Preparation method of intumescent flame retardant based on piperazine pyrophosphate/melamine cyanurate/ammonium polyphosphate

A technology of melamine cyanurate and intumescent flame retardant, which is applied in the field of preparation of new intumescent flame retardants, can solve problems such as low production efficiency and inability to realize continuous production, and achieve improved production efficiency, novel structure, The effect of precise formula ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

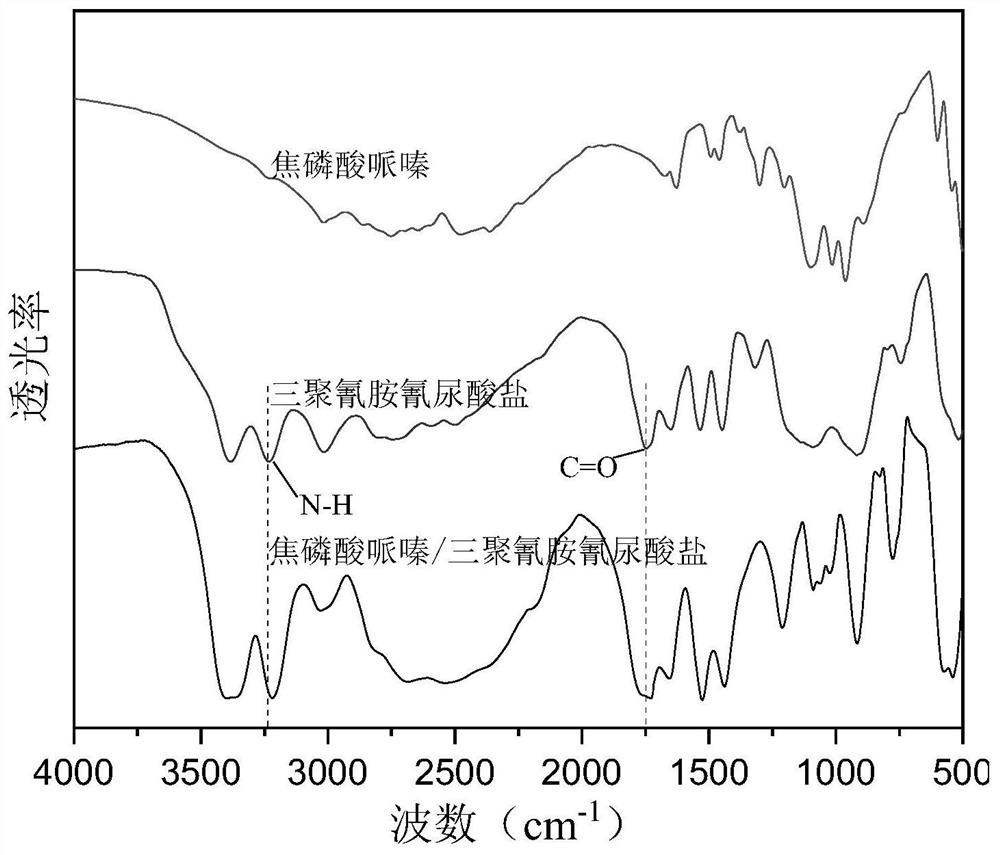

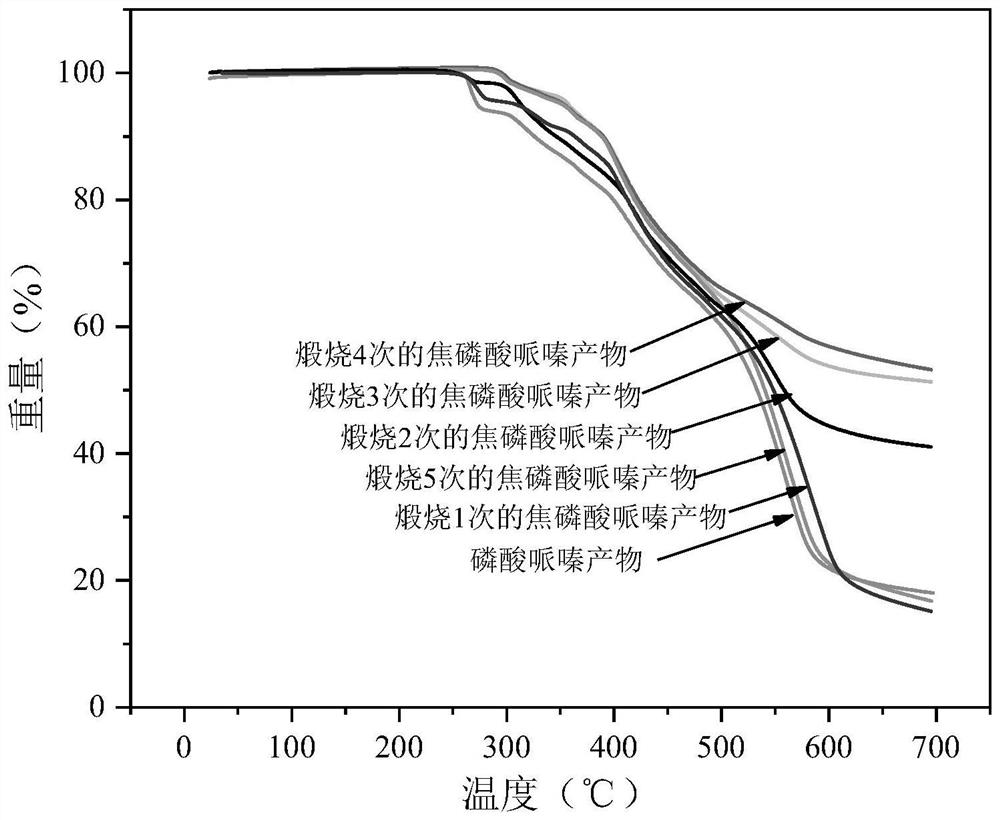

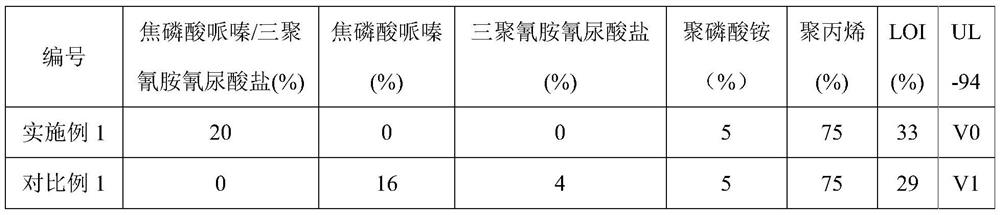

[0025] Using phosphoric acid and anhydrous piperazine as raw materials, weigh the molar ratio of phosphoric acid and anhydrous piperazine to be 2.3:1, add anhydrous piperazine to 85wt% phosphoric acid aqueous solution, heat to 80°C, and fully stir for 4 hours , and finally the piperazine phosphate was obtained through the steps of ice bath, standing, and drying. Put the prepared piperazine phosphate into the crushing equipment for crushing, and crush the piperazine phosphate to an average particle size of 20 microns; place the crushed piperazine phosphate powder in the calcining equipment, and heat at 280°C under the protection of nitrogen 0.5 hours. The material obtained continues to be pulverized and calcined according to the above-mentioned steps, and the pulverization-calcination process is carried out 3 times to obtain piperazine pyrophosphate. After the prepared piperazine pyrophosphate and melamine cyanurate were mixed according to the weight ratio of 4:1, the mixture ...

Embodiment 2

[0034] Using phosphoric acid and anhydrous piperazine as raw materials, weigh the molar ratio of phosphoric acid and anhydrous piperazine to be 2.4:1, add anhydrous piperazine to 30wt% phosphoric acid aqueous solution, heat to 85°C, and fully stir for 2.5 hours , and finally the piperazine phosphate was obtained through the steps of ice bath, standing, and drying. Put the prepared piperazine phosphate into the crushing equipment for crushing, and crush the piperazine phosphate to an average particle size of 25 microns; place the crushed piperazine phosphate powder in the calcining equipment, and heat at 270°C under the protection of nitrogen 1 hour. The material obtained continues to be pulverized and calcined according to the above steps, and the pulverization-calcination process is carried out 4 times to obtain piperazine pyrophosphate. After the prepared piperazine pyrophosphate and melamine cyanurate were mixed according to the weight ratio of 4:1, the mixture was ball mi...

Embodiment 3

[0036] Using phosphoric acid and anhydrous piperazine as raw materials, weigh the molar ratio of phosphoric acid and anhydrous piperazine to be 2.4:1, add anhydrous piperazine to 30wt% phosphoric acid aqueous solution, heat to 85°C, and fully stir for 2.5 hours , and finally the piperazine phosphate was obtained through the steps of ice bath, standing, and drying. Put the prepared piperazine phosphate into the crushing equipment for crushing, and crush the piperazine phosphate to an average particle size of 25 microns; place the crushed piperazine phosphate powder in the calcining equipment, and heat at 270°C under the protection of nitrogen 1 hour. The material obtained continues to be pulverized and calcined according to the above steps, and the pulverization-calcination process is carried out 4 times to obtain piperazine pyrophosphate. After the prepared piperazine pyrophosphate and melamine cyanurate were mixed according to the weight ratio of 4:1, the mixture was ball mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com