Multi-section plasma cracking carbonaceous material reactor system

A reactor system, plasma technology, used in hydrocarbon oil cracking, cracking, educts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

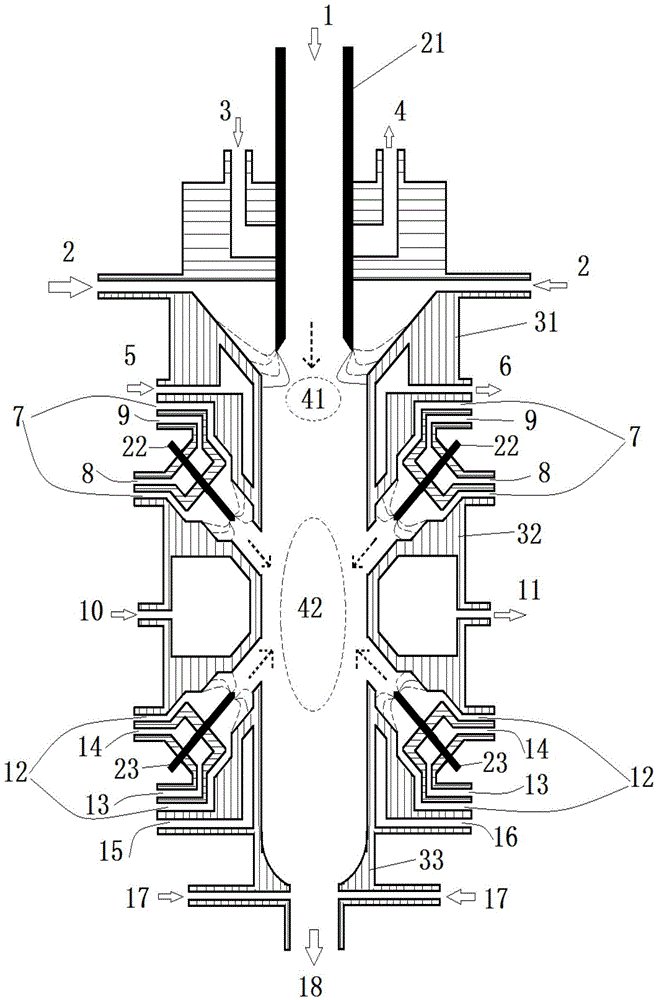

[0075] Schematic for figure 1 The reactor system of the present invention for multi-stage plasma cracking of carbonaceous materials is used to convert coal tar to acetylene and other chemicals. A coal tar produced during coal pyrolysis was used as a carbonaceous material, and its properties are shown in Table 1.

[0076] Table 1

[0077]

[0078] In the above-mentioned multi-stage plasma reactor system of the present invention, the input power of the hollow cathode 21 of the preheating section and its plasma torch is 5kW, and the input power of the four cathode rods 22 and 23 of the mixed reaction section and its plasma torch are both It is 5kW, in order to form one arc area for generating plasma in the preheating section and four arc areas for generating plasma in the mixing reaction section.

[0079] like figure 1As shown, the 300K coal tar feed 1 is introduced into the reaction tube of the preheating section through the hollow channel of the hollow cathode 21 under th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com