Preparation method for nanoscale rare earth oxide powder

A rare earth oxide, nano-scale technology, applied in rare earth metal compounds, chemical instruments and methods, nanotechnology and other directions, can solve the problems of high equipment requirements, inability to large-scale production, poor process controllability, etc., and achieve uniform nano-powder. , with market competitiveness and high washing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

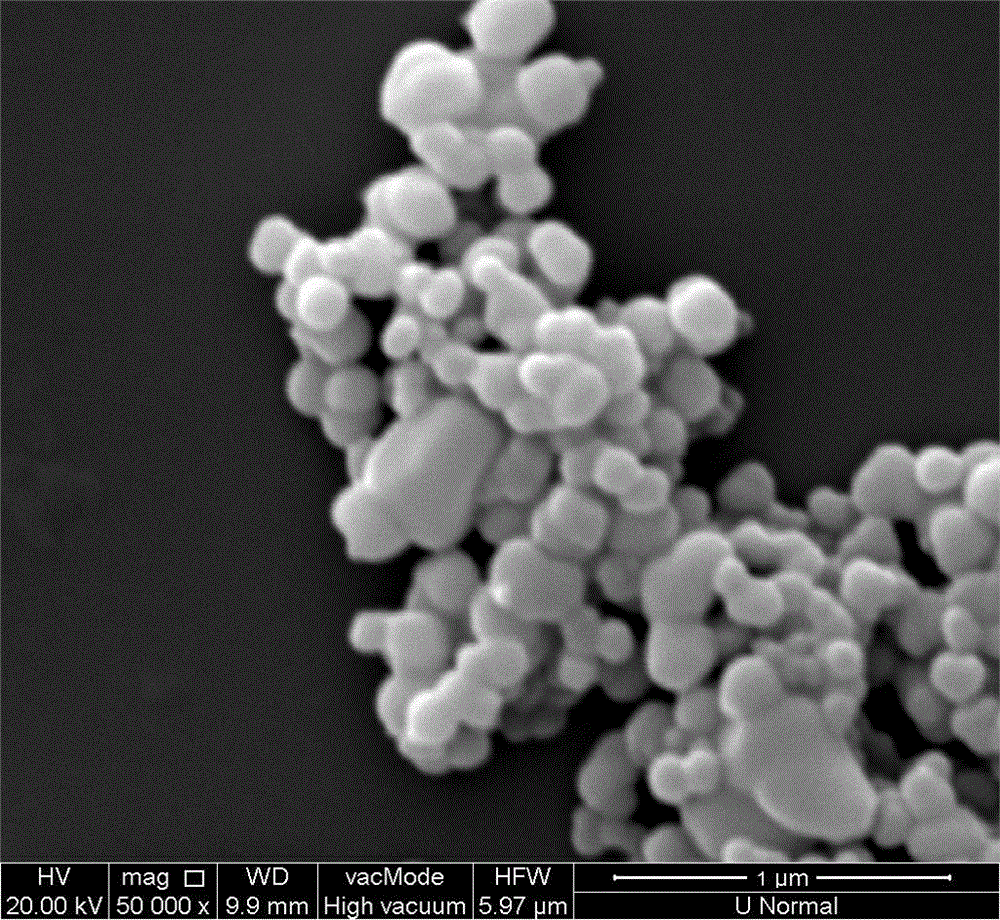

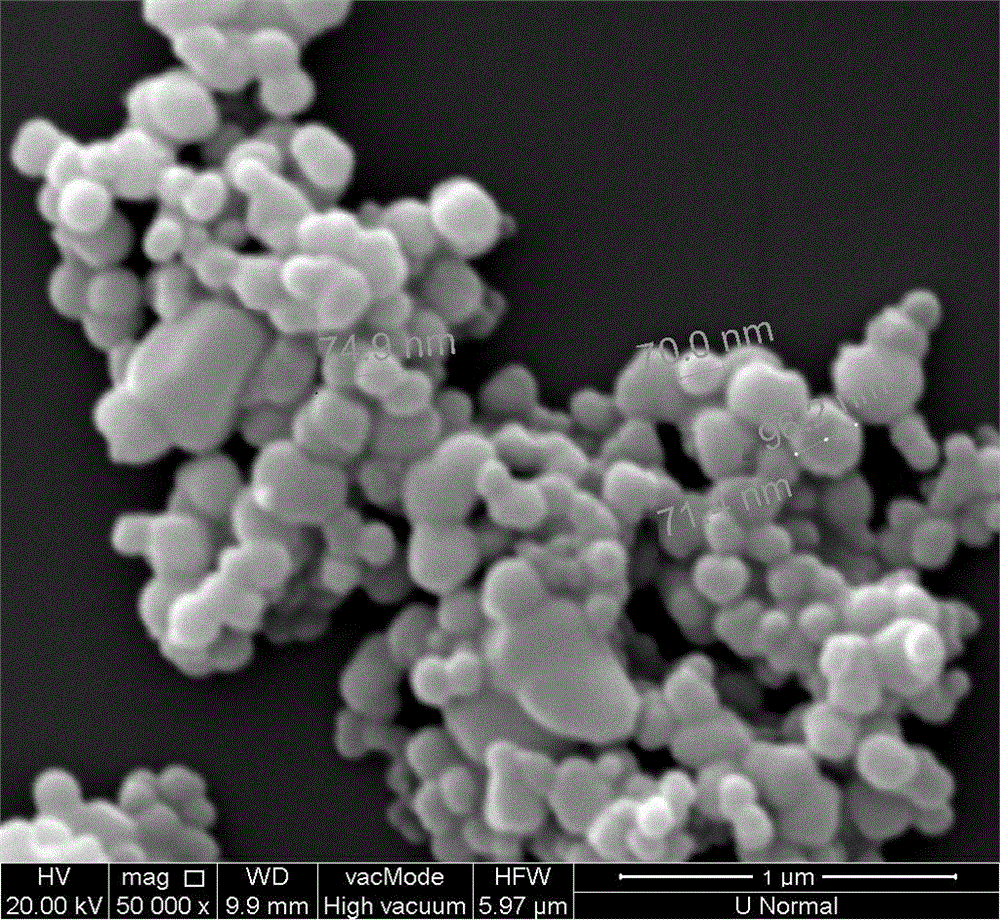

Image

Examples

Embodiment 1

[0037] a. In the hydrochloric acid medium, prepare a feed solution with a cerium oxide content of 1mol / L, and add an inorganic dispersant with 1% cerium oxide weight in a stirred state; Prepared with 5 parts of aluminum chloride, 30 parts of sodium fluoride and 30 parts of sodium hydroxide;

[0038] b. Slowly heat up to 100°C while stirring, and add sodium carbonate with a molar concentration of 2mol / L as a precipitant to precipitate until the reaction is complete;

[0039] c. At the end of the precipitation reaction, add a grain growth inhibitor of 1% by weight of ceria in step a, and age for 0.5h; the inorganic grain growth inhibitor component is, in parts by weight, ammonium dihydrogen phosphate 13 20 parts of ammonia water are prepared;

[0040] d. Wash four times, and the clarification time during the washing process is less than 30 minutes. After washing, filter with a vacuum filter funnel, and dry the filtrate at 100-150°C to obtain a loose nano-powder precursor;

[0...

Embodiment 2

[0044] a. In the hydrochloric acid medium, prepare a feed liquid with a lanthanum oxide content of 1.5mol / L, and add an inorganic dispersant with 3% of the weight of lanthanum oxide under stirring; the inorganic dispersant component is polymerized chlorine It is prepared by 15 parts of aluminum chloride, 50 parts of sodium fluoride and 50 parts of sodium hydroxide;

