Patents

Literature

57results about How to "Low smoke toxicity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength environment-friendly flame-retarding fiberboard and manufacturing method thereof

ActiveCN101905475AReduce the temperatureDelay in pyrolysis combustion reactionWood working apparatusDomestic articlesFiberSocial benefits

The invention discloses a high-strength environment-friendly flame-retarding fiberboard which comprises the following raw materials of plant fibers, flame retardants, adhesives and waterproofing agents, wherein the weight ratio of the plant fibers to the flame retardants to the adhesives to the waterproofing agents is 100:(3-30):(3-30):(0.1-4). The invention also discloses a manufacturing method of the high-strength environment-friendly flame-retarding fiberboard. Not only are the mechanical properties of the flame-retarding fiberboard obviously improved, but also the combustion property can conform to the regulations of GB8624 Class B or Class C, and the formaldehyde emission, the smoke volume produced and the smoke toxicity are also reduced. Thus, the high-strength environment-friendly flame-retarding fiberboard has good quality and low price, can be widely applied to the fields of building furnishings, flame-retarding furniture production, flame-retarding floor production, wooden fireproof door production, ship and vehicle furnishings and the like, and has good economical and social benefits.

Owner:北京盛大华源科技有限公司 +1

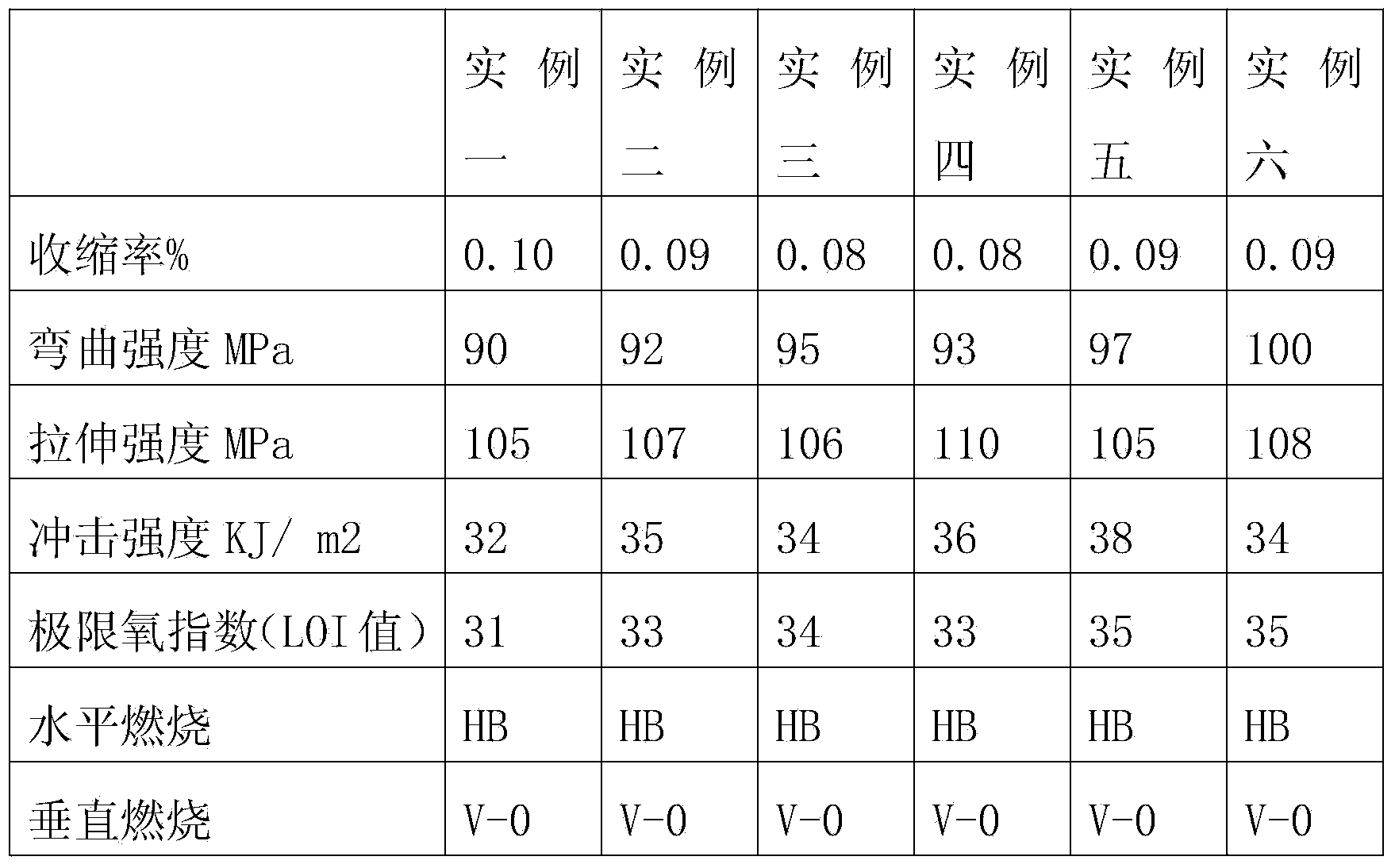

Low-shrinkage medium-temperature-cured high-efficiency flame-retardant unsaturated polyester fiberglass reinforced plastic board and preparation method thereof

The invention discloses a low-shrinkage medium-temperature-cured high-efficiency flame-retardant unsaturated polyester fiberglass reinforced plastic board and a preparation method thereof. The low-shrinkage medium-temperature-cured high-efficiency flame-retardant unsaturated polyester fiberglass reinforced plastic board is prepared from the following components in parts by weight: 50-60 parts of unsaturated polyester resin, 20-30 parts of a low-shrinkage additive, 1-3 parts of an accelerant, 0.5-2 parts of an initiator, 2-5 parts of a medium-temperature curing agent, 0.1-0.5 part of a thickening agent, 8-15 parts of a novel halogen-free flame retardant, 100-130 parts of inorganic filler, 2-3 parts of a release agent and 100-150 parts of fiberglass. The curing degree, the bending strength and the flexibility of the low-shrinkage medium-temperature-cured high-efficiency flame-retardant unsaturated polyester fiberglass reinforced plastic board can be improved; residual styrene in the fiberglass reinforced plastic board is reduced.

Owner:扬州万盛实业有限公司

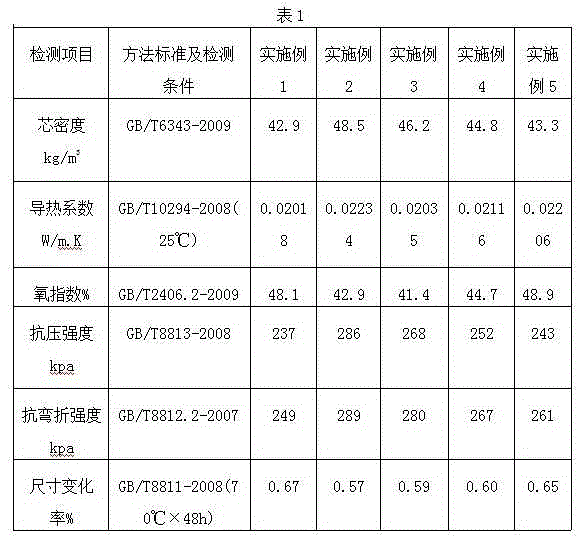

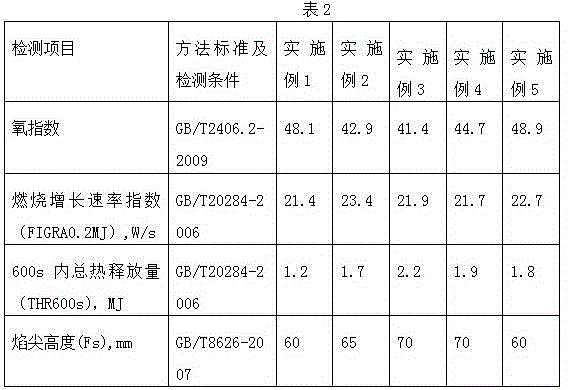

Flame-retardant rigid polyurethane foam heat insulation plate

The invention relates to a flame-retardant rigid polyurethane foam heat insulation plate. The flame-retardant rigid polyurethane foam heat insulation plate comprises a component A and a component B, wherein the component A is formed by mixing flame-retardant polyether or flame-retardant polyether polyol, amidogen ether polyol, common polyether polyol, a foam stabilizer, a catalyst, a reactive flame retardant, modified expandable graphite and a foaming agent according to a certain proportion. The component B is isocyanate. The component A and the component B are mixed, and then are subjected to compression molding to obtain the flame-retardant heat insulation plate. According to the prepared flame-retardant rapid polyurethane foam heat insulation plate, flame-retardant testing data exceed a GB8624-2012B1-grade flame-retardant standard, the oxygen index is up to 48.9, and the heat conduction coefficient is about 0.02W / m.k. The flame-retardant rigid polyurethane foam heat insulation plate has excellent compressive strength and bending resistance strength. The flame-retardant rigid polyurethane foam heat insulation plate is suitable for being applied to the fields of flame retardance and heat insulation of building walls, refrigeration houses, refrigerators, solar water heaters and the like.

Owner:WEIHAI YUNSHAN TECH +1

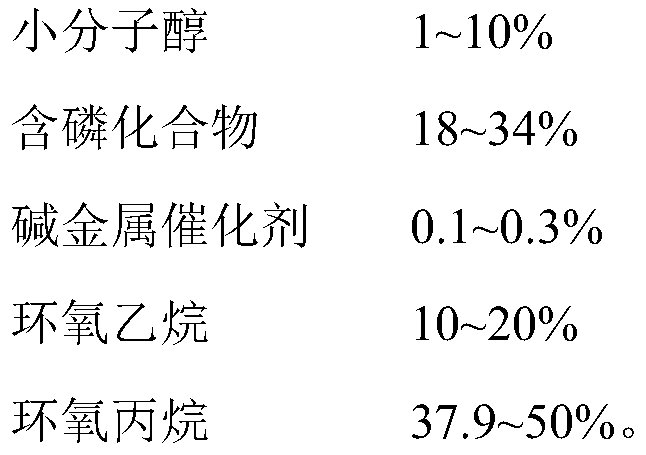

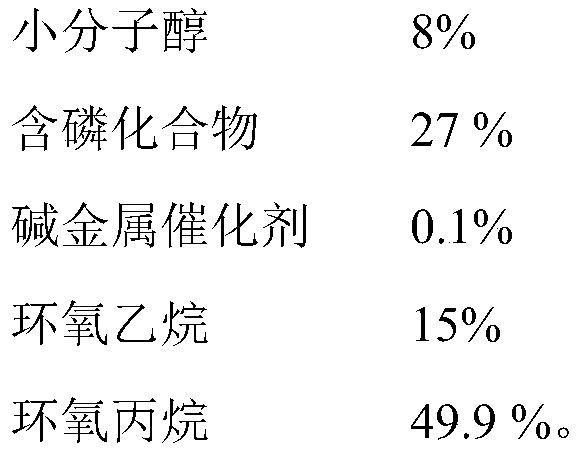

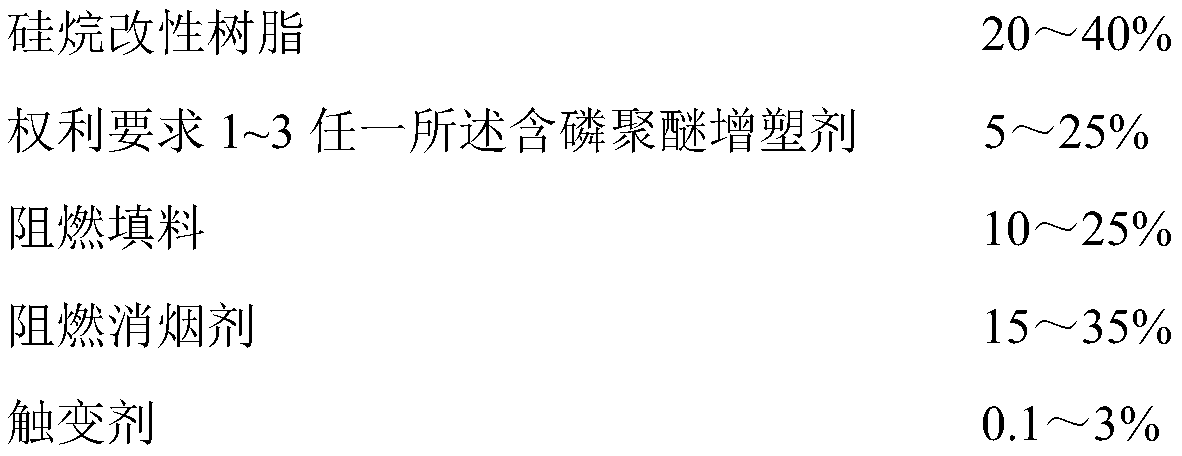

Phosphorus-containing polyether plasticizer and flame-retardant single-component silane modified sealant, and preparation methods and application thereof

ActiveCN110511369AGood compatibilityHigh flame retardant gradeNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer scienceSilanes

The invention relates to a phosphorus-containing polyether plasticizer and a flame-retardant single-component silane modified sealant, and preparation methods and application thereof. The phosphorus-containing polyether plasticizer is composed of the following components in percentage by mass: 1 to 10% of small molecular alcohol, 18 to 34% of a phosphorus-containing compound, 0.1 to 0.3% of an alkali metal catalyst, 10 to 20% of ethylene oxide, and 37.9 to 50% of propylene oxide. The phosphorus-containing polyether plasticizer provided by the invention has chain segments similar to the main chain structures of a silane modified sealant, and has good compatibility with silane modified resin; meanwhile, the phosphorus-containing polyether plasticizer can be cooperatively used with a flame-retardant filler and a flame-retardant smoke suppressor for synergistic flame retardance, so a flame retardance grade is improved, and smoke density and smoke toxicity are reduced. The sealant preparedfrom the phosphorus-containing polyether plasticizer, silane modified resin and the like has the advantages of lower smoke density, low smoke toxicity, low VOC content, excellent mechanical propertiesand bonding properties, and a flame retardant grade of 94V-0 grade, and meet the use requirements on sealants for rail transit.

