Halogen-free flame retardant and flame-retardant resin composition with good flame retardance and processability

A processability and flame retardant technology, which is applied in the field of polymer material preparation, can solve the problems of deteriorating material mechanical properties, high requirements for processing equipment, and low melting point of silicone oil, so as to improve processing tolerance and production efficiency, improve quality and Continuity, the effect of reducing screw shear force and processing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention will be further described in detail below. It should be understood that the description of the embodiments of the present invention here is not intended to limit the protection scope of the present invention.

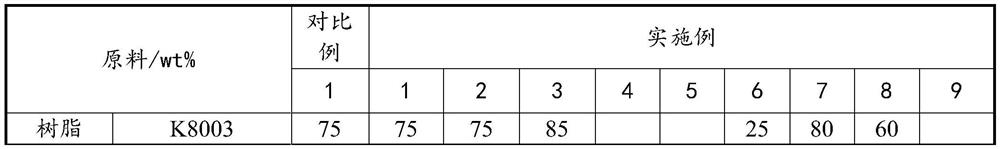

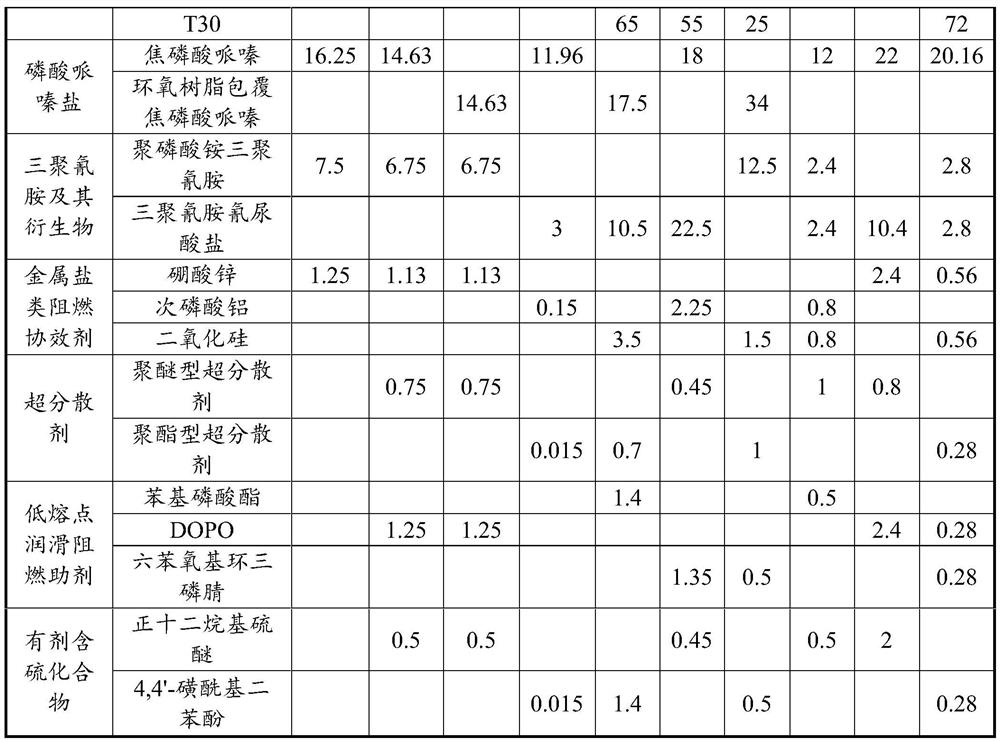

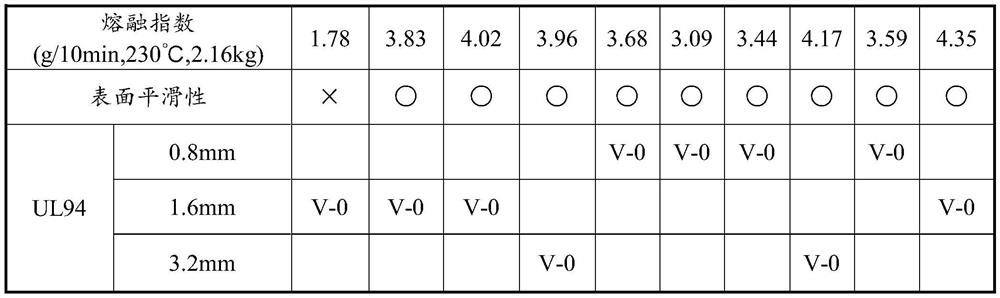

[0019] The halogen-free flame retardant with good flame retardancy and processability provided by the present invention consists of piperazine phosphate salt, melamine and its derivatives, metal salt flame retardant synergist, hyperdispersant, low melting point lubricating flame retardant aid, And the composition of organic sulfur-containing compounds, specifically, in the halogen-free flame retardant, the mass percentage of the piperazine phosphate salt is 40-80%, and the mass percentage of the melamine and its derivatives is 20-50% , the mass percentage of the metal salt flame retardant synergist is 1-10%, the mass percentage of the hyperdispersant is 0.01-5%, and the mass percentage of the low melting point lubrica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com