In-situ micro-nanometer mechanics testing and scoring machining integrated machine

A micro-nano, all-in-one technology, applied in nanotechnology, testing material hardness, etc., can solve the problems of restricting the rapid development of in-situ nanoindentation testing technology, and achieve the effect of compact structure, improved processing quality, and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

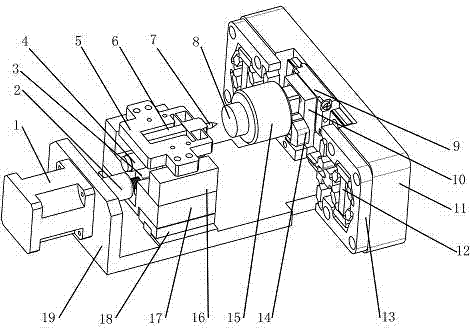

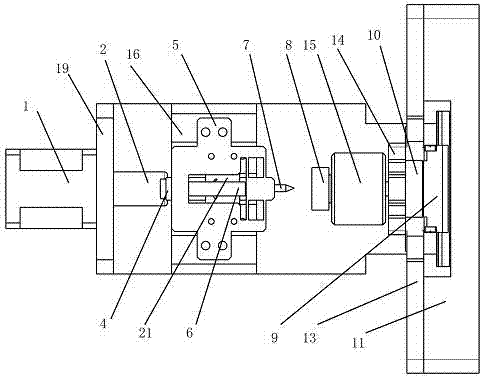

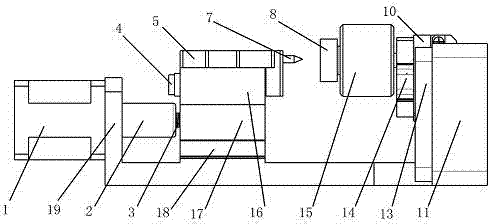

[0017] The detailed content and specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0018] See Figure 1 to Figure 4 , The in-situ micro-nano mechanical testing and scribing integrated machine of the present invention includes a stepping motor 1, a coupling 2, a screw nut 3, a precision displacement sensor 4, a flexible hinge a5, a piezoelectric stack a6, a diamond pressure Head 7, stage 8, precision rail slider a9, mover 10, tailstock 11, piezoelectric stack b12, flexible hinge b13, flexible hinge c14, precision force sensor 15, transition block 16, connector a17, precision The guide rail slider b18, the base 19, the piezoelectric stack c20 and the connecting piece b21, in which the diamond indenter 7 is fastened to the front end of the flexible hinge a5 by screws, and the flexible hinge a 5 is fixed and installed on the transition block 16 by screws, with precise displacement The sensor 4 is fixedly ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com