Preparation method of mineral feed mold removing agent

A technology for mineral feed and mildew remover is applied in the field of preparation of mineral feed mildew remover. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

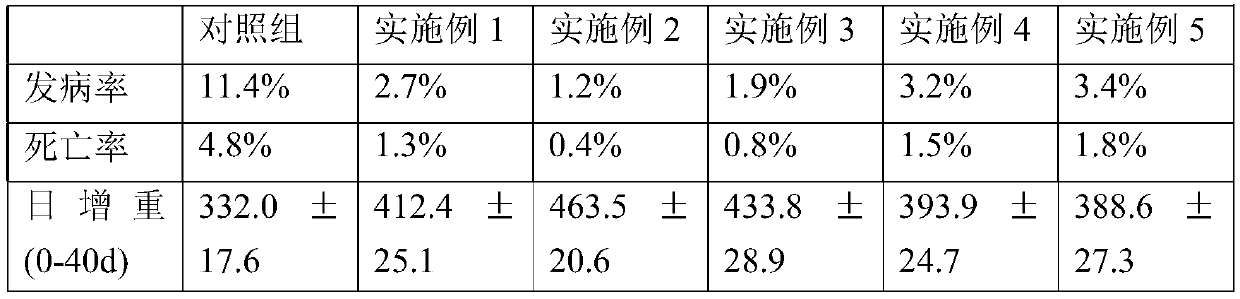

Examples

preparation example Construction

[0021] The preparation method of mineral feed mildew remover of the present invention, the process of this method is:

[0022] 2) Weigh the attapulgite, rectorite and tourmaline, mix the materials by wet ball milling at a speed of 500-1000r / min, ball mill for 8-12 hours, dry at 150-250°C for 2 hours, and grind to obtain the mixture;

[0023] 2) Weigh the quaternary ammonium salt cationic surfactant and add it to deionized water, heat and stir at 50-100°C until it is completely dissolved in water, and the mass ratio of the attapulgite to the quaternary ammonium salt cationic surfactant is 50:1 ~5:1;

[0024] 3) Add the mixture obtained in step 1) to the quaternary ammonium salt cationic surfactant solution obtained in step 2) to form a suspension, and mix it in a constant temperature water bath at 50-100°C. The mixing process is stirring or Ultrasonic treatment, the stirring time is 1-6h, and the ultrasonic time is 10-90min;

[0025] 4) After mixing, centrifuge at 2500-5000r / ...

Embodiment 1

[0034] Weigh 200g attapulgite, 10g rectorite and 10g tourmaline, wet ball mill at 500r / min for 12h, dry at 150°C for 2h, and grind to obtain a mixture. Weigh 10 g of octadecyltrimethylammonium chloride, add it into 2100 ml of deionized water, heat and stir at 80° C. until completely dissolved. Add the mixed material to the octadecyltrimethylammonium chloride solution to form a suspension, and ultrasonicate at a constant temperature of 70°C for 50min. Centrifuge at 5000r / min for 10min, remove the supernatant, wash with deionized water for several times until the washing liquid is free of Cl ions, dry at 100°C for 4h, grind through a 200-mesh sieve to obtain a mold remover for mineral feed.

Embodiment 2

[0036] Weigh 100g attapulgite, 10g rectorite and 10g tourmaline, wet ball mill at 600r / min for 11h, dry at 250°C for 2h, and grind to obtain a mixture. Weigh 10g of octadecyltrimethylammonium chloride, add it into 2200ml of deionized water, heat and stir at 50°C until completely dissolved. Add the mixed material to the octadecyltrimethylammonium chloride solution to form a suspension, and ultrasonicate at a constant temperature of 50°C for 90min. Centrifuge at 5000r / min for 10min, remove the supernatant, wash with deionized water several times until the washing liquid is free of Cl ions, dry at 150°C for 4h, and grind through a 200-mesh sieve to obtain a mold remover for mineral feed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com