Halogen-free flame-retardation thermoplastic dynamic sulfurated ethylene-propylene-diene monomer rubber/polypropylene composition and preparation method thereof

A technology of polypropylene composition and EPDM rubber, which is applied in the field of thermoplastic dynamic vulcanized rubber preparation, can solve the problems of high melt viscosity of EPDM rubber, uneven dispersion of materials, difficulty in uniform dispersion, etc., and achieve excellent mechanical properties and flame retardant performance, the production process is simple and easy to operate, and the effect of reducing degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

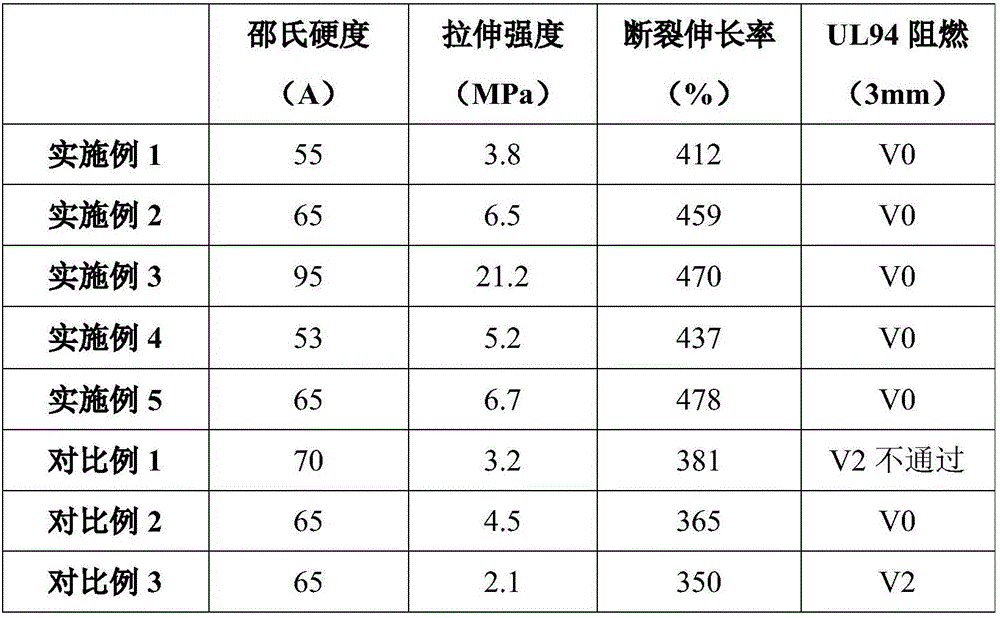

Examples

preparation example Construction

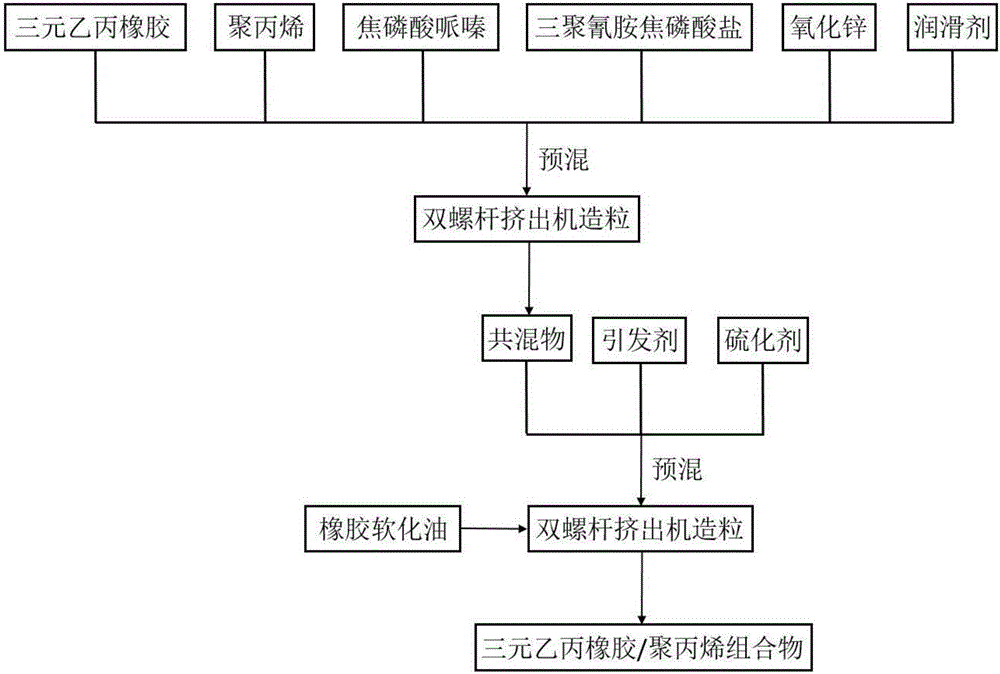

[0064] The preparation method of the halogen-free flame-retardant thermoplastic dynamically vulcanized EPDM rubber / polypropylene composition includes the following steps:

[0065] 1) Add EPDM rubber, polypropylene, piperazine pyrophosphate, melamine pyrophosphate, zinc oxide, EPDM rubber grafted maleic anhydride and lubricant into the high-speed mixer, and mix well;

[0066] 2) Transfer the mixed materials in step 1) to a twin-screw extruder, melt extrusion, and pelletize;

[0067] 3) Add the mixed materials, initiator and vulcanizing agent in step 2) into the high-speed mixer, mix them evenly, and then transfer the materials to the twin-screw extruder, add rubber softening oil, extrude, and granulate to obtain halogen-free resistance Thermoplastic dynamic vulcanization EPDM rubber / polypropylene composition.

[0068] Preferably, the screw length-to-diameter ratio L / D of the twin-screw extruder is (48-60):1, the screw speed is 200-280 rpm, and the extrusion temperature is 80-200°C.

[0...

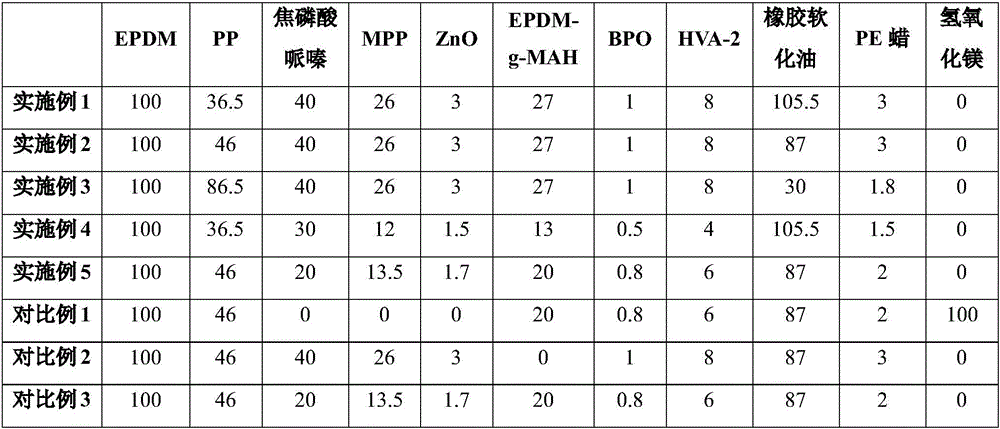

Embodiment 1

[0073] A halogen-free flame-retardant thermoplastic dynamically vulcanized EPDM rubber / polypropylene composition, the raw material composition of which is as follows (mass parts):

[0074] EPDM (2.3wt% diene, Mitsui Japan): 100 parts;

[0075] PP: 36.5 copies;

[0076] Flame retardant piperazine pyrophosphate: 40 parts;

[0077] Flame retardant melamine pyrophosphate (MPP): 26 parts;

[0078] Flame retardant synergist ZnO: 3 parts;

[0079] Compatibilizer EPDM-g-MAH: 27 parts;

[0080] Initiator BPO: 1 part;

[0081] Vulcanizing agent N, N'-m-phenylene bismaleimide (HVA-2): 8 parts;

[0082] Rubber softening oil: 105.5 parts;

[0083] Lubricant PE wax: 3 parts.

[0084] The preparation method of the halogen-free flame-retardant thermoplastic dynamically vulcanized EPDM rubber / polypropylene composition includes the following steps:

[0085] 1) Add EPDM, PP, flame retardant piperazine pyrophosphate, flame retardant MPP, flame retardant synergist ZnO, compatibilizer EPDM-g-MAH and lubricant PE wa...

Embodiment 2

[0090] A halogen-free flame-retardant thermoplastic dynamically vulcanized EPDM rubber / polypropylene composition, the raw material composition of which is as follows (mass parts):

[0091] EPDM (4.2wt% diene, ExxonMobil, USA): 100 parts;

[0092] PP: 46 parts;

[0093] Piperazine pyrophosphate: 40 parts;

[0094] MPP: 26 copies;

[0095] ZnO: 3 parts;

[0096] EPDM-g-MAH: 27 copies;

[0097] BPO: 1 copy;

[0098] HVA-2: 8 copies;

[0099] Rubber softening oil: 87 parts;

[0100] PE wax: 3 parts.

[0101] The preparation method of the halogen-free flame-retardant thermoplastic dynamically vulcanized EPDM rubber / polypropylene composition includes the following steps:

[0102] 1) Add EPDM, PP, flame retardant piperazine pyrophosphate, flame retardant MPP, flame retardant synergist ZnO, compatibilizer EPDM-g-MAH and lubricant PE wax into the high-speed mixer, and mix well;

[0103] 2) Transfer the mixed premix in step 1) to a parallel co-rotating twin-screw extruder, melt extrusion, and pelletize; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com