Rotaryshaft gas-supply rotor engine

A technology of a rotary engine and a rotating shaft, which is applied to machines/engines, mechanisms that generate mechanical power, and mechanical equipment, etc., can solve problems such as fuel consumption, pollution, and complex structural design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

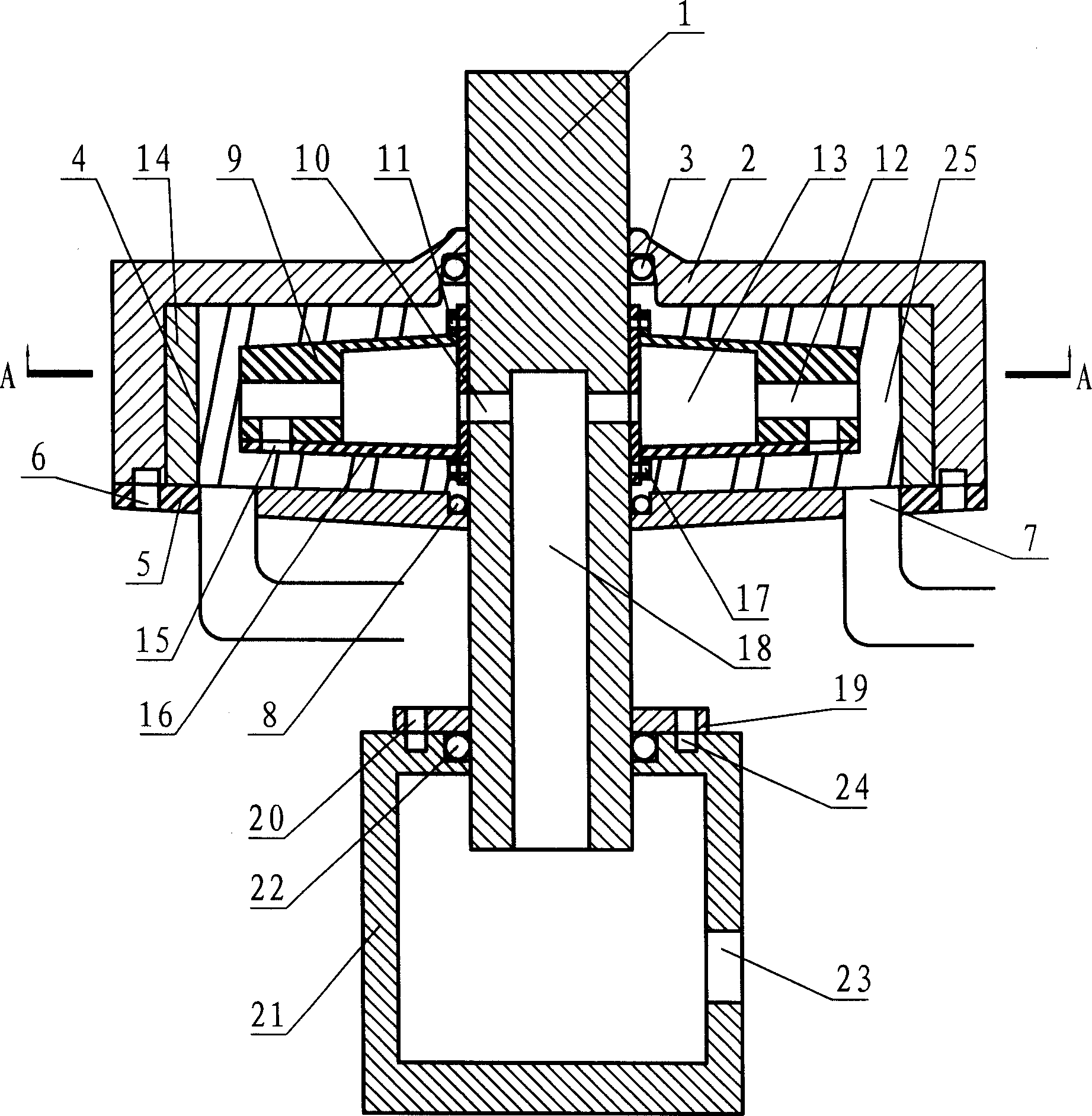

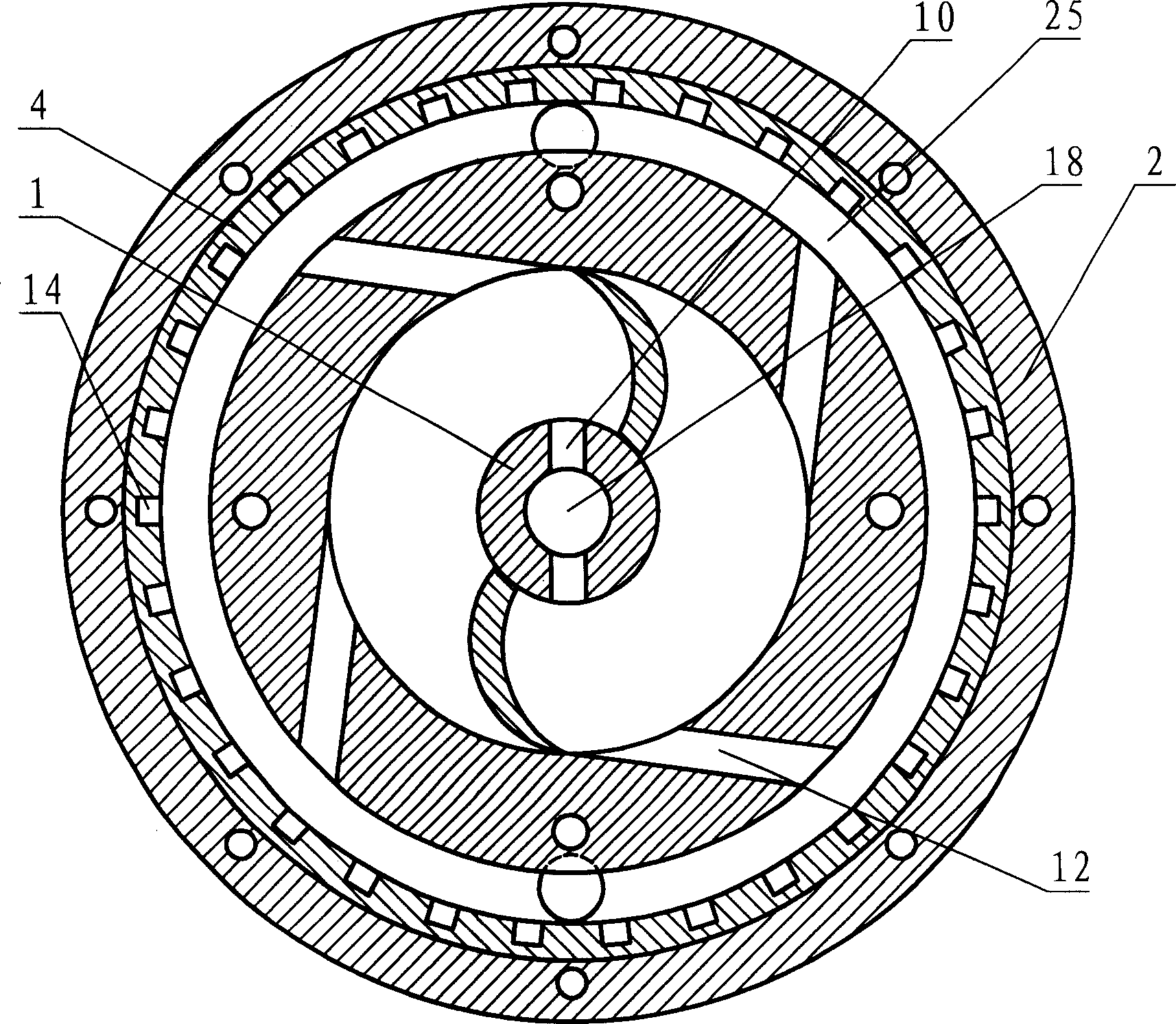

[0012] Referring to accompanying drawing: in the embodiment that accompanying drawing provides, the concrete technical scheme that the present invention adopts is as follows:

