Compression roller of splitting machine rewinding shaft

A technology of winding shaft and slitting machine, which is applied in the direction of winding strips, thin material processing, transportation and packaging, etc. It can solve the problems affecting the appearance and quality of products, and achieve the effect of improving appearance and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

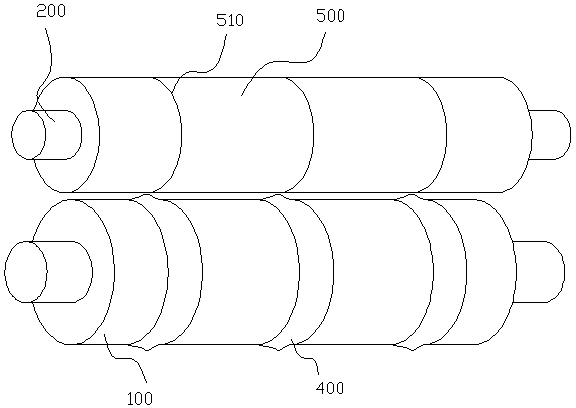

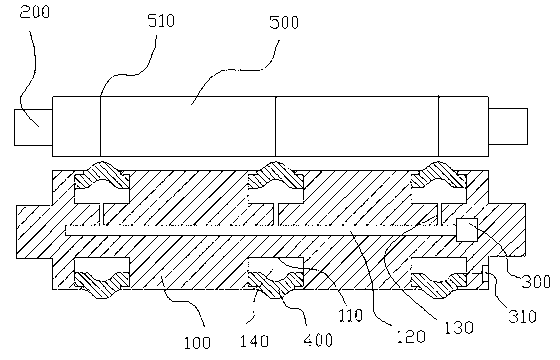

[0022] figure 1 It is a schematic diagram of the axonometric structure of an embodiment of the rewinding shaft pressure roller of the slitting machine, figure 2 It is the rewinding shaft pressure roller of the slitting machine figure 1 The structural representation of the embodiment, in order to illustrate the problem, will now figure 1 , figure 2 The present invention is explained as the same embodiment.

[0023] In this embodiment, the slitting machine winding shaft pressure roller includes a pressing roller 100, which is arranged parallel to the slitting machine winding shaft 200, and the pressing roller 100 is close to the product 500 on the winding shaft 200, The pressure roller 100 is provided with a groove 110 corresponding to the slit 510 of the cut product 500, and a rubber ring 400 matching it is arranged in the groove 110, and the rubber ring 400 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com