Flame retardant composition having improved processability, flame-retardant synthetic resin composition, and molded article of the flame-retardant synthetic resin composition

A technology for synthetic resins and compositions, applied to the field of flame retardant compositions with improved processability, flame-retardant synthetic resin compositions, and molded products thereof, capable of solving problems such as reduced mechanical strength, reduced productivity, and poor appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] [Preparation of flame retardant composition]

[0078] 50 parts by mass of piperazine pyrophosphate (nitrogen atom of piperazine: phosphorus atom of pyrophosphoric acid = 1:1) (component (A)) and melamine pyrophosphate (nitrogen atom of melamine: phosphorus atom of pyrophosphoric acid = 3:1 ) (component (B)) 50 parts by mass was put into a jet mill (manufactured by Seishin Co., Ltd.: Co-JET System α-mkIII), and pulverized at room temperature with a nozzle pressure of 0.8 mPa and a supply rate of 500 g / hour to obtain a flame retardant powder . 1.2 parts by mass of dimethyl silicone oil (component (C); manufactured by Shin-Etsu Chemical Co., Ltd., product name KF-96) and 0.7 parts by mass of glyceryl monostearate (component (D)) were added to the obtained flame retardant powder For 10 minutes, the flame retardant composition powder of the present invention was obtained using an FM mixer (manufactured by Mitsui Mining Co., Ltd.: FM20C / I) at 120° C. at a rotation speed of 2...

Embodiment 2~8

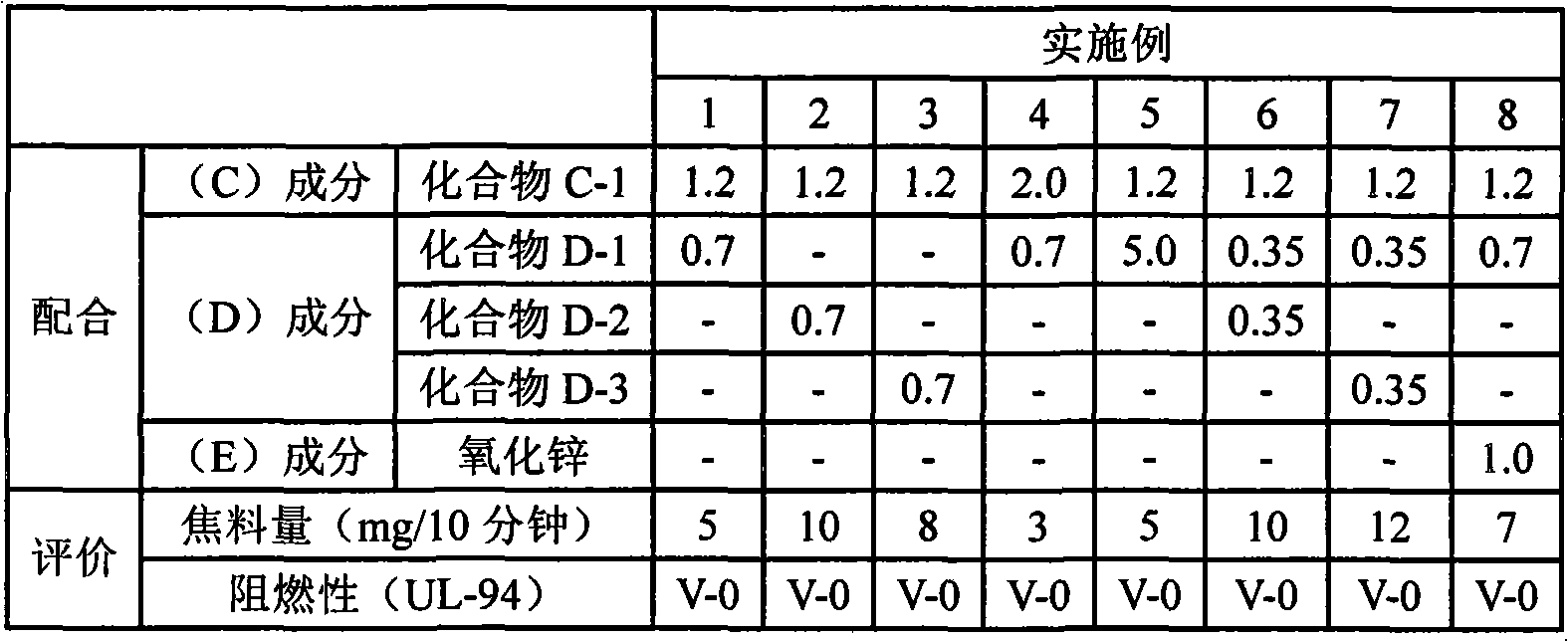

[0083] Fix 50 parts by mass of piperazine pyrophosphate ((A) component) and 50 parts by mass of melamine pyrophosphate ((B) component), change the compounding amounts of (C) component and (D) component to the following [Table 1], Other than that, a flame retardant composition and a flame retardant synthetic resin composition were prepared and evaluated under the same conditions as in Example 1 above. The results are shown together in [Table 1].

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com