[0013] The rotary shaft gas supply rotor engine includes a rotary shaft 1 and an air supply cabin 21; wherein: the rotary shaft has an axial air intake channel 18 and a radial air guide hole 10 communicating with the gas supply cabin, and the rotary shaft is installed on the stator through a sealed bearing seat 3 In the air chamber, there is a rotor air chamber 13 fixed to the rotating shaft in the stator air chamber 25, and the rotor air chamber has an air inlet to communicate with the radial air guide hole, and the rotor air chamber has air nozzles distributed in the same tangential direction; The chamber has an exhaust hole 7 communicating with the exhaust chamber.

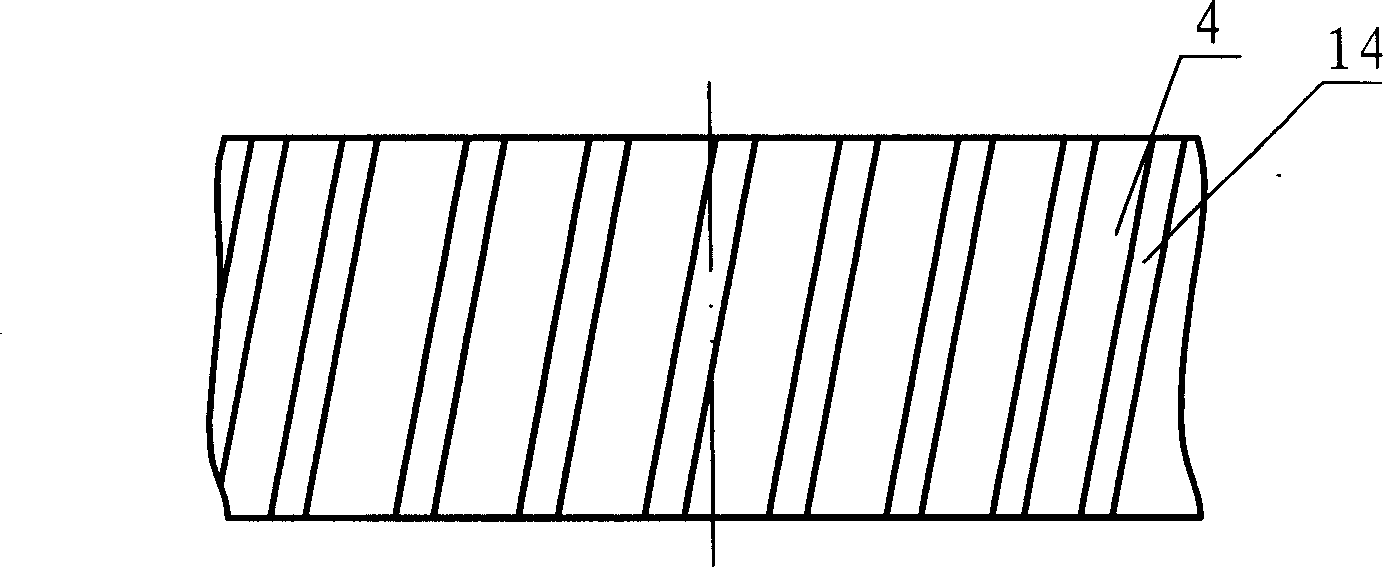

[0014] In the embodiment shown in the drawings, in order to facilitate processing, the rotor air chamber 13 is composed of the fixed co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com