A processing device and processing method for photovoltaic glass

A photovoltaic glass and processing method technology, applied in sustainable manufacturing/processing, climate sustainability, coating, etc., can solve the problems of difficult to remove, anti-reflection coating devitrification and fouling, battery power attenuation, etc. Friction damage, beneficial to long-term use, the effect of protecting the pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

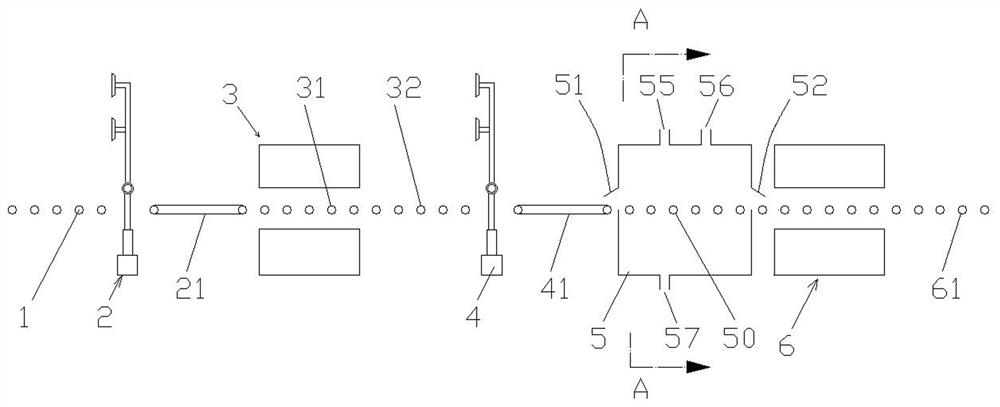

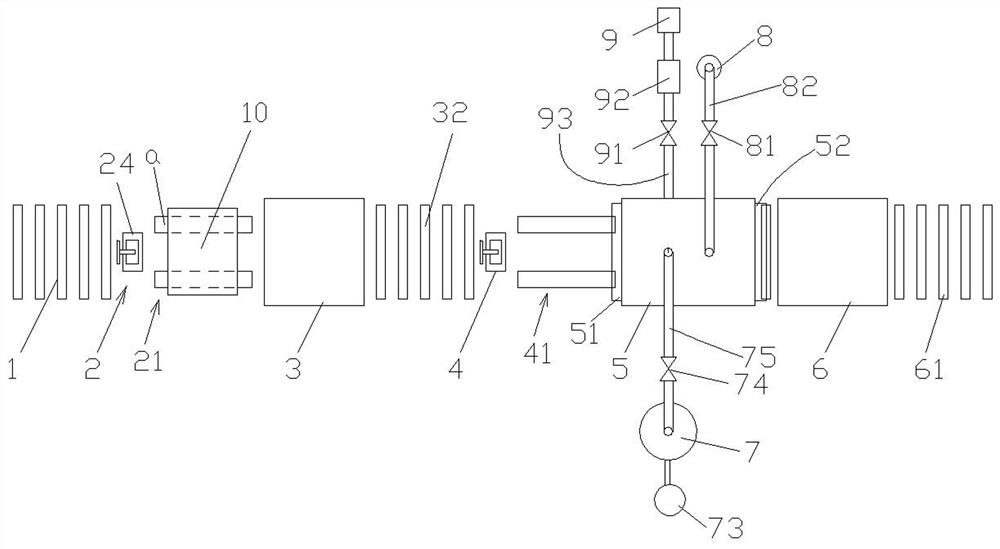

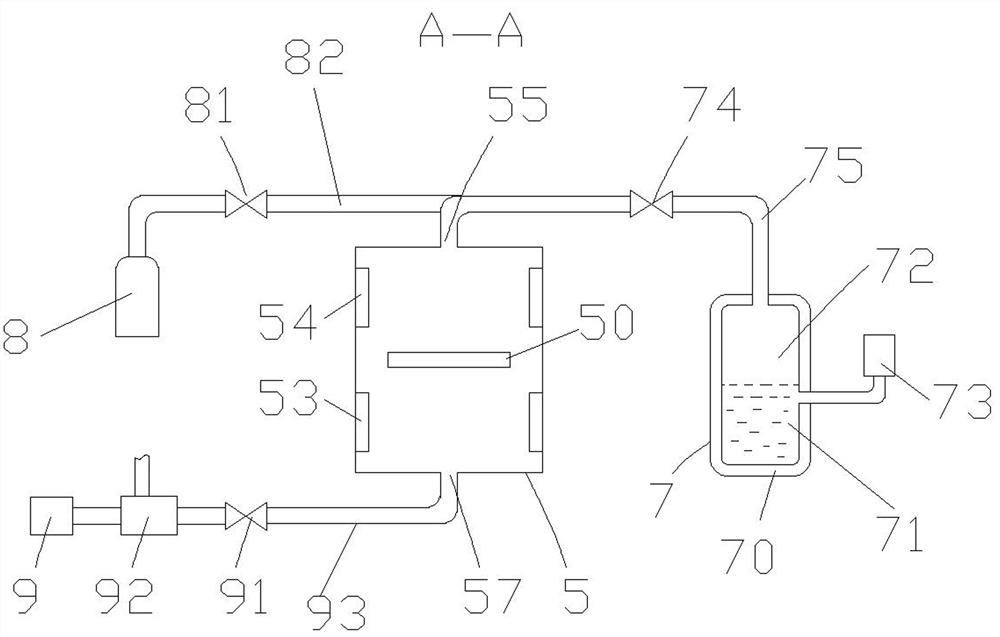

[0033] Such as Figure 1-4 As shown, a processing device for photovoltaic glass, which includes a first turner 2, a first conveyor belt 21, a spraying machine 3, and a second turner 4, which are sequentially arranged on the end side of the lower stage 1 of the tempering furnace. , the second conveyor belt 41, the vacuum chamber 5 and the washing machine 6. A process gas tank 7 , a compressed nitrogen tank 8 and a vacuum pump 9 are also communicated with the vacuum chamber 5 through pipelines.

[0034] The first film turning machine 2 includes a base 20 arranged below one side of the tempering furnace lower table 1, a vertically distributed cylinder 26 is fixedly connected to the base 20, and the output shaft 22 of the cylinder 26 The end is fixedly connected with a frame 27 distributed along the width direction of the tempering furnace lower table 1, and a rotating shaft 23 distributed along the width direction of the tempering furnace lower table 1 is uploaded on the frame 2...

Embodiment 2

[0053] Adopt the same processing device of a kind of photovoltaic glass as in Example 1 to process (therefore, the specific structure of a processing device of photovoltaic glass is not repeated here), that is, a processing method of photovoltaic glass, which includes the following steps : (1) The suction cup arm 24 of the first film turning machine 2 rotates 90 degrees to the left with the rotation axis 23, and the telescopic rod 22 descends, so that the suction cup 25 contacts and absorbs the anti-reflection coating surface of the photovoltaic glass, and then rotates the rotation axis 23 to The right side rotates 180 degrees, the suction cup 25 falls between the two parallel timing belts of the first conveyor belt 21, and the telescopic rod 22 continues to descend, so that the anti-reflection coating surface of the photovoltaic glass 10 contacts the first conveyor belt 21, and the suction cup desorbs. The bottom surface of the photovoltaic glass 10 falls on the first conveyor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com