Ultraviolet-yellowing-resistant halogen-free flame-retardant thermoplastic elastomer composition and preparation method thereof

A thermoplastic elastomer, UV-resistant technology, used in the field of flame-retardant materials and flame-retardant compositions, can solve the problems of unsatisfactory yellowing resistance, unable to meet the long-term use of light-colored or white products without discoloration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation method of the piperazine polyphosphate modified by metal ion comprises the steps:

[0034] 1. Salt forming step: put piperazine into the reaction vessel, slowly add polyphosphoric acid (P 2 o 5 The mass percentage is 79.5~86.8%), the mol ratio of the phosphorus atom in the system and piperazine is about 1.6-3:1 at this moment; The oxazine molar ratio is 0.05-0.1:1, continue to heat up to 140-150°C and react for 2-3 hours, then cool and pulverize to obtain the primary product of metal ion-modified piperazine polyphosphate;

[0035] 2. Polycondensation step: Heat the primary product of metal ion-modified piperazine polyphosphate under nitrogen protection to 190-210°C for 3-4 hours, cool and pulverize to obtain metal ion-modified piperazine polyphosphate, whiteness ≥95, the particle size D50 is 1.0-3.0μm, and the D98 is 7.0-18.0μm. It is a flame retardant and can be used to prepare halogen-free flame-retardant compositions. The addition amount is 25-40wt%...

