Preparation method of high-temperature pressure-resistant heat-insulation carbon fiber sheet

A carbon fiber cloth, high temperature technology, applied in the field of textile processing and preparation, can solve the problems of poor high temperature compression resistance, thermal insulation performance to be improved, poor fire resistance of carbon fiber cloth, etc., and achieve the effect of large thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

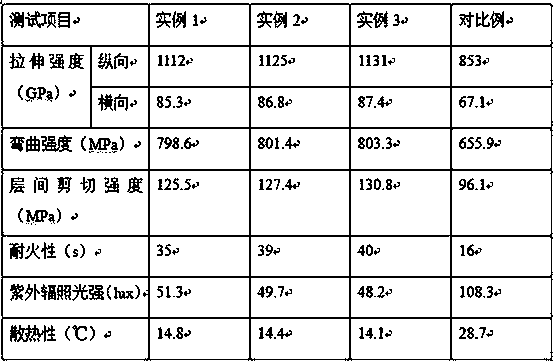

Examples

example 1

[0029] Take 150mL of methyl silicone oil and add it to a three-necked flask equipped with a thermometer and a reflux device. Under the protection of nitrogen, move the three-necked flask into a sand bath, control the temperature of the sand bath at 420°C, keep it warm for 1 hour, then raise the temperature to 460°C, and continue to keep warm React for 40 minutes, and cool to room temperature naturally after the reaction to obtain the product; add 200 mL of xylene to the above product, stir and mix for 10 minutes, then filter to obtain the filtrate, transfer the filtrate to a rotary evaporator, and concentrate by rotary evaporation at 80°C for 40 minutes. To obtain the concentrated solution, take 30 g of zirconium boride and add it to a pulverizer to pulverize for 30 minutes to obtain zirconium boride powder, add the zirconium boride powder, concentrated solution, and 100 mL of deionized water into a beaker, stir and mix for 15 minutes, and obtain a binder; In terms of parts by ...

example 2

[0031] Take 170mL of methyl silicone oil and add it to a three-necked flask equipped with a thermometer and a reflux device. Under the protection of nitrogen, move the three-necked flask into a sand bath, control the temperature of the sand bath at 425°C, keep it warm for 1 hour, then raise the temperature to 470°C, and continue to keep warm React for 45 minutes, and cool to room temperature naturally after the reaction to obtain the product; add 250 mL of xylene to the above product, stir and mix for 13 minutes, then filter to obtain the filtrate, transfer the filtrate to a rotary evaporator, and concentrate by rotary evaporation at 85°C for 45 minutes. To obtain the concentrated solution, take 35g of zirconium boride and add it to a pulverizer to pulverize for 35 minutes to obtain zirconium boride powder, add the zirconium boride powder, concentrated solution, and 150mL deionized water into the beaker, stir and mix for 17 minutes, and obtain the binder; In terms of parts by w...

example 3

[0033] Take 200mL of methyl silicone oil and add it to a three-necked flask equipped with a thermometer and a reflux device. Under the protection of nitrogen, move the three-necked flask into a sand bath, control the temperature of the sand bath at 430°C, keep it warm for 2 hours, then raise the temperature to 480°C, and continue to keep warm React for 50 minutes. After the reaction, cool down to room temperature naturally to obtain the product; add 300 mL of xylene to the above product, stir and mix for 15 minutes, then filter to obtain the filtrate, transfer the filtrate to a rotary evaporator, and concentrate by rotary evaporation at 90°C for 50 minutes. To obtain the concentrated solution, take 40 g of zirconium boride and put it into a pulverizer to pulverize for 40 minutes to obtain zirconium boride powder, add the zirconium boride powder, concentrated solution, and 200 mL of deionized water into a beaker, stir and mix for 20 minutes, and obtain a binder; In terms of part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com