Owner:GUANGDONG PUSTAR SEALED RAYON CO LTD

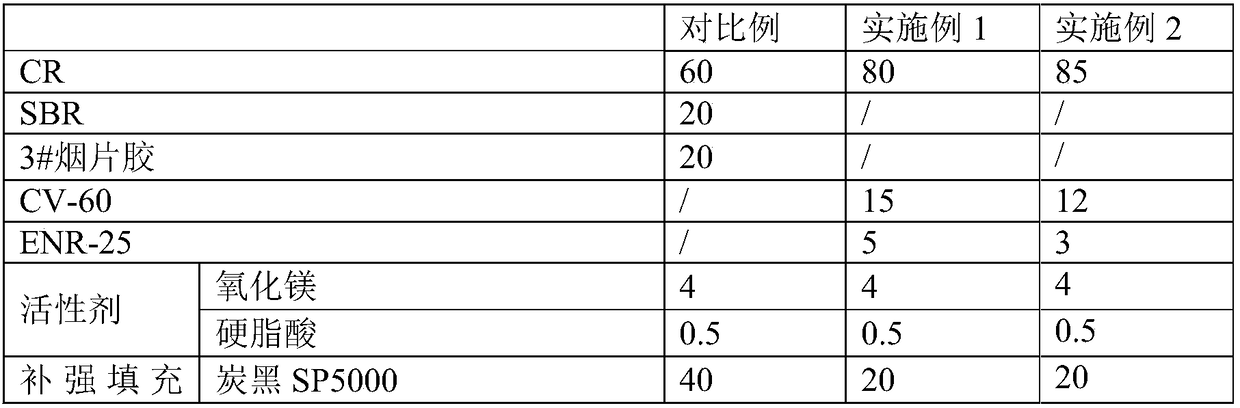

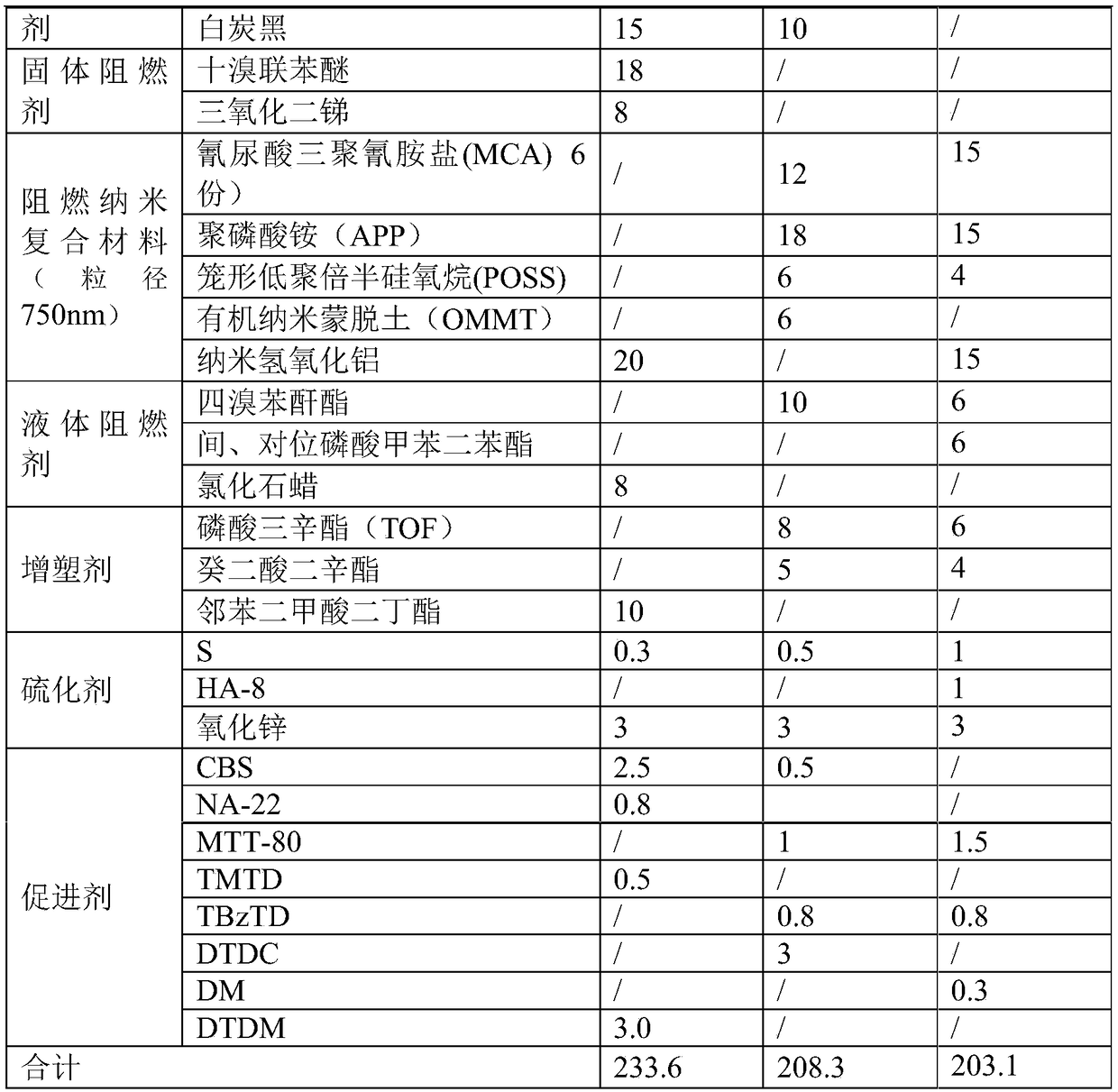

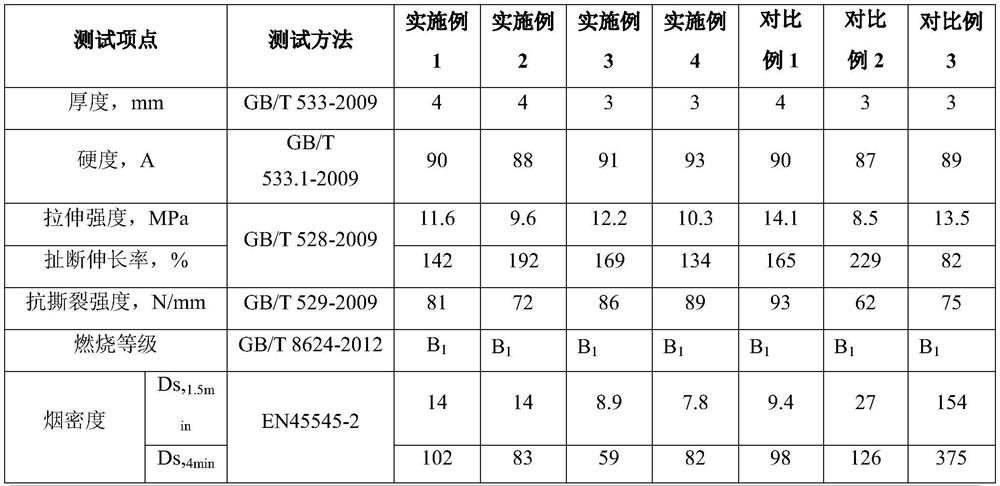

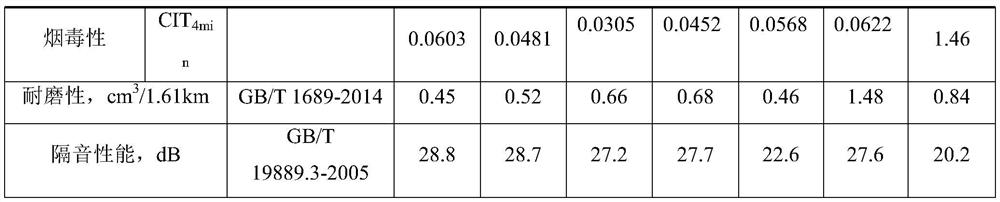

Fire-proof rubber material for air spring and preparation method thereof, air spring and preparation method thereof

InactiveCN109438794AOvercome spaceGood physical and mechanical propertiesRubber materialActive agent

The invention discloses a fire-proof rubber material for an air spring. The fire-proof rubber material for the air spring is mainly prepared by raw rubber, a flame-retardant nano composite material, aliquid fire retardant, a plasticizer, an active agent, reinforcement filler, and a vulcanization accelerant, wherein the raw rubber is formed by chloroprene rubber, general solid natural rubber and epoxidized natural rubber, and the flame-retardant nano composite material is a composite nano fire retardant mainly formed by melamine cyanurate, ammonium polyphosphate, polyhedral oligometric silsesquioxane, and organic nano montmorillonite, or the composite nano fire retardant mainly formed by the melamine cyanurate, the ammonium polyphosphate, the polyhedral oligometric silsesquioxane, and nanoaluminum hydroxide. The invention further discloses a preparation method for the fire-proof rubber material. The fire-proof rubber material is capable of keeping a good physical mechanical property of outer rubber of the air spring, and flexing resistance, improving ozone resistance, low-temperature resistance, and oil resistance, and meeting requirements of a European Union rail traffic fire protection standard EN45545-2.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

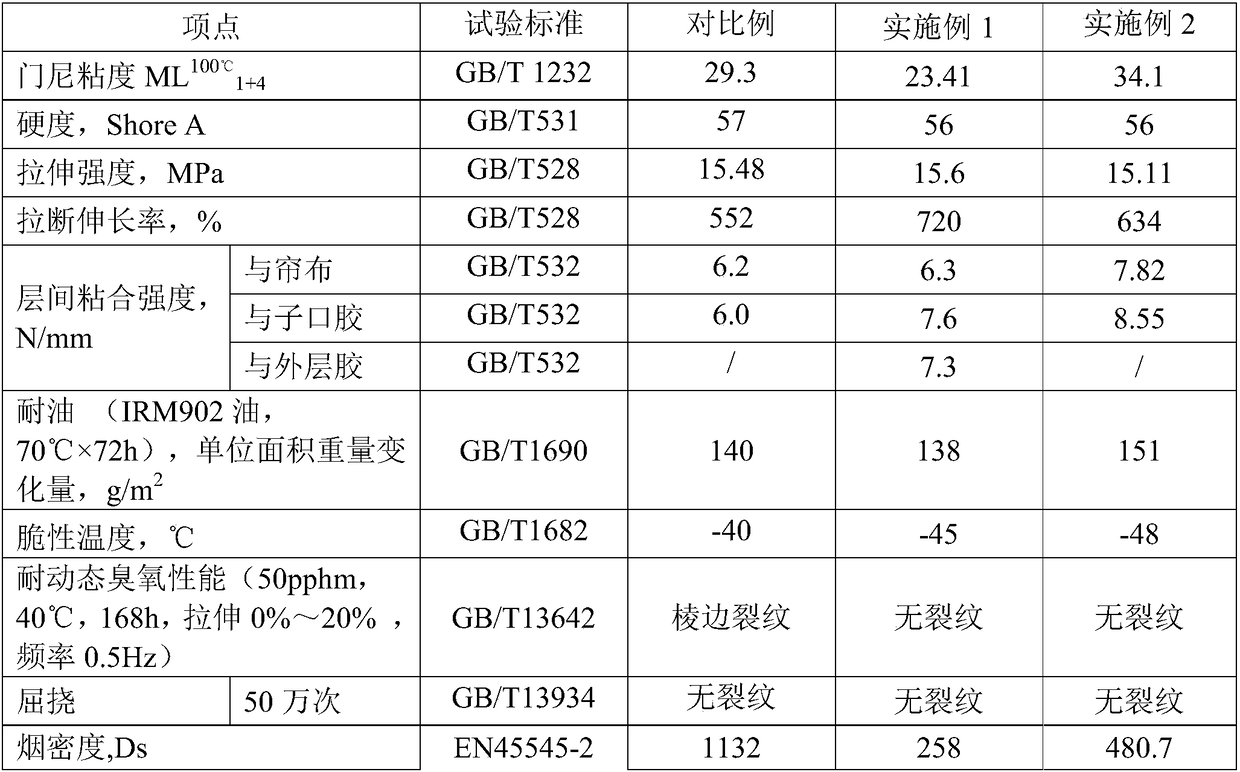

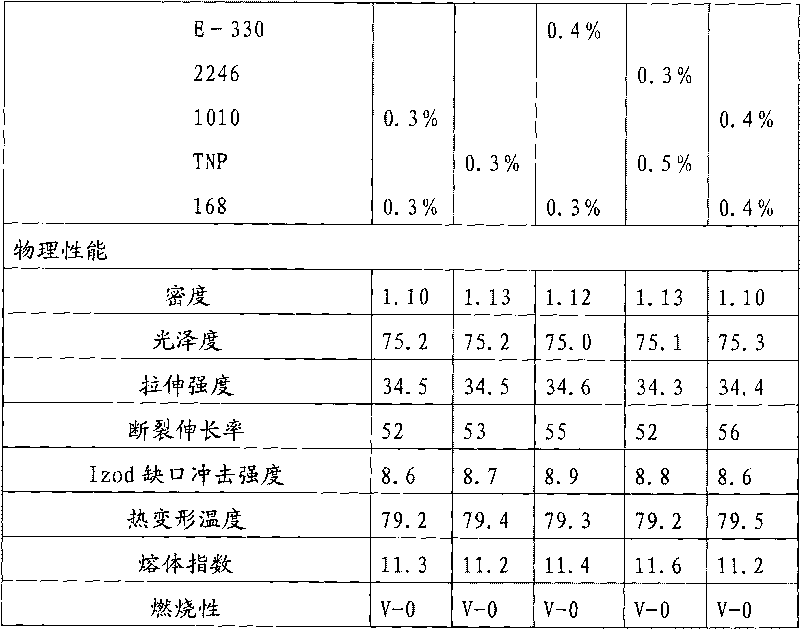

Flame-retardant high impact polystyrene compound and preparation method thereof

The invention provides a flame-retardant high impact polystyrene compound and a preparation method thereof. The flame-retardant high impact polystyrene compound comprises the following components in percentage by weight: 40 to 60 percent of high impact polystyrene, 8 to 12 percent of nano-scale kaolin, 8 to 10 percent of phenolic resin, 8 to 12 percent of bromine-nitrogen flame retardant, 5 to 10 percent of antimonous oxide, 10 to 16 percent of composite toughening agent, and 0.6 to 10 percent of antioxidant. The material performance of the prepared high impact polystyrene compound can accord with environment-friendly requirements of European Union, namely the fireproof performance 1 / 12 meets the UL94V-0 requirement; and the high impact polystyrene compound can be widely applied to the situations such as household appliances, office equipment, instruments and the like with higher requirement on the flame-retardant performance of materials, and has the advantages of simple manufacturing process, high processing efficiency, convenient material acquisition, low cost, high whiteness, and good flame-retardant property and physical property.

Owner:东莞市中洲石化有限公司

Modified expandable graphite, flame retardant as well as preparation method and application thereof in polyurethane foam

The invention relates to the technical field of flame retardants, and specifically relates to modified expandable graphite, a flame retardant, a preparation method and application thereof in polyurethane foam, and the modified expandable graphite is characterized in that one or more layer of polymer surface modifying agents with special functional groups is / are adsorbed on the surface of expandable graphite, the preparation method of the modified expandable graphite comprises: carrying out surface modification on the expandable graphite by using an organic modifier containing hydroxyl and a polar six-membered ring structure, adding a dispersing agent, uniformly mixing, and crushing and sieving to obtain the modified graphite; after adding of the modified graphite into polyurethane composite polyether according to a certain ratio and uniform mixing, the modified graphite can be uniformly dispersed and suspended in the polyether; the flame retardancy of the obtained polyurethane thermalinsulation material is greatly improved, the other performances of the polyurethane rigid foam are not influenced, the flame retardancy is good, the flame retardant effect is durable, the oxygen index is greatly improved, and the heat release rate peak value is greatly reduced.

Owner:WEIHAI YUNSHAN TECH

Flame-retardant and tear-resistant silicon rubber and preparation method thereof

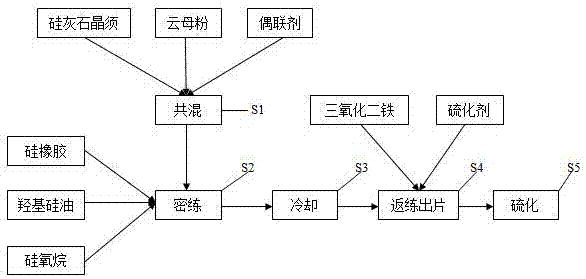

The invention discloses flame-retardant and tear-resistant silicon rubber. The flame-retardant and tear-resistant silicon rubber comprises the following components: silicon rubber, an inner lubricating agent, a structure control agent, reinforcing filler, a flame retardant, a heat-resistant active agent, a vulcanizing agent and a coupling agent. Simultaneously, the invention also discloses a preparation method of the flame-retardant and tear-resistant silicon rubber. The preparation comprises the following steps: blending, mixing, cooling, remixing for discharging pieces, and vulcanizing and the like. The flame-retardant and tear-resistant silicon rubber disclosed by the invention has the advantages that wollastonite whiskers are fibrous crystal, mica powder is superfine powder with a layered structure, and 'filler-filler' structures are not easily generated by different powder structures under the action of the coupling agent; different powder structures can cause different stress deflections, so that the reinforcing effect is achieved; and the flame-retardant and tear-resistant silicon rubber is good in tear strength and mechanical strength as well as flame-retardant and heat-insulating properties, does not contain any halogen, and has the characteristics of less smoke generation amount and low smoke toxicity.