Embodiment 2

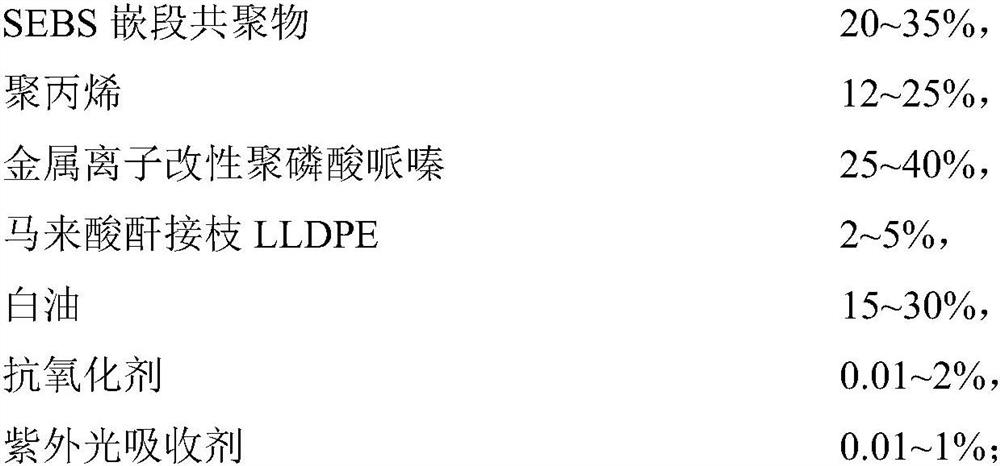

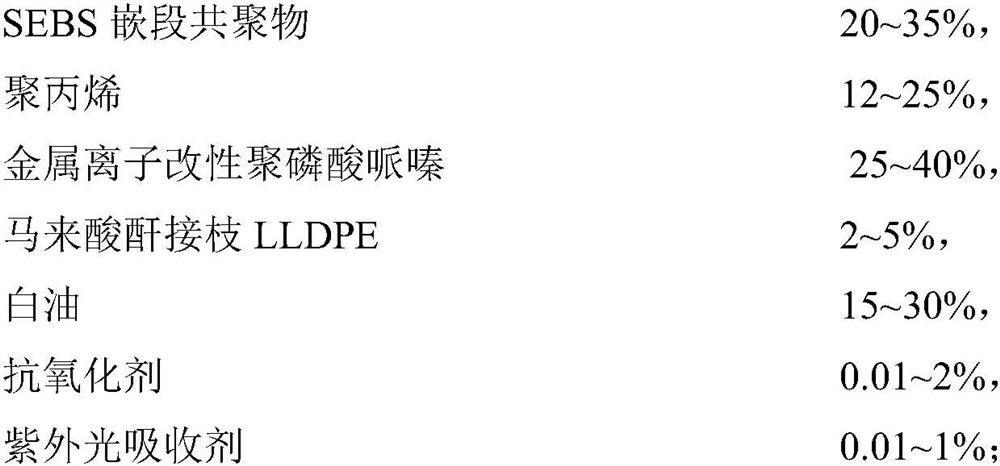

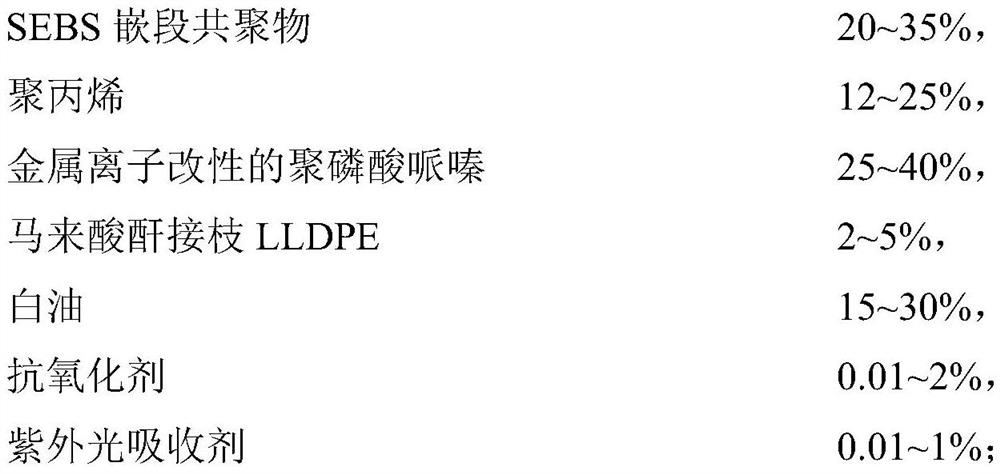

[0037] A halogen-free flame-retardant thermoplastic elastomer composition resistant to ultraviolet yellowing, its raw materials include the following components by mass percentage:

[0038]

[0039] Among them, the metal ion-modified piperazine polyphosphate is mixed with a coupling agent (such as KH550) in a kneader at 90-110° C., cooled and pulverized, and sieved with 200 meshes for use. The feeding ratio of the coupling agent is 0.5wt% of the flame retardant. The above raw materials are put into a twin-screw extruder in proportion, and the halogen-free flame-retardant thermoplastic elastomer composition is obtained after extruding water-cooled strands and pelletizing. The twin-screw processing temperature is 180°C to 200°C, and the aspect ratio is 44:1. For other forms of flame retardants, those skilled in the art can make adaptive changes under the existing technology and teaching.

[0040]Among them, the molecular structure of the SEBS block copolymer is linear, the ...

Embodiment 3

[0048] Salt formation: Put 8.62Kg of piperazine into the horizontal reactor, slowly add polyphosphoric acid (P 2 o 5 Mass fraction = 84.03%) 17.32Kg, keep the temperature at 55±10°C, stir and react for 0.5 hours, add 0.81Kg of zinc oxide and stir evenly, heat up to 140-150°C, continue to react for 3 hours, cool and pulverize to obtain zinc ion modified Primary piperazine polyphosphate;

[0049] Polycondensation: The primary product of zinc ion-modified piperazine polyphosphate was reacted for 3 hours at 210°C under the protection of nitrogen, cooled and pulverized to obtain zinc ion-modified piperazine polyphosphate halogen-free flame retardant.

[0050] Product morphology description: whiteness 97, particle size D50=2.7μm, D98=12μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com