A powder-removing method for three-dimensional printing of thin-walled porous metal blanks by 3dp method

A technology of three-dimensional printing and porous metal, applied in the direction of cleaning methods using liquids, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of difficulty in removing powder from porous blanks, low bonding force, and low strength of printed blanks, and achieve Realize the effects of powder removal mechanization, low cost, and simple powder removal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

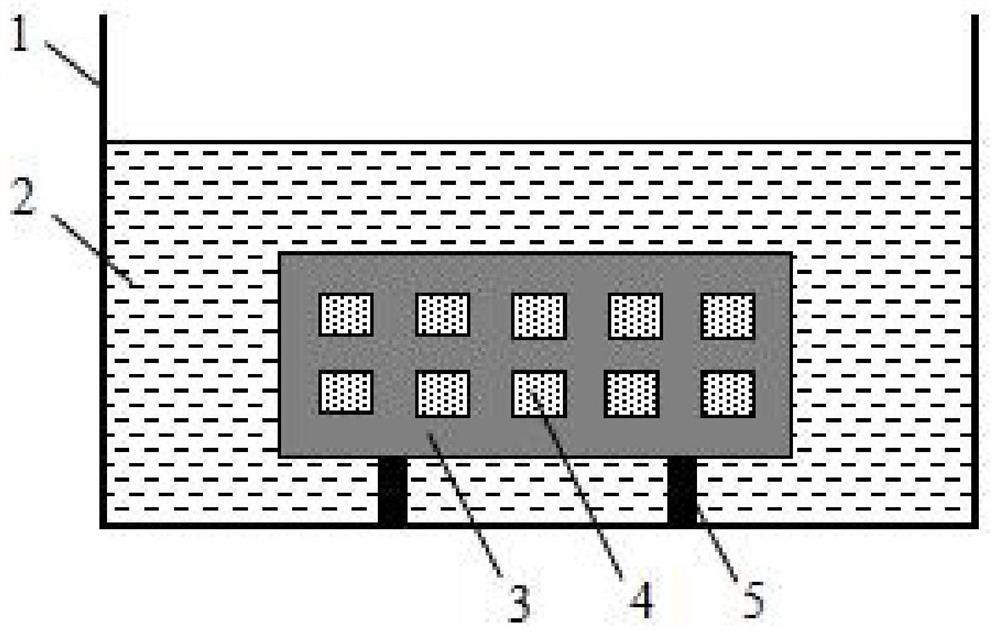

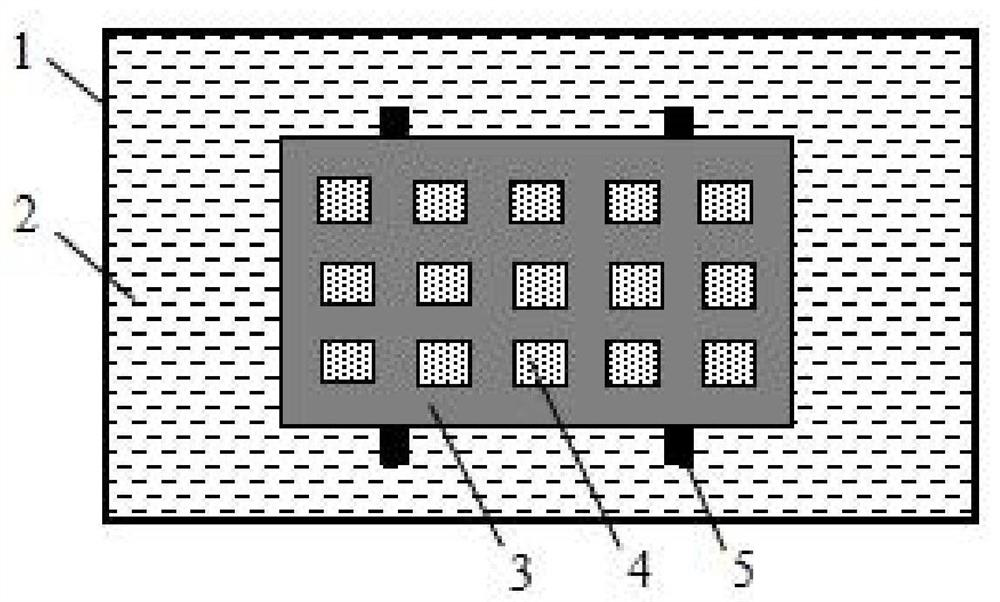

Image

Examples

Embodiment 1

[0031] 316L stainless steel powder is selected as the forming powder, and the stainless steel powder is directly sprayed with UV glue to form. The particle size of the 316L stainless steel powder used is in the range of 15-45 μm, and the shape is spherical. Using the 3DP three-dimensional printing technology, the stainless steel powder is placed in the powder storage tank of the printer, and the powder is spread into a powder layer in the forming tank by the powder spreading device. The printing head sprays UV glue to the powder layer, and irradiates the powder layer with ultraviolet light. The UV glue is cured to a certain extent so that the stainless steel powder is initially bonded and formed. Repeat the process of spreading powder and printing until the printing is completed. The forming model is a thin-walled porous part, and the cross-section of the channel is a square with a side length of 5 mm.

[0032]Take the printed blank together with the substrate and the powder ...

Embodiment 2

[0035] 316L stainless steel powder is selected as the forming powder, mixed with viscous powder PVA and starch, and the powder is bonded and formed by spraying a water-based binder solution. Among them, the particle size of 316L stainless steel powder is in the range of 15-45 μm, and the shape is spherical; the particle size of PVA powder is 300 mesh, and the shape is flake; the particle size of starch is in the range of 5-20 μm, and the shape is nearly spherical. The PVA powder content is 10%, the starch content is 2%, and the three-dimensional mixer is used to mix the three powders evenly to obtain the mixed powder. The water-based binder solution is an aqueous solution with 0.05 wt% polyvinylpyrrolidone (PVP) added.

[0036] Using 3DP three-dimensional printing technology, the mixed powder is placed in the powder storage tank of the printer, and the powder is spread into a powder layer in the forming tank by the powder spreading device, and the printing head sprays the bind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com