Owner:CHANGSHA KENREACH POLYMER MATERIALS

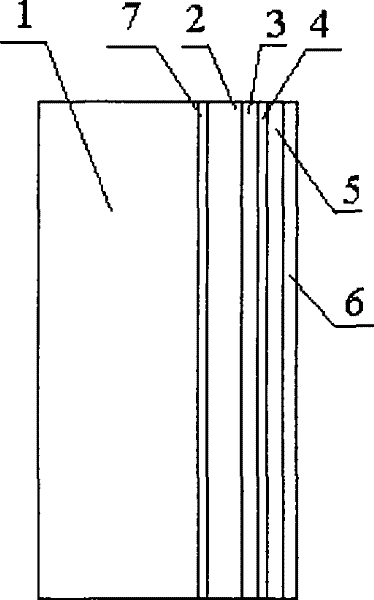

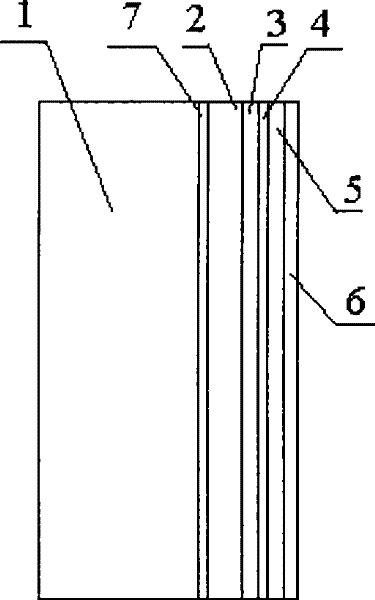

Pnenolic aldehyde foam board exterior wall internal insulation system and construction method

InactiveCN101302879AImprove insulation effectConvenient sourceCovering/liningsClimate change adaptationNon toxicityPolystyrene

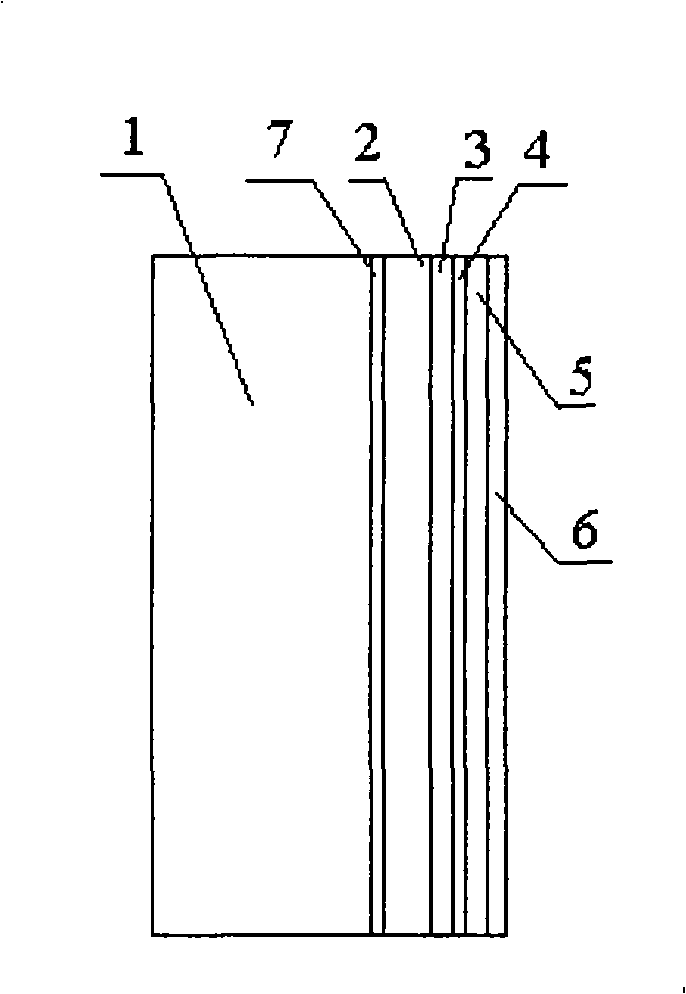

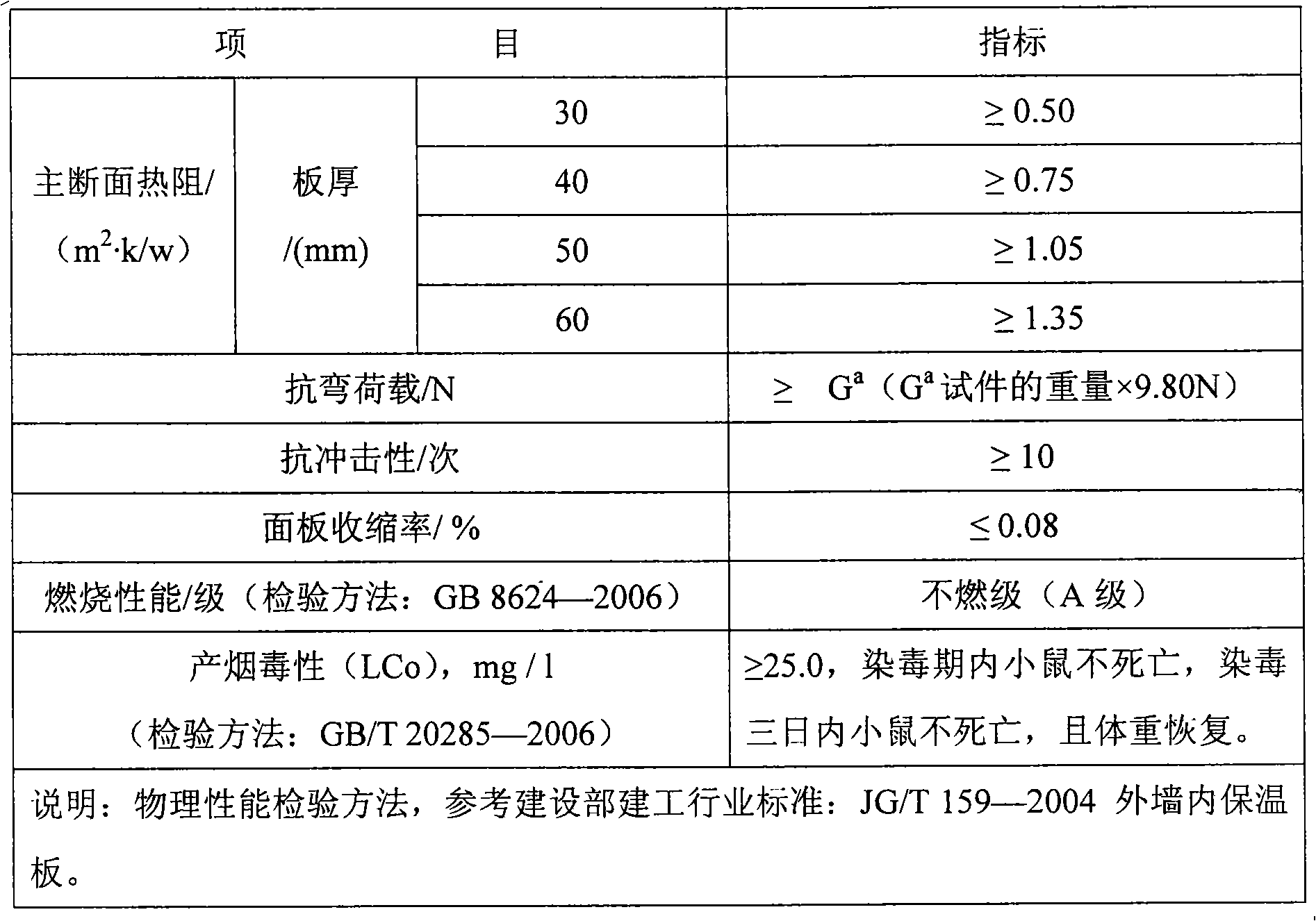

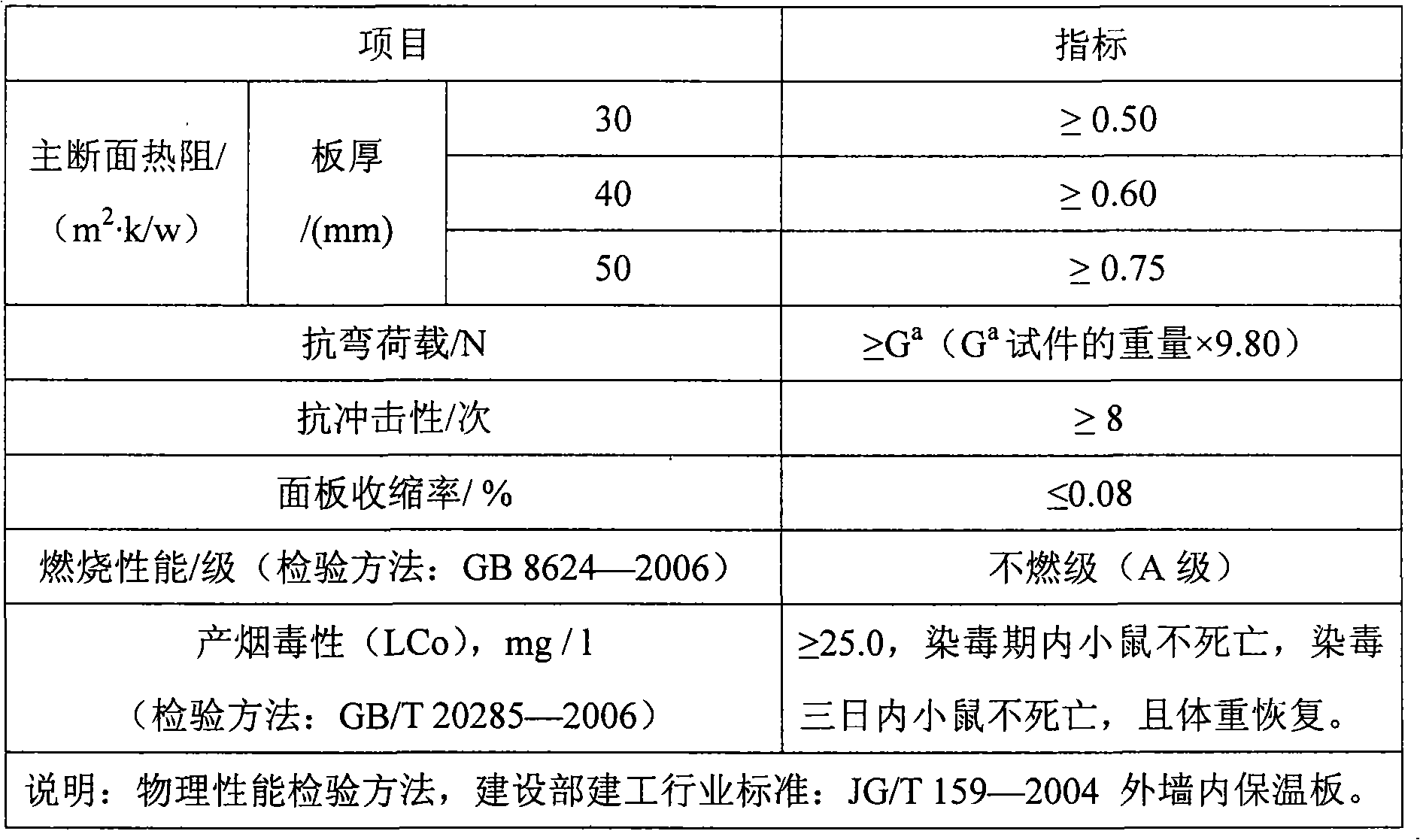

The invention discloses a phenolic aldehyde foam board inner thermal insulation system for outer walls and a construction method thereof. The phenolic aldehyde foam board inner thermal insulation system for outer walls comprises a binder layer (7) coated on a foundation wall (1) of the outer wall, an integral skin phenolic aldehyde foam board (2) adhered to the binder layer (7), a plastering inner layer (3) adhered to one side of the integral skin phenolic aldehyde foam board (2), a piece of fiberglass mesh cloth (4) adhered to the outside of the plastering inner layer (3) and a plastering outer layer (5) adhered to the outside of the fiberglass mesh cloth (4). The phenolic aldehyde foam board inner thermal insulation system for outer walls disclosed by the invention has good thermal insulation performance, combustion performance up to a non-combustible grade, smoke toxicity up to standard safety grade, intensity up to or exceeding that of polystyrene inner thermal insulation board for outer walls (construction industry standard JG / T 159-2004 of inner thermal insulation board issued by Ministry of Housing and Urban-Rural Development of the People's Republic of China), as well as non-toxicity, good environmental performance, air permeability, no cracking, convenient material source, energy-saving construction and wide application.

Owner:沈石山 +1

Micro-interpenetrating network cross-linked low-smoke halogen-free flame-retardant cable material and preparation method thereof

InactiveCN109651693AGood performanceGood service lifePlastic/resin/waxes insulatorsLow-density polyethyleneCross-link

The invention discloses a micro-interpenetrating network cross-linked low-smoke halogen-free flame-retardant cable material and a preparation method thereof. The cable material includes, by weight, 10-25 parts of ethylene-vinyl acetate copolymer, 20-40 parts of silane-grafted linear low-density polyethylene, 15-25 parts of a polyolefin thermoplastic elastomer, 10-25 parts of ultra-low-density polyethylene, 10-15 parts of functionalized polyolefin resin, 0.5-2.5 parts of high molecular weight polysiloxane, 0.5-1.5 parts of a crosslinking sensitizer, 0.5-2 parts of an auxiliary crosslinking agent, 0.1-0.5 part of a chain extender, 120-180 parts of a high efficiency composite flame retardant, 0.5-2.5 parts of a tubular microcrystalline nano-carbon forming agent, 1-2 parts of organosilane, 0.5-2 parts of an anti-oxidant, and 0.5-1.5 parts of a processing auxiliary agent. The cable material has excellent comprehensive performance and service life, good mechanical property, good dielectric and insulating properties and small creep poles, and is high and low temperature resistant, water resistant, acid and alkali resistant, solvent resistant, wear resistant, creep resistant, ozone resistant and bending resistant; and the cable material can meet different application scene demands of cables, and has the comprehensive performance of dealing with complex and changeable environments.

