Flame retardant composition with enhanced fluidity, flame retardant resin composition and molding thereof

一种组合物、阻燃剂的技术,应用在无机磷类阻燃剂领域,能够解决不能使用等问题,达到耐吸湿性优良、阻燃性和电阻的持续性优良、分散性优良的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

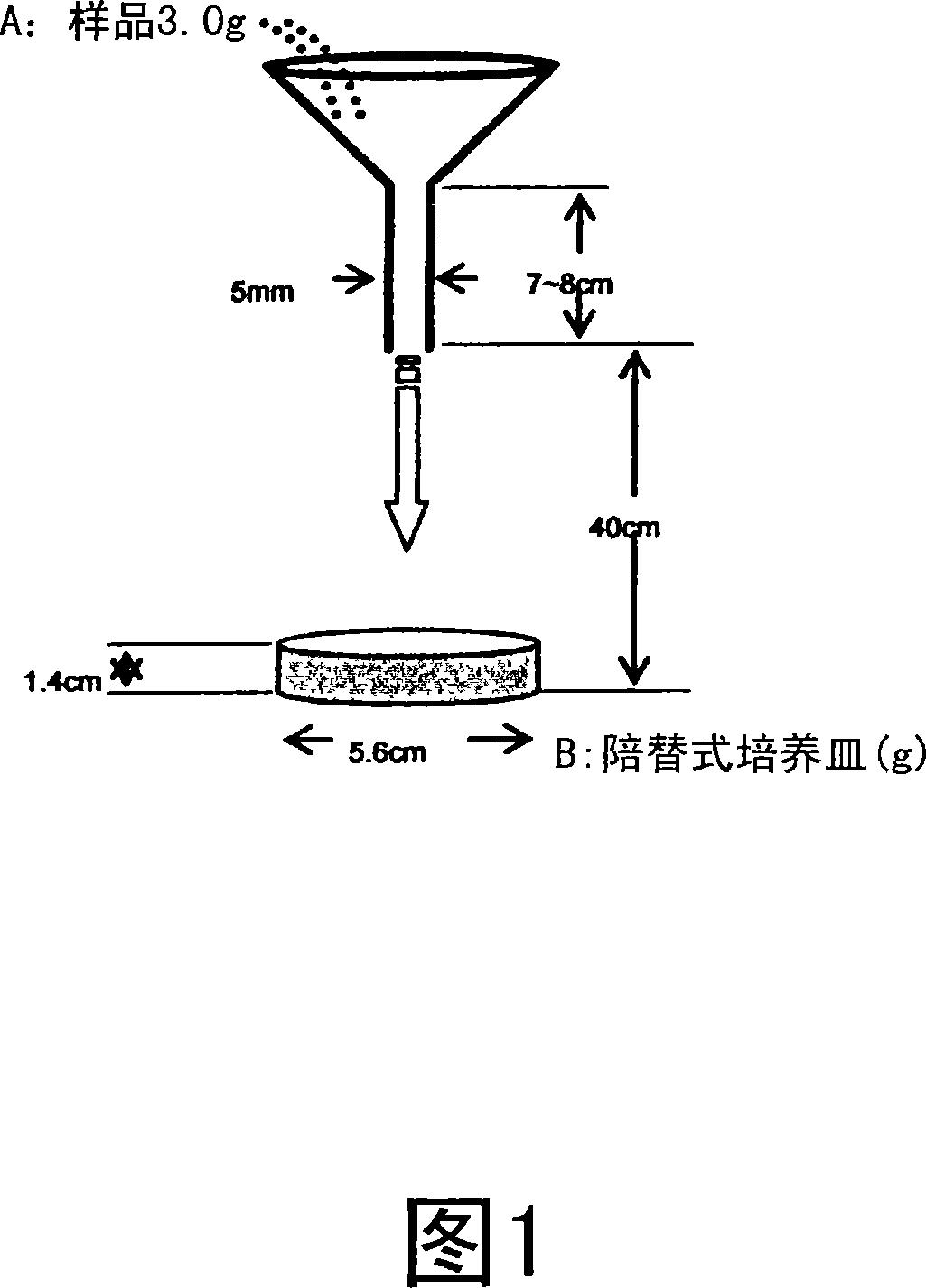

Image

Examples

Embodiment 1( Embodiment 1-1~1-4 and comparative example 1-1~1-3

[0055] Put 50 parts by weight of piperazine pyrophosphate (the molar ratio of piperazine and pyrophosphoric acid is 1:1) and 50 parts by weight of melamine pyrophosphate (the molar ratio of melamine and pyrophosphoric acid is 2:1) into the jet mill (manufactured by Seishin Co., Ltd.: Co-JET System α-mkIII), and pulverized at room temperature at a nozzle pressure of 0.8 mPA and a supply rate of 500 g / hour to obtain a flame retardant powder. The obtained powder and 1 part by weight of the surface treatment agent (see Table 1) were stirred at 120° C. at 2800 rpm for 10 minutes using a Henschel mixer (manufactured by Mitsui Seizan Co., Ltd.: FM20C / I) to obtain a silicone oil-coated flame retardant .

[0056] The obtained powder was subjected to ultrasonic treatment with a methanol solvent, and the average particle diameter was measured using a particle diameter measuring device (manufactured by Shimadzu Corporation: SALD-2100), which was used as the primary particle diameter. In ...

Embodiment 2

[0073] Example 2 (Silicone oil combined effect) (Examples 2-1 to 2-7)

[0074] 50 parts by weight of piperazine pyrophosphate and 50 parts by weight of melamine pyrophosphate used in Example 1 were charged into a jet mill (manufactured by Seishin Enterprise Co., Ltd.: Co-JET System α-mkIII), and the nozzle pressure was 0.8 at room temperature. The pulverization was carried out at mPa and a supply rate of 500 g / hour to obtain a flame retardant powder. The obtained powder and 1 part by weight of the surface treatment agent (see Table 2) were stirred in a nitrogen atmosphere at 2800 rpm at 150° C. for 10 minutes using a Henschel mixer (manufactured by Mitsui Seizan Co., Ltd.: FM20C / I) to obtain a silicone oil Coated flame retardant.

[0075] The obtained silicone oil coated flame retardant is dispersed in methanol (concentration is 0.3g / 100ml methanol), after ultrasonic treatment (bench type manufactured by Branson Company, treated at room temperature for 10 minutes), particle s...

Embodiment 3

[0082] Embodiment 3 (modified silicone oil) (embodiment 3-1~3-5)

[0083] 50 parts by weight of piperazine pyrophosphate and 50 parts by weight of melamine pyrophosphate used in Example 1 were charged into a jet mill (manufactured by Seishin Enterprise Co., Ltd.: Co-JET System α-mkIII), and the nozzle pressure was 0.8 at room temperature. The pulverization was carried out at mPa and a supply rate of 500 g / hour to obtain a flame retardant powder. The obtained powder and 1 part by weight of the surface treatment agent (refer to Table 3) were stirred in a nitrogen atmosphere at 150° C. at 2800 rpm for 10 minutes using a Henschel mixer (manufactured by Mitsui Seizan Co., Ltd.: FM20C / I) to obtain a silicone oil Coated flame retardant.

[0084] The obtained powder was evaluated in the same manner as in Example 2.

[0085] The results are shown in Table 3.

[0086] Example

3-1

3-2

3-3

3-4

3-5

X-22-2000 *9

1

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com