Flame-retardant PP material and preparation method thereof

A technology of flame retardant and flame retardant synergist, which is used in the material field of rail vehicles to achieve the effect of low smoke density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The preparation method of flame retardant PP material is as follows:

[0049] After mixing each raw material in a high-speed mixer for 5 minutes, the mixture is placed in a twin-screw extruder. The processing technology is: the temperature of the first zone is 170-180 ° C, the temperature of the second zone is 175-185 ° C, and the temperature of the third zone is 180 ° C. -190°C, the temperature of the four zones is 180-190°C, the temperature of the five zones is 180-190°C, the temperature of the machine head is 180-200°C, and the speed of the main engine is 300-500 rpm. Extrusion and granulation to obtain flame retardant PP material for rail vehicles.

Embodiment 1-4

[0051] Table 1 is the formula of the flame retardant PP material in Examples 1-4.

[0052] Table 1

[0053]

Example 1

Example 2

Example 3

Example 4

PP resin

57

67

77

87

39

29

19

9

Molybdenum disulfide C

3

3

3

3

0.5

0.5

0.5

0.5

Lubricant EBS

0.5

0.5

0.5

0.5

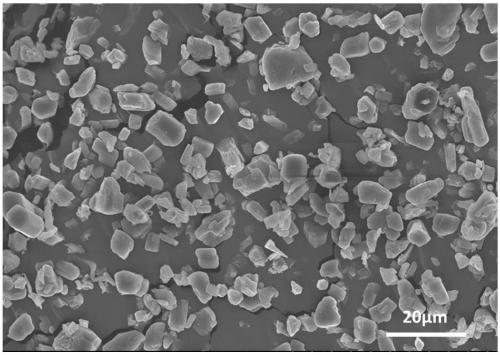

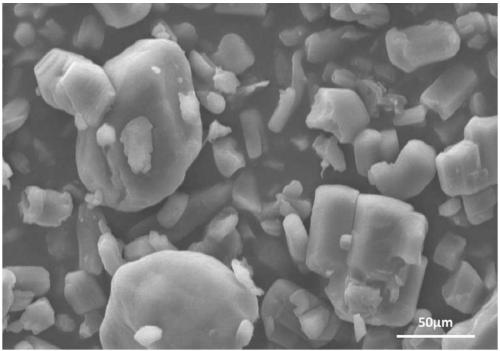

[0054] Among them, the scanning electron microscope image of piperazine pyrophosphate A is as follows figure 1 As shown, the average particle size ranges from 0.1 μm to 10 μm.

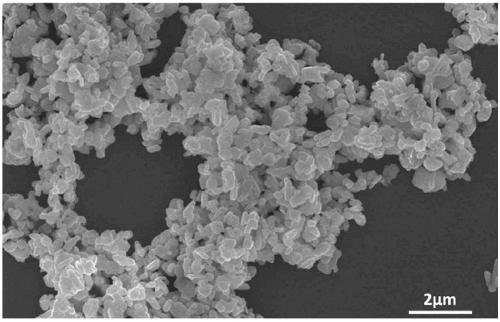

[0055] The scanning electron microscope image of molybdenum disulfide C is as follows figure 2 As shown, the average particle size ranges from 0.01 μm to 1 μm.

[0056] The antioxidant is a mixture of hindered phenol antioxidant 1010 and phosphite antioxidant 168 in a mass ratio of 1:1.

[0057] PP resin is a mixture of homo-PP and copolymerized PP in a mass ratio of 4:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com