On-site desorption experimental device and method for shale gas decompression and fracturing at high temperature

An experimental method and experimental device technology, applied in the field of shale gas field desorption experimental device for high temperature pressure reduction and fracturing, can solve the problem of desorption gas content and residual gas content less than the experimental test, destroy shale pore structure, natural gas Can not be fully desorbed and other problems, to achieve the effect of improving reliability and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

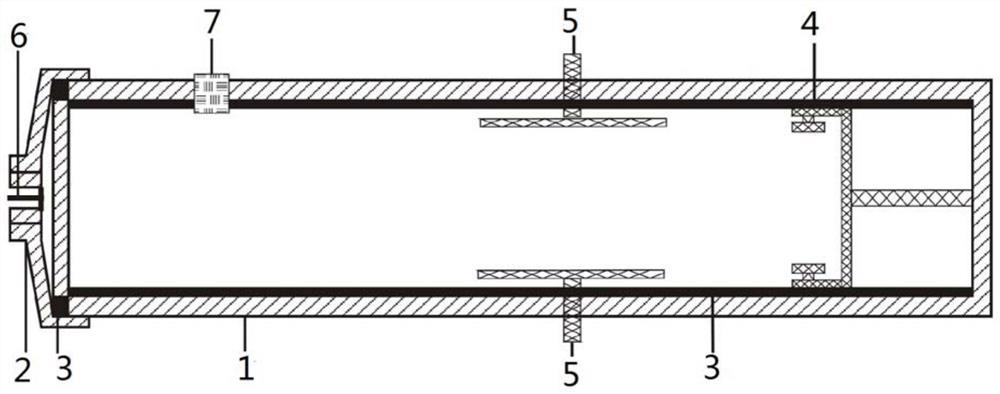

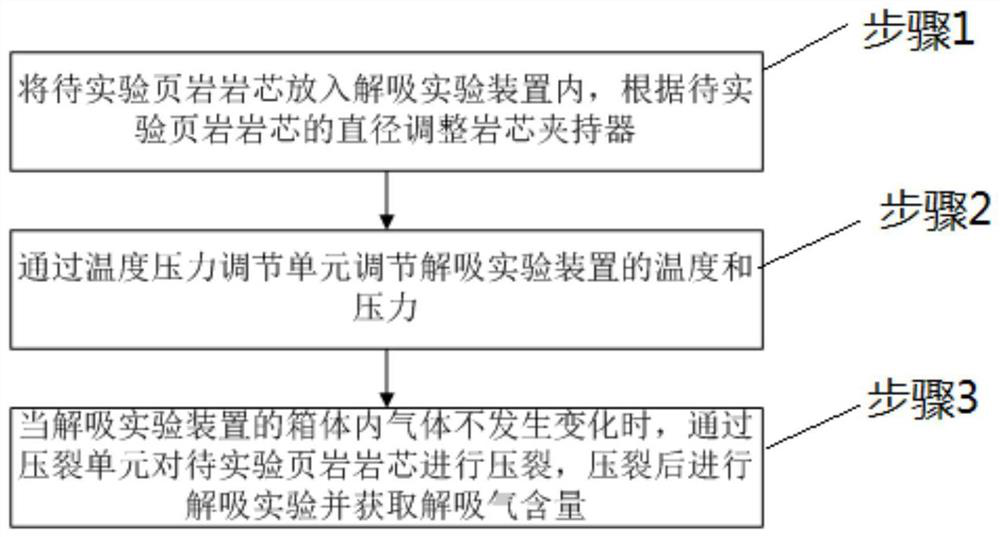

[0060] figure 1 A schematic structural diagram of an on-site desorption experimental device for high-temperature depressurization and fracturing of shale gas is shown according to an exemplary embodiment of the present invention. figure 2 A flow chart of an on-site desorption experiment method for high-temperature depressurization and fracturing of shale gas according to the present invention is shown.

[0061] According to an exemplary embodiment of the present invention, an on-site desorption experimental device for high-temperature decompression and fracturing of shale gas includes: a closed desorption box and a temperature and pressure adjustment unit 7 penetrating through the outer wall of the closed desorption box.

[0062] The airtight desorption box includes: a box body 1; a box body top cover 2, which is connected to the box body 1 by threads, and sealed by a sealing ring 3, and an opening is provided on the box body top cover 2; an air duct 6 is arranged on the The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com