Owner:WUXI JAKE PLASTIC

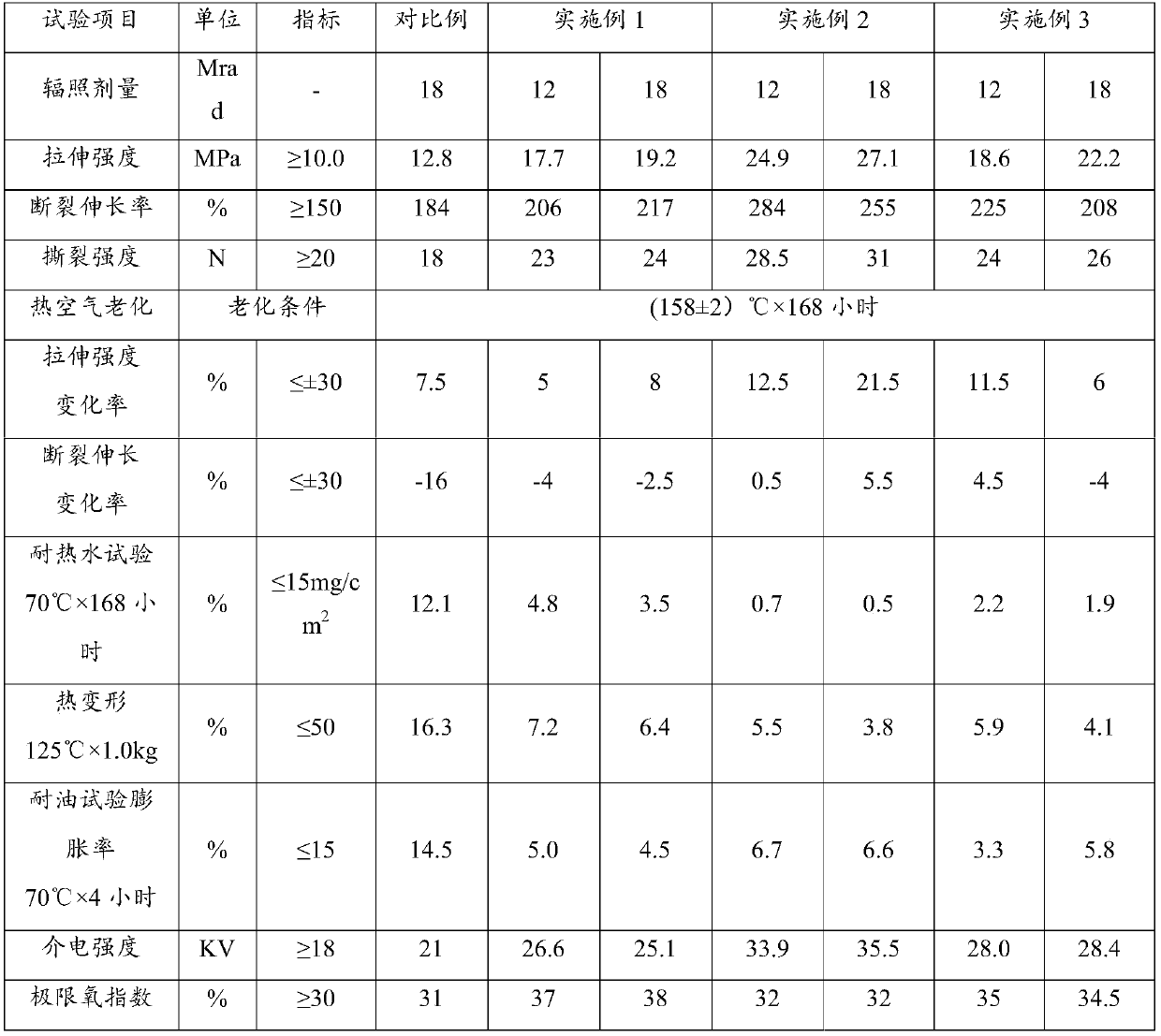

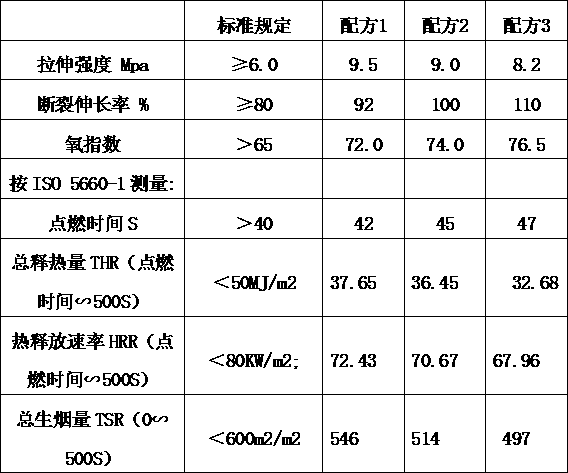

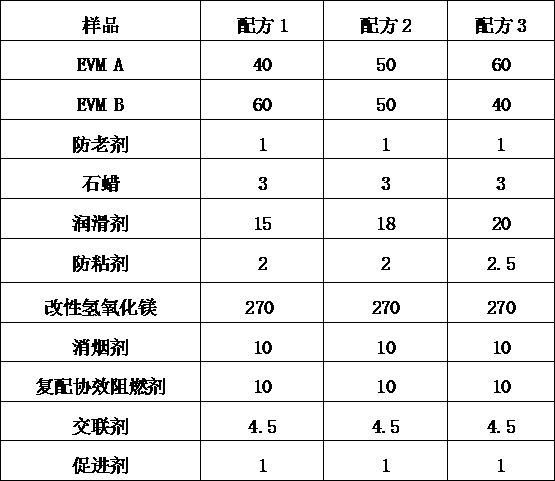

Halogen-free low-smoke ethylene-vinyl acetate inner sheath material for B1-level flame-retardant cable and preparation method

InactiveCN109503933ALow water absorptionImprove waterproof performancePlastic/resin/waxes insulatorsCross-linkSilanes

The invention relates to a halogen-free low-smoke ethylene-vinyl acetate inner sheath material for a B1-level flame-retardant cable and a preparation method and belongs to the technical field of cables. The halogen-free low-smoke ethylene-vinyl acetate inner sheath material is prepared from the following ingredients in parts by weight: 40 to 60 parts of ethylene-vinyl acetate copolymer ingredientA, 40 to 60 parts of ethylene-vinyl acetate copolymer B, 250 to 300 parts of special silane modified magnesium hydroxide, 5 to 10 parts of a smoke suppressor, 3 to 5 parts of paraffin, 15 to 20 partsof a lubricant, 1 to 2 parts of an anti-sticking agent, 1 to 2 parts of an anti-ageing agent, 8 to 10 parts of a compound synergistic flame retardant, 3 to 5 parts of a cross-linking agent and 1 to 2parts of an accelerant, wherein the lubricant is one or several in DOTP, zinc stearate and a fluorine containing polymer. The inner sheath material disclosed by the invention has excellent propertiesof ultrahigh oxygen index, low heat release rate / total amount, low smoke production rate / total amount, low smoke toxicity, low corrosivity, incombustible dripping, waterproofness and the like. A prepared subway direct-current traction cable can meet fireproof requirements of B1-level flame retardance, d1-level combustion dripping / particles, t0-level smoke toxicity, a1-level corrosivity and the like in GB31247-2014.

Owner:BAOSHENG SCI & TECH INNOVATION

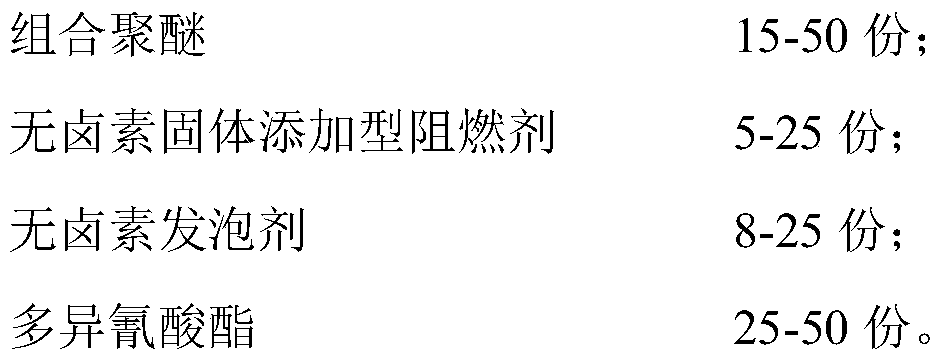

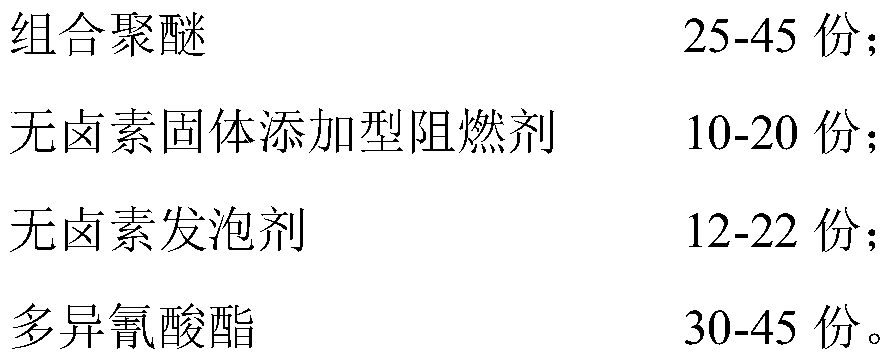

High flame-retardant, halogen-free, low-smoke, low-toxicity single-component polyurethane foam sealant with oxygen index ≥ 32 and preparation method thereof

The invention relates to the field of single-component polyurethane foam sealants and in particular relates to a high-flame-retarding, halogen-free, low-smoke and low-toxin single-component polyurethane foam sealant with an oxygen index greater than or equal to 32 and a preparation method thereof. The high-flame-retarding, halogen-free, low-smoke and low-toxin single-component polyurethane foam sealant with oxygen index greater than or equal to 32, provided by the invention, is prepared from a halogen-free polyurethane foam sealant basic material, a reaction type flame retardant which has a lasting flame-retarding property, contains phosphorus, nitrogen, silicon and a heteroaromatic ring and has no halogen, a halogen-free solid addition type flame retardant with an expansion property, a halogen-free liquid addition type flame retardant with low viscosity, plasticity and compatibility, and an environment-friendly, cheap and easy-to-obtain halogen-free foaming agent. By adopting the raw materials, the whole single-component polyurethane foam sealant has no halogen component and has the oxygen index greater than or equal to 32, high flame-retarding property, low smoke density and low smoke toxicity; the high-flame-retarding, halogen-free, low-smoke and low-toxin single-component polyurethane foam sealant is especially applicable to fields including special buildings with strict high-flame-retarding and high-environment-friendly requirements, important transportation means and the like.

Owner:成都高端聚合物科技有限公司

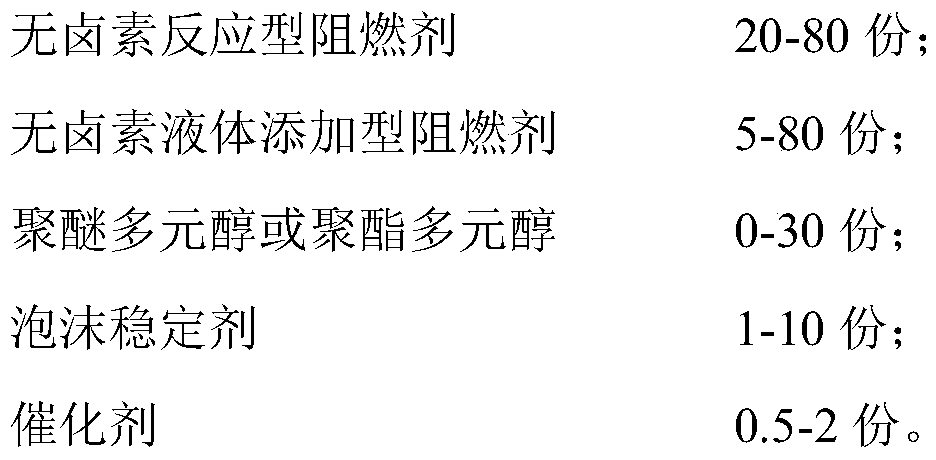

Ethylene-propylene-diene monomer flame-retardant rubber and production method thereof

The invention provides ethylene-propylene-diene monomer flame-retardant rubber and a production method thereof. The ethylene-propylene-diene monomer flame-retardant rubber comprises an ethylene-propylene-diene monomer, a reinforcing filler, encapsulated red phosphorous, phenolic resin, an activator, a lubricant, sulfur, an accelerator and an antiager. The production method comprises premixing, internal mixing, open milling, molding and vulcanization. The ethylene-propylene-diene monomer flame-retardant rubber and the production method thereof solve the technical problem that the existing flame-retardant rubber has poor tensile properties, large cigarette toxicity and a high price.

Owner:CHANGSHA KENREACH POLYMER MATERIALS

Flame-retardant and aging-resistant epoxy resin glass fiber reinforced plastic for shell of four-wheel electric vehicle

The invention discloses flame-retardant and aging-resistant epoxy resin glass fiber reinforced plastic for the shell of a four-wheel electric vehicle. The flame-retardant and aging-resistant epoxy resin glass fiber reinforced plastic comprises, by weight, 70-85 parts of epoxy resin, 4-9 parts of polysiloxane, 4-9 parts lignin, 3-9 parts of curing agent, 2-4 parts of diluent, 10-20 parts of glass fibers, 1-9 parts of carbon fibers, 2-9 parts of graphene oxide, 1-3 parts of molybdenum disulfide, 2-7 parts of carbon nanotube, 3-9 parts of modified expandable graphite, 2-3.2 parts of samarium oxide, 1-5 parts of nano zinc oxide, 2-9 parts of nano titanium dioxide, 2-8 parts of dioctyl phthalate, 2-9 parts of triglycidyl isocyanurate, 2-3.8 parts of silane coupling agent KH-560, 2-9 parts of sepiolite and 2-11 parts of ammonium polyphosphate. The flame-retardant and aging-resistant epoxy resin glass fiber reinforced plastic is good in heat resistance and excellent in flame retardance and aging resistance.