[0045] b. Slowly heat up to 60°C while stirring, and add ammonium bicarbonate with a molar concentration of 3mol / L as a precipitant to precipitate until the reaction is complete;

[0046] c. At the end of the precipitation reaction, add a grain growth inhibitor of 2% by weight of lanthanum oxide in step a, and age for 0.6h; the inorganic grain growth inhibitor component is 30 parts by weight of ammonium dihydrogen phosphate , prepared from 85 parts of ammonia water;

[0047] d. Wash four times, and the clarification time during the washing process is less than 30 minutes. After washing, filter with a vacuum filte...

Embodiment 3

[0051] a. In the nitric acid medium, prepare a feed liquid with a cerium oxide content of 0.6mol / L, and add an inorganic dispersant with 4% cerium oxide weight in a stirring state; the inorganic dispersant component is in parts by weight, as Prepared by 10 parts of polyaluminium chloride, 40 parts of sodium fluoride and 40 parts of sodium hydroxide;

[0052] b. Slowly heat up to 80°C while stirring, and add ammonium carbonate with a molar concentration of 2mol / L as a precipitant to precipitate until the reaction is complete;

[0053] c. At the end of the precipitation reaction, add a grain growth inhibitor of 1% by weight of ceria in step a, and age for 0.4h; In parts by weight, it is prepared from 20 parts of ammonium dihydrogen phosphate and 40 parts of ammonia water;

[0054] d. Wash four times, and the clarification time during the washing process is less than 30 minutes. After washing, filter with a vacuum filter funnel, and dry the filtrate at 100-150°C to obtain a loos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com