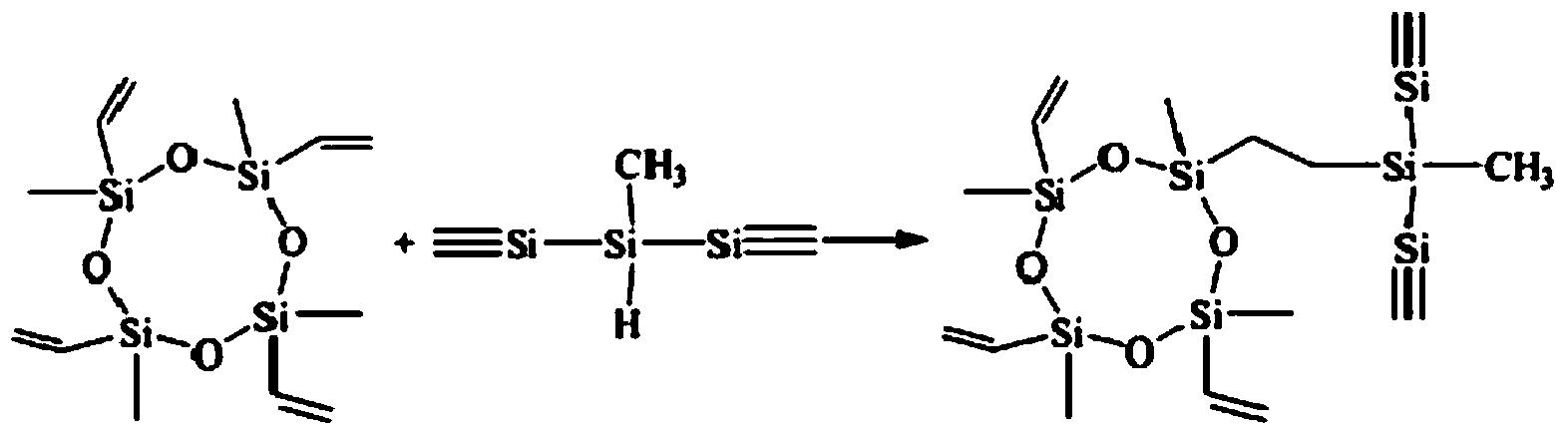

Method used

Image

Examples

Embodiment 1

[0033] A kind of ablation-resistant, fire-proof flame-retardant sealant, by weight, comprises the following components: Silicone polymer: 50 parts (PHMS and D 4 Vi ratio is 1:1), feldspar powder: 25 parts, platinum complex catalyst: 1 part (methyl vinyl siloxane coordination platinum catalyst), methyl cellulose: 3 parts, fumed silica: 2 parts, TaC: 12 parts, γ-aminopropyltriethoxysilane: 0.3 parts, BN whiskers: 5 parts.

[0034] The preparation method is:

[0035] (1) Weigh 5 parts of BN whiskers, 25 parts of feldspar powder, and 12 parts of TaCl and soak in 0.3 parts of γ-aminopropyltriethoxysilane for 30 minutes for surface treatment; the particle size of the feldspar is 1-10um , TaC particle size 2 ~ 5um;

[0036] (2) Weigh 50 parts of siloxane polymer (PHMS and D 4 The ratio of Vi is 1:1), 1 part of platinum complex catalyst, BN whiskers, feldspar powder, TaC, 3 parts of methyl cellulose and 2 parts of fumed silica after step 1), followed by Stir evenly after adding un...

Embodiment 2

[0040] A kind of ablation-resistant, fireproof and flame-retardant sealant, by weight, comprises the following components: Silicone polymer: 60 parts (PHMS and D 4 Vi ratio is 1:1.5), mica powder: 30 parts, platinum complex catalyst: 1.5 parts (chloroplatinic acid (H 2 Ptcl 6 .6H 2 O), hydroxypropyl methylcellulose: 3 parts, organic bentonite: 5 parts (calcium-based organic bentonite), TiO 2 : 20 parts, γ-glycidyloxypropyltrimethoxysilane: 0.2 parts, SiC whiskers: 8 parts.

[0041] The preparation method is:

[0042] (1) Weigh 8 parts of SiC whiskers, 30 parts of mica powder, TiO 2 : 20 parts are immersed in 0.2 parts of γ-glycidyl etheroxypropyl trimethoxysilane for 30 minutes for surface treatment; the particle size of the mica powder is 1-10um, TiO 2 Particle size 2 ~ 5um;

[0043] (2) Weigh 60 parts of siloxane polymer (PHMS and D 4 The ratio of Vi is 1:1.5), 1.5 parts of platinum complex catalyst, SiC whiskers, mica powder, TiO 2 , and 3 parts of hydroxypropyl met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Adhesive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com