Simple and convenient method of preparing magnetic bagasse based active carbon by one step

A sugarcane bagasse and activated carbon technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of unfavorable mass production, high preparation cost, complex preparation process of technological process, etc., and achieves curbing secondary cracking reaction. , the effect of reducing activation energy and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

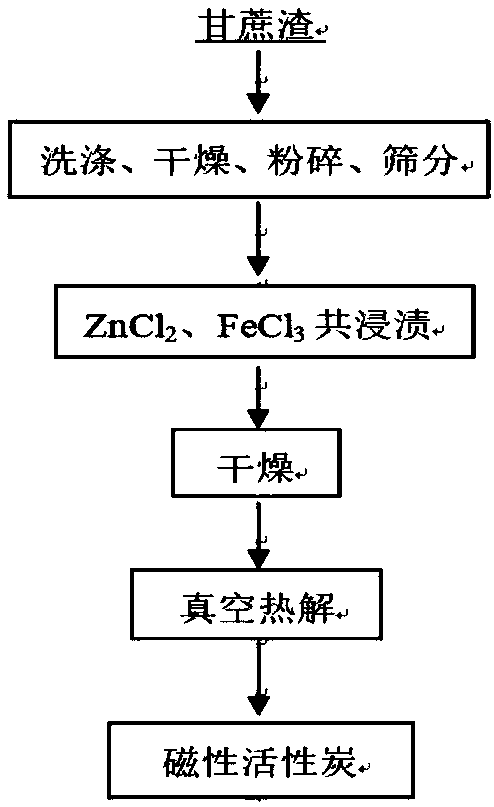

Method used

Image

Examples

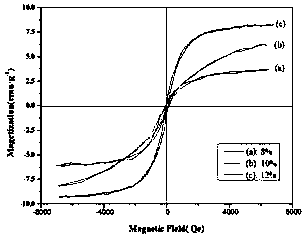

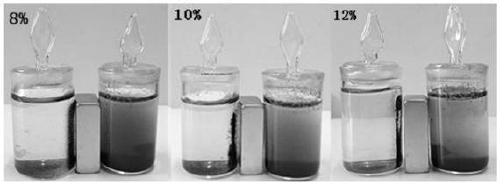

Embodiment 1

[0019] Take a certain quality of zinc chloride and ferric chloride (the ratio of bagasse to activator and magnetic additive is 1:1:12%) and dissolve them in 80mL of distilled water, add 10g of bagasse to the mixed solution, and use Stir the solution with a stirrer at medium speed for 2 h. Then stand at room temperature for 22 hours, and dry to obtain the mixed raw material. Put the dried mixed raw materials in a self-made stainless steel reactor, and place the stainless steel reactor in a resistance furnace to ensure that the device is correctly connected to the vacuum pump and the exhaust gas absorption device and has good airtightness. Start the vacuum pump to keep the internal pressure of the reactor at 10kPa, raise the temperature to 500°C, and pyrolyze for 60min. The solid product was taken out and boiled with distilled water for 30 minutes, washed, dried and ground to obtain powdered magnetic bagasse-based activated carbon A.

Embodiment 2

[0021] Take a certain quality of zinc chloride and ferric chloride (the ratio of bagasse to activator and magnetic additive is 1:1:10%) and dissolve it in 80mL of distilled water, add 10g of bagasse to the mixed solution, and use Stir the solution with a stirrer at medium speed for 2 h. Then stand at room temperature for 22 hours, and dry to obtain the mixed raw material. Put the dried mixed raw materials in a self-made stainless steel reactor, and place the stainless steel reactor in a resistance furnace to ensure that the device is correctly connected to the vacuum pump and the exhaust gas absorption device and has good airtightness. Start the vacuum pump to keep the internal pressure of the reactor at 10kPa, raise the temperature to 500°C, and pyrolyze for 60min. The solid product was taken out and boiled with distilled water for 30 minutes, washed, dried and ground to obtain powdered magnetic bagasse-based activated carbon B.

Embodiment 3

[0023] Take a certain quality of zinc chloride and ferric chloride (the ratio of bagasse to activator and magnetic additive is 1:1:8%) and dissolve it in 80mL of distilled water, add 10g of bagasse to the mixed solution, and use Stir the solution with a stirrer at medium speed for 2 h. Then stand at room temperature for 22 hours, and dry to obtain the mixed raw material. Put the dried mixed raw materials in a self-made stainless steel reactor, and place the stainless steel reactor in a resistance furnace to ensure that the device is correctly connected to the vacuum pump and the exhaust gas absorption device and has good airtightness. Start the vacuum pump to keep the internal pressure of the reactor at 10kPa, raise the temperature to 500°C, and pyrolyze for 60min. The solid product was taken out and boiled with distilled water for 30 minutes, washed, dried and ground to obtain powdered magnetic bagasse-based activated carbon C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com