Lithium iron phosphate anode material and its preparing method

A positive electrode material, lithium iron phosphate technology, applied in the direction of electrode manufacturing, chemical instruments and methods, lithium compounds, etc., can solve the problems of low conductivity and tap density of lithium iron phosphate, improve the discharge platform, facilitate industrialization, and discharge good performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Weigh ferrous oxalate, diammonium hydrogen phosphate and lithium hydroxide according to the mass ratio (4.3:3.1:1) and place them in an agate ball mill jar, add 12 g of ethanol as a lubricant, and ball mill for 36 hours at 175 r / min. Then put the ball-milled mixture into a tube furnace and feed it with argon as an inert protective gas, first raise the temperature to 350°C at room temperature at a rate of 5°C / min and calcinate for 10h, and then at 5°C / min The heating rate is raised to 650 °C and calcined for 24 hours, and finally cooled to room temperature to obtain pure lithium iron phosphate, and its conductivity was measured to be 3.76×10 -7 s cm -1 , the tap density is 0.60g·cm -3 .

[0023] Weigh 2.475g lithium iron phosphate (LiFePO 4 ) and 0.025g calcium boride (CaB 6 ), adding 5g of ethanol as a lubricant, milling at a ball milling speed of 175r / min for 10h, then heating up to 650°C at a heating rate of 5°C / min and calcining for 10h, and cooling to room tempe...

Embodiment 2

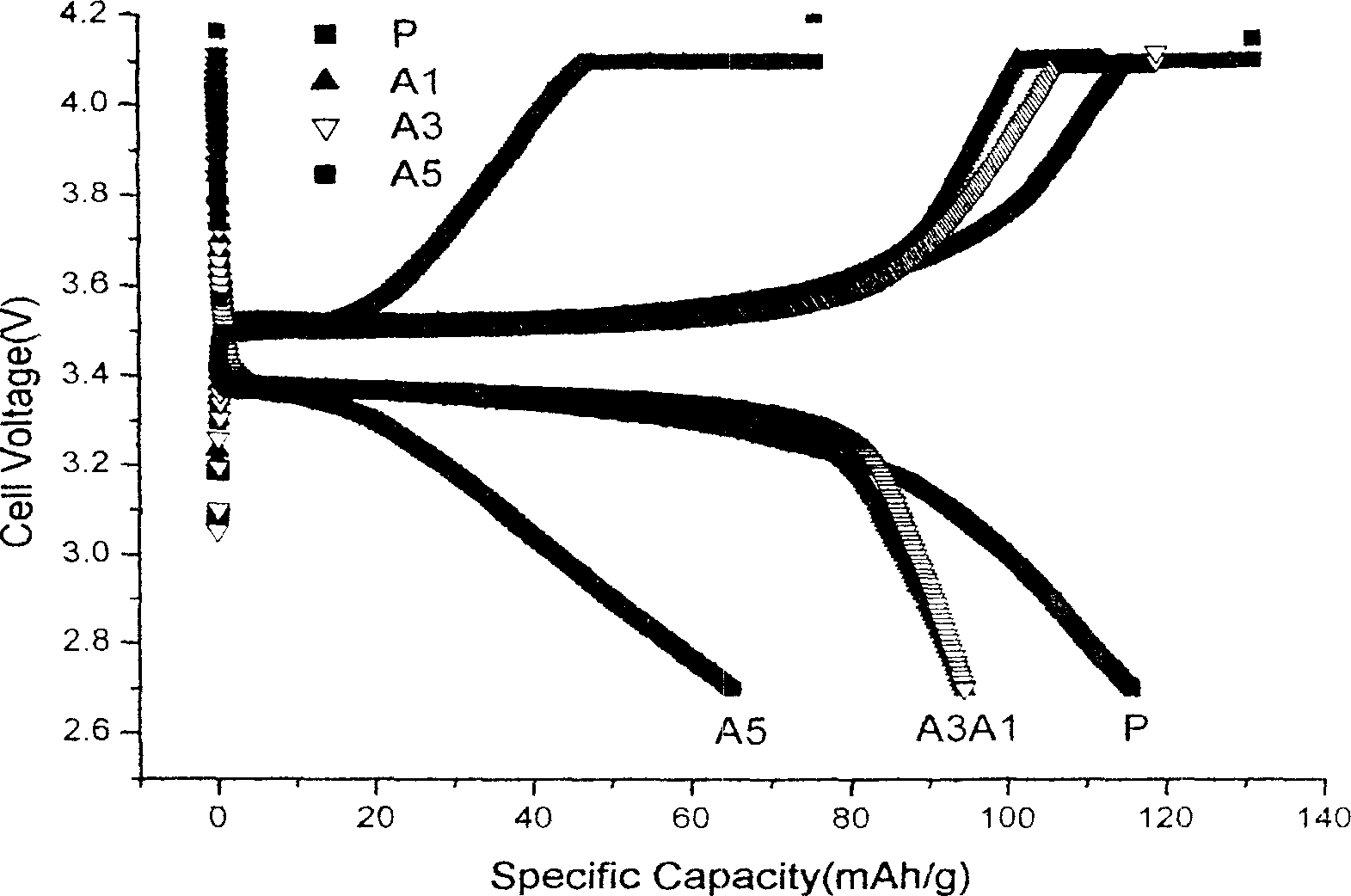

[0025] The synthesis method of lithium iron phosphate with 3% calcium boride added is the same as in Example 1, except that the quality of calcium boride is changed to 0.075g, and the product A3 containing 3% calcium boride can be obtained. And conduct conductivity and tap density measurements on A3, the values are 2.15×10 -3 s cm -1 and 0.99g cm -3 . Compared with pure lithium iron phosphate, it can be seen that after adding 3% calcium boride, the electrical conductivity has been improved by 4 orders of magnitude, and the tap density has been improved by 65% (see Table 1 and figure 1 ).

Embodiment 3

[0027] Weigh 0.125g calcium boride and 2.375g lithium iron phosphate, its synthetic method is the same as embodiment 1, finally obtain the lithium iron phosphate product A5 that adds 5% calcium boride, its electrical conductivity and tap density value are respectively 2.80×10 -4 s cm -1 and 0.84g cm -3 . Compared with pure lithium iron phosphate, the conductivity has been improved by 3 orders of magnitude, and the tap density has been improved by 40% (see Table 1 and figure 1 ).

[0028] It can be seen from the above examples that after a comprehensive comparison of the performance of lithium iron phosphate after calcium boride is added, when 1 to 3% calcium boride is added, lithium iron phosphate should have the largest tap density and the highest electrical conductivity, and The material performance is excellent, and the discharge platform is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com