Owner:安徽佳龙车业有限公司

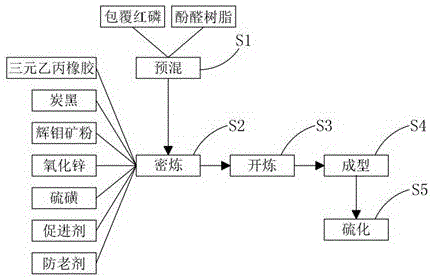

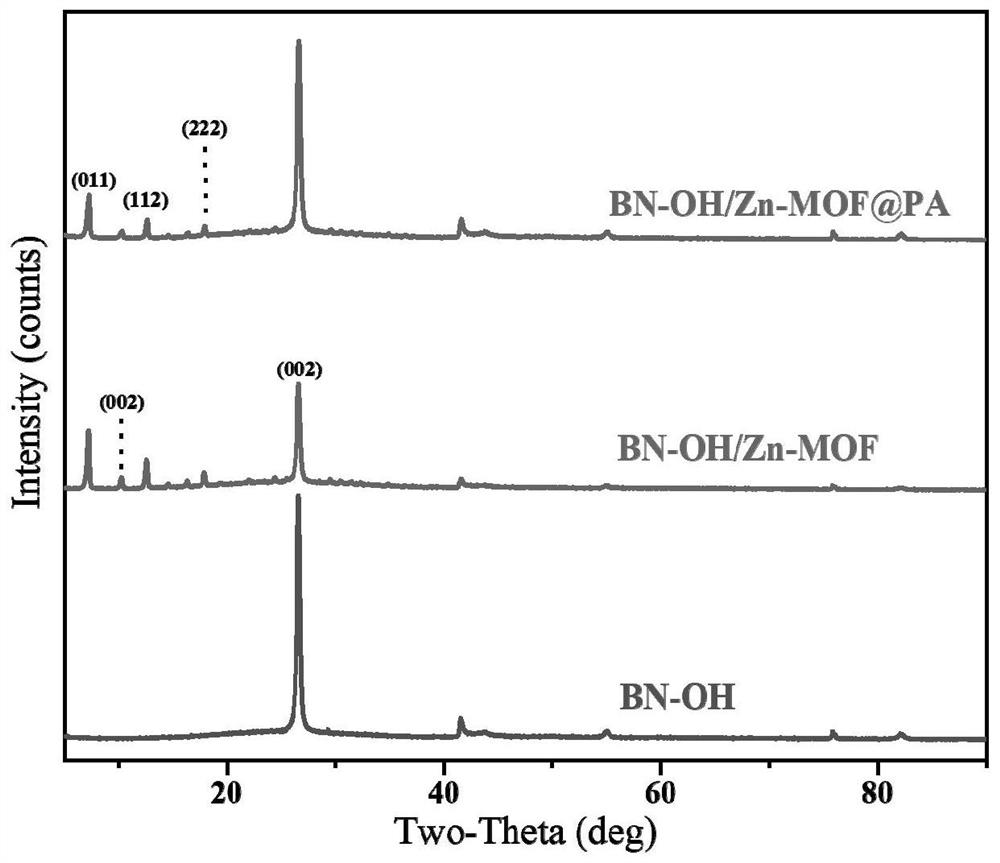

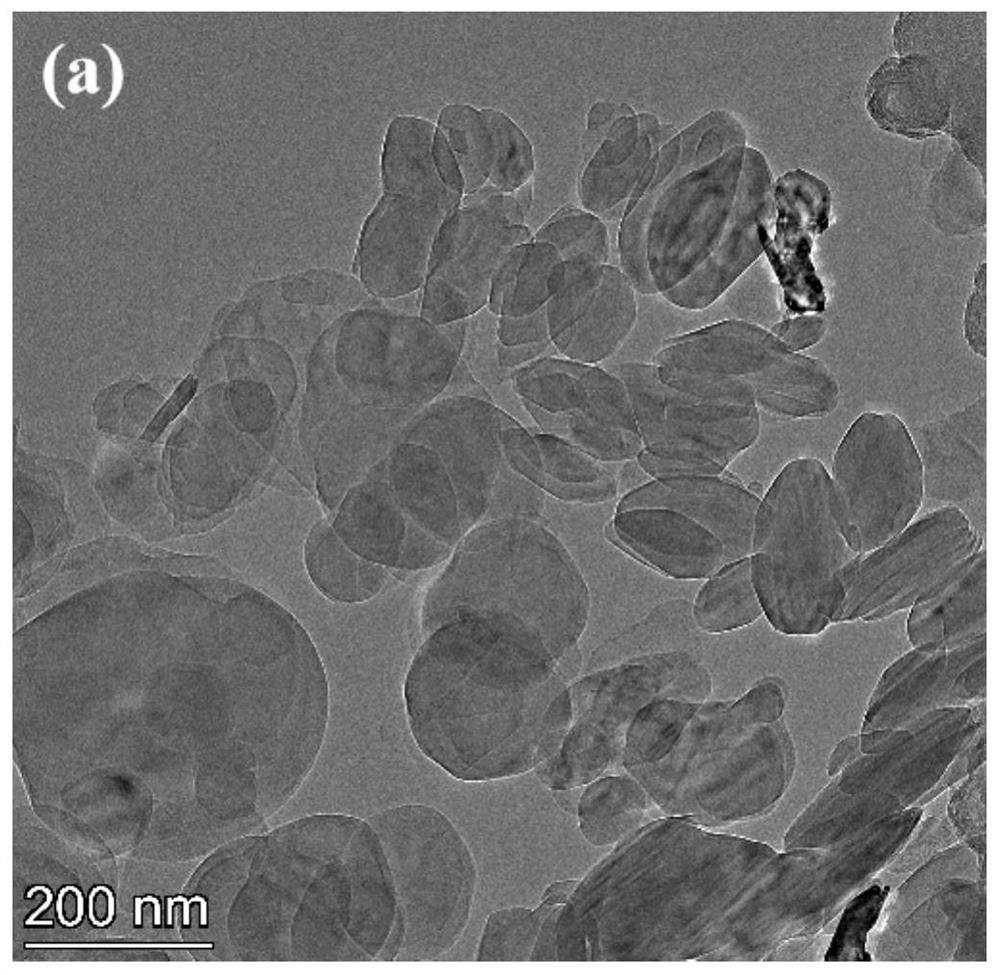

Bio-based nano synergistic flame retardant, and preparation method and application thereof

The invention discloses a bio-based nano synergistic flame retardant, and a preparation method and application thereof. The bio-based nano synergistic flame retardant comprises a transition metal organic framework, a two-dimensional material and phytic acid, the transition metal organic framework is intercalated in the two-dimensional material, and the phytic acid wraps the transition metal organic framework. The preparation method comprises the following steps: preparing a two-dimensional material suspension; respectively adding a transition metal salt solution and a 2-methylimidazole solution into the two-dimensional material suspension, uniformly stirring, and centrifuging, washing and drying after the reaction is finished to obtain an intermediate product; and uniformly mixing the intermediate product suspension with a phytic acid solution, and carrying out an ion complexation reaction to obtain the bio-based nano synergistic flame retardant. When the bio-based nano synergistic flame retardant prepared by the invention is added into epoxy resin and polylactic acid materials, the flame retardant property of a polymer composite material can be improved, so that the polymer composite material reaches the standard of flame retardancy or extinguishment after being away from fire, and the fireproof safety performance of the epoxy resin and polylactic acid materials can be improved.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

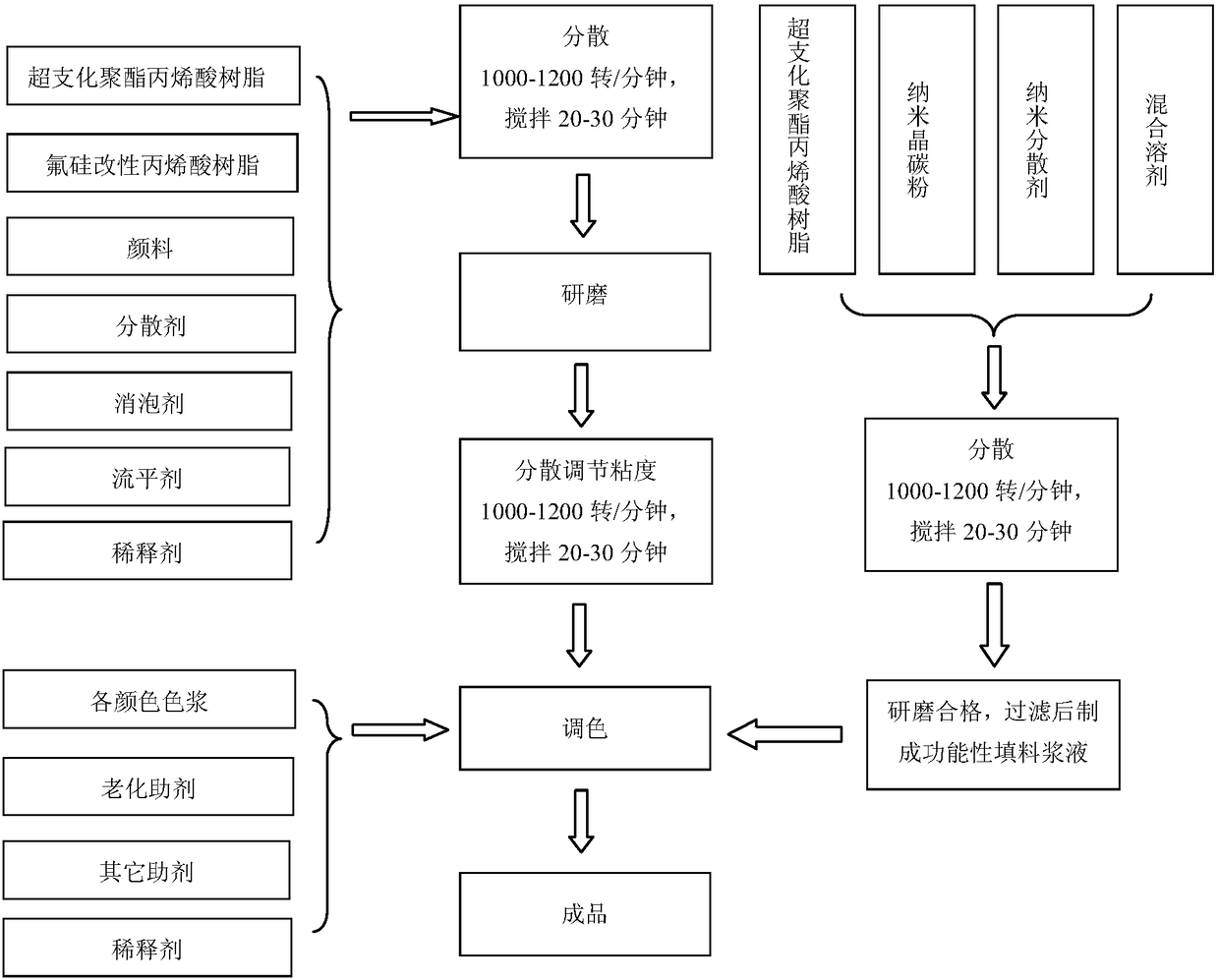

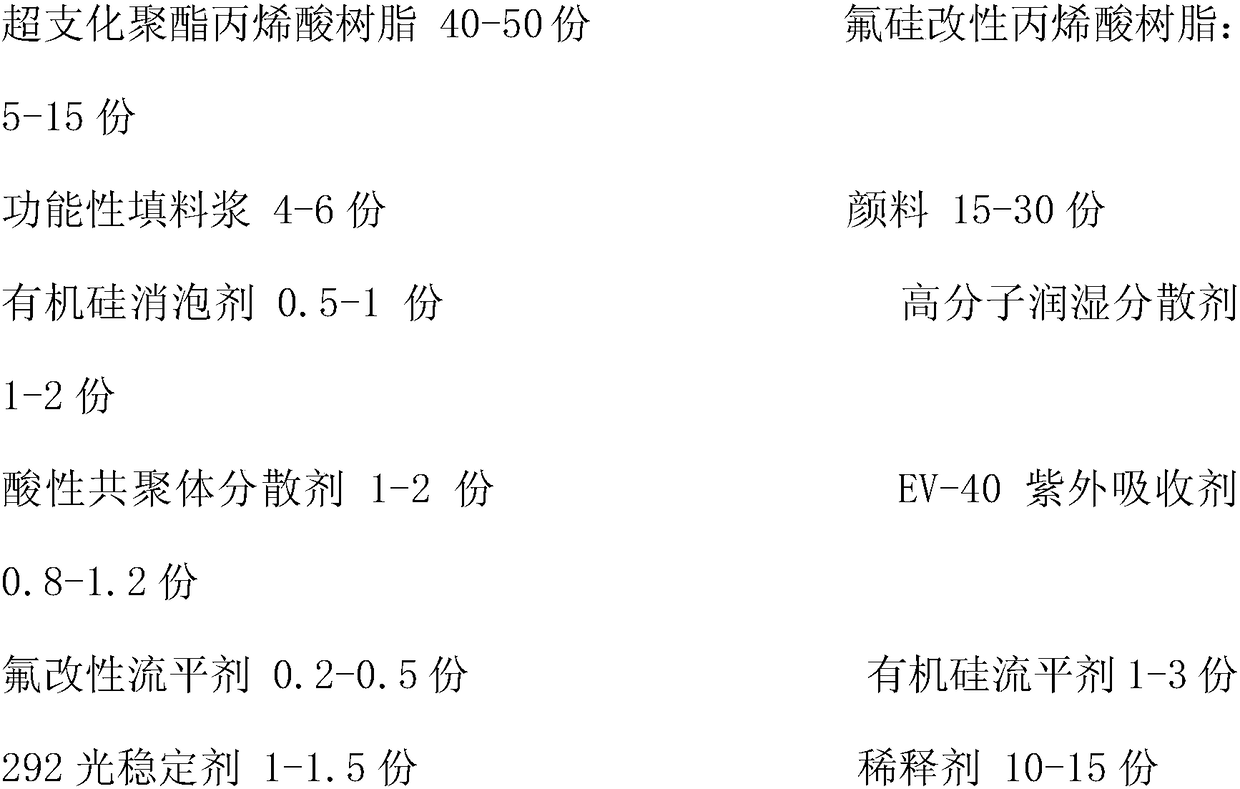

Hyperbranched polyurethane finishing coat for urban railway vehicles

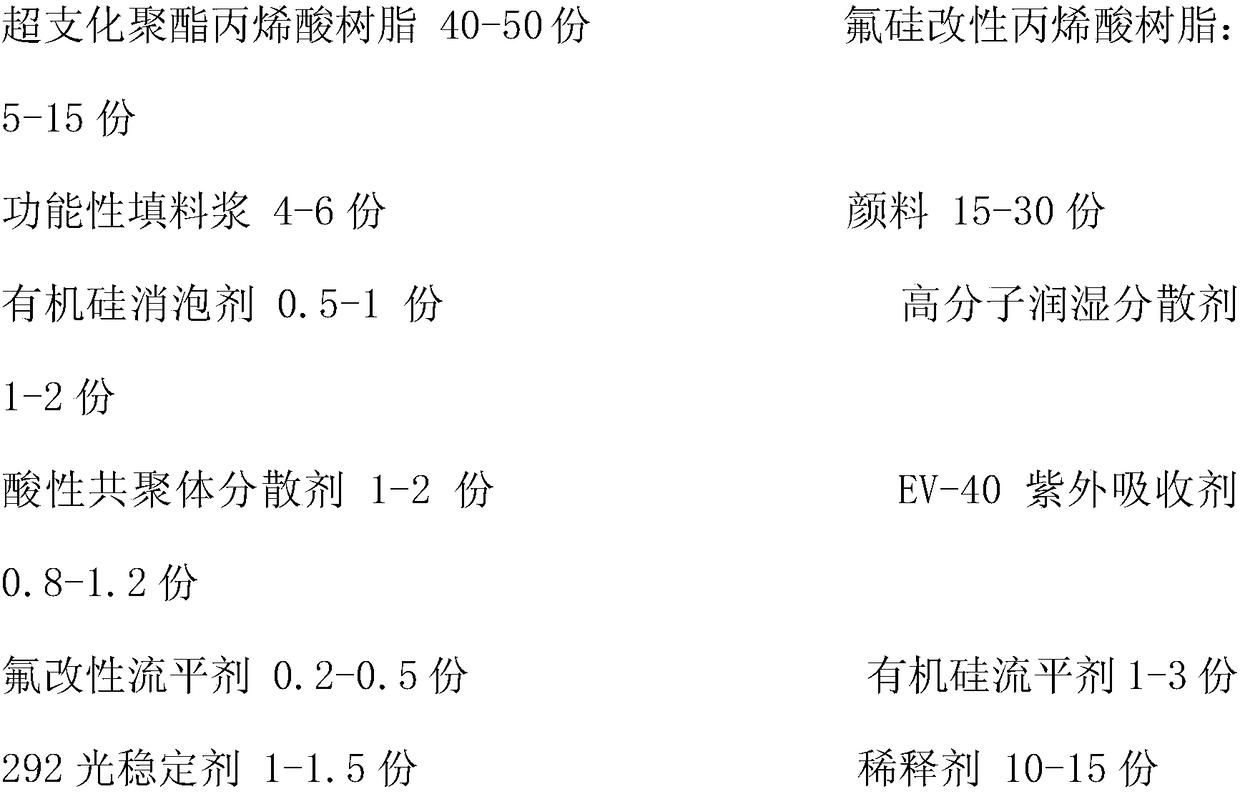

ActiveCN108129980AExcellent color and gloss retentionGood flexibilityFireproof paintsPolyurea/polyurethane coatingsAcrylic resinLacquer

The invention relates to a hyperbranched polyurethane finishing coat for urban railway vehicles, and a preparation method thereof. The finishing coat is characterized in that hyperbranched polyester acrylic resin, fluorosilicone modified acrylic resin, a pigment, a functional filler slurry, an assistant and a solvent form a paint; IPDI (isophorone diisocyanate) and the solvent form a curing agent;and the finishing coat is prepared from the paint and the curing agent according o a weight ratio of the paint to the curing agent of 100:40 when constructed, and a proper amount of a diluent can beadded to adjust the construction velocity in order to facilitate the construction. The finishing coat for urban railway vehicles has the advantages of high weather resistance, good wear resistance, good scratch resistance, good scrub resistance, good resistance to acids and alkalis, high hardness, good flame retardancy, low smoke toxicity, good water resistance and good elasticity. The finishing coat can adapt to sandstorm, acids-alkalis, moisture, ultraviolet rays and various other harsh weather conditions, and can adapt to frequent cleaning using cleaning agents having different pH values, apaint film formed by the finishing coat can maintain glossy and avoids great color difference change for a long time, and the service life reaches 10 years or more, and is far longer than the current4-6 year requirement of paints.

