Method for identifying structure and composition of non-rubber component in natural rubber through thermogravimetry-PGC (pyrolysis gas chromatography)-MS (mass spectrum)

A technology for pyrolysis gas chromatography and natural rubber, which is applied in the field of identification of molecular structure and composition, and can solve the problems of failing to fully reflect the actual composition of acetone solubles and the large influence of chromatographic peaks, achieving information integrity and timeliness sexually superior effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation of the present invention will be further described below in conjunction with the examples and drawings, but the implementation of the present invention is not limited thereto.

[0028] 1. Use acetone to extract raw natural rubber for 72 hours, then rotary steam at 70°C for 10 minutes, and finally dry in an oven at 60°C for 10 hours to obtain concentrated acetone-soluble AS.

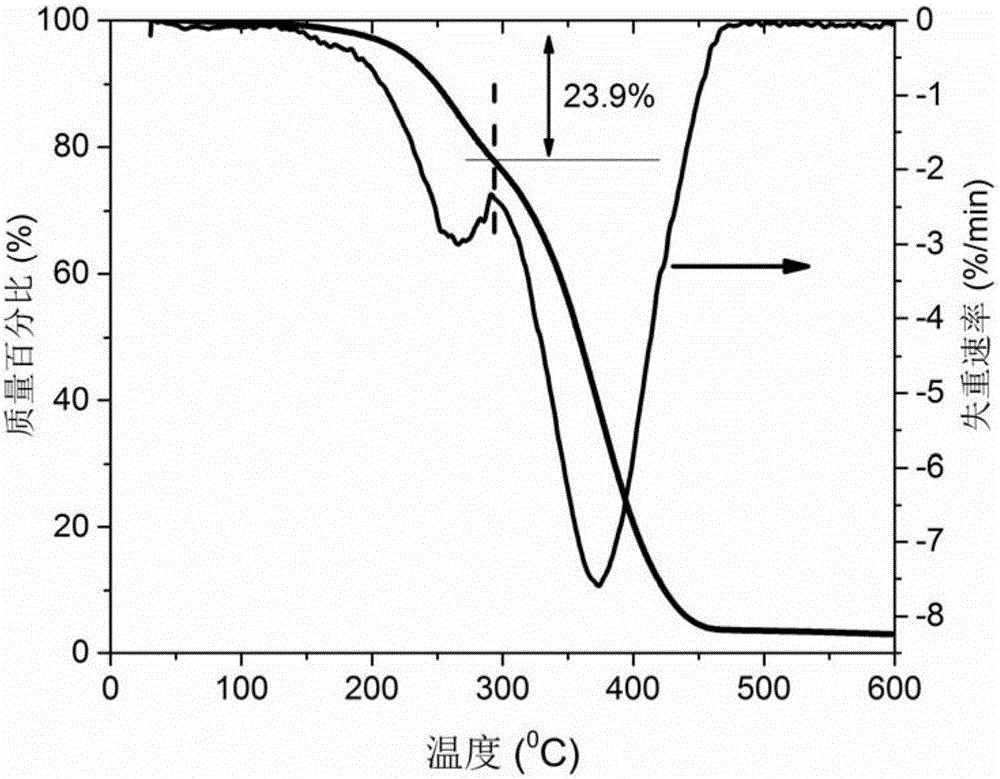

[0029] 2. Take 5 mg of acetone soluble matter AS, and conduct thermogravimetric analysis under a nitrogen atmosphere. The temperature range is 30°C to 600°C, and the heating rate is 20°C / min. The thermogravimetric curve of AS (WF-AS) is obtained, which shows obvious The two thermogravity steps of , such as figure 1 shown.

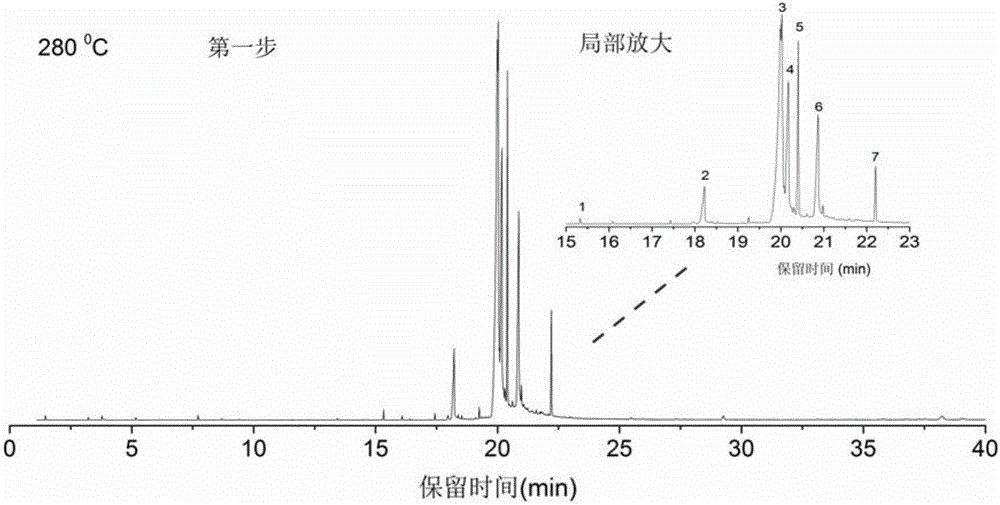

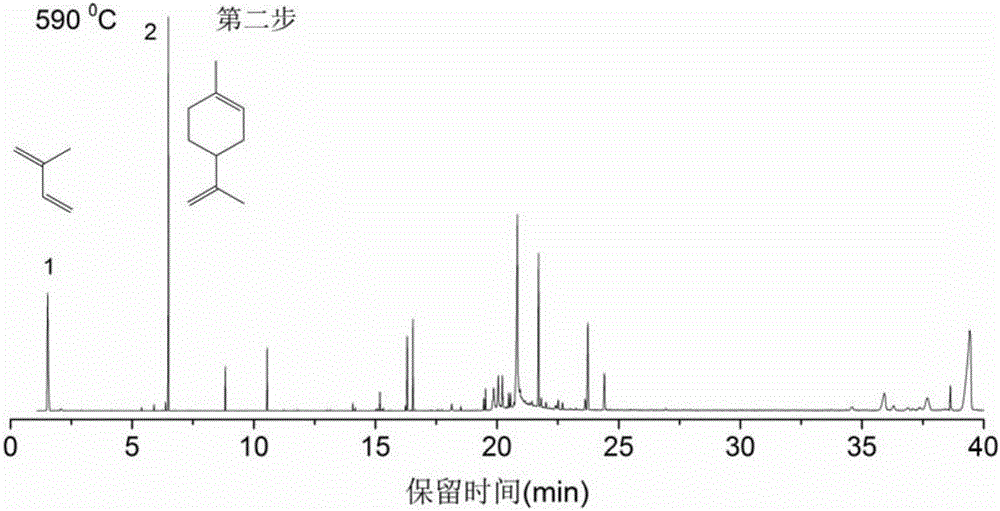

[0030]3. In view of the two obvious weight loss steps presented in the AS thermogravimetric curve, a two-step cracking method was further used to analyze the mixture. The JHI-07Hybrid Curie point cracker is directly connected to the inlet of the HP ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com