Hydrotreating catalyst, preparation method and application thereof

A hydrogenation treatment and catalyst technology, applied in the field of catalysis, can solve the problems of poor denitrification effect, high metal content, limited effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

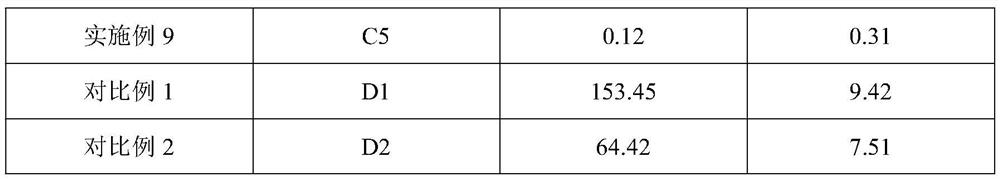

Examples

preparation example Construction

[0053] In yet another aspect, according to yet another embodiment of the present invention, a method for preparing a hydroprocessing catalyst is provided, the method comprising the steps of:

[0054] The carrier is uniformly mixed with a solution of a Ni-containing compound, a Co-containing compound and a W-containing compound to obtain a mixture A, which is dried or calcined to obtain the hydrogenation treatment catalyst.

[0055] In some preferred examples, the W-containing compound is selected from one or more of ammonium tungstate, ammonium metatungstate, ammonium paratungstate, and ethyl ammonium metatungstate; the Ni-containing compound is a water-soluble salt of Ni, Preferably one or more of Ni nitrates, acetates, carbonates, and basic carbonates; the Co-containing compound is a water-soluble salt of Co, preferably Co nitrates, acetates One or more of , carbonate, and basic carbonate.

[0056] In yet another preferred example, the mixing method is joint impregnation or...

Embodiment 1

[0080] The present embodiment is the carrier of preparation catalyst, comprises the following steps:

[0081] (1) Take 200g of γ-Al 2 o 3 powder, mixed with 350mL magnesium nitrate hexahydrate solution containing 76.8g for beating, mixed thoroughly, and dried at 120°C for 3h to obtain Mg-containing γ-Al 2 o 3 pink. Weigh 150g of γ-Al containing Mg 2 o 3 The powder was saturated and soaked in 143 mL of aqueous solution containing 20 g of glucose, dried at 120 ° C, and roasted in an argon atmosphere at 225 ° C for 3 hours (the content of C in the powder was 4.9%).

[0082] (2) The above powder was mixed with 73.6g of pseudo-boehmite at a mass ratio of 2:1 (on an alumina dry basis). Then in the mixed powder, add 5.5g of scallop powder, mix evenly, weigh 6.2mL of nitric acid and water to make 141mL solution, add this solution to the mixed powder under stirring, knead, and extrude to make a diameter of 1.6mm Clover-shaped wet strips, followed by drying the wet strips at 120°...

Embodiment 2

[0084] The present embodiment is the carrier of preparation catalyst, comprises the following steps:

[0085] (1) Take 300g of γ-Al 2 o 3 powder, mixed with 425mL of magnesium-containing solution containing 111g of magnesium nitrate hexahydrate, and then dried at 140°C for 3 hours to obtain Mg-containing γ-Al 2 o 3 pink. 140g of γ-Al containing Mg 2 o 3 The powder is soaked in saturated 126mL aqueous solution containing 33g of glucose, dried at 120°C, and roasted in a nitrogen atmosphere at 250°C for 2.5 hours (the content of C element in the powder is 7.8%).

[0086] (2) Mix the above powder with 73.6g of pseudo-boehmite at a ratio of 2:1 (calculated on a dry basis of alumina). Then in the mixed powder, add 5.7g of scallop powder, mix evenly, weigh 5.6mL of nitric acid and water to make 101mL solution, add this solution to the mixed powder under stirring, knead, and extrude to make a diameter of 1.6mm Clover-shaped wet strips, followed by drying the wet strips at 120°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com