Owner:株洲市九华新材料涂装实业有限公司

Environment-friendly composite damping board for vibration and noise reduction and preparation method

ActiveCN111114039AEnhancement effect is goodImprove acceleration performanceMetal layered productsEpoxyGlass fiber

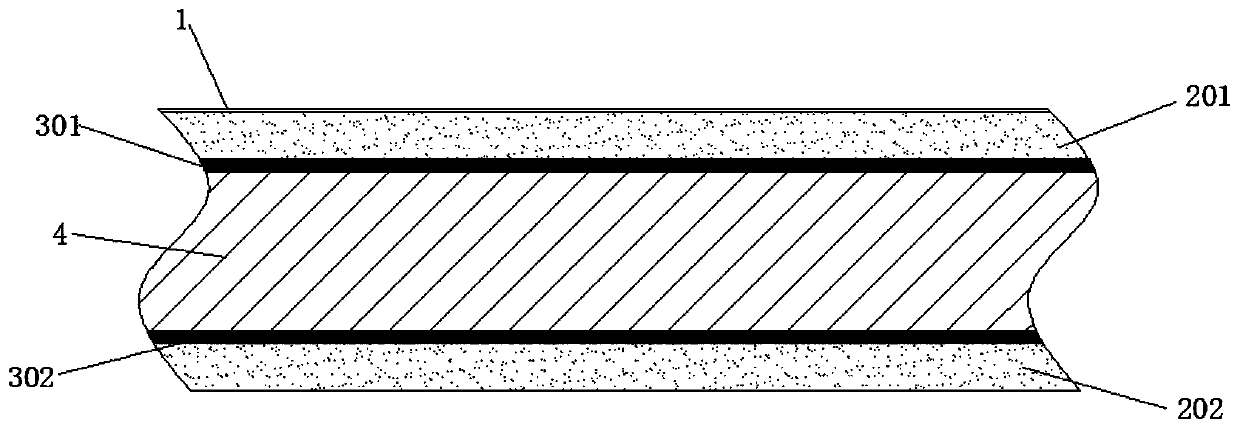

The invention discloses an environment-friendly composite damping board for vibration and noise reduction and a preparation method. The environment-friendly composite damping board comprises a dampinglayer, a restraint layer and a bonding layer; the damping layer and the restraint layer are compounded through the bonding layer; and the damping layer is prepared from the following components in parts by weight: 100 parts of rubber, 5-15 parts of carbon black, 5-15 parts of reinforced fibers, 10-15 parts of a plasticizer, 25-45 parts of a damping agent, 200-500 parts of a flame retardant and 30-50 parts of tackifying resin, wherein the reinforced fibers comprise aramid staple fibers subjected to surface preprocessing and long glass fibers subjected to surface preprocessing, and the surfacepreprocessing is carried out through dipping processing of a phosphoric acid solution and an epoxy resin solution in sequence. The damping board material is environmentally friendly, free of peculiarsmell, good in flame retardant property and low in smoke density and smoke toxicity during combustion; the damping board has high shearing strength, is firmly adhered to a base material and is not easy to fall off; the damping value is high, the damping temperature range is wide, and the vibration and noise reduction effect is excellent.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Sound insulation type elastic coiled material floor for rail transit and preparation method thereof

InactiveCN112031330AImprove sound insulationWeight increaseCovering/liningsFlooring insulationsElastomerPolyolefin

The invention discloses a sound insulation type elastic coiled material floor for rail transit and a preparation method of the sound insulation type elastic coiled material floor. The sound insulationtype elastic coiled material floor is formed by hot-pressing compounding of a sound insulation layer and a wear-resistant layer, the sound insulation layer is prepared from the following components including,10-30 parts of polyolefin elastomer, 5-25 parts of styrene elastomer, 60-150 parts of heavy filler, 20-100 parts of a flame retardant and 2-6 parts of auxiliaries, and the wear-resistant layer is prepared from the following components including, 5-30 parts of polyolefin elastomer, 10-30 parts of styrene elastomer, 5-30 parts of wear-resistant reinforced resin, 10-60 parts of a flame retardant, 1-8 parts of a compatilizer, 2-15 parts of a wear-resistant agent and 2-5 parts of auxiliaries. Through compounding of the sound insulation layer and the wear-resistant layer, the sound insulation performance of the coiled material floor is greatly improved, additional use of sound insulation materials is reduced, the comprehensive cost is reduced, the coiled material floor has lower smoke density and smoke toxicity, zero plasticizer addition can be achieved, and the coiled material floor has very good environmental friendliness.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

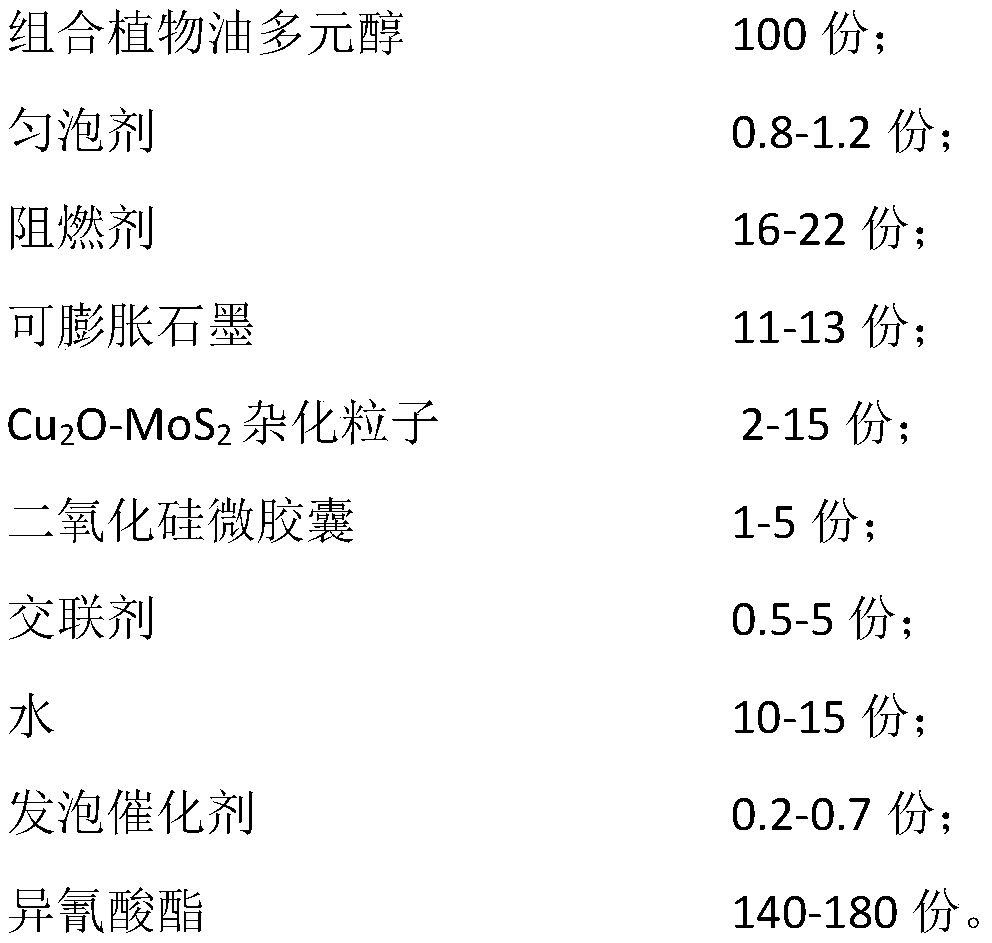

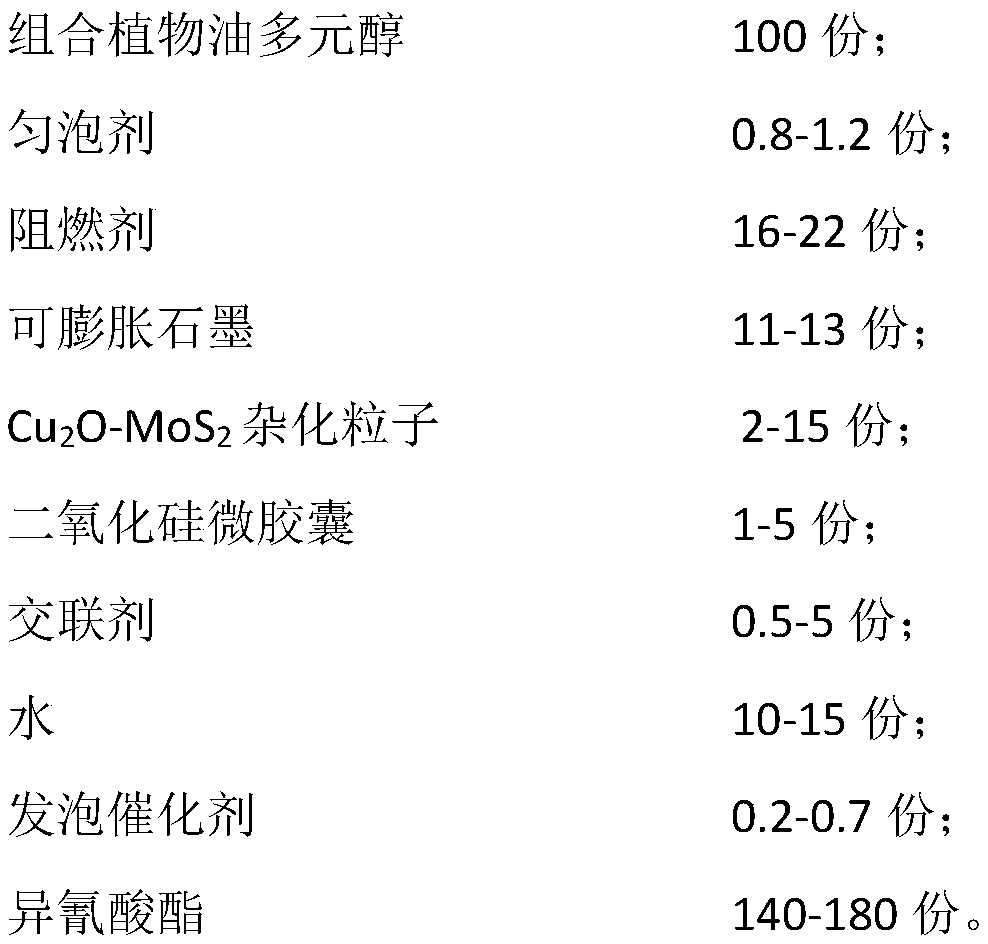

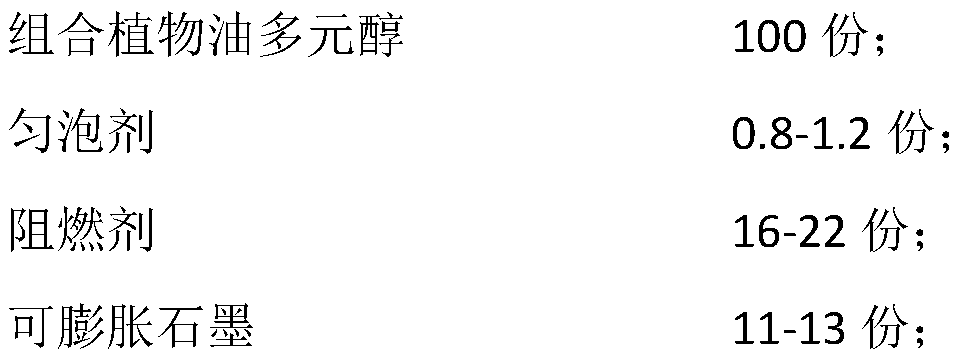

Sound-absorbing flame-retardant vegetable oil-based polyurethane foam material and preparation method thereof

ActiveCN111040104AImprove smoke and poison suppression propertiesGood sound-absorbing and flame-retardant propertiesPolymer scienceVegetable oil

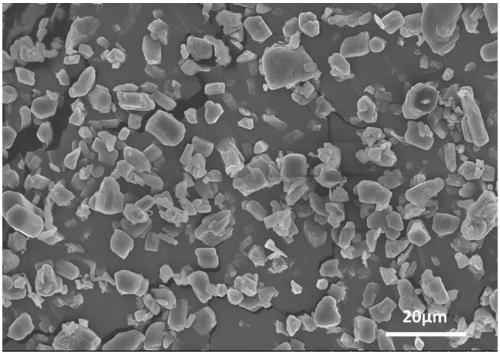

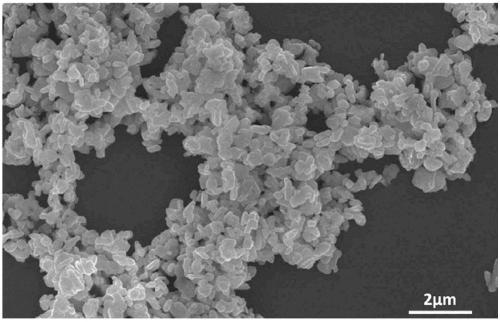

The invention discloses a sound-absorbing and flame-retardant vegetable oil-based polyurethane foaming material and a preparation method thereof, wherein the foaming material is prepared from the following raw materials in parts by weight: combined vegetable oil polyol, a foam stabilizer, a flame retardant, expandable graphite, Cu2O-MoS2 hybrid particles, silicon dioxide microcapsules, a cross-linking agent, water, a foaming catalyst, isocyanate and the like. The sound-absorbing and flame-retardant vegetable oil-based polyurethane foaming material disclosed by the invention has good sound-absorbing and flame-retardant properties; due to the addition of Cu2O-MoS2 hybrid particles, the smoke inhibition and toxicity inhibition characteristics of the flame-retardant material are effectively improved; the silicon dioxide microcapsules are added, and the foam bare board is preheated, so that the appearance of a formed part is smooth and flawless; and after the foam bare board is preheated, the foam aperture ratio is increased, and the sound absorption performance of foam is improved.

Owner:浙江华江科技股份有限公司

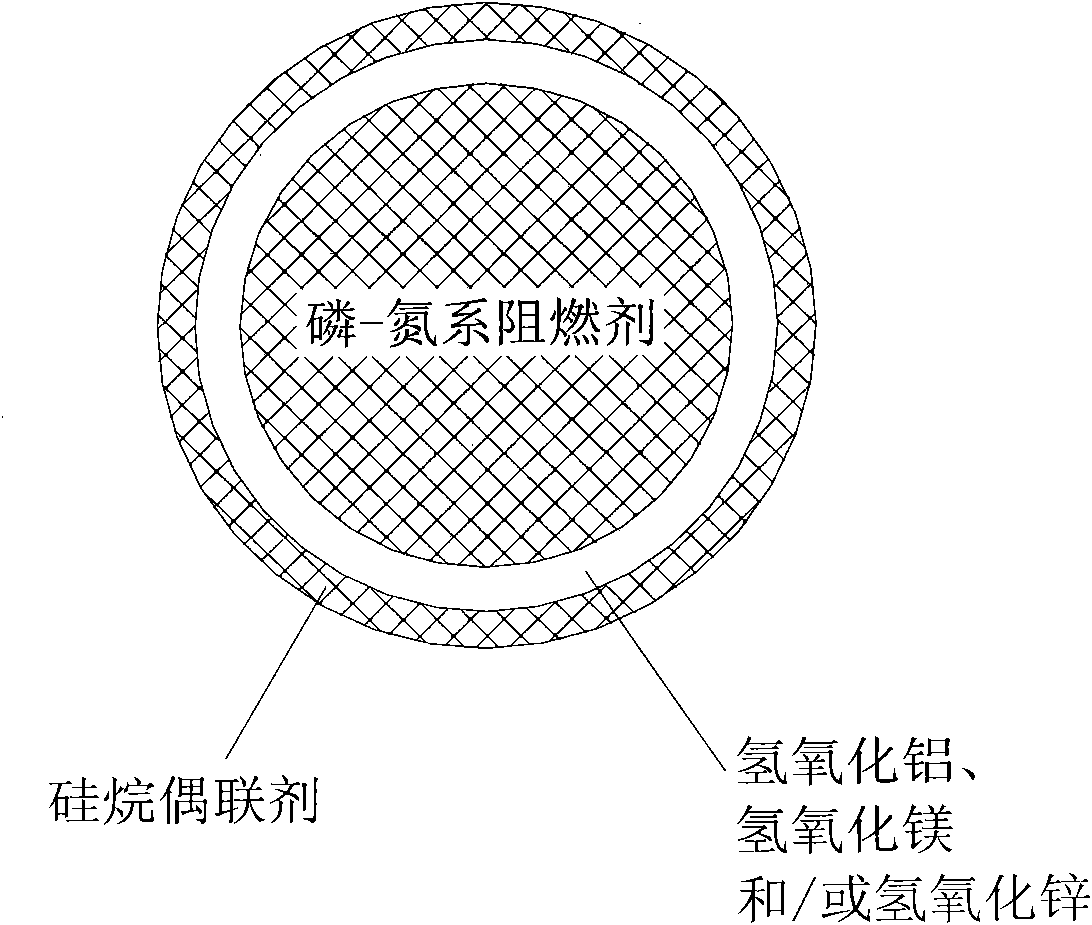

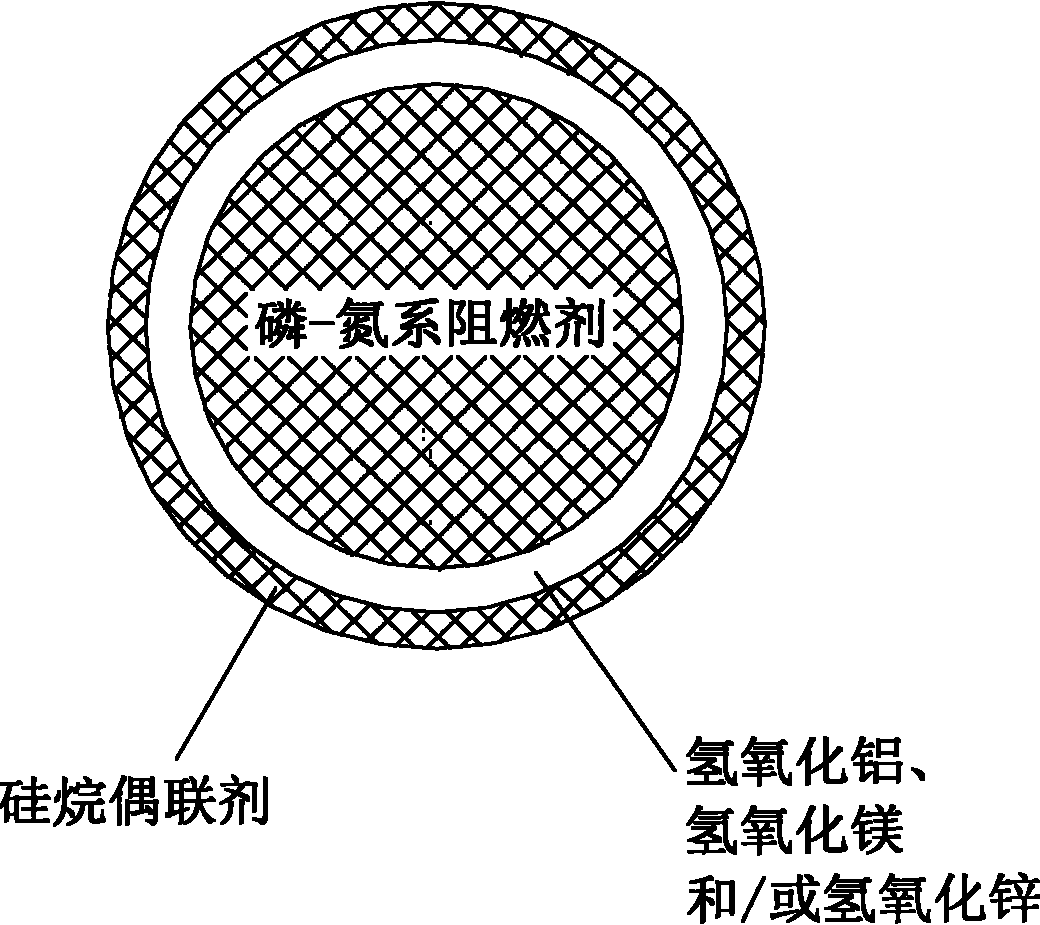

Inorganic material filled flame retardant PP material and preparation method thereof

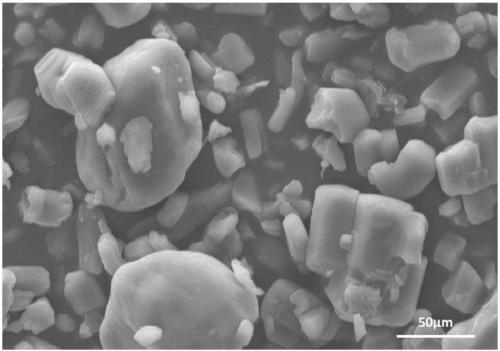

InactiveCN109486022AImprove flame retardant performanceHigh critical radiant fluxMelamine phosphatePhosphate

The invention relates to an inorganic material filled flame retardant PP material which is prepared from the following raw materials in percent by mass: 57-77% of PP resin, 9-29% of a flame retardant,1-5% of a flame retardant synergist, 3-20% of inorganic material filler, 0.1-0.6% of an antioxidant and 0.3-1% of a lubricant. The flame retardant is selected from one or more of melamine phosphate,the average grain sizes of which are 0.1-10 [mu]m and piperazine phosphate, the average grain sizes of which are 0.1-10 [mu]m. The flame retardant synergist is selected from one or more of molybdenumdisulfide and tungsten disulfide, the average grain sizes of which are 0.1-10 [mu]m. The inorganic material filled flame retardant PP material has efficient flame retardance.

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

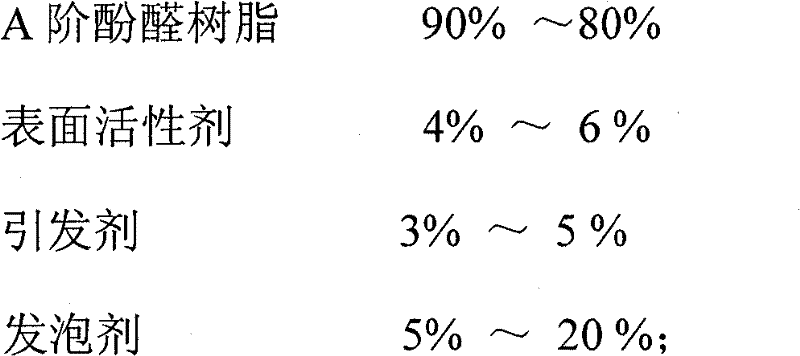

Environment-friendly refractory foam material and preparation method thereof

An environment-friendly refractory foam material and a preparation method thereof. The invention relates to a novel foam material capable of being used for energy-saving buildings and preparation thereof. The foam material includes: a sodium silicate component, a polyurethane component, and regular assistant materials and additives. The sodium silicate component (A) includes more than 60% of sodium silicate and also contains more than 0.5% of a catalyst and / or a co-catalyst so that in a normal-temperature foaming reaction, surface dry can be achieved within 10 min. The double components also contain more than 10% of a polyol or a polyol derivative. The polyurethane component (B) is a polyurethane prepolymer or is a combination of the polyurethane with a proper amount of polyisocyanate and / or an organic solvent and / or a plasticizer, wherein the polyurethane prepolymer is formed through a reaction of polyester polyol and / or polyether polyol and polyisocyanate, NCO content being 8-25% or8-13%. The weight ratio of component A to the component B is 1:1-1.5. The foam material is environment-friendly and refractory and has excellent heat insulation effect, is low in smoke density and toxicity, has good dimensional stability, has both rigidity and flexibility, and is low in manufacturing cost.

Owner:CHONGQING LIERDA SCI & TECH DEV

Medium-temperature fast-curing flame-retardant epoxy resin composition and flame-retardant prepreg

The invention discloses a medium-temperature fast-curing flame-retardant epoxy resin composition and a flame-retardant prepreg. The composition is composed of bisphenol F epoxy resin, novolac epoxy resin, cyclotriphosphazene DOPO flame-retardant epoxy resin, a modified inorganic flame-retardant filler, a dicyandiamide curing agent and a modification accelerator; the resin composition is a composition cured at low temperature and stored at normal temperature. The resin composition is halogen-free, environment-friendly, efficient, flame-retardant, low in smoke amount, low in smoke toxicity and low in heat release, can be quickly cured for 5-10 minutes at the temperature of 150 DEG C by adopting a modification accelerator, has an ultra-long effective storage period at the normal temperature,and has the storage period of more than 30 days at the temperature of 25 DEG C. The flame-retardant prepreg laminated board has the advantages of quick curing at the medium temperature, long normal-temperature storage validity and longer operation time, has the characteristics of no halogen, environment friendliness, low smoke amount, low smoke toxicity, low heat release and the like, and meets the requirements of rail transit EN45545 / R1 / HL3 flame-retardant grade and aircraft cabin internal material FAR 25.853 flame-retardant grade.

Owner:深圳市郎搏万先进材料有限公司

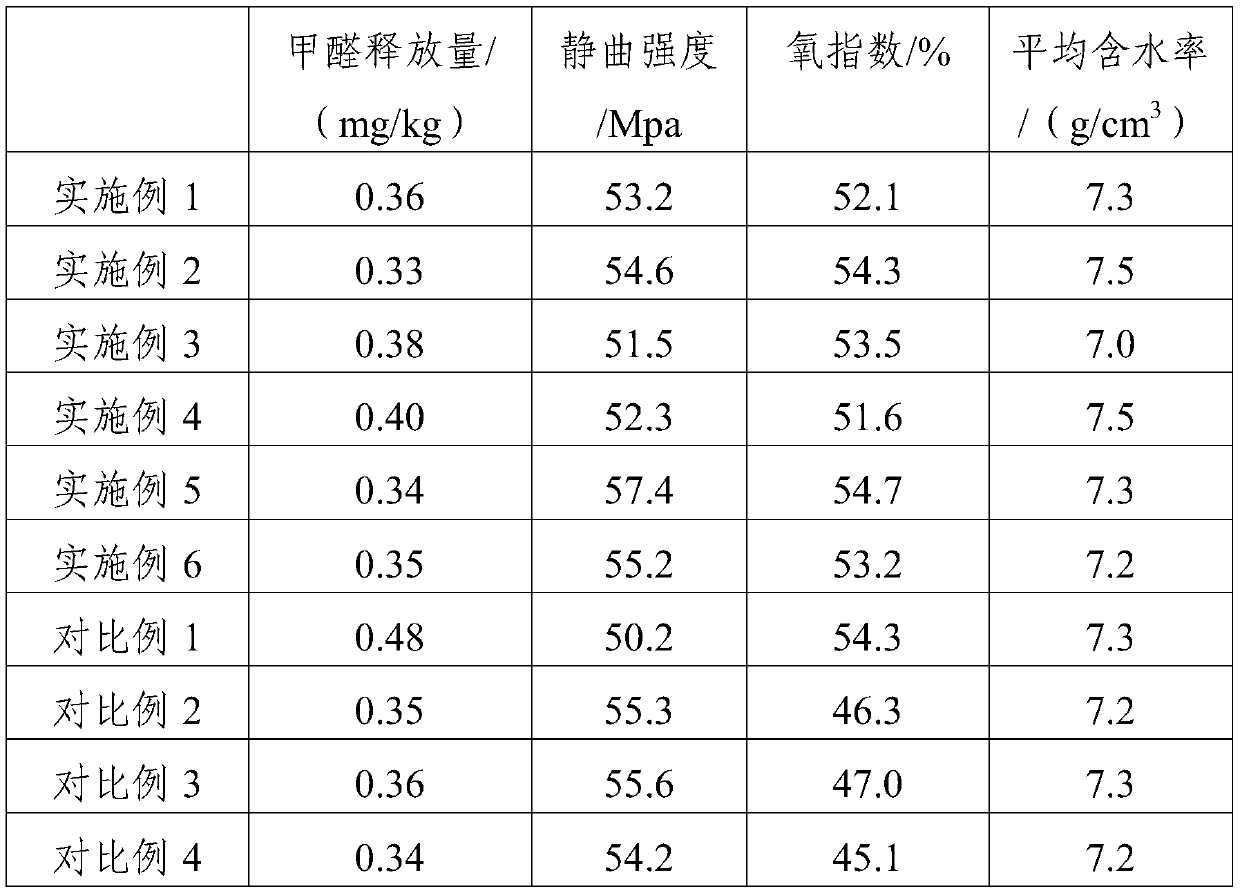

Composite flame-retardant solid wood floor and preparation process thereof

InactiveCN111173226AIncrease elasticityFeel goodCovering/liningsNon-macromolecular adhesive additivesSolid woodPolymer science

The invention provides a composite flame-retardant solid wood floor and a preparation process thereof, and relates to the technical field of wood floors. The composite flame-retardant solid wood flooris sequentially provided with a finishing coat layer, a carbonized flame-retardant plate layer I, a flame-retardant layer I, a solid wood flame-retardant plate layer, a flame-retardant layer II and acarbonized flame-retardant plate layer II from top to bottom; and the thickness ratio of the carbonized flame-retardant plate layer I to the flame-retardant layer I to the solid wood flame-retardantplate layer to the flame-retardant layer II to the carbonized flame-retardant plate layer II is (10-14):(2.5-3.5):(35-48):(2.5-3.5):(10-14). The composite flame-retardant solid wood floor prepared bythe method has the advantages of small formaldehyde emission, less smoke and low smoke toxicity; and the overall structural performance is stable, and the phenomena of cracking, warping, bubbling andthe like cannot occur after long-time use.

Owner:安徽五秒达网络科技有限公司

High-strength environment-friendly flame-retarding fiberboard and manufacturing method thereof

ActiveCN101905475BImprove mechanical propertiesReduce releaseWood working apparatusDomestic articlesFiberEnvironmental resistance

The invention discloses a high-strength environment-friendly flame-retarding fiberboard which comprises the following raw materials of plant fibers, flame retardants, adhesives and waterproofing agents, wherein the weight ratio of the plant fibers to the flame retardants to the adhesives to the waterproofing agents is 100:(3-30):(3-30):(0.1-4). The invention also discloses a manufacturing method of the high-strength environment-friendly flame-retarding fiberboard. Not only are the mechanical properties of the flame-retarding fiberboard obviously improved, but also the combustion property can conform to the regulations of GB8624 Class B or Class C, and the formaldehyde emission, the smoke volume produced and the smoke toxicity are also reduced. Thus, the high-strength environment-friendly flame-retarding fiberboard has good quality and low price, can be widely applied to the fields of building furnishings, flame-retarding furniture production, flame-retarding floor production, wooden fireproof door production, ship and vehicle furnishings and the like, and has good economical and social benefits.

Owner:北京盛大华源科技有限公司 +1

Application of homogeneous A2-grade polyurethane foam in thermal insulation material and preparation process of homogeneous A2-grade polyurethane foam

ActiveCN112679938AImprove thermal conductivityGood dimensional stabilityPolymer scienceInorganic particle

The invention relates to the technical field of polyurethane foam, and in particular, relates to an application of homogeneous A2-grade polyurethane foam in a thermal insulation material and a preparation process of the homogeneous A2-grade polyurethane foam. The homogeneous A2-grade polyurethane foam is mainly prepared from a component A, a component B and a component C according to a weight ratio of (5.4-10.3):(4.5-6.7):(80-90); the component A is prepared by mixing the following raw materials in parts by weight: 80-88 parts of urethane combined polyether, 9-14 parts of a toughening agent, 1-2 parts of an opening agent, 1-2 parts of a smoke suppressant and 1-2 parts of a light stabilizer; the component B is prepared by mixing the following raw materials in parts by weight: 65-85 parts of polymethylene polyphenyl isocyanate and 20-30 parts of a diisocyanate monomer; and the component C is a modified inorganic particle filler. The combustion performance of the polyurethane foam reaches A2 level, the advantages of low heat conductivity coefficient, low water absorption, good dimensional stability and the like of rigid polyurethane foam are reserved, and the polyurethane foam can be widely applied to the field of thermal insulation materials.

Owner:WEIHAI YUNSHAN TECH

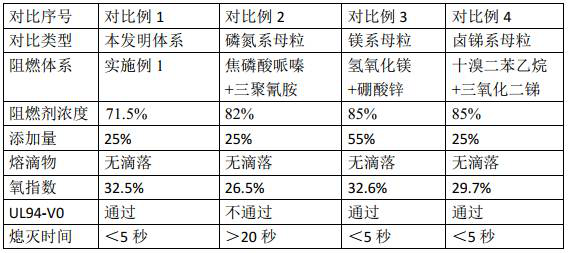

A polymethacrylimide foam with low smoke, low toxicity and high flame retardancy

ActiveCN110804121BImprove mechanical propertiesImprove flame retardant performanceImideFoaming agent

The invention discloses a polymethacrylimide (PMI) foam material with low smoke, low toxicity and high flame retardancy. body, flame retardant system, foaming agent, nucleating agent, initiator and crosslinking agent are mixed to obtain a mixed solution, which is obtained by polymerization and foaming. The mass fraction of the flame retardant system in the mixed solution is 10wt ~40wt%, the present invention finally obtains excellent mechanical properties and excellent flame retardant properties by adding a flame retardant system to the molding raw materials of the PMI foam material, which can be extinguished immediately (within 2s), and has a Very low smoke density and smoke toxicity, it is a low smoke, low toxicity and high flame retardant PMI foam material.

Owner:HUNAN BOOM NEW MATERIALS

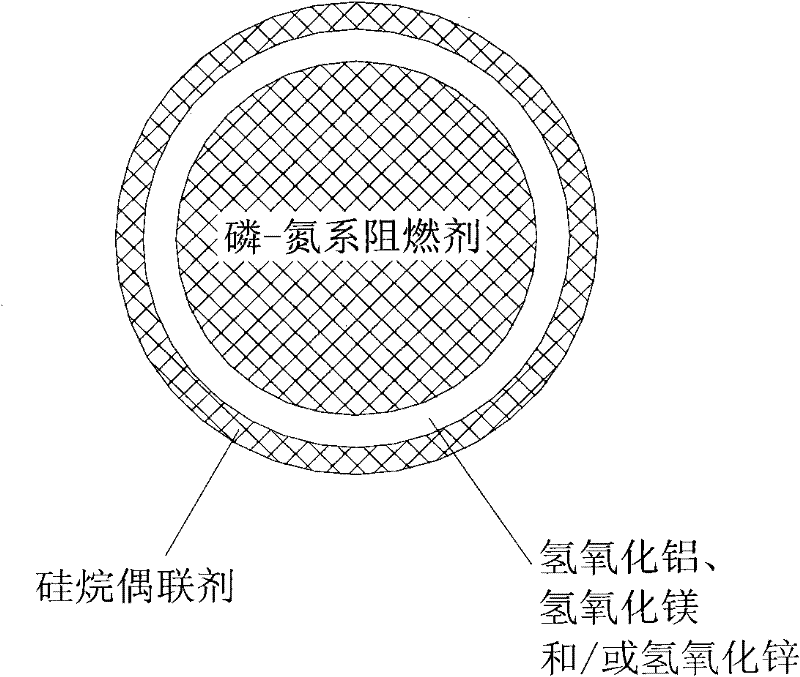

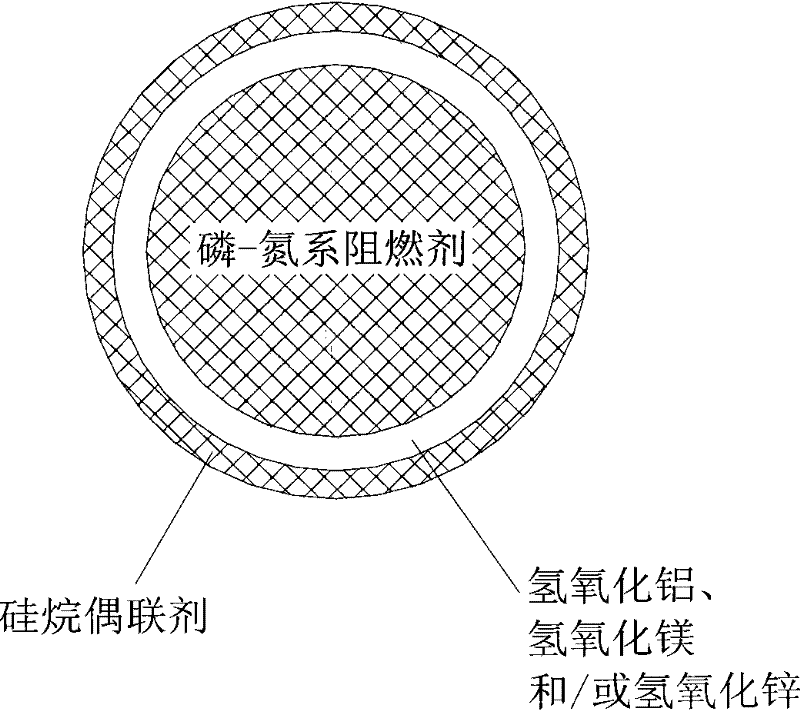

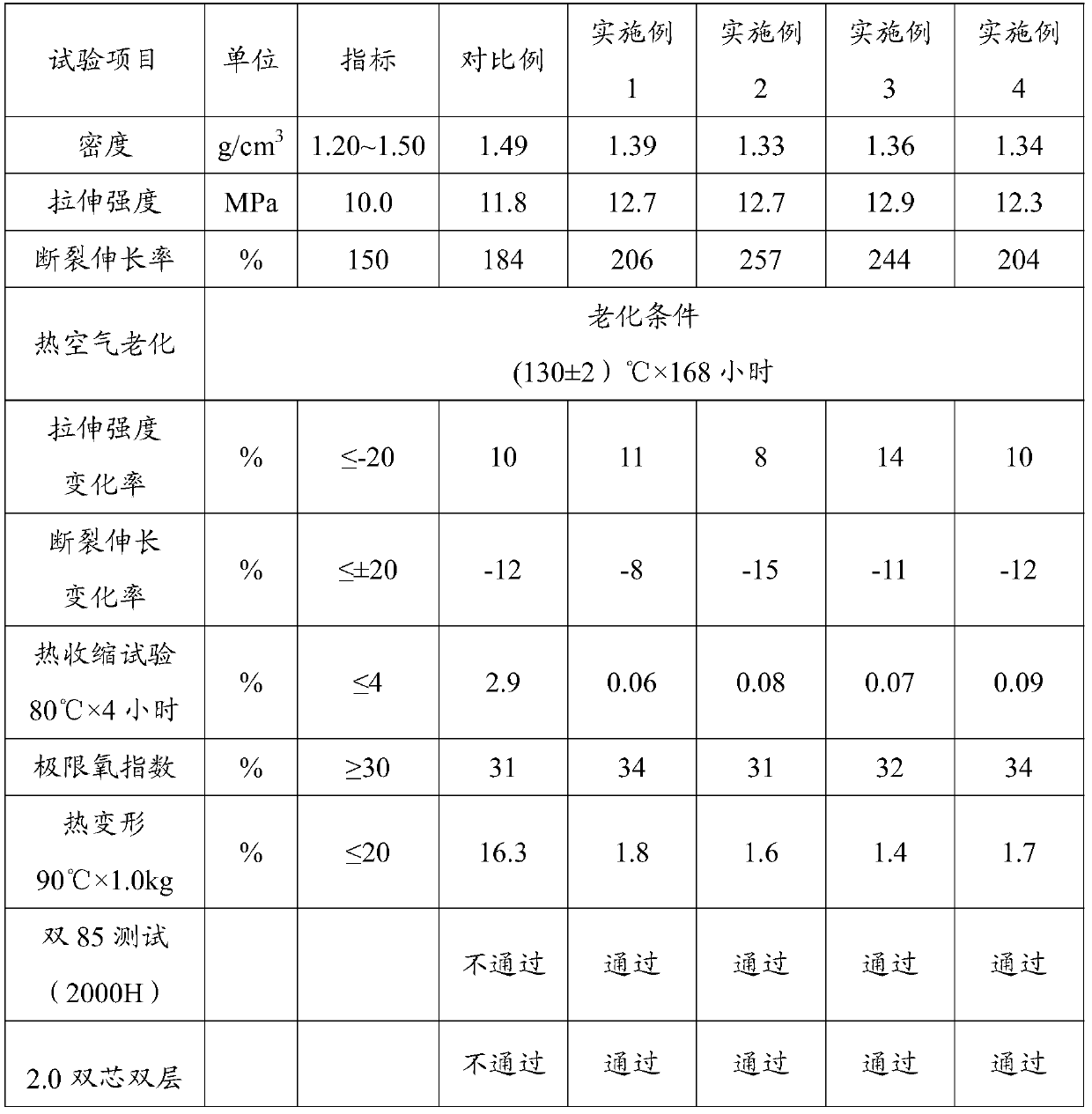

High temperature resistant, low-contraction, halogen-free, and flame-retardant sheath material and preparation method thereof

The invention discloses a high temperature resistant, low-contraction, halogen-free, and flame-retardant sheath material and a preparation method thereof, and belongs to the technical field of polymermaterials. The high temperature resistant, low-contraction, halogen-free, and flame-retardant sheath material comprises following components in parts by weight: 30 to 60 parts of thermoplastic elastomer, 16 to 30 parts of functional polyolefin resin, 16 to 25 parts of grafted linear low density polyethylene, 0.1 to 2 parts of a surface slipping agent, 0.5 to 2 parts of an antioxidant, 1 to 3 parts of a processing aid, 120 to 180 parts of a flame retardant, and 1 to 3 parts of a tubular microcrystal nano charring agent. The sheath material has the advantages of good flame retardant performance, high toughness, high temperature resistance, low contraction, and high stability, does not generate any toxic gas when being burned, and is suitable for small size cables with different structures such as single layer, multiply layers, single core, multiple cores, and the like.

Owner:WUXI JAKE PLASTIC

Preparation method of thermal expansion type polyurethane

ActiveCN111978704AHigh bonding strengthMechanical properties are not affectedThermal dilatationPolymer science

The invention discloses a preparation method of thermal expansion type polyurethane. The preparation method comprises the following steps: adding a raw material modified expanding agent, a halogen-containing flame retardant and a thermoplastic polyurethane elastomer into an internal mixer according to a weight ratio of (2-4): (1-2): (35-45), performing blending, and carrying out hot press moldingto obtain the thermal expansion type polyurethane. The defects in prior art are overcome. The flame retardant has relatively small influence on the mechanical properties of polyurethane, and has favorable flame-retardant effect.

Owner:安徽嘉明新材料科技有限公司

A low-temperature ceramic flame retardant functional masterbatch and its preparation method

The invention relates to a low-temperature ceramic flame-retardant functional masterbatch, which comprises the following components by mass: 10-25 parts of silicone rubber, 5-15 parts of silicone resin, 2-6 parts of aluminum hypophosphite, and 2-10 parts of glass microspheres 2-8 parts of montmorillonite, 10-25 parts of natural bone powder, 25-50 parts of synthetic ceramic bone powder, 1-2 parts of coupling agent, 1-3 parts of lubricant and 1-3 parts of dispersing agent. The invention also relates to a method for preparing low-temperature ceramicized flame retardant functional masterbatch, which improves the dispersibility and increases the carbon formation rate, so that the carbon layer with a multi-dimensional stable structure has a high precipitation rate and integrity rate. The flame retardant masterbatch prepared by the invention can be ceramicized at low temperature when the material encounters flame attack, and can form a continuous and dense ceramic oxygen barrier layer, which has the characteristics of high efficiency and environmental protection.

Owner:见喜新材料股份有限公司

Pnenolic aldehyde foam board exterior wall internal insulation system and construction method

InactiveCN101302879BImprove insulation effectConvenient sourceCovering/liningsClimate change adaptationNon toxicityPolystyrene

The invention discloses a phenolic aldehyde foam board inner thermal insulation system for outer walls and a construction method thereof. The phenolic aldehyde foam board inner thermal insulation system for outer walls comprises a binder layer (7) coated on a foundation wall (1) of the outer wall, an integral skin phenolic aldehyde foam board (2) adhered to the binder layer (7), a plastering inner layer (3) adhered to one side of the integral skin phenolic aldehyde foam board (2), a piece of fiberglass mesh cloth (4) adhered to the outside of the plastering inner layer (3) and a plastering outer layer (5) adhered to the outside of the fiberglass mesh cloth (4). The phenolic aldehyde foam board inner thermal insulation system for outer walls disclosed by the invention has good thermal insulation performance, combustion performance up to a non-combustible grade, smoke toxicity up to standard safety grade, intensity up to or exceeding that of polystyrene inner thermal insulation board for outer walls (construction industry standard JG / T 159-2004 of inner thermal insulation board issued by Ministry of Housing and Urban-Rural Development of the People's Republic of China), as well as non-toxicity, good environmental performance, air permeability, no cracking, convenient material source, energy-saving construction and wide application.

Owner:沈石山 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com