High-fluidity anti-separation-out halogen-free flame retardant and preparation method and application thereof

A high fluidity, flame retardant technology, used in the field of flame retardant compositions, can solve problems such as reducing production efficiency, affecting appearance, affecting resin dispersion, etc., to solve the problem of poor dispersion and compatibility, and improve product appearance. , the effect of reducing the difficulty of selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The preparation process of the above-mentioned high fluidity precipitation-resistant halogen-free flame retardant is as follows:

[0055] (1) Preparation of the powder body of the halogen-free flame retardant:

[0056] Put piperazine phosphate, melamine and its derivatives and inorganic metal zinc compound into a 300L high-speed mixer with a preheating temperature of 80-120°C according to the formula, mix at a low speed of 250-600rpm for 5-30min, remove the moisture in the material, and then Turn to high speed 800~1200rpm and mix to obtain the powder body of the halogen-free flame retardant;

[0057] (2) Preparation of surface treatment agent:

[0058] Dispersing lubricants into silicone oils to obtain the surface treatment agent;

[0059] (3) Preparation of halogen-free flame retardant:

[0060] Add the prepared surface treatment agent into the high-speed mixer equipped with the powder body of the halogen-free flame retardant by spraying or dropping, at a temperatur...

Embodiment 1

[0078] A high-fluidity, precipitation-resistant, halogen-free flame retardant. Its raw material formula is shown in Table 1. The preparation process is to put piperazine phosphate, melamine and its derivatives, and metal zinc compounds in proportion to the preheating temperature. In a 300L high-speed mixer at 120°C, mix at a low speed of 475rpm for 10 minutes to remove the moisture in the material (the water content is reduced to less than 0.1%), then turn to a high speed of 1000rpm and mix the silicone oil dispersed with a lubricant through a spray device. Spray into the kettle, mix at high speed for 15 minutes, then cool, and discharge to obtain a well-mixed and surface-treated compound flame-retardant system. The obtained powder and material test results are shown in Table 1; the silicone oil used in this example has a viscosity of 50mPa. s.

Embodiment 2

[0080] The implementation process is the same as that of Example 1, except that the preheating temperature of the 300L kettle is 150° C., and the high-speed mixing time is 5 minutes during the surface treatment process except for compounding the flame retardant. See Table 1 for other materials and their proportions, and see Table 1 for the test results of the obtained powder and materials. The silicone oil used in this example has a viscosity of 60 mPa·s.

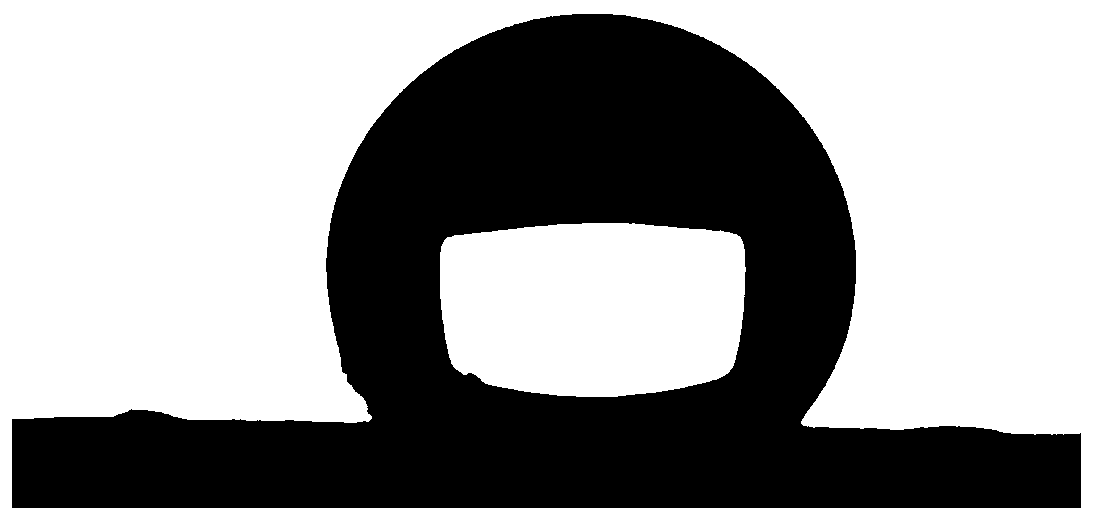

[0081] The hydrophobicity of the surface treatment flame retardant obtained in this embodiment is tested, and the contact angle photo of the halogen-free flame retardant is obtained, as figure 1 As shown, it is found that distilled water is distributed in the form of water droplets on the surface of the flame retardant powder, and the contact angle is 160°, which shows that the hydrophobicity of the powder is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com