High-color gamut LED backlight source and processing method thereof

A technology of LED backlight and processing method, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of reducing high voltage and achieve the effect of improving color reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

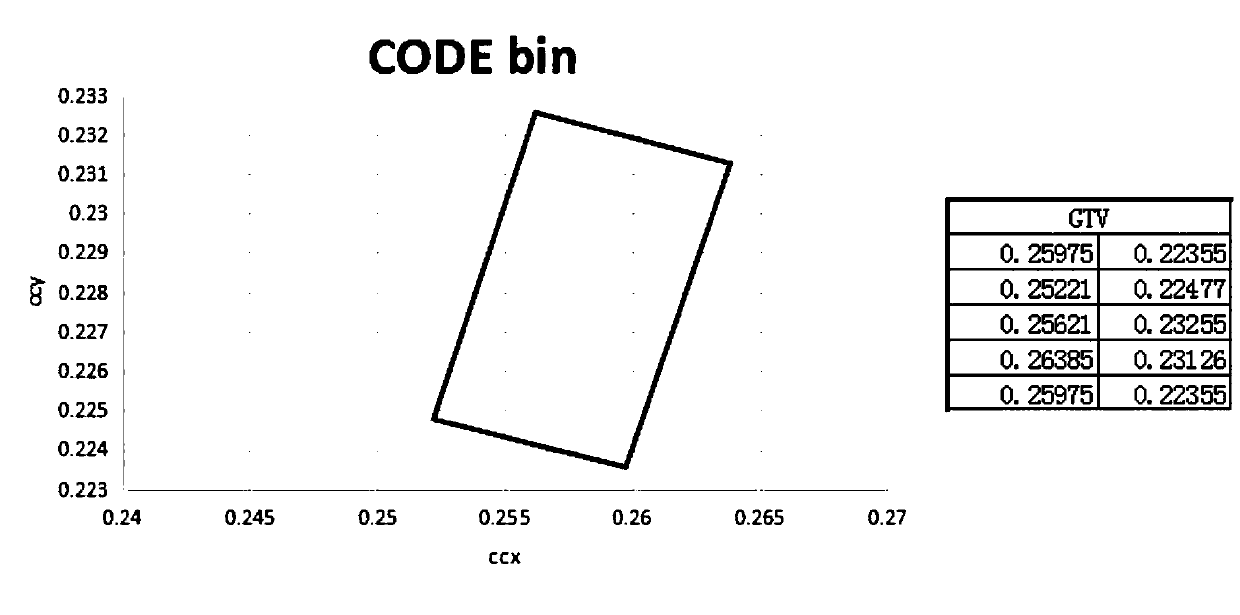

[0030] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

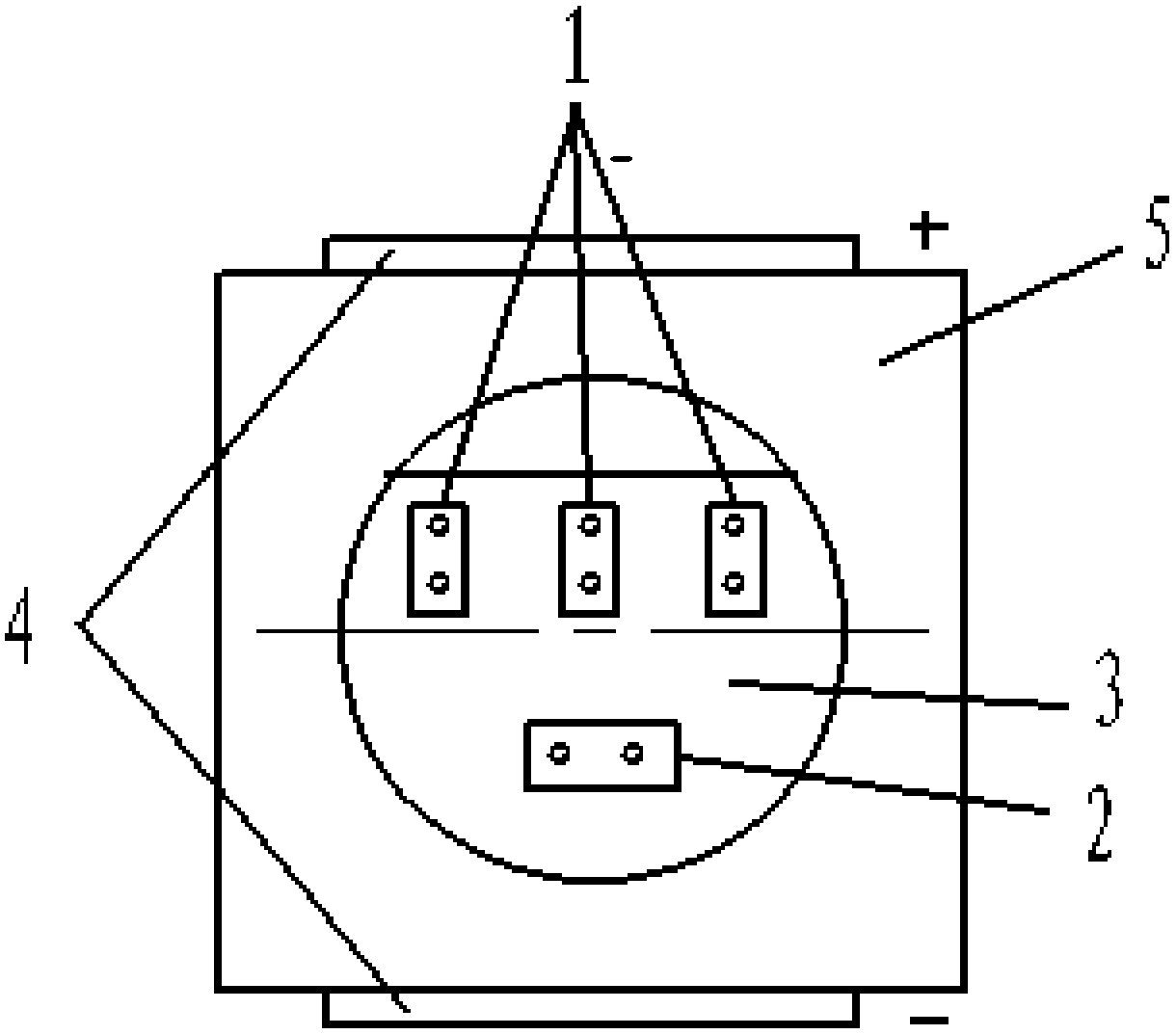

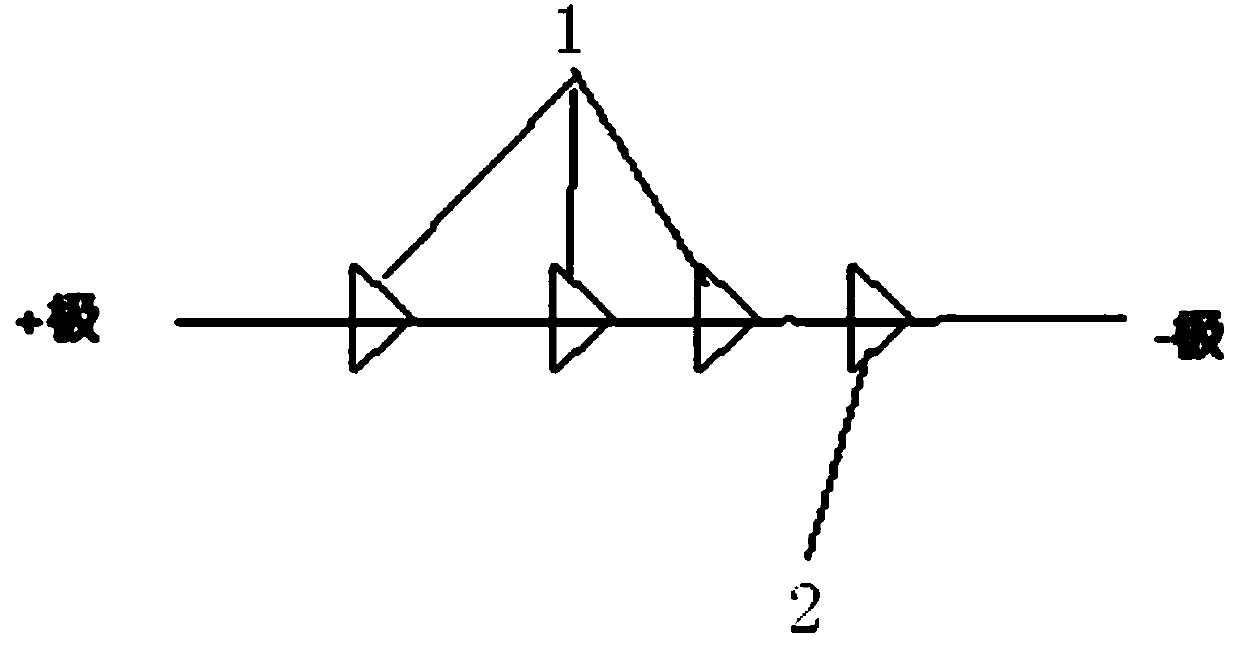

[0031] A high color gamut LED backlight, such as figure 1 As shown, it includes an SMC support, on which a UV LED chip and several blue LED chips are arranged in series; the LED chip after series connection is connected with the pin 4 of the positive and negative electrodes of the SMC support by gold wire bonding technology; Fluorescent glue is attached to the wafer, and the fluorescent glue is made of yellow-green powder, KSF red powder and glue.

[0032] Specifically, there is one UV LED chip, and a UV LED chip with a wavelength of 390-395 nm is used.

[0033] There are three blue LED chips, and blue LED chips with a wavelength of 445-450nm are used.

[0034] The UV LED chip and the blue LED chip are fixed on the SMC bracket by a crystal-bonding glue, and the crystal-bonding glue is insulating glue or silver glue.

[0035] The ratio of